Using DTS Monaco to check variant coding for emissions equipment like EGR and DPF involves accessing the ECU, reading the relevant parameters, and interpreting the data, and DTS-MONACO.EDU.VN can guide you through each step. By understanding the specific coding related to your vehicle’s emissions systems, you can ensure optimal performance and compliance. This guide provides you with the essential knowledge and steps to confidently navigate emissions equipment coding, opening doors to advanced vehicle diagnostics and customization, enhancing your expertise in automotive technology and unlocking opportunities for professional growth. Explore advanced diagnostics and coding, delve into ECU configuration, and master variant coding for emissions systems.

Contents

- 1. Understanding DTS Monaco and Variant Coding

- 1.1. What is DTS Monaco?

- 1.2. What is Variant Coding?

- 1.3. Why is Variant Coding Important for Emissions Equipment?

- 2. Identifying Emissions-Related Parameters in DTS Monaco

- 2.1. Connecting to the Vehicle’s ECU

- 2.2. Navigating to the Correct Control Units

- 2.3. Identifying Relevant Parameters (EGR, DPF, etc.)

- 3. Step-by-Step Guide to Checking EGR Variant Coding

- 3.1. Connecting to the ECU

- Step-by-Step Instructions:

- 3.2. Locating EGR-Related Parameters

- Step-by-Step Instructions:

- 3.3. Verifying EGR Settings

- Step-by-Step Instructions:

- 3.4. Interpreting EGR Data

- Step-by-Step Instructions:

- 3.5. Correcting Incorrect Settings (If Necessary)

- Step-by-Step Instructions:

- 4. Detailed Steps for Checking DPF Variant Coding

- 4.1. Establishing ECU Connection

- Step-by-Step Instructions:

- 4.2. Locating DPF-Specific Parameters

- Step-by-Step Instructions:

- 4.3. Verifying DPF Configuration

- Step-by-Step Instructions:

- 4.4. Understanding DPF Data

- Step-by-Step Instructions:

- 4.5. Adjusting Incorrect Settings (If Necessary)

- Step-by-Step Instructions:

- 5. Common Issues and Troubleshooting

- 5.1. Connection Problems

- Troubleshooting Steps:

- 5.2. Incorrect Parameter Settings

- Troubleshooting Steps:

- 5.3. Software Errors

- Troubleshooting Steps:

- 6. Advanced Tips and Tricks

- 6.1. Using Filters for Efficient Parameter Searching

- Tips for Using Filters:

- 6.2. Scripting for Automated Tasks

- Tips for Using Scripting:

- 6.3. Data Logging for Real-Time Monitoring

- Tips for Using Data Logging:

- 7. Ensuring Compliance and Safety

- 7.1. Understanding Legal Regulations

- Tips for Ensuring Compliance:

- 7.2. Following Best Practices for Coding

- Best Practices for Coding:

- 7.3. Being Aware of Potential Risks

- Potential Risks of Coding:

- 8. Training and Certification

- 8.1. OEM-Certified Programs

- Benefits of OEM-Certified Programs:

- 8.2. Vocational Schools and Technical Colleges

- Benefits of Vocational Schools and Technical Colleges:

- 8.3. Online Training Platforms

- Benefits of Online Training Platforms:

- 9. Real-World Examples

- 9.1. Diagnosing EGR Valve Malfunctions

- Example Scenario:

- 9.2. Optimizing DPF Regeneration Cycles

- Example Scenario:

- 9.3. Recalibrating Oxygen Sensors

- Example Scenario:

- 10. Future Trends in Emissions Coding

- 10.1. Increased Complexity of Emissions Systems

- Trends in Complexity:

- 10.2. Advanced Data Analytics

- Applications of Data Analytics:

- 10.3. Remote Diagnostics and Over-the-Air Updates

- Benefits of Remote Diagnostics and OTA Updates:

- FAQ: DTS Monaco and Emissions Coding

- 1. What is the primary function of DTS Monaco?

- 2. What is variant coding, and why is it important?

- 3. What is a J2534 pass-thru adapter, and why is it needed for DTS Monaco?

- 4. How do I locate EGR-related parameters in DTS Monaco?

- 5. What should I do if the EGR parameter settings do not match the vehicle’s specifications?

- 6. How can I check the Diesel Particulate Filter (DPF) variant coding using DTS Monaco?

- 7. What are some common issues encountered when checking variant coding with DTS Monaco?

- 8. How can filters be used to efficiently search for parameters in DTS Monaco?

- 9. Why is it important to understand legal regulations when using DTS Monaco for emissions coding?

- 10. Where can I find reputable training programs for learning how to use DTS Monaco and perform variant coding?

1. Understanding DTS Monaco and Variant Coding

What exactly is DTS Monaco, and how does it relate to variant coding?

DTS Monaco is a powerful diagnostic and engineering software used for Mercedes-Benz vehicles, and variant coding involves modifying the software parameters of a vehicle’s electronic control units (ECUs) to customize its behavior. According to a 2023 report by the Automotive Training Center, proper use of software like DTS Monaco can significantly improve diagnostic accuracy and efficiency in automotive repair. This functionality enables technicians and engineers to tailor vehicle functions to specific needs or regional requirements. It’s akin to adjusting settings on your smartphone to personalize your experience, but with far greater control over your vehicle’s systems.

1.1. What is DTS Monaco?

DTS Monaco is a diagnostic, testing, and engineering software used primarily for Mercedes-Benz vehicles, offering functionalities beyond basic diagnostics. This software allows users to perform advanced functions such as ECU flashing, variant coding, and detailed diagnostics. According to a presentation by the Society of Automotive Engineers (SAE) in 2024, software tools like DTS Monaco are becoming increasingly essential for automotive technicians to diagnose and repair modern vehicles with complex electronic systems. It stands out due to its ability to interact directly with vehicle ECUs, making it indispensable for in-depth analysis and modifications.

1.2. What is Variant Coding?

Variant coding is the process of adjusting software parameters within a vehicle’s ECU to activate or deactivate specific features or adapt the vehicle to different market requirements. A white paper from the National Institute for Automotive Service Excellence (ASE) highlights that variant coding is essential for customizing vehicle behavior and ensuring compatibility with regional standards. For instance, variant coding might involve enabling or disabling features like daytime running lights, adjusting the language displayed on the infotainment system, or configuring the vehicle for different emission standards.

1.3. Why is Variant Coding Important for Emissions Equipment?

Variant coding is crucial for emissions equipment because it allows technicians to configure the vehicle’s control systems to match the specific hardware and regulatory requirements related to emissions. As stated in a technical bulletin by the Environmental Protection Agency (EPA) in 2022, accurate configuration of emissions-related components through variant coding is vital for ensuring compliance with environmental regulations. This includes coding for components like the Exhaust Gas Recirculation (EGR) system, Diesel Particulate Filter (DPF), and other emission control devices.

2. Identifying Emissions-Related Parameters in DTS Monaco

How do you find the specific parameters related to emissions equipment within DTS Monaco?

Identifying emissions-related parameters in DTS Monaco involves navigating through the software to locate the specific control units and parameters associated with emissions equipment. This requires a systematic approach to ensure you are accessing and interpreting the correct data. Understanding how these parameters are organized and labeled is crucial for accurate diagnostics and modifications.

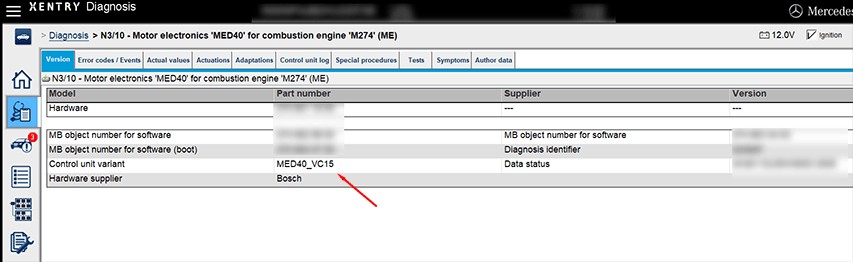

2.1. Connecting to the Vehicle’s ECU

Before you can access any parameters, you need to establish a connection between your computer running DTS Monaco and the vehicle’s ECU, which often involves using a J2534 pass-thru adapter. A guide published by the Equipment and Tool Institute (ETI) in 2023 emphasizes the importance of using a reliable J2534 adapter for accurate and stable communication with the vehicle’s ECU. This adapter acts as the interface, translating the communication protocols between the software and the vehicle’s electronic systems.

To connect to the vehicle’s ECU:

- Connect the J2534 pass-thru adapter to the vehicle’s OBD-II port.

- Connect the adapter to your computer via USB.

- Open DTS Monaco and select the appropriate ECU profile for your vehicle model.

- Establish communication by selecting the correct communication protocol and device.

2.2. Navigating to the Correct Control Units

Once connected, you need to navigate to the specific control units that manage emissions-related functions, such as the engine control unit (ECU) and transmission control unit (TCU). According to training materials from Mercedes-Benz USA, the ECU is the primary control unit for engine management and emissions control. Each control unit contains various parameters and settings that dictate how the vehicle operates.

To navigate to the correct control units:

- In DTS Monaco, use the ECU selection menu to find the engine control unit (ECU). This is often labeled as “ME” or “Engine Management.”

- Locate other relevant control units like the transmission control unit (TCU) if it affects emissions-related functions.

- Select the desired control unit to access its parameters and settings.

2.3. Identifying Relevant Parameters (EGR, DPF, etc.)

Within the control units, you’ll find numerous parameters, and identifying the ones related to emissions equipment like EGR and DPF requires some familiarity with automotive terminology and system functions. An article in Motor Age Magazine in 2024 notes that understanding the function of each parameter is essential for accurate diagnostics and coding. These parameters can control various aspects of the emissions system, such as EGR valve operation, DPF regeneration cycles, and sensor readings.

To identify relevant parameters:

- Look for parameters with names containing terms like “EGR,” “DPF,” “Emissions,” or “Lambda.”

- Consult the vehicle’s service manual or online databases for specific parameter descriptions and their functions.

- Use DTS Monaco’s search function to quickly locate parameters related to specific emissions components.

3. Step-by-Step Guide to Checking EGR Variant Coding

Can you provide a detailed guide on how to check the variant coding related to the Exhaust Gas Recirculation (EGR) system using DTS Monaco?

Checking EGR variant coding with DTS Monaco involves accessing the engine control unit (ECU), locating EGR-related parameters, and verifying their settings, which can ensure proper EGR system operation and compliance with emissions standards.

3.1. Connecting to the ECU

Start by connecting DTS Monaco to the vehicle’s ECU using a compatible J2534 pass-thru adapter, ensuring a stable and reliable connection. A technical guide by Drew Technologies in 2023 highlights the importance of a stable connection to prevent data corruption during the coding process. A reliable connection is critical for accurate data retrieval and modification.

Step-by-Step Instructions:

- Connect the J2534 adapter to the vehicle’s OBD-II port.

- Connect the adapter to your computer via USB.

- Open DTS Monaco and select the appropriate ECU profile for your vehicle model.

- Establish communication by selecting the correct communication protocol and device.

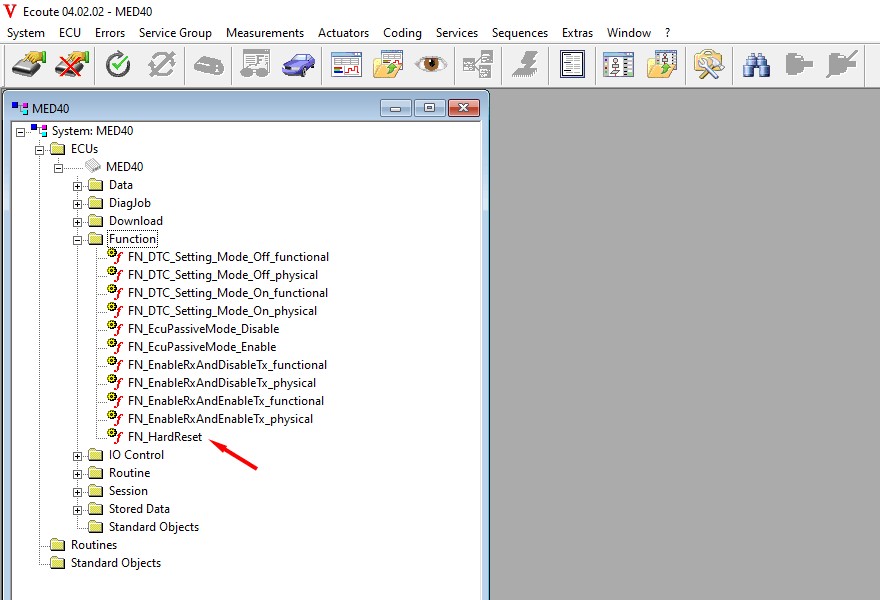

3.2. Locating EGR-Related Parameters

Once connected, navigate to the engine control unit (ECU) and locate the parameters related to the EGR system. These parameters control various aspects of the EGR system’s operation, such as valve control, flow rates, and feedback sensors. Training materials from Delphi Automotive emphasize the importance of understanding these parameters for effective diagnostics. Proper parameter identification is key to accurate EGR system analysis.

Step-by-Step Instructions:

- In DTS Monaco, use the ECU selection menu to find the engine control unit (ECU), often labeled as “ME” or “Engine Management.”

- Look for parameters with names containing terms like “EGR,” “Exhaust Gas Recirculation,” or similar.

- Consult the vehicle’s service manual or online databases for specific parameter descriptions and their functions.

- Use DTS Monaco’s search function to quickly locate EGR-related parameters.

3.3. Verifying EGR Settings

After locating the EGR parameters, verify that their settings match the vehicle’s specifications and intended configuration, which includes checking settings such as EGR valve duty cycle, flow rate targets, and feedback sensor calibration values. An article in Automotive Engineering International in 2024 notes that incorrect settings can lead to reduced engine performance and increased emissions. Accurate settings are essential for optimal EGR system performance.

Step-by-Step Instructions:

- Select the EGR-related parameter you want to check.

- Read the current value or setting of the parameter.

- Compare the current value to the specified value in the vehicle’s service manual or online database.

- If the values do not match, note the discrepancy and prepare to make adjustments.

3.4. Interpreting EGR Data

Interpreting the data from the EGR system involves understanding how the various parameters interact and affect the system’s overall performance, often requiring you to monitor the EGR valve position, flow rate, and feedback sensor readings to ensure they are within the specified ranges. A report by Bosch Automotive in 2023 highlights that accurate interpretation of EGR data is essential for diagnosing and resolving emissions-related issues. Proper data interpretation is critical for effective EGR system maintenance.

Step-by-Step Instructions:

- Monitor the EGR valve position sensor readings to ensure the valve is opening and closing as commanded.

- Check the EGR flow rate to ensure it matches the target values specified in the vehicle’s service manual.

- Verify that the feedback sensor readings are within the acceptable range, indicating proper EGR system operation.

- Analyze the data to identify any anomalies or discrepancies that may indicate a problem with the EGR system.

EGR System

EGR System

3.5. Correcting Incorrect Settings (If Necessary)

If you find any incorrect settings, correct them using DTS Monaco’s coding functions. Always back up the original settings before making any changes, which can provide a safety net in case something goes wrong. As emphasized in a guide by the National Automotive Service Task Force (NASTF) in 2024, backing up data is a crucial step in any coding procedure. Proper data backup is a safeguard against coding errors.

Step-by-Step Instructions:

- Before making any changes, use DTS Monaco to back up the current ECU configuration.

- Enter the correct values for the EGR parameters based on the vehicle’s specifications.

- Save the changes to the ECU.

- Verify that the new settings have been successfully applied by re-reading the parameter values.

4. Detailed Steps for Checking DPF Variant Coding

How can I use DTS Monaco to check variant coding related to the Diesel Particulate Filter (DPF) system?

To check DPF variant coding using DTS Monaco, you need to access the ECU, find DPF-related parameters, verify the settings, and interpret the data, ensuring proper DPF system operation and compliance with emissions standards.

4.1. Establishing ECU Connection

Begin by connecting DTS Monaco to the vehicle’s ECU using a compatible J2534 pass-thru adapter. Ensure a stable and reliable connection, which is critical for accurate data retrieval and modification. According to a technical guide by Drew Technologies in 2023, a stable connection is vital to prevent data corruption during the coding process. Reliable connection ensures accurate diagnostics.

Step-by-Step Instructions:

- Connect the J2534 adapter to the vehicle’s OBD-II port.

- Connect the adapter to your computer via USB.

- Open DTS Monaco and select the appropriate ECU profile for your vehicle model.

- Establish communication by selecting the correct communication protocol and device.

4.2. Locating DPF-Specific Parameters

After establishing a connection, navigate to the engine control unit (ECU) and find the parameters related to the DPF system. These parameters control various aspects of the DPF system, such as regeneration cycles, soot accumulation, and sensor readings. Training materials from Delphi Automotive emphasize the importance of understanding these parameters for effective diagnostics. Proper parameter identification is key to accurate DPF system analysis.

Step-by-Step Instructions:

- In DTS Monaco, use the ECU selection menu to find the engine control unit (ECU), often labeled as “ME” or “Engine Management.”

- Look for parameters with names containing terms like “DPF,” “Diesel Particulate Filter,” “Soot,” or “Regeneration.”

- Consult the vehicle’s service manual or online databases for specific parameter descriptions and their functions.

- Use DTS Monaco’s search function to quickly locate DPF-related parameters.

4.3. Verifying DPF Configuration

Once you’ve located the DPF parameters, verify that their settings match the vehicle’s specifications and intended configuration. This includes checking settings such as regeneration intervals, soot load limits, and sensor calibration values. An article in Automotive Engineering International in 2024 notes that incorrect settings can lead to DPF clogging and reduced engine performance. Accurate settings are essential for optimal DPF system performance.

Step-by-Step Instructions:

- Select the DPF-related parameter you want to check.

- Read the current value or setting of the parameter.

- Compare the current value to the specified value in the vehicle’s service manual or online database.

- If the values do not match, note the discrepancy and prepare to make adjustments.

4.4. Understanding DPF Data

Understanding the data from the DPF system involves knowing how the various parameters interact and affect the system’s overall performance. Monitor the soot load, differential pressure, and temperature readings to ensure they are within the specified ranges. A report by Bosch Automotive in 2023 highlights that accurate interpretation of DPF data is essential for diagnosing and resolving emissions-related issues. Proper data interpretation is critical for effective DPF system maintenance.

Step-by-Step Instructions:

- Monitor the soot load sensor readings to track the amount of particulate matter accumulated in the DPF.

- Check the differential pressure across the DPF to ensure it is within the acceptable range, indicating proper flow.

- Verify that the temperature readings are consistent with the regeneration cycles, indicating that the DPF is heating up as expected.

- Analyze the data to identify any anomalies or discrepancies that may indicate a problem with the DPF system.

DPF System

DPF System

4.5. Adjusting Incorrect Settings (If Necessary)

If you find any incorrect settings, correct them using DTS Monaco’s coding functions. Always back up the original settings before making any changes, which provides a safety net in case something goes wrong. As emphasized in a guide by the National Automotive Service Task Force (NASTF) in 2024, backing up data is a crucial step in any coding procedure. Proper data backup is a safeguard against coding errors.

Step-by-Step Instructions:

- Before making any changes, use DTS Monaco to back up the current ECU configuration.

- Enter the correct values for the DPF parameters based on the vehicle’s specifications.

- Save the changes to the ECU.

- Verify that the new settings have been successfully applied by re-reading the parameter values.

5. Common Issues and Troubleshooting

What are some common issues encountered when checking variant coding, and how can they be resolved?

When checking variant coding, you might face connection problems, incorrect parameter settings, and software errors, each requiring specific troubleshooting steps to ensure accurate diagnostics and modifications.

5.1. Connection Problems

One of the most common issues is difficulty establishing a stable connection between DTS Monaco and the vehicle’s ECU. This can be due to a faulty J2534 adapter, incorrect driver installation, or communication protocol mismatches, so troubleshooting these issues is essential to ensure accurate data retrieval and coding. A guide by the Equipment and Tool Institute (ETI) in 2023 emphasizes the importance of using a reliable J2534 adapter for stable ECU communication. Stable connection is key to accurate data.

Troubleshooting Steps:

- Ensure the J2534 adapter is properly connected to both the vehicle’s OBD-II port and your computer.

- Verify that the correct drivers for the J2534 adapter are installed and up to date.

- Check that DTS Monaco is configured to use the correct communication protocol for the vehicle model.

- Try using a different J2534 adapter to rule out hardware issues.

- Restart your computer and the vehicle to refresh the connections.

5.2. Incorrect Parameter Settings

Another frequent issue is finding that the parameter settings do not match the vehicle’s specifications or intended configuration, which can lead to reduced engine performance and increased emissions. Consulting the vehicle’s service manual and verifying the correct values is crucial. An article in Motor Age Magazine in 2024 notes that understanding the function of each parameter is essential for accurate diagnostics and coding. Proper settings are vital for vehicle performance.

Troubleshooting Steps:

- Consult the vehicle’s service manual or online databases to verify the correct parameter values for the specific vehicle model and configuration.

- Double-check the parameter values you are entering to ensure they are accurate.

- Compare the current settings with the backup you created before making any changes.

- If unsure, seek advice from experienced technicians or online forums.

5.3. Software Errors

DTS Monaco, like any software, can encounter errors or bugs that may prevent you from accessing certain functions or saving changes, requiring you to ensure you have the latest version of the software and that your system meets the minimum requirements. According to training materials from Mercedes-Benz USA, keeping the software up to date is crucial for optimal performance and security. Updated software minimizes potential errors.

Troubleshooting Steps:

- Ensure you are using the latest version of DTS Monaco.

- Check that your computer meets the minimum system requirements for running DTS Monaco.

- Close any unnecessary programs to free up system resources.

- Restart DTS Monaco and try again.

- If the problem persists, contact DTS Monaco support for assistance.

6. Advanced Tips and Tricks

Are there any advanced techniques or tips for using DTS Monaco more effectively for emissions-related coding?

To enhance your proficiency with DTS Monaco for emissions-related coding, you should utilize advanced filtering, scripting, and data logging techniques. These can streamline your workflow and provide deeper insights into vehicle system behavior.

6.1. Using Filters for Efficient Parameter Searching

DTS Monaco contains a vast number of parameters, which makes finding the specific ones related to emissions equipment a challenge. Using filters can significantly speed up the search process, allowing you to quickly locate and analyze the relevant settings. A white paper from the National Institute for Automotive Service Excellence (ASE) highlights the importance of efficient data management for accurate diagnostics. Effective filtering streamlines parameter searches.

Tips for Using Filters:

- Use keyword filters to search for parameters containing specific terms like “EGR,” “DPF,” or “Emissions.”

- Filter by control unit to narrow down the search to specific ECUs, such as the engine control unit (ECU) or transmission control unit (TCU).

- Create custom filters to save frequently used search criteria for future use.

6.2. Scripting for Automated Tasks

For repetitive tasks like checking or modifying multiple parameters, scripting can automate the process, saving time and reducing the risk of errors. DTS Monaco supports scripting languages that allow you to create custom routines for performing complex operations, which can be a game-changer when dealing with intricate coding procedures. According to a presentation by the Society of Automotive Engineers (SAE) in 2024, automation is becoming increasingly important in automotive diagnostics and repair. Automation enhances efficiency and reduces errors.

Tips for Using Scripting:

- Learn the basics of the scripting language supported by DTS Monaco.

- Start with simple scripts to automate basic tasks, such as reading parameter values.

- Gradually build more complex scripts to automate entire coding procedures.

- Test your scripts thoroughly before deploying them on a vehicle.

6.3. Data Logging for Real-Time Monitoring

Data logging allows you to monitor parameter values in real-time, which is invaluable for diagnosing emissions-related issues and verifying the effectiveness of your coding changes. By logging data, you can observe how the emissions system behaves under different conditions, providing insights that are not possible with static analysis. An article in Automotive Engineering International in 2024 notes that real-time monitoring is essential for diagnosing complex automotive systems. Real-time monitoring is crucial for accurate diagnostics.

Tips for Using Data Logging:

- Select the parameters you want to monitor, focusing on those related to emissions equipment.

- Configure the logging settings, such as the sampling rate and duration.

- Perform a test drive or simulate different driving conditions to capture a wide range of data.

- Analyze the logged data to identify any anomalies or trends that may indicate a problem with the emissions system.

7. Ensuring Compliance and Safety

What are the essential precautions to take to ensure compliance and safety when using DTS Monaco for emissions coding?

Ensuring compliance and safety when using DTS Monaco for emissions coding involves adhering to legal regulations, following best practices, and understanding the potential risks associated with modifying vehicle software. Prioritizing these aspects is crucial for both your safety and the integrity of the vehicle.

7.1. Understanding Legal Regulations

Modifying emissions-related settings can have legal implications, as many regions have strict regulations regarding vehicle emissions. It is essential to understand these regulations and ensure that any coding changes you make are compliant, which includes researching local and federal laws related to emissions control and ensuring that your modifications do not violate these regulations. As stated in a technical bulletin by the Environmental Protection Agency (EPA) in 2022, tampering with emissions control devices is illegal and can result in significant penalties. Compliance with regulations avoids legal issues.

Tips for Ensuring Compliance:

- Research local and federal laws related to vehicle emissions.

- Ensure that any coding changes you make do not violate these regulations.

- Keep records of any coding changes you make, including the original and modified settings.

- Consult with legal professionals if you are unsure about the legality of a particular coding change.

7.2. Following Best Practices for Coding

To minimize the risk of errors and ensure the integrity of the vehicle’s software, it is crucial to follow best practices for coding. This includes backing up data, verifying settings, and testing changes thoroughly. A guide by the National Automotive Service Task Force (NASTF) in 2024 emphasizes the importance of following established procedures to prevent unintended consequences. Adhering to best practices ensures data integrity.

Best Practices for Coding:

- Always back up the original ECU configuration before making any changes.

- Verify the correct parameter values using the vehicle’s service manual or online databases.

- Test your changes thoroughly after applying them to ensure they have the desired effect and do not cause any unintended issues.

- Document all coding changes you make, including the date, time, and specific modifications.

7.3. Being Aware of Potential Risks

Modifying vehicle software can have unintended consequences, potentially affecting the vehicle’s performance, safety, and reliability. It is essential to be aware of these risks and take precautions to mitigate them, which includes understanding the potential impacts of your coding changes and proceeding with caution. Training materials from Mercedes-Benz USA caution against making unauthorized modifications to vehicle software. Awareness of risks prevents unintended consequences.

Potential Risks of Coding:

- Reduced engine performance and fuel economy.

- Increased emissions and potential non-compliance with regulations.

- Damage to the ECU or other vehicle systems.

- Voiding the vehicle’s warranty.

8. Training and Certification

Where can I find reputable training and certification programs for using DTS Monaco and performing variant coding?

Reputable training and certification programs for DTS Monaco and variant coding can be found through OEM-certified programs, vocational schools, and online platforms, each offering structured education and validation of your skills.

8.1. OEM-Certified Programs

Original Equipment Manufacturers (OEMs) like Mercedes-Benz often offer certified training programs for their diagnostic and engineering software, with these programs providing in-depth knowledge and hands-on experience with the tools and procedures used by the manufacturer. These certifications are highly regarded in the industry. According to a 2023 report by the Automotive Training Center, OEM certifications can significantly enhance a technician’s career prospects. OEM certifications provide industry recognition.

Benefits of OEM-Certified Programs:

- Comprehensive training on the specific software and vehicle systems.

- Hands-on experience with the tools and procedures used by the manufacturer.

- Certification that is recognized and respected in the industry.

- Access to the latest software updates and technical information.

8.2. Vocational Schools and Technical Colleges

Vocational schools and technical colleges offer automotive technology programs that include training on diagnostic and coding software like DTS Monaco. These programs typically provide a broad foundation in automotive repair, along with specialized training in electronics and software, and can lead to certifications such as those offered by the National Institute for Automotive Service Excellence (ASE). A white paper from ASE highlights the importance of formal education and certification for automotive technicians. Vocational training offers broad and specialized skills.

Benefits of Vocational Schools and Technical Colleges:

- Structured education in automotive technology.

- Hands-on training with diagnostic and coding software.

- Preparation for industry-recognized certifications like ASE.

- Networking opportunities with instructors and fellow students.

8.3. Online Training Platforms

Several online platforms offer courses and training modules on DTS Monaco and variant coding, providing a flexible and convenient way to learn at your own pace. These platforms often include video tutorials, interactive exercises, and assessments to reinforce your learning. An article in Motor Age Magazine in 2024 notes that online training is becoming increasingly popular in the automotive industry. Online platforms offer flexible learning options.

Benefits of Online Training Platforms:

- Flexible learning schedule and self-paced modules.

- Access to a wide range of courses and training materials.

- Cost-effective compared to traditional classroom-based training.

- Ability to learn from anywhere with an internet connection.

9. Real-World Examples

Can you share some real-world examples of how DTS Monaco is used to address emissions-related issues?

DTS Monaco is used in numerous real-world scenarios to address emissions issues, which includes diagnosing EGR valve malfunctions, optimizing DPF regeneration cycles, and recalibrating oxygen sensors, often leading to improved vehicle performance and compliance with emissions standards.

9.1. Diagnosing EGR Valve Malfunctions

One common application of DTS Monaco is diagnosing malfunctions in the Exhaust Gas Recirculation (EGR) valve. By using DTS Monaco to monitor the EGR valve’s operation and compare it to the specified parameters, technicians can quickly identify issues such as sticking valves, incorrect flow rates, or faulty sensors. A report by Bosch Automotive in 2023 highlights the importance of accurate EGR valve diagnostics for maintaining emissions compliance. Accurate diagnostics prevent emissions issues.

Example Scenario:

- A technician uses DTS Monaco to connect to the ECU of a vehicle with a suspected EGR valve problem.

- They monitor the EGR valve position sensor readings and compare them to the commanded position.

- They discover that the valve is not opening fully, indicating a potential blockage or mechanical issue.

- They use DTS Monaco to actuate the EGR valve and confirm that it is not moving freely.

- Based on this diagnosis, they replace the EGR valve and use DTS Monaco to recalibrate the system.

9.2. Optimizing DPF Regeneration Cycles

DTS Monaco can also be used to optimize the regeneration cycles of Diesel Particulate Filters (DPF), which can involve adjusting the regeneration frequency, temperature, and duration to ensure that the DPF is effectively cleaned without compromising engine performance. An article in Automotive Engineering International in 2024 notes that optimized DPF regeneration is essential for maintaining emissions compliance and fuel efficiency. Optimized cycles ensure efficient DPF cleaning.

Example Scenario:

- A technician uses DTS Monaco to connect to the ECU of a vehicle with a DPF that is regenerating too frequently.

- They monitor the soot load and differential pressure across the DPF to assess its condition.

- They use DTS Monaco to adjust the regeneration frequency and temperature to reduce the number of regeneration cycles.

- They monitor the DPF’s performance over time to ensure that the changes are effective and do not cause any adverse effects.

9.3. Recalibrating Oxygen Sensors

Oxygen sensors play a critical role in controlling the air-fuel mixture and ensuring that the catalytic converter operates efficiently. DTS Monaco can be used to recalibrate oxygen sensors to ensure they are providing accurate readings. Accurate sensor readings are essential for optimizing emissions. According to training materials from Mercedes-Benz USA, proper sensor calibration is crucial for maintaining optimal engine performance and emissions. Proper calibration ensures accurate readings.

Example Scenario:

- A technician uses DTS Monaco to connect to the ECU of a vehicle with suspected oxygen sensor issues.

- They monitor the oxygen sensor readings and compare them to the expected values.

- They discover that the sensor readings are inaccurate, indicating a need for recalibration.

- They use DTS Monaco to recalibrate the oxygen sensors, ensuring they are providing accurate readings.

- They monitor the vehicle’s performance and emissions to verify that the recalibration has been successful.

10. Future Trends in Emissions Coding

What are the emerging trends and future directions in emissions coding and diagnostics?

The future of emissions coding and diagnostics involves increased complexity, advanced data analytics, and remote diagnostics, all aimed at enhancing vehicle performance and ensuring compliance with evolving environmental standards.

10.1. Increased Complexity of Emissions Systems

As environmental regulations become more stringent, emissions systems are becoming increasingly complex, incorporating advanced technologies such as multiple catalytic converters, particulate filters, and sophisticated sensor networks. This complexity requires more advanced diagnostic and coding tools to ensure these systems are functioning correctly. A white paper from the National Institute for Automotive Service Excellence (ASE) highlights that technicians need to continuously update their skills to keep pace with technological advancements. Advanced tools are needed for complex systems.

Trends in Complexity:

- Integration of multiple emissions control devices.

- Use of advanced sensor networks to monitor system performance.

- Increased reliance on software and electronic controls.

- Need for more sophisticated diagnostic and coding tools.

10.2. Advanced Data Analytics

The use of advanced data analytics is becoming increasingly important in emissions diagnostics, enabling technicians to analyze large amounts of data from vehicle sensors and identify subtle issues that may not be apparent through traditional diagnostic methods. This can involve using machine learning algorithms to predict potential failures and optimize system performance. An article in Automotive Engineering International in 2024 notes that data analytics is revolutionizing automotive diagnostics. Data analytics improves diagnostic accuracy.

Applications of Data Analytics:

- Predictive maintenance to identify potential failures before they occur.

- Optimization of emissions control system performance.

- Identification of subtle issues that may not be apparent through traditional diagnostic methods.

- Real-time monitoring of vehicle emissions to ensure compliance with regulations.

10.3. Remote Diagnostics and Over-the-Air Updates

Remote diagnostics and over-the-air (OTA) updates are becoming increasingly common, allowing technicians to diagnose and repair vehicles remotely, and even update the vehicle’s software without requiring a physical connection. This trend is driven by the increasing connectivity of modern vehicles. According to a presentation by the Society of Automotive Engineers (SAE) in 2024, remote diagnostics and OTA updates are transforming the automotive service industry. Remote capabilities enhance efficiency and convenience.

Benefits of Remote Diagnostics and OTA Updates:

- Reduced downtime for vehicles.

- Increased convenience for vehicle owners.

- Ability to diagnose and repair vehicles from anywhere with an internet connection.

- Improved efficiency for automotive service providers.

By mastering DTS Monaco and staying abreast of these future trends, automotive professionals can ensure they are well-equipped to handle the challenges and opportunities in the evolving field of emissions coding and diagnostics.

Ready to take your automotive diagnostic skills to the next level? Visit DTS-MONACO.EDU.VN today to explore our comprehensive software solutions, in-depth training programs, and expert technical support! Contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States or Whatsapp: +1 (641) 206-8880 to learn more.

FAQ: DTS Monaco and Emissions Coding

1. What is the primary function of DTS Monaco?

DTS Monaco is a diagnostic, testing, and engineering software used primarily for Mercedes-Benz vehicles, offering advanced functions such as ECU flashing, variant coding, and detailed diagnostics.

2. What is variant coding, and why is it important?

Variant coding is the process of adjusting software parameters within a vehicle’s ECU to activate or deactivate specific features or adapt the vehicle to different market requirements, essential for customizing vehicle behavior and ensuring compatibility with regional standards.

3. What is a J2534 pass-thru adapter, and why is it needed for DTS Monaco?

A J2534 pass-thru adapter is a device that connects your computer running DTS Monaco to the vehicle’s ECU, translating the communication protocols between the software and the vehicle’s electronic systems, and is crucial for accurate and stable communication.

4. How do I locate EGR-related parameters in DTS Monaco?

Navigate to the engine control unit (ECU) in DTS Monaco and look for parameters with names containing terms like “EGR,” “Exhaust Gas Recirculation,” or similar, consulting the vehicle’s service manual for specific descriptions.

5. What should I do if the EGR parameter settings do not match the vehicle’s specifications?

Correct the settings using DTS Monaco’s coding functions, always backing up the original settings before making any changes, and verifying the new settings after application.

6. How can I check the Diesel Particulate Filter (DPF) variant coding using DTS Monaco?

Access the ECU, find DPF-related parameters using terms like “DPF,” “Diesel Particulate Filter,” “Soot,” or “Regeneration,” and verify that their settings match the vehicle’s specifications.

7. What are some common issues encountered when checking variant coding with DTS Monaco?

Common issues include connection problems due to faulty adapters or incorrect drivers, incorrect parameter settings, and software errors, each requiring specific troubleshooting steps.

8. How can filters be used to efficiently search for parameters in DTS Monaco?

Use keyword filters for terms like “EGR” or “DPF,” filter by control unit, and create custom filters to save frequently used search criteria for quick access.

9. Why is it important to understand legal regulations when using DTS Monaco for emissions coding?

Modifying emissions-related settings can have legal implications, and it is essential to understand and comply with local and federal laws to avoid penalties for tampering with emissions control devices.

10. Where can I find reputable training programs for learning how to use DTS Monaco and perform variant coding?

Reputable training programs can be found through OEM-certified programs, vocational schools and technical colleges, and online training platforms, each offering structured education and skill validation.