DTS Monaco can access data related to ECU internal temperature sensors if they are available as parameters within the ECU’s diagnostic data. This allows technicians to monitor critical operating conditions and diagnose potential issues related to overheating or temperature-related malfunctions, crucial for modern vehicle maintenance. DTS Monaco’s advanced diagnostic capabilities, enhanced by resources like DTS-MONACO.EDU.VN, empower professionals to conduct thorough ECU analysis and coding. Understanding ECU data parameters and leveraging car coding techniques ensures optimal vehicle performance and longevity.

Contents

- 1. What is DTS Monaco and How Does it Work?

- 1.1. Key Features of DTS Monaco

- 1.2. Diagnostic Protocols Supported by DTS Monaco

- 1.3. Benefits of Using DTS Monaco in Automotive Diagnostics

- 2. Understanding ECU Internal Temperature Sensors

- 2.1. The Role of Temperature Sensors in ECU Operation

- 2.2. Types of Temperature Sensors Used in ECUs

- 2.3. Common Issues Related to ECU Temperature Sensors

- 3. Accessing ECU Data with DTS Monaco

- 3.1. Connecting DTS Monaco to the Vehicle’s ECU Network

- 3.2. Navigating the DTS Monaco Interface to Find Temperature Sensor Data

- 3.3. Interpreting ECU Temperature Sensor Readings

- 4. Verifying Temperature Sensor Availability

- 4.1. Checking Vehicle Documentation and Specifications

- 4.2. Using DTS Monaco’s ECU Identification Function

- 4.3. Scanning for Available Parameters in DTS Monaco

- 5. Practical Examples of Using DTS Monaco for Temperature Monitoring

- 5.1. Diagnosing Overheating Issues

- 5.2. Identifying Faulty Cooling Systems

- 5.3. Monitoring ECU Performance Under Different Conditions

- 5.4. Verifying the Correct Operation of Aftermarket Components

- 6. Potential Limitations and Considerations

- 6.1. ECU Compatibility

- 6.2. Data Parameter Availability

- 6.3. Data Interpretation Challenges

- 6.4. Software Updates and Licensing

- 7. Advanced Techniques for Temperature Data Analysis

- 7.1. Data Logging and Trend Analysis

- 7.2. Custom Diagnostic Routines

- 7.3. Integration with External Sensors and Devices

- 7.4. Use of Third-Party Diagnostic Databases

- 8. Training and Resources for DTS Monaco Users

- 8.1. Formal Training Courses

- 8.2. Online Tutorials and Documentation

- 8.3. User Forums and Communities

- 8.4. Vendor Support and Updates

- 9. Case Studies: Real-World Applications of DTS Monaco

- 9.1. Case Study 1: Diagnosing Intermittent Engine Stalling

- 9.2. Case Study 2: Identifying a Faulty Thermostat

- 9.3. Case Study 3: Resolving a Transmission Overheating Issue

- 10. Future Trends in ECU Diagnostics and Temperature Monitoring

- 10.1. Increased Use of Wireless Diagnostics

- 10.2. Integration of Artificial Intelligence (AI)

- 10.3. Enhanced Security Measures

- 10.4. Standardization of Diagnostic Protocols

- FAQ Section

- 1. Can DTS Monaco read ECU temperature data?

- 2. What types of temperature sensors are used in ECUs?

- 3. How do I connect DTS Monaco to a vehicle’s ECU?

- 4. Where can I find the temperature sensor data within the DTS Monaco interface?

- 5. How do I interpret ECU temperature sensor readings?

- 6. What are some common issues related to ECU temperature sensors?

- 7. Is DTS Monaco compatible with all vehicles?

- 8. Can DTS Monaco help diagnose overheating issues?

- 9. What kind of training is available for DTS Monaco users?

- 10. What future trends are expected in ECU diagnostics?

1. What is DTS Monaco and How Does it Work?

DTS Monaco (Diagnostic Tool Set Monaco) is a comprehensive diagnostic software used for ECU (Engine Control Unit) diagnostics, flashing, and car coding in the automotive industry. It serves as a powerful tool for automotive technicians and engineers to interact with vehicle ECUs, perform advanced diagnostics, and customize vehicle functions. DTS Monaco works by establishing a communication link with the vehicle’s ECUs via diagnostic protocols such as CAN, K-Line, and Ethernet. Once connected, users can access a wide range of diagnostic functions, including reading and clearing diagnostic trouble codes (DTCs), monitoring live data parameters, performing ECU programming and flashing, and executing car coding procedures to enable or disable specific vehicle features. DTS Monaco’s intuitive interface and robust functionality make it an indispensable tool for modern automotive diagnostics and car coding.

1.1. Key Features of DTS Monaco

DTS Monaco offers a broad spectrum of features that cater to various diagnostic and car coding needs. Key features include:

- ECU Identification: Allows users to quickly identify and gather information about the connected ECUs, including part numbers, software versions, and manufacturing dates.

- Diagnostic Trouble Code (DTC) Reading and Clearing: Enables users to read and clear DTCs stored in the ECUs, providing insights into potential vehicle malfunctions and allowing for efficient troubleshooting.

- Live Data Monitoring: Provides real-time monitoring of various ECU parameters, such as engine speed, temperature, voltage, and sensor readings, enabling users to assess vehicle performance and diagnose issues.

- ECU Flashing and Programming: Supports ECU flashing and programming operations, allowing users to update ECU software, install new calibrations, and perform ECU replacements.

- Car Coding: Facilitates car coding procedures, enabling users to customize vehicle functions, enable or disable features, and personalize vehicle settings according to customer preferences.

- Diagnostic Protocols Support: Supports a wide range of diagnostic protocols, including CAN, K-Line, Ethernet, and DoIP, ensuring compatibility with various vehicle makes and models.

- Automation and Scripting: Offers automation and scripting capabilities, allowing users to create custom diagnostic routines, automate repetitive tasks, and streamline diagnostic workflows.

- Offline Data Analysis: Enables users to analyze diagnostic data offline, allowing for in-depth analysis, trend identification, and report generation without requiring a live connection to the vehicle.

1.2. Diagnostic Protocols Supported by DTS Monaco

DTS Monaco supports a multitude of diagnostic protocols, guaranteeing compatibility with a diverse range of vehicles. Here are some of the key protocols supported:

| Protocol | Description |

|---|---|

| CAN | Controller Area Network, a widely used protocol for in-vehicle communication. |

| K-Line | A single-wire communication protocol commonly used in older vehicles. |

| Ethernet | A high-speed communication protocol increasingly used in modern vehicles for advanced diagnostics and programming. |

| DoIP | Diagnostics over Internet Protocol, enabling remote diagnostics and programming via Ethernet. |

| UDS | Unified Diagnostic Services, a standardized diagnostic protocol used across various vehicle manufacturers. |

| J1939 | A communication protocol used in heavy-duty vehicles and off-highway equipment. |

| ISO 15765 | A standard for diagnostic communication over CAN, defining the transport layer and diagnostic services. |

| ISO 14229 | A standard specifying the Unified Diagnostic Services (UDS) protocol used in automotive ECUs. |

| KW2000 | A diagnostic protocol used in older vehicles, particularly those from European manufacturers. |

| Keyword 2000 | Another name for KW2000, a diagnostic protocol used in older vehicles. |

1.3. Benefits of Using DTS Monaco in Automotive Diagnostics

Utilizing DTS Monaco in automotive diagnostics presents numerous advantages for technicians and automotive businesses. These include:

- Enhanced Diagnostic Capabilities: DTS Monaco offers advanced diagnostic capabilities, allowing technicians to perform in-depth diagnostics, identify complex issues, and troubleshoot vehicle malfunctions effectively.

- Increased Efficiency: With its intuitive interface, automation features, and comprehensive diagnostic functions, DTS Monaco streamlines the diagnostic process, saving time and increasing efficiency.

- Improved Accuracy: DTS Monaco provides access to accurate and reliable diagnostic data, enabling technicians to make informed decisions, avoid misdiagnosis, and ensure accurate repairs.

- Expanded Service Offerings: DTS Monaco empowers automotive businesses to offer a wider range of services, including ECU programming, car coding, and advanced diagnostics, attracting more customers and increasing revenue.

- Future-Proofing: DTS Monaco is continuously updated with support for the latest vehicle models, diagnostic protocols, and technologies, ensuring that automotive businesses stay ahead of the curve and remain competitive.

- Customization: Users can customize vehicle functions, enable or disable features, and personalize vehicle settings according to customer preferences.

2. Understanding ECU Internal Temperature Sensors

ECU internal temperature sensors play a vital role in monitoring the operating temperature of the ECU and protecting it from overheating. These sensors are typically located within the ECU housing and are designed to measure the temperature of critical components, such as microprocessors, memory chips, and power modules. The data provided by these sensors is used by the ECU to regulate its internal temperature, optimize performance, and prevent damage caused by excessive heat.

2.1. The Role of Temperature Sensors in ECU Operation

Temperature sensors within the ECU safeguard against overheating, optimize performance, and prevent damage. These sensors monitor the temperature of critical components like microprocessors and memory chips. The data collected helps the ECU manage its internal temperature by adjusting parameters such as clock speed, voltage, and cooling fan operation.

By monitoring internal temperatures, the ECU can:

- Prevent Overheating: High temperatures can cause irreversible damage to electronic components, leading to ECU failure. Temperature sensors allow the ECU to detect overheating conditions and take corrective actions, such as reducing power consumption or activating cooling mechanisms.

- Optimize Performance: Temperature affects the performance of electronic components. By monitoring temperature, the ECU can adjust its operating parameters to maintain optimal performance within the safe temperature range.

- Ensure Reliability: Maintaining stable operating temperatures helps prolong the lifespan of the ECU and ensures reliable operation over the long term.

2.2. Types of Temperature Sensors Used in ECUs

Several types of temperature sensors are commonly used in ECUs, each with its own characteristics and operating principles. These include:

- Thermistors: Thermistors are temperature-sensitive resistors whose resistance changes with temperature. They are widely used in ECUs due to their small size, high sensitivity, and low cost. NTC (Negative Temperature Coefficient) thermistors are commonly used, where resistance decreases as temperature increases.

- Resistance Temperature Detectors (RTDs): RTDs are precision temperature sensors that utilize the principle of resistance change with temperature. They offer excellent accuracy and stability over a wide temperature range but are typically larger and more expensive than thermistors.

- Thermocouples: Thermocouples are temperature sensors that generate a voltage proportional to the temperature difference between two dissimilar metals. They are suitable for high-temperature applications but may require signal amplification and compensation circuitry.

- Integrated Temperature Sensors: Integrated temperature sensors are complete temperature sensing solutions that integrate the sensor element, signal conditioning circuitry, and communication interface into a single package. They offer ease of use, high accuracy, and digital output for seamless integration with the ECU.

2.3. Common Issues Related to ECU Temperature Sensors

Several issues can arise with ECU temperature sensors, leading to inaccurate temperature readings, ECU malfunctions, and drivability problems. Common issues include:

- Sensor Failure: Temperature sensors can fail due to age, thermal stress, or physical damage. A failed sensor may provide incorrect temperature readings or no readings at all, leading to ECU errors and drivability issues.

- Wiring Problems: Damaged, corroded, or loose wiring connections can disrupt the signal from the temperature sensor to the ECU, resulting in inaccurate temperature readings or intermittent sensor failures.

- Contamination: Dirt, moisture, or contaminants can accumulate on the temperature sensor, affecting its accuracy and reliability. Regular cleaning and maintenance are essential to prevent contamination-related issues.

- Calibration Drift: Over time, temperature sensors may experience calibration drift, where their accuracy degrades due to aging or environmental factors. Recalibration or replacement of the sensor may be necessary to restore accuracy.

- ECU Malfunctions: In some cases, ECU malfunctions can interfere with the temperature sensor signal processing, leading to erroneous temperature readings or sensor errors.

3. Accessing ECU Data with DTS Monaco

DTS Monaco provides a comprehensive interface for accessing and analyzing ECU data, including data from internal temperature sensors. By connecting to the vehicle’s ECU network and utilizing DTS Monaco’s diagnostic capabilities, technicians can monitor ECU temperature in real-time, diagnose temperature-related issues, and perform necessary repairs or adjustments. DTS Monaco facilitates efficient and accurate ECU data access, contributing to improved diagnostic outcomes and vehicle performance.

3.1. Connecting DTS Monaco to the Vehicle’s ECU Network

To begin accessing ECU data with DTS Monaco, the first step is to establish a connection between the software and the vehicle’s ECU network. This typically involves the following steps:

- Hardware Interface: Connect a compatible hardware interface (e.g., a diagnostic interface or a vehicle communication interface (VCI)) to the vehicle’s diagnostic port (usually an OBD-II port).

- Software Configuration: Configure DTS Monaco to recognize and communicate with the hardware interface. This involves selecting the appropriate interface type, communication protocol, and COM port settings within the DTS Monaco software.

- Vehicle Selection: Select the correct vehicle make, model, and year in DTS Monaco to ensure compatibility with the vehicle’s ECU network.

- ECU Selection: Choose the specific ECU you want to connect to from the list of available ECUs. This may include the engine control unit (ECU), transmission control unit (TCU), or other relevant ECUs.

- Connection Establishment: Initiate the connection process in DTS Monaco, which will establish a communication link between the software and the selected ECU.

3.2. Navigating the DTS Monaco Interface to Find Temperature Sensor Data

Once connected to the ECU, navigating the DTS Monaco interface to locate temperature sensor data typically involves the following steps:

- Data Identification: Identify the specific diagnostic service or data identifier (DID) that corresponds to the ECU internal temperature sensor. This information may be available in the vehicle’s service manual, diagnostic documentation, or ECU description file.

- Service Selection: Select the appropriate diagnostic service in DTS Monaco that allows you to read or monitor ECU data parameters. This may include services such as “Read Data By Identifier” or “Read Dynamic Data Identifier.”

- Data Parameter Selection: Enter the data identifier (DID) or select the corresponding parameter from a list of available parameters. This will specify the ECU internal temperature sensor data that you want to access.

- Data Display: View the temperature sensor data in real-time or as a snapshot, depending on the selected diagnostic service. DTS Monaco typically displays the data in a numerical format, along with units of measurement (e.g., degrees Celsius or Fahrenheit).

- Data Logging: Enable data logging in DTS Monaco to record the temperature sensor data over time. This allows you to analyze temperature trends, identify temperature fluctuations, and diagnose temperature-related issues.

3.3. Interpreting ECU Temperature Sensor Readings

Interpreting ECU temperature sensor readings is crucial for accurately diagnosing temperature-related issues and ensuring proper ECU operation. Here are some key considerations for interpreting ECU temperature sensor readings:

- Reference Values: Compare the temperature sensor readings to the vehicle manufacturer’s specifications or reference values. This will help you determine whether the temperature is within the normal operating range or if there is a potential issue.

- Operating Conditions: Consider the vehicle’s operating conditions when interpreting temperature sensor readings. Factors such as ambient temperature, engine load, and vehicle speed can affect ECU temperature.

- Trend Analysis: Analyze the temperature sensor data over time to identify trends and patterns. This can help you detect gradual temperature increases, sudden temperature spikes, or other temperature-related anomalies.

- Correlation with Symptoms: Correlate the temperature sensor readings with the vehicle’s symptoms or drivability issues. This can help you pinpoint the root cause of the problem and guide your diagnostic efforts.

- Diagnostic Trouble Codes (DTCs): Check for any diagnostic trouble codes (DTCs) related to the ECU temperature sensor. DTCs can provide valuable information about sensor malfunctions, wiring problems, or ECU issues.

4. Verifying Temperature Sensor Availability

Confirming the availability of temperature sensor data in the ECU is essential before attempting to access it with DTS Monaco. This involves verifying that the ECU is equipped with internal temperature sensors and that the corresponding data parameters are accessible via diagnostic protocols. Verifying temperature sensor availability ensures that diagnostic efforts are focused on valid data sources, leading to more accurate diagnoses and efficient repairs.

4.1. Checking Vehicle Documentation and Specifications

Consulting vehicle documentation and specifications is a reliable way to verify the availability of ECU internal temperature sensors and their corresponding data parameters. Vehicle service manuals, technical bulletins, and wiring diagrams often provide detailed information about ECU sensor configurations, data parameter lists, and diagnostic procedures. By reviewing these resources, technicians can determine whether the ECU is equipped with temperature sensors and identify the specific data identifiers (DIDs) or diagnostic services required to access the temperature data.

4.2. Using DTS Monaco’s ECU Identification Function

DTS Monaco’s ECU identification function provides a quick and convenient way to gather information about the connected ECU, including the availability of temperature sensor data. By connecting to the ECU and using the ECU identification function, technicians can view a list of supported data parameters, diagnostic services, and ECU features. This can help verify whether the ECU is equipped with internal temperature sensors and whether the corresponding temperature data is accessible via DTS Monaco.

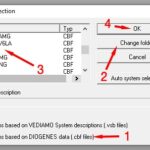

4.3. Scanning for Available Parameters in DTS Monaco

DTS Monaco allows users to scan for available parameters within the ECU, providing a dynamic way to identify accessible data points, including temperature sensor readings. This feature can be particularly useful when documentation is lacking or incomplete. By initiating a parameter scan, DTS Monaco will automatically search for and display a list of available data parameters within the ECU, along with their corresponding data identifiers (DIDs) and descriptions. Technicians can then review the scan results to determine whether temperature sensor data is available and identify the appropriate parameters for monitoring.

5. Practical Examples of Using DTS Monaco for Temperature Monitoring

DTS Monaco proves invaluable in various practical scenarios for monitoring ECU temperature and diagnosing related issues. Here are some examples:

5.1. Diagnosing Overheating Issues

When a vehicle exhibits symptoms of overheating, such as engine knocking, loss of power, or coolant leaks, DTS Monaco can be used to monitor the ECU internal temperature in real-time. By comparing the temperature readings to the manufacturer’s specifications, technicians can determine whether the ECU is overheating and identify potential causes, such as a faulty cooling fan, a blocked radiator, or a malfunctioning thermostat.

5.2. Identifying Faulty Cooling Systems

DTS Monaco can help identify faulty cooling system components by monitoring the ECU internal temperature and correlating it with other engine parameters. For example, if the ECU temperature remains high despite the cooling fan operating at full speed, it may indicate a problem with the water pump, radiator, or cooling fan control circuit.

5.3. Monitoring ECU Performance Under Different Conditions

DTS Monaco allows technicians to monitor ECU performance under various operating conditions, such as during acceleration, deceleration, or idle. By logging the ECU internal temperature data over time, technicians can identify temperature-related performance issues, such as thermal throttling, which occurs when the ECU reduces power output to prevent overheating.

5.4. Verifying the Correct Operation of Aftermarket Components

When installing aftermarket performance parts, such as ECU tuning software or performance chips, DTS Monaco can be used to verify the correct operation of these components and ensure that they do not cause the ECU to overheat. By monitoring the ECU internal temperature before and after installation, technicians can assess the impact of the aftermarket components on ECU temperature and make necessary adjustments to prevent damage.

6. Potential Limitations and Considerations

While DTS Monaco is a powerful tool for accessing and monitoring ECU data, there are potential limitations and considerations to keep in mind. Understanding these limitations can help technicians use DTS Monaco effectively and avoid potential pitfalls.

6.1. ECU Compatibility

DTS Monaco may not be compatible with all vehicle makes and models, particularly older vehicles or vehicles with proprietary diagnostic protocols. Before using DTS Monaco, it’s essential to verify that the software supports the vehicle’s ECU network and diagnostic protocols.

6.2. Data Parameter Availability

Not all ECUs provide access to internal temperature sensor data via diagnostic protocols. Some ECUs may not be equipped with temperature sensors, or the temperature data may be inaccessible due to security restrictions or proprietary data formats. Technicians should verify the availability of temperature sensor data before attempting to access it with DTS Monaco.

6.3. Data Interpretation Challenges

Interpreting ECU temperature sensor readings can be challenging, particularly if the vehicle manufacturer does not provide detailed specifications or reference values. Technicians may need to rely on their experience, technical knowledge, and diagnostic skills to accurately interpret the data and diagnose temperature-related issues.

6.4. Software Updates and Licensing

DTS Monaco requires regular software updates and licensing to maintain compatibility with the latest vehicle models, diagnostic protocols, and ECU features. Technicians should ensure that their DTS Monaco software is up-to-date and properly licensed to avoid potential issues.

7. Advanced Techniques for Temperature Data Analysis

For advanced diagnostics and in-depth analysis of temperature data, technicians can utilize several advanced techniques with DTS Monaco:

7.1. Data Logging and Trend Analysis

DTS Monaco’s data logging capabilities allow technicians to record ECU temperature data over time and analyze trends using graphing tools or spreadsheet software. By analyzing temperature trends, technicians can identify temperature fluctuations, gradual increases, or sudden spikes that may indicate underlying issues.

7.2. Custom Diagnostic Routines

DTS Monaco supports the creation of custom diagnostic routines using scripting languages such as OTX (Open Test sequence eXchange). Technicians can create custom routines to automate temperature monitoring, perform specific tests under different conditions, and generate detailed diagnostic reports.

7.3. Integration with External Sensors and Devices

DTS Monaco can be integrated with external sensors and devices, such as thermocouples or infrared thermometers, to gather additional temperature data and correlate it with ECU internal temperature readings. This can provide a more comprehensive view of the vehicle’s thermal behavior and help pinpoint the source of temperature-related issues.

7.4. Use of Third-Party Diagnostic Databases

Technicians can leverage third-party diagnostic databases and knowledge bases to access detailed information about ECU temperature sensors, data parameters, and diagnostic procedures. These resources can provide valuable insights and guidance for diagnosing complex temperature-related issues.

8. Training and Resources for DTS Monaco Users

To effectively utilize DTS Monaco and master advanced diagnostic techniques, technicians can benefit from specialized training and resources:

8.1. Formal Training Courses

Enrolling in formal training courses on DTS Monaco and automotive diagnostics can provide technicians with comprehensive knowledge and hands-on experience. These courses typically cover topics such as ECU communication protocols, diagnostic procedures, data interpretation, and advanced troubleshooting techniques. DTS-MONACO.EDU.VN offers specialized training programs designed to enhance your skills.

8.2. Online Tutorials and Documentation

Numerous online tutorials, documentation, and knowledge bases are available for DTS Monaco users. These resources provide step-by-step instructions, troubleshooting tips, and practical examples for using DTS Monaco in various diagnostic scenarios.

8.3. User Forums and Communities

Participating in user forums and online communities dedicated to DTS Monaco and automotive diagnostics can provide technicians with valuable networking opportunities, access to expert advice, and a platform for sharing knowledge and experiences.

8.4. Vendor Support and Updates

Staying connected with the DTS Monaco vendor and subscribing to software updates can ensure that technicians have access to the latest features, bug fixes, and technical support. Vendor support channels can provide assistance with software installation, configuration, and troubleshooting.

9. Case Studies: Real-World Applications of DTS Monaco

Examining real-world case studies highlights the practical benefits of using DTS Monaco for temperature monitoring and diagnostics.

9.1. Case Study 1: Diagnosing Intermittent Engine Stalling

A vehicle experiencing intermittent engine stalling was diagnosed using DTS Monaco. By monitoring the ECU internal temperature, technicians discovered that the ECU was overheating due to a faulty cooling fan. Replacing the cooling fan resolved the overheating issue and eliminated the engine stalling problem.

9.2. Case Study 2: Identifying a Faulty Thermostat

A vehicle exhibiting poor fuel economy and sluggish performance was diagnosed using DTS Monaco. By comparing the ECU internal temperature to the engine coolant temperature, technicians identified a faulty thermostat that was causing the engine to run too cold. Replacing the thermostat restored the engine to its normal operating temperature and improved fuel economy and performance.

9.3. Case Study 3: Resolving a Transmission Overheating Issue

A vehicle experiencing transmission slipping and erratic shifting was diagnosed using DTS Monaco. By monitoring the transmission control unit (TCU) temperature, technicians discovered that the transmission was overheating due to a clogged transmission cooler. Clearing the transmission cooler resolved the overheating issue and restored normal transmission operation.

10. Future Trends in ECU Diagnostics and Temperature Monitoring

The field of ECU diagnostics and temperature monitoring is continuously evolving, driven by advancements in automotive technology and the increasing complexity of vehicle systems. Several trends are expected to shape the future of ECU diagnostics and temperature monitoring:

10.1. Increased Use of Wireless Diagnostics

Wireless diagnostic interfaces and cloud-based diagnostic platforms are becoming increasingly popular, enabling technicians to perform remote diagnostics, access real-time data, and collaborate with experts from anywhere in the world.

10.2. Integration of Artificial Intelligence (AI)

AI-powered diagnostic tools are emerging, capable of analyzing vast amounts of vehicle data, identifying patterns, and predicting potential failures before they occur. AI algorithms can also assist technicians with data interpretation, troubleshooting, and repair recommendations.

10.3. Enhanced Security Measures

As vehicles become more connected and reliant on software, cybersecurity threats are becoming a growing concern. Future diagnostic tools will incorporate enhanced security measures to protect vehicle ECUs from unauthorized access and malicious attacks.

10.4. Standardization of Diagnostic Protocols

Efforts are underway to standardize diagnostic protocols and data formats across vehicle manufacturers, making it easier for technicians to diagnose and repair vehicles from different brands using a single diagnostic tool.

Can DTS Monaco access data related to ECU internal temperature sensors? Absolutely, if the data is available as a parameter. Leveraging resources like DTS-MONACO.EDU.VN can help you master the techniques needed for effective ECU analysis and car coding. By understanding ECU data parameters, technicians can optimize vehicle performance, troubleshoot efficiently, and stay ahead in the rapidly evolving automotive industry. Exploring options such as diagnostic tools and automotive diagnostic software is crucial for staying competitive.

Are you ready to elevate your automotive diagnostic skills? Visit DTS-MONACO.EDU.VN today to explore our comprehensive training programs and unlock the full potential of DTS Monaco. Master car coding techniques and gain expertise in advanced ECU analysis. Contact us now to learn more and take your career to the next level! Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880.

FAQ Section

1. Can DTS Monaco read ECU temperature data?

Yes, DTS Monaco can read ECU temperature data if the ECU provides this data as a readable parameter.

2. What types of temperature sensors are used in ECUs?

Common types include thermistors, RTDs (Resistance Temperature Detectors), thermocouples, and integrated temperature sensors.

3. How do I connect DTS Monaco to a vehicle’s ECU?

Connect a compatible hardware interface to the vehicle’s diagnostic port, configure DTS Monaco to recognize the interface, select the vehicle and ECU, and establish a connection.

4. Where can I find the temperature sensor data within the DTS Monaco interface?

Navigate through the diagnostic services, identify the data identifier (DID) for temperature, and select the appropriate parameter to display the data.

5. How do I interpret ECU temperature sensor readings?

Compare the readings to the vehicle manufacturer’s specifications, consider operating conditions, analyze trends over time, and correlate with any symptoms or DTCs.

6. What are some common issues related to ECU temperature sensors?

Common issues include sensor failure, wiring problems, contamination, and calibration drift.

7. Is DTS Monaco compatible with all vehicles?

DTS Monaco may not be compatible with all vehicle makes and models, especially older ones or those with proprietary diagnostic protocols.

8. Can DTS Monaco help diagnose overheating issues?

Yes, DTS Monaco can monitor ECU internal temperature in real-time to diagnose overheating and identify potential causes like a faulty cooling fan or blocked radiator.

9. What kind of training is available for DTS Monaco users?

Formal training courses, online tutorials, user forums, and vendor support are available to help technicians effectively use DTS Monaco. DTS-MONACO.EDU.VN offers specialized training programs.

10. What future trends are expected in ECU diagnostics?

Future trends include increased use of wireless diagnostics, integration of artificial intelligence (AI), enhanced security measures, and standardization of diagnostic protocols.