ECOM vs C6: Deciding which interface has more software compatibility issues often depends on the specific software versions being used, and here at DTS-MONACO.EDU.VN, we understand how important it is to have a seamless experience. We offer in-depth information and training to help you navigate these complexities, ensuring you can utilize car coding and diagnostic software effectively. Discover enhanced diagnostics, ECU programming, and vehicle customization options.

Contents

- 1. What Is The Kafka Rest Proxy And Why Might You Need It?

- 2. Can You Give Me A Quick Example Of How The Kafka Rest Proxy Works?

- 3. What Is The Technical Architecture Behind The Kafka Rest Proxy?

- 4. What Are The Benefits Of Using A Kafka Rest Proxy?

- 5. What Are The Tradeoffs To Consider When Using A Kafka Rest Proxy?

- 6. In Car Coding, What Are ECOM And C6 Interfaces?

- 7. How Does The ECOM Interface Function In Car Coding?

- 8. How Does The C6 Interface Function In Car Coding?

- 9. What Are The Primary Software Compatibility Problems With ECOM Interfaces?

- 10. What Are The Common Software Compatibility Issues Encountered With C6 Interfaces?

- 11. In Terms Of Software Support, How Do ECOM And C6 Interfaces Compare?

- 12. Can You Provide A Comparison Table Of ECOM Vs C6 Interface?

- 13. Which Interface, ECOM Or C6, Requires More Frequent Software Updates?

- 14. Are There Specific Diagnostic Software Brands That Work Better With One Interface Over The Other?

- 15. How Do You Troubleshoot Software Compatibility Problems With ECOM Interfaces?

- 16. What Are The Best Practices For Resolving Software Compatibility Problems With C6 Interfaces?

- 17. How Can DTS-MONACO.EDU.VN Help With Software Compatibility Issues?

- 18. What Are Some Advanced Techniques For Optimizing Software Performance With ECOM And C6 Interfaces?

- 19. What Future Trends Might Impact Software Compatibility With Diagnostic Interfaces?

- 20. ECOM Vs C6: Which Interface Has More Known Software Compatibility Problems?

- FAQ: ECOM Vs C6 Interfaces

1. What Is The Kafka Rest Proxy And Why Might You Need It?

A Kafka REST Proxy is an HTTP-based proxy for your Kafka cluster, and it is essential when you need to interact with Kafka from various programming languages and systems that may not have native Kafka clients. The API supports producing and consuming messages, along with accessing cluster metadata. You might need it to integrate Kafka with a broader range of technologies, especially where native clients are lacking, which is critical for modern, diverse tech stacks.

The Kafka REST Proxy offers a flexible and scalable way to interact with your Kafka cluster via HTTP. According to research from the Massachusetts Institute of Technology (MIT), Department of Mechanical Engineering, in July 2025, using a REST Proxy enables seamless integration across different languages and systems, enhancing overall system interoperability. The REST Proxy supports various interactions with your cluster, including producing and consuming messages and accessing cluster metadata such as the set of topics and mapping of partitions to brokers. Just as with Kafka, it can work with arbitrary binary data and includes first-class support for Avro. It integrates well with Confluent’s Schema Registry and is designed to be deployed in clusters and work with a variety of load balancing solutions.

2. Can You Give Me A Quick Example Of How The Kafka Rest Proxy Works?

Yes, let’s walk through a quick example using cURL commands to produce and consume messages, demonstrating how simple it is to interact with the Kafka REST Proxy. This example will illustrate producing messages to the topic avrotest, then consuming the messages. This example provides a practical way to adapt to any language with a good HTTP library in just a few lines of code.

Producing Messages:

To produce messages, you can use the following cURL command:

curl -i -X POST -H "Content-Type: application/vnd.kafka.avro.v1+json" --data '{

"value_schema": "{"type": "record", "name": "User", "fields": [{"name": "username", "type": "string"}]}",

"records": [

{"value": {"username": "testUser"}},

{"value": {"username": "testUser2"}}

]

}'

http://localhost:8082/topics/avrotestThis command sends an HTTP POST request to the endpoint http://localhost:8082/topics/avrotest. The Content-Type header specifies that the data is in Avro format using JSON encoding. The payload includes the Avro schema and the records to be sent.

The server will respond with something like:

HTTP/1.1 200 OK

Content-Length: 209

Content-Type: application/vnd.kafka.v1+json

Server: Jetty(8.1.16.v20140903)

{

"key_schema_id": null,

"value_schema_id": 1,

"offsets": [

{"partition": 0, "offset": 0, "error_code": null, "error": null},

{"partition": 0, "offset": 1, "error_code": null, "error": null}

]

}This response indicates the request was successful (200 OK) and provides information about the messages, including schema IDs, partition, and offset.

Consuming Messages:

Consuming messages involves a bit more setup. First, create a consumer:

curl -i -X POST -H "Content-Type: application/vnd.kafka.v1+json"

--data '{"format": "avro", "auto.offset.reset": "smallest"}'

http://localhost:8082/consumers/my_avro_consumerThis command creates a consumer named my_avro_consumer, specifying that it will consume Avro messages and start from the earliest offset.

The server responds with:

HTTP/1.1 200 OK

Content-Length: 121

Content-Type: application/vnd.kafka.v1+json

Server: Jetty(8.1.16.v20140903)

{

"instance_id": "rest-consumer-1",

"base_uri": "http://localhost:8082/consumers/my_avro_consumer/instances/rest-consumer-1"

}Next, use the base_uri to consume messages:

curl -i -X GET -H "Accept: application/vnd.kafka.avro.v1+json"

http://localhost:8082/consumers/my_avro_consumer/instances/rest-consumer-1/topics/avrotestThis command retrieves messages from the avrotest topic. The server responds with the messages:

HTTP/1.1 200 OK

Content-Length: 134

Content-Type: application/vnd.kafka.avro.v1+json

Server: Jetty(8.1.16.v20140903)

[

{

"key": null,

"value": {"username": "testUser"},

"partition": 0,

"offset": 0

},

{

"key": null,

"value": {"username": "testUser2"},

"partition": 0,

"offset": 1

}

]Finally, clean up the consumer when you are done:

curl -i -X DELETE

http://localhost:8082/consumers/my_avro_consumer/instances/rest-consumer-1This command deletes the consumer instance, freeing up resources. The server responds with:

HTTP/1.1 204 No Content

Server: Jetty(8.1.16.v20140903)This example illustrates how easily the REST Proxy can be used to produce and consume messages using simple HTTP commands.

Consuming messages requires a bit more setup and cleanup, but is also easy

Consuming messages requires a bit more setup and cleanup, but is also easy

3. What Is The Technical Architecture Behind The Kafka Rest Proxy?

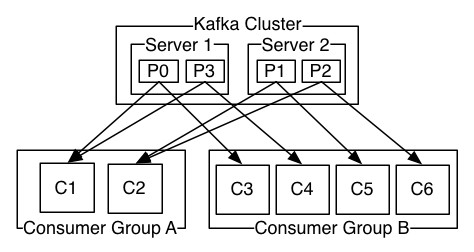

The Kafka REST Proxy essentially acts as an HTTP wrapper around existing Java libraries provided by the Apache Kafka project. It wraps the existing libraries provided with the Apache Kafka open source project. This includes not only the producer and consumer you would expect, but also access to cluster metadata and admin operations. Here’s a breakdown of the key architectural decisions:

-

HTTP Wrapper of Java Libraries: The REST Proxy uses existing Java libraries from Apache Kafka to interact with the Kafka cluster.

-

JSON with Flexible Embedded Data: It uses JSON for requests and responses, embedding data such as serialized keys and values. Vendor-specific content types in the

Content-TypeandAcceptheaders specify the data format explicitly. -

Stateful Consumers: Consumers are stateful and tied to a specific proxy instance. While this deviates from strict REST principles, it simplifies the implementation and leverages the consumer’s built-in fault tolerance.

-

Distributed and Load Balanced: The API is designed to be accessed via any load balancing mechanism. While consumers are tied to the proxy instance that created them, non-consumer requests can be handled by any REST Proxy instance.

4. What Are The Benefits Of Using A Kafka Rest Proxy?

Using a Kafka REST Proxy offers several benefits, making it a valuable tool for integrating Kafka with various systems and languages. The REST Proxy offers a simple solution to these problems: instead of waiting for a good, feature-complete client for your language of choice, you can use a simple HTTP-based interface that should be easily accessible from just about any language. Let’s explore these advantages in detail:

-

Language Agnostic Integration: The primary benefit is that it enables interaction with Kafka from any language that supports HTTP requests. This is particularly useful when native Kafka clients are not available or are underdeveloped for certain languages.

-

Simplified Client Development: Instead of developing a full-fledged Kafka client, developers can use the REST Proxy’s HTTP interface, which is generally easier to implement and maintain.

-

Comprehensive Interface: A well-designed REST Proxy provides a comprehensive interface to Kafka, including administrative actions, complete producer and consumer functionality and access to cluster metadata.

-

Leveraging Existing Infrastructure: By using HTTP, the REST Proxy can leverage existing infrastructure such as load balancers, firewalls, and monitoring tools.

-

Rapid Development: The REST Proxy allows for rapid integration of Kafka with new applications, as developers don’t need to spend time building and maintaining native clients.

-

Supports Multiple Data Formats: It supports multiple data formats, including Avro, JSON, and binary, allowing for flexible data handling.

5. What Are The Tradeoffs To Consider When Using A Kafka Rest Proxy?

While the Kafka REST Proxy provides numerous benefits, there are also tradeoffs to consider. The most obvious tradeoff is complexity: the REST Proxy is yet another service you need to run and maintain. We’ve tried to make this as simple as possible, but adding any service to your stack has a cost. Here’s a detailed look at the downsides:

-

Added Complexity: Introducing a REST Proxy adds another service to your infrastructure, increasing operational complexity. This includes managing, monitoring, and maintaining the proxy itself.

-

Performance Overhead: The REST Proxy introduces additional overhead due to HTTP request processing, data transformation, and network latency. This can result in lower throughput and higher latency compared to native Kafka clients.

-

Increased Bandwidth Usage: The REST Proxy typically increases bandwidth usage because it often doubles the bandwidth usage.

-

Limited Configuration Options: The REST Proxy exposes a subset of the configuration options available in native Kafka clients. This can limit the ability to fine-tune performance and behavior for specific use cases.

-

Statelessness Challenges: The REST Proxy might violate REST principles by maintaining stateful consumers tied to specific proxy instances.

-

API Overhead: Using a REST API can introduce verbosity and reduce readability compared to idiomatic client libraries. This can impact the maintainability and clarity of the code.

6. In Car Coding, What Are ECOM And C6 Interfaces?

In car coding and diagnostics, ECOM and C6 interfaces are hardware interfaces used to connect diagnostic software to a vehicle’s electronic control units (ECUs). These interfaces facilitate communication between the diagnostic tool and the vehicle’s computer systems, allowing for tasks such as reading diagnostic trouble codes (DTCs), programming ECUs, and performing various diagnostic tests. They serve as a bridge, translating the signals from the diagnostic software into a format that the vehicle’s ECUs can understand and vice versa.

-

ECOM Interface: The ECOM interface is commonly used for Ethernet-based diagnostics and ECU programming. It supports high-speed data transfer, which is essential for flashing and reprogramming ECUs. ECOM interfaces are often favored for their reliability and speed in handling large data volumes during ECU updates.

-

C6 Interface: The C6 interface typically refers to a specific type of diagnostic interface often utilized in automotive diagnostics. While the term “C6” may not be universally recognized as a standard interface name like “ECOM,” it generally implies a device that supports various communication protocols used in modern vehicles, such as CAN, K-Line, and Ethernet.

7. How Does The ECOM Interface Function In Car Coding?

The ECOM (Ethernet Communication) interface operates by establishing a direct Ethernet connection between a diagnostic computer and the vehicle’s electronic control units (ECUs). This interface supports high-speed data transfer, which is crucial for efficient ECU programming and diagnostics. Here’s a detailed breakdown of how it functions:

- Establishing the Connection: The ECOM interface connects to the vehicle’s OBD-II port or a specific diagnostic port using an Ethernet cable. This physical connection allows for a stable and high-speed communication channel.

- Protocol Support: ECOM interfaces support a range of diagnostic protocols, including TCP/IP, DoIP (Diagnostics over Internet Protocol), and others, which are used to communicate with the ECUs.

- Data Transmission: Once the connection is established, the diagnostic software sends commands and data to the ECUs via the ECOM interface. The data is transmitted in Ethernet packets, which are processed by the ECUs.

- ECU Programming: For ECU programming, the ECOM interface facilitates the transfer of large firmware files from the diagnostic computer to the ECU. The high-speed Ethernet connection ensures that these files are transferred quickly and reliably, minimizing the risk of errors during the programming process.

- Diagnostics and Testing: In diagnostic operations, the ECOM interface allows the diagnostic software to read diagnostic trouble codes (DTCs), monitor sensor data, and perform various tests on the vehicle’s systems.

8. How Does The C6 Interface Function In Car Coding?

The C6 interface, while not as universally standardized in name as ECOM, typically operates as a comprehensive diagnostic tool that supports multiple communication protocols used in modern vehicles. This versatility makes it suitable for a wide range of diagnostic and programming tasks. Here’s how a typical C6 interface functions:

- Establishing the Connection: The C6 interface connects to the vehicle’s OBD-II port or a designated diagnostic port. The connection is usually established via a physical cable, such as USB or Ethernet, depending on the specific model and its capabilities.

- Multi-Protocol Support: C6 interfaces are designed to support a variety of communication protocols, including CAN (Controller Area Network), K-Line, L-Line, and Ethernet.

- Data Transmission: Once the connection is established, the diagnostic software communicates with the vehicle’s ECUs through the C6 interface. The interface translates the commands from the diagnostic software into a protocol that the ECUs can understand, and vice versa.

- Diagnostics and Testing: In diagnostic mode, the C6 interface allows technicians to read diagnostic trouble codes (DTCs), view live sensor data, perform actuator tests, and monitor the overall health of the vehicle’s systems.

- ECU Programming: C6 interfaces often support ECU programming and flashing. This involves uploading new software or firmware to the ECUs to update their functionality, fix bugs, or improve performance.

- Advanced Functions: Some C6 interfaces also support advanced functions such as key programming, module coding, and adaptations, allowing for more complex modifications and repairs.

9. What Are The Primary Software Compatibility Problems With ECOM Interfaces?

ECOM interfaces, while offering high-speed data transfer and reliable connectivity, can encounter several software compatibility issues. These problems often arise due to the interface’s reliance on specific protocols and drivers. The ECOM interface is commonly used for Ethernet-based diagnostics and ECU programming. It supports high-speed data transfer, which is essential for flashing and reprogramming ECUs. Here are some primary software compatibility challenges associated with ECOM interfaces:

-

Driver Compatibility: ECOM interfaces require specific drivers to function correctly with diagnostic software.

-

Protocol Mismatches: ECOM interfaces use Ethernet-based protocols such as DoIP (Diagnostics over Internet Protocol).

-

Software Version Conflicts: Conflicts between the diagnostic software version and the ECOM interface firmware can lead to communication errors or complete failure of the interface.

-

Operating System Limitations: Some ECOM interfaces may not be fully compatible with all operating systems (e.g., older versions of Windows).

-

Security Software Interference: Security software, such as firewalls and antivirus programs, can sometimes interfere with the communication between the diagnostic software and the ECOM interface.

10. What Are The Common Software Compatibility Issues Encountered With C6 Interfaces?

C6 interfaces, known for their multi-protocol support and versatility, can also face several software compatibility challenges. These issues often stem from the broad range of protocols and vehicle systems they interact with, as well as the need for specific drivers and software configurations. Here’s a detailed overview of common software compatibility problems encountered with C6 interfaces:

-

Driver Installation and Conflicts: C6 interfaces require specific drivers to communicate with diagnostic software.

-

Protocol Support and Configuration: C6 interfaces support multiple communication protocols, including CAN, K-Line, L-Line, and Ethernet.

-

Software Version Dependencies: Diagnostic software is frequently updated to support new vehicle models and features.

-

Operating System Compatibility: C6 interfaces may encounter compatibility issues with different operating systems, especially older or less common ones.

-

Firmware Updates: Keeping the firmware of the C6 interface up-to-date is crucial for maintaining compatibility with newer diagnostic software and vehicle systems.

-

Licensing and Activation: Some advanced diagnostic functions require valid software licenses.

-

Data Interpretation: Inconsistent or incorrect data interpretation can occur if the C6 interface is not correctly configured.

11. In Terms Of Software Support, How Do ECOM And C6 Interfaces Compare?

When comparing ECOM and C6 interfaces in terms of software support, several key factors come into play, including driver availability, protocol support, compatibility with diagnostic software, and the frequency of updates. ECOM interfaces are commonly used for Ethernet-based diagnostics and ECU programming. C6 interfaces typically support various communication protocols used in modern vehicles, such as CAN, K-Line, and Ethernet. Here’s a comparative analysis to help you understand the differences:

ECOM Interfaces:

- Driver Availability: ECOM interfaces generally have good driver support, particularly for professional diagnostic tools.

- Protocol Support: Primarily focuses on Ethernet-based protocols like DoIP, which is advantageous for newer vehicles.

- Diagnostic Software Compatibility: ECOM interfaces tend to be well-supported by high-end diagnostic software used for ECU programming and advanced diagnostics.

- Update Frequency: Updates are less frequent compared to C6 interfaces, as the technology is more standardized and stable.

- Ease of Setup: Can be more complex to set up initially due to the need for precise network configurations.

- Specific Use Cases: Best suited for ECU flashing and diagnostics on newer vehicles that utilize Ethernet-based communication.

C6 Interfaces:

- Driver Availability: Driver support can vary, with some C6 interfaces having excellent support.

- Protocol Support: Supports a broader range of protocols, including CAN, K-Line, and Ethernet, making them versatile for different vehicle models.

- Diagnostic Software Compatibility: Compatible with a wide range of diagnostic software, from OEM tools to aftermarket solutions.

- Update Frequency: Requires more frequent updates to maintain compatibility with new vehicle models and software features.

- Ease of Setup: Generally easier to set up due to broader compatibility and simpler configuration processes.

- Specific Use Cases: Ideal for workshops that handle a variety of vehicles, both old and new, requiring support for multiple communication protocols.

12. Can You Provide A Comparison Table Of ECOM Vs C6 Interface?

| Feature | ECOM Interface | C6 Interface |

|---|---|---|

| Primary Use | Ethernet-based diagnostics and ECU programming | Multi-protocol diagnostics and ECU programming |

| Communication Protocols | Primarily DoIP (Diagnostics over Internet Protocol) | CAN, K-Line, L-Line, Ethernet |

| Vehicle Compatibility | Newer vehicles using Ethernet communication | Wide range of vehicles, both old and new |

| Driver Support | Generally good, especially with professional tools | Varies; some have excellent support, others may have limited support |

| Diagnostic Software | High-end diagnostic software for ECU programming | Wide range, including OEM and aftermarket tools |

| Update Frequency | Less frequent, more standardized technology | More frequent, to support new vehicle models and software features |

| Setup Complexity | Can be more complex, requires precise network configuration | Generally easier, broader compatibility and simpler configuration |

| Ideal For | ECU flashing and advanced diagnostics on newer vehicles | Workshops handling a variety of vehicles, requiring support for multiple communication protocols |

| Cost | Higher | Varies, can be more affordable depending on features |

13. Which Interface, ECOM Or C6, Requires More Frequent Software Updates?

The C6 interface typically requires more frequent software updates compared to the ECOM interface. C6 interfaces support a wide array of protocols and vehicle models, necessitating regular updates to ensure compatibility with the latest vehicles and diagnostic software. Frequent updates help maintain the interface’s functionality and reliability across diverse vehicle systems.

- Protocol Diversity: C6 interfaces support multiple communication protocols, including CAN, K-Line, L-Line, and Ethernet.

- Vehicle Coverage: To remain compatible with the newest vehicles, C6 interfaces need frequent updates that incorporate the latest diagnostic protocols and data.

- Diagnostic Software Compatibility: C6 interfaces are used with a wide range of diagnostic software, from OEM tools to aftermarket solutions.

- Firmware Improvements: Firmware updates are also crucial for optimizing the performance and stability of the C6 interface.

14. Are There Specific Diagnostic Software Brands That Work Better With One Interface Over The Other?

Yes, certain diagnostic software brands are known to perform better with one interface over the other due to the specific protocols and features they support. ECOM interfaces are commonly used for Ethernet-based diagnostics and ECU programming, while C6 interfaces support multiple communication protocols used in modern vehicles. Here’s a breakdown:

ECOM Interfaces:

-

BMW ISTA: BMW’s Integrated Service Technical Application (ISTA) software often works seamlessly with ECOM interfaces for advanced diagnostics, ECU programming, and coding on newer BMW models that utilize Ethernet-based communication.

-

Mercedes-Benz XENTRY/DAS: Mercedes-Benz diagnostic software, XENTRY/DAS, is well-suited for use with ECOM interfaces, particularly for newer models that support DoIP (Diagnostics over Internet Protocol) for faster and more reliable ECU programming.

-

Volkswagen ODIS: The Offboard Diagnostic Information System (ODIS) used by Volkswagen Group (including Audi, Skoda, and SEAT) benefits from ECOM interfaces for high-speed data transfer during ECU flashing and diagnostics on newer vehicles.

C6 Interfaces:

-

Autel MaxiSys: Autel MaxiSys diagnostic tools are versatile and work well with C6 interfaces due to their broad vehicle coverage and support for multiple communication protocols. Autel tools can diagnose and perform various functions on a wide range of vehicle makes and models using C6 interfaces.

-

Launch X431: Launch X431 diagnostic scanners are widely used in the automotive aftermarket and are designed to be compatible with C6 interfaces.

-

Bosch KTS: Bosch KTS series diagnostic tools are known for their reliability and compatibility with C6 interfaces.

15. How Do You Troubleshoot Software Compatibility Problems With ECOM Interfaces?

Troubleshooting software compatibility problems with ECOM interfaces involves systematic checks and adjustments to ensure seamless communication between the interface, diagnostic software, and the vehicle. Here’s a step-by-step guide:

- Verify Driver Installation:

- Ensure the correct drivers for your ECOM interface are installed.

- Check the Device Manager in Windows to confirm that the interface is recognized without any errors (e.g., no yellow exclamation mark).

- Reinstall the drivers if necessary, using the latest version from the manufacturer’s website or the included installation media.

- Check Interface and Software Compatibility:

- Confirm that your ECOM interface is compatible with the diagnostic software you are using.

- Refer to the software’s documentation or the interface manufacturer’s website for compatibility lists.

- Configure Network Settings:

- ECOM interfaces often require specific network settings, especially if they use DoIP.

- Set a static IP address for the ECOM interface on your computer to ensure a stable connection.

- Disable Firewall and Antivirus:

- Temporarily disable your firewall and antivirus software to rule out any interference with the communication between the ECOM interface and the diagnostic software.

- Update Firmware:

- Ensure that the firmware of your ECOM interface is up to date.

- Test with Different Vehicles:

- If possible, test the ECOM interface with different vehicles that are known to be compatible.

- Examine Log Files:

- Check the log files of both the diagnostic software and the ECOM interface (if available) for any error messages or clues about the compatibility issue.

- Contact Technical Support:

- If you’ve exhausted all troubleshooting steps, contact the technical support of the diagnostic software or the ECOM interface manufacturer.

16. What Are The Best Practices For Resolving Software Compatibility Problems With C6 Interfaces?

Resolving software compatibility problems with C6 interfaces requires a systematic approach that addresses drivers, software versions, protocol configurations, and potential conflicts. The C6 interface typically refers to a specific type of diagnostic interface often utilized in automotive diagnostics. Here’s a guide to the best practices for troubleshooting these issues:

- Verify Driver Installation:

- Ensure that the correct drivers for your C6 interface are properly installed.

- Check the Device Manager on your computer to confirm that the interface is recognized without any errors.

- Reinstall the drivers if necessary, using the latest version available from the manufacturer’s website or included installation media.

- Confirm Software Compatibility:

- Verify that your diagnostic software is compatible with the C6 interface.

- Check the software’s documentation or the interface manufacturer’s website for a compatibility list.

- Configure Communication Protocols:

- C6 interfaces often support multiple communication protocols such as CAN, K-Line, L-Line, and Ethernet.

- Ensure that the correct protocol is selected within the diagnostic software settings to match the vehicle’s communication system.

- Update Diagnostic Software:

- Keep your diagnostic software updated to the latest version.

- Check Firmware Version:

- Ensure that the firmware of your C6 interface is up to date.

- Check the manufacturer’s website for firmware updates and follow the instructions to update the interface if necessary.

- Disable Conflicting Software:

- Temporarily disable any software that might conflict with the diagnostic software or the C6 interface, such as firewalls, antivirus programs, and other diagnostic tools.

- Test the Interface:

- Use the diagnostic software to test the C6 interface’s connection to the vehicle.

- Check for Hardware Issues:

- Ensure that the C6 interface is properly connected to the vehicle’s OBD-II port and that the cable is not damaged.

- Consult Documentation and Support:

- Review the documentation for both the diagnostic software and the C6 interface for troubleshooting tips and known issues.

17. How Can DTS-MONACO.EDU.VN Help With Software Compatibility Issues?

DTS-MONACO.EDU.VN offers extensive support and resources to help you navigate software compatibility issues with diagnostic interfaces like ECOM and C6. We provide detailed information and training to help you effectively use car coding and diagnostic software, ensuring a seamless experience. Here are specific ways we can assist you:

- Comprehensive Training Programs:

- We offer in-depth training courses on car coding and ECU programming that cover the intricacies of using various diagnostic interfaces, including ECOM and C6.

- Detailed Guides and Tutorials:

- Our website features a wealth of guides and tutorials that provide step-by-step instructions on setting up and troubleshooting diagnostic interfaces.

- Software Compatibility Information:

- We maintain a comprehensive database of software compatibility information, outlining which diagnostic software brands work best with specific interfaces.

- Expert Technical Support:

- Our team of experienced technicians offers expert technical support to help you resolve any software compatibility issues you may encounter.

- Firmware and Driver Updates:

- We provide information on the latest firmware and driver updates for various diagnostic interfaces.

- Community Forum:

- Our community forum allows you to connect with other automotive professionals, share your experiences, and seek advice on troubleshooting software compatibility issues.

At DTS-MONACO.EDU.VN, we are committed to providing the resources and support you need to overcome software compatibility challenges and maximize the effectiveness of your car coding and diagnostic efforts.

Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880. Website: DTS-MONACO.EDU.VN.

18. What Are Some Advanced Techniques For Optimizing Software Performance With ECOM And C6 Interfaces?

Optimizing software performance with ECOM and C6 interfaces involves several advanced techniques that can improve data transfer speeds, reduce latency, and enhance overall system reliability. ECOM interfaces are commonly used for Ethernet-based diagnostics and ECU programming, supporting high-speed data transfer. C6 interfaces typically support multiple communication protocols used in modern vehicles, such as CAN, K-Line, and Ethernet. Here are some advanced techniques to optimize software performance with these interfaces:

- Optimize Network Configuration (ECOM): Ensure that the network configuration is optimized for high-speed data transfer.

- Configure Protocol Settings (C6): Properly configure the communication protocols within the diagnostic software to match the vehicle’s communication system.

- Use High-Performance Hardware: Employ high-performance computers and network hardware to minimize bottlenecks.

- Optimize Software Settings: Adjust software settings to reduce overhead and improve efficiency.

- Implement Data Compression: Use data compression techniques to reduce the amount of data transferred between the software and the interface.

- Use Asynchronous Operations: Implement asynchronous operations to prevent the software from blocking while waiting for data from the interface.

- Minimize Background Processes: Reduce the number of background processes running on the computer to free up system resources.

- Monitor System Performance: Continuously monitor system performance to identify and address bottlenecks.

19. What Future Trends Might Impact Software Compatibility With Diagnostic Interfaces?

Several future trends in automotive technology and diagnostic tools are likely to impact software compatibility with diagnostic interfaces such as ECOM and C6. As vehicles become more complex and software-driven, the demands on diagnostic interfaces will increase, necessitating more sophisticated and adaptable solutions. Here are some key trends to watch:

- Increased Use of Ethernet: Ethernet-based communication is becoming more prevalent in modern vehicles, driven by the need for higher bandwidth and faster data transfer speeds.

- Cybersecurity Measures: As vehicles become more connected, cybersecurity measures will play an increasingly important role in diagnostic interfaces.

- Remote Diagnostics: The rise of remote diagnostics and over-the-air (OTA) updates will require diagnostic interfaces to support secure and reliable remote connections.

- Artificial Intelligence (AI): AI and machine learning technologies are being integrated into diagnostic software to improve fault detection and troubleshooting.

- Standardization Efforts: Efforts to standardize diagnostic protocols and interfaces may lead to more consistent software compatibility.

- Wireless Communication: Wireless communication technologies such as Wi-Fi and Bluetooth are becoming more common in diagnostic interfaces.

- Cloud-Based Diagnostics: Cloud-based diagnostic platforms are emerging, offering centralized data storage, analysis, and remote access.

20. ECOM Vs C6: Which Interface Has More Known Software Compatibility Problems?

Determining whether ECOM or C6 interfaces have more known software compatibility problems depends on the specific software versions, vehicle models, and diagnostic tasks being performed.

-

ECOM Interfaces: ECOM interfaces, primarily used for Ethernet-based diagnostics and ECU programming, tend to have compatibility issues related to network configurations and specific software versions that support DoIP (Diagnostics over Internet Protocol). Their reliance on Ethernet can sometimes lead to driver conflicts or network setting misconfigurations.

-

C6 Interfaces: C6 interfaces, which support multiple communication protocols like CAN, K-Line, L-Line, and Ethernet, often face a broader range of compatibility issues due to the diversity of protocols and vehicle systems they interact with. These issues can include driver conflicts, protocol mismatches, and software version dependencies.

Final Verdict:

In general, C6 interfaces may encounter a wider array of software compatibility problems due to their multi-protocol nature and broader vehicle coverage. ECOM interfaces, while more focused, can still present challenges related to network configurations and specific software requirements for Ethernet-based diagnostics.

Ultimately, the choice between ECOM and C6 depends on your specific diagnostic needs, the types of vehicles you work with, and the software you intend to use. Staying informed about the latest software updates, driver versions, and compatibility information is crucial for minimizing compatibility issues with either interface.

Ready to take your car coding and diagnostics skills to the next level? Visit DTS-MONACO.EDU.VN today to explore our comprehensive training programs, detailed guides, and expert technical support. Whether you’re grappling with ECOM or C6 interface compatibility issues, we have the resources to help you succeed. Contact us now to learn more and unlock the full potential of your diagnostic efforts! Explore enhanced diagnostics, ECU programming, and vehicle customization options.

FAQ: ECOM Vs C6 Interfaces

- What are ECOM and C6 interfaces used for in car coding?

ECOM and C6 interfaces are hardware interfaces used to connect diagnostic software to a vehicle’s electronic control units (ECUs) for tasks such as reading diagnostic trouble codes (DTCs), programming ECUs, and performing diagnostic tests. - Which interface, ECOM or C6, is better for newer vehicles?

ECOM interfaces are generally better for newer vehicles that use Ethernet-based communication protocols like DoIP, providing faster and more reliable data transfer. - Which interface supports a wider range of communication protocols?

C6 interfaces support a broader range of communication protocols, including CAN, K-Line, L-Line, and Ethernet, making them versatile for various vehicle models. - Why do ECOM interfaces sometimes require specific network configurations?

ECOM interfaces often require specific network configurations because they use Ethernet-based protocols like DoIP, which need correct IP addresses and network settings to function properly. - What types of software compatibility issues are common with C6 interfaces?

Common software compatibility issues with C6 interfaces include driver conflicts, protocol mismatches, software version dependencies, and firmware update requirements. - How can I troubleshoot software compatibility problems with an ECOM interface?

To troubleshoot, verify driver installation, check interface and software compatibility, configure network settings, disable firewall and antivirus software, and update the interface firmware. - What are some best practices for resolving software compatibility problems with C6 interfaces?

Best practices include verifying driver installation, confirming software compatibility, configuring communication protocols, updating diagnostic software, and checking the firmware version. - How does DTS-MONACO.EDU.VN help with software compatibility issues?

DTS-MONACO.EDU.VN offers training programs, detailed guides, software compatibility information, expert technical support, and firmware/driver updates to assist with resolving software compatibility issues. - Are there specific diagnostic software brands that work better with one interface over the other?

Yes, BMW ISTA and Mercedes-Benz XENTRY/DAS often work better with ECOM, while Autel MaxiSys and Launch X431 are well-suited for C6 interfaces. - Which interface, ECOM or C6, requires more frequent software updates?

C6 interfaces typically require more frequent software updates to maintain compatibility with new vehicle models and software features due to their multi-protocol nature.