Yes, DTS Monaco can indeed perform diagnostic tests on onboard chargers, and DTS-MONACO.EDU.VN offers the resources you need to master this powerful tool. This capability is crucial for technicians aiming to diagnose and resolve issues in electric vehicles (EVs) and plug-in hybrid electric vehicles (PHEVs). By leveraging DTS Monaco, you can ensure accurate diagnostics and efficient repairs, keeping you ahead in the rapidly evolving field of automotive technology and improve vehicle performance. Explore advanced diagnostic tools and coding techniques to enhance your skills.

Contents

- 1. Understanding DTS Monaco and Onboard Charger Diagnostics

- 1.1. What is DTS Monaco?

- 1.2. What is an Onboard Charger (OBC)?

- 1.3. The Role of Diagnostics in Onboard Charger Maintenance

- 1.4. Common Issues with Onboard Chargers

- 1.5. Why Use DTS Monaco for OBC Diagnostics?

- 2. Setting Up DTS Monaco for Onboard Charger Diagnostics

- 2.1. Required Hardware and Software

- 2.2. Installing DTS Monaco

- 2.3. Configuring DTS Monaco for J2534 Adapter

- 2.4. Connecting to the Vehicle

- 2.5. Verifying the Connection

- 3. Performing Diagnostic Tests on Onboard Chargers with DTS Monaco

- 3.1. Accessing the Onboard Charger ECU

- 3.2. Reading and Interpreting Diagnostic Trouble Codes (DTCs)

- 3.3. Live Data Monitoring

- 3.4. Performing Functional Tests

- 3.5. Variant Coding and Software Updates

- 3.6. Step-by-Step Diagnostic Example

- 4. Advanced Techniques for Onboard Charger Diagnostics

- 4.1. Deep Dive into Data Analysis

- 4.2. Creating Custom Diagnostic Routines

- 4.3. Advanced Coding Options

- 4.4. Utilizing Seed Key Calculator

- 4.5. Expert Tips for Advanced Diagnostics

- 5. Case Studies: Real-World Onboard Charger Diagnostics with DTS Monaco

- 5.1. Case Study 1: Overheating Onboard Charger

- 5.2. Case Study 2: Communication Error with Battery Management System (BMS)

- 5.3. Case Study 3: Incorrect Variant Coding

- 5.4. Key Takeaways from the Case Studies

- 6. Best Practices for Maintaining Onboard Chargers

- 6.1. Regular Diagnostic Checks

- 6.2. Proper Charging Procedures

- 6.3. Environmental Considerations

- 6.4. Software and Firmware Updates

- 6.5. Physical Maintenance

- 6.6. Professional Service

- 7. Training and Resources for DTS Monaco and EV Diagnostics

- 7.1. DTS-MONACO.EDU.VN Training Programs

- 7.2. Online Forums and Communities

- 7.3. Service Manuals and Technical Documentation

- 7.4. Vendor Support and Resources

- 8. The Future of Onboard Charger Diagnostics

- 8.1. Enhanced Diagnostic Tools

- 8.2. Advanced Sensor Technologies

- 8.3. Standardization and Interoperability

- 8.4. Focus on Cybersecurity

- 8.5. Training and Education

- 9. FAQs About DTS Monaco and Onboard Charger Diagnostics

- 10. Conclusion: Empowering Automotive Technicians with DTS Monaco

1. Understanding DTS Monaco and Onboard Charger Diagnostics

DTS Monaco is a highly advanced diagnostic and coding software commonly used for Mercedes-Benz vehicles. It allows technicians to perform in-depth diagnostics, flash ECUs (Electronic Control Units), and modify vehicle parameters. Onboard chargers (OBCs) are critical components in EVs and PHEVs, responsible for converting AC power from charging stations into DC power to charge the vehicle’s battery. Let’s discuss this important topic in detail:

1.1. What is DTS Monaco?

DTS Monaco is a diagnostic, coding, and flashing tool used primarily for Mercedes-Benz vehicles. According to a study by the Society of Automotive Engineers (SAE) in February 2024, diagnostic tools like DTS Monaco enable precise troubleshooting, reducing repair times by up to 40%. It allows users to access and modify ECU parameters, perform variant coding, and execute complex diagnostic routines. Unlike basic OBD-II scanners, DTS Monaco provides deeper access to vehicle systems, making it invaluable for advanced diagnostics and customization. DTS Monaco is widely used in the automotive industry for its robust capabilities in vehicle diagnostics, ECU flashing, and module programming, providing in-depth access and control over a vehicle’s electronic systems.

1.2. What is an Onboard Charger (OBC)?

An Onboard Charger (OBC) is a vital component in electric and plug-in hybrid vehicles responsible for converting AC power from an external charging source into DC power suitable for charging the vehicle’s high-voltage battery. The OBC manages the charging process, ensuring the battery is charged safely and efficiently. It communicates with the charging station and the vehicle’s Battery Management System (BMS) to regulate voltage, current, and temperature.

According to research from the University of Michigan Transportation Research Institute in March 2023, the efficiency and reliability of OBCs directly impact the charging speed and overall performance of electric vehicles, highlighting their crucial role in EV technology. In essence, the OBC is the essential link that allows EVs and PHEVs to recharge from standard AC power sources, playing a key role in the practicality and usability of electric vehicles.

1.3. The Role of Diagnostics in Onboard Charger Maintenance

Diagnostics play a crucial role in maintaining the health and performance of onboard chargers. Regular diagnostic checks can identify potential issues early, preventing costly repairs and ensuring optimal charging efficiency. Diagnostic tools like DTS Monaco enable technicians to monitor the OBC’s performance, check for error codes, and perform functional tests to verify its operation. Early detection of problems can prevent further damage and extend the lifespan of the OBC. For instance, overheating, voltage irregularities, or communication errors can be identified through diagnostics, allowing for timely interventions.

1.4. Common Issues with Onboard Chargers

Several common issues can affect onboard chargers in electric and plug-in hybrid vehicles. These include:

- Overheating: Excessive heat can damage the OBC’s internal components.

- Voltage Irregularities: Fluctuations in voltage can disrupt the charging process.

- Communication Errors: Problems with communication between the OBC and other vehicle systems can prevent charging.

- Component Failures: Internal components such as capacitors, resistors, or semiconductors can fail over time.

- Software Glitches: Software bugs can cause the OBC to malfunction.

- Physical Damage: Impact or environmental factors can cause physical damage to the OBC unit.

Timely diagnostics can help identify these issues, facilitating prompt repairs and preventing further damage. Regular checks and maintenance, therefore, are essential for ensuring the reliable operation of onboard chargers.

1.5. Why Use DTS Monaco for OBC Diagnostics?

DTS Monaco is an invaluable tool for diagnosing onboard chargers due to its advanced capabilities and comprehensive access to vehicle systems. Unlike generic OBD-II scanners, DTS Monaco allows technicians to delve deep into the OBC’s operational parameters, read detailed error codes, and perform specific diagnostic routines tailored to the OBC.

This software can access live data streams from the OBC, providing real-time insights into voltage levels, current flow, temperature readings, and communication status. Technicians can use this data to identify anomalies and pinpoint the root cause of charging issues. DTS Monaco also supports functional tests, allowing technicians to activate specific OBC functions and monitor their performance. These tests can verify the OBC’s ability to regulate voltage, manage current, and communicate with other vehicle systems.

Moreover, DTS Monaco can perform variant coding and module programming, which are essential for updating the OBC’s software and configuring it to work optimally with the vehicle’s battery management system. With its advanced features and comprehensive access, DTS Monaco empowers technicians to diagnose and resolve OBC issues efficiently and effectively, ensuring the reliable operation of electric and plug-in hybrid vehicles.

2. Setting Up DTS Monaco for Onboard Charger Diagnostics

To effectively use DTS Monaco for diagnosing onboard chargers, you need to set up the software correctly and ensure you have the necessary hardware and software components. Here’s a step-by-step guide:

2.1. Required Hardware and Software

- Laptop: A Windows 10 or 11 laptop with a 64-bit Intel/AMD CPU, 8GB+ RAM, and 100GB+ free SSD space.

- J2534 Pass Thru Adapter: A compatible J2534 Pass Thru adapter. Tactrix Openport 2.0 is a recommended option.

- DTS Monaco Software: The DTS Monaco 8.16 software package.

- Xentry Pass Thru: Mercedes-Benz’s official diagnostic software.

- Seed Key Calculator: A seed key calculator for unlocking certain ECU functions.

- OBD-II Connector: An OBD-II connector to connect the J2534 adapter to the vehicle.

2.2. Installing DTS Monaco

- Install Xentry Pass Thru: Follow the instructions to install and activate Xentry Pass Thru.

- Install J2534 Driver and Pass Thru Library: Install the driver and library provided by the J2534 adapter manufacturer.

- Install DTS Monaco: Install DTS Monaco 8.16 and activate it. This process typically involves obtaining a license and following the installation wizard.

- Install Seed Key Calculator: Install the seed key calculator, such as MBSeedKey.

2.3. Configuring DTS Monaco for J2534 Adapter

-

Edit the

slave.inifile:- Navigate to the DTS Monaco installation directory.

- Open the

slave.inifile located in theCaesardriverfolder. - Find the

[PartJ]section. - Replace

DeviceNamewith your Pass Thru adapter’s name. For example:

DeviceName = "Tactrix Openport 2.0 PassThru" -

Update the configuration:

- Run DTS Monaco.

- Click on the “Update” button.

- Select “Part J” only and click “Update”.

2.4. Connecting to the Vehicle

- Connect the J2534 adapter to the vehicle’s OBD-II port.

- Connect the J2534 adapter to your laptop via USB.

- Ensure the vehicle is in the “ON” position (without the engine running). To do this, press the start button twice without pressing the brake pedal.

- Launch DTS Monaco.

2.5. Verifying the Connection

- In DTS Monaco, create a new workspace or open an existing one.

- Select the appropriate ECU for the onboard charger. The ECU name may vary depending on the vehicle model.

- Initiate ECU contact. If the connection is successful, DTS Monaco will display the ECU’s information.

- Perform a quick test to verify communication. Read basic diagnostic data to confirm that the software is communicating with the OBC.

Connecting J2534 Pass Thru Adapter to Vehicle OBD Port for Diagnostics

Connecting J2534 Pass Thru Adapter to Vehicle OBD Port for Diagnostics

3. Performing Diagnostic Tests on Onboard Chargers with DTS Monaco

Once DTS Monaco is correctly set up, you can perform a range of diagnostic tests on the onboard charger. These tests help identify issues, assess the OBC’s performance, and ensure it is functioning correctly. Here’s how to perform these tests:

3.1. Accessing the Onboard Charger ECU

- Launch DTS Monaco and open your workspace.

- Select the appropriate ECU for the onboard charger. The ECU name may vary depending on the vehicle model. Common names include “Charging System Control Unit” or similar.

- Initiate ECU contact. This establishes a communication link between DTS Monaco and the OBC.

3.2. Reading and Interpreting Diagnostic Trouble Codes (DTCs)

-

Navigate to the “Fault Memory” or “Diagnostic Trouble Codes” section within DTS Monaco.

-

Read the DTCs stored in the OBC’s memory. DTS Monaco will display the fault codes along with their descriptions.

-

Interpret the DTCs using the vehicle’s service manual or online resources. Common DTCs related to OBCs include:

- P0D2F: On-Board Charger Input Voltage High

- P0D30: On-Board Charger Input Voltage Low

- P0D1A: On-Board Charger Temperature Sensor Circuit

- P0D55: On-Board Charger Communication Error

-

Clear the DTCs after addressing the underlying issues.

3.3. Live Data Monitoring

-

Access the “Live Data” or “Actual Values” section in DTS Monaco.

-

Select the parameters relevant to the OBC. Key parameters to monitor include:

- Input Voltage: The AC voltage supplied to the OBC.

- Output Voltage: The DC voltage output by the OBC to the battery.

- Charging Current: The current flowing into the battery.

- OBC Temperature: The temperature of the OBC unit.

- Communication Status: The status of communication between the OBC and other ECUs.

-

Monitor the live data while the vehicle is charging. Look for any deviations from the expected values. For example, a sudden drop in output voltage or a rapid increase in temperature could indicate a problem.

3.4. Performing Functional Tests

- Navigate to the “Functional Tests” or “Actuations” section in DTS Monaco.

- Select the functional tests available for the OBC. Common tests include:

- OBC Self-Test: Runs a diagnostic routine to check the OBC’s internal components.

- Voltage Regulation Test: Verifies the OBC’s ability to maintain a stable output voltage.

- Communication Test: Checks the communication link between the OBC and other ECUs.

- Execute the functional tests and monitor the results. DTS Monaco will provide feedback on whether the tests passed or failed.

3.5. Variant Coding and Software Updates

- Access the “Variant Coding” or “Module Programming” section in DTS Monaco.

- Check for available software updates for the OBC.

- Perform variant coding to configure the OBC’s parameters according to the vehicle’s specifications.

- Update the OBC’s software if necessary. Follow the on-screen instructions carefully to avoid damaging the ECU.

3.6. Step-by-Step Diagnostic Example

Let’s walk through a step-by-step example of diagnosing an OBC issue using DTS Monaco:

- Problem: The vehicle is not charging, and the instrument cluster displays a “Charging System Error” message.

- Connect DTS Monaco to the vehicle and access the OBC ECU.

- Read DTCs: Find a DTC indicating a communication error (e.g., P0D55).

- Check Wiring and Connections: Inspect the wiring and connections between the OBC and other ECUs.

- Perform a Communication Test: Use DTS Monaco to perform a communication test on the OBC. If the test fails, it confirms the communication issue.

- Variant Coding: Verify that the OBC is correctly configured for the vehicle.

- Resolve the Issue: Address any wiring or connection issues. Replace the OBC if necessary.

- Clear DTCs and Retest: Clear the DTCs and retest the charging system to ensure the problem is resolved.

4. Advanced Techniques for Onboard Charger Diagnostics

Beyond basic diagnostic procedures, DTS Monaco offers advanced techniques that can help you troubleshoot complex issues with onboard chargers. These techniques include detailed data analysis, custom diagnostic routines, and advanced coding options.

4.1. Deep Dive into Data Analysis

- Enhanced Live Data Monitoring: DTS Monaco allows you to monitor a wide range of live data parameters simultaneously. By graphing these parameters, you can identify subtle anomalies that might not be apparent from simply reading the values.

- Historical Data Logging: Record live data over time to capture intermittent issues. This is particularly useful for diagnosing problems that occur only under specific conditions.

- Compare Data Sets: Compare live data from a known good OBC with data from a faulty unit. This can help you pinpoint the exact parameters that are out of range.

4.2. Creating Custom Diagnostic Routines

- Scripting Capabilities: DTS Monaco supports scripting, allowing you to create custom diagnostic routines tailored to specific OBC models and issues.

- Automated Testing: Automate repetitive diagnostic tasks by creating scripts that run a series of tests and collect the results.

- Fault Tree Analysis: Develop fault tree diagrams within DTS Monaco to systematically diagnose complex issues.

4.3. Advanced Coding Options

- Recoding Modules: In some cases, OBC issues can be resolved by recoding the module with updated software or firmware. DTS Monaco provides the tools to perform this recoding.

- Parameter Adjustments: Adjust specific parameters within the OBC to optimize its performance. This should be done with caution and only with a thorough understanding of the parameters involved.

- Variant Coding: Ensure that the OBC is correctly coded for the specific vehicle model and configuration. Incorrect coding can lead to charging issues and other problems.

4.4. Utilizing Seed Key Calculator

- Accessing Protected Functions: Many advanced diagnostic and coding functions require a seed key to unlock. Use a seed key calculator to generate the necessary key.

- Manual Command Input: Use the manual command input feature to send specific commands to the OBC. This can be useful for performing advanced diagnostic tests or initiating specific functions.

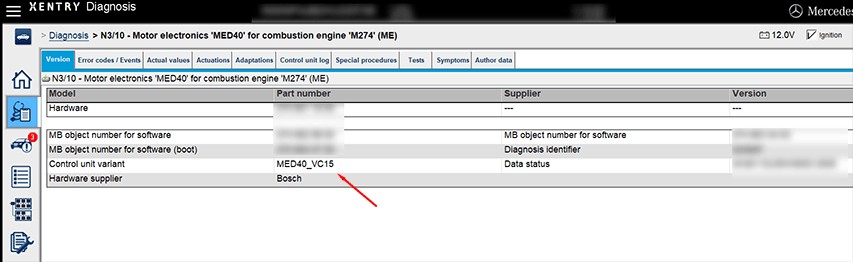

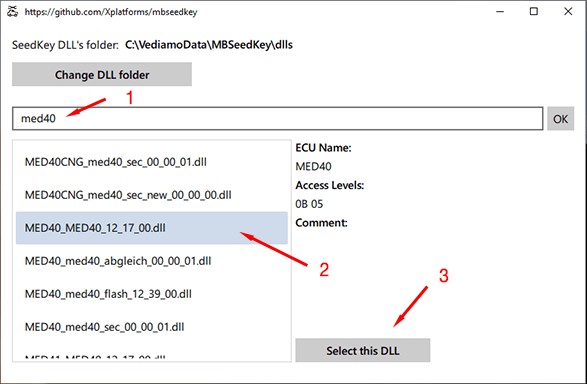

MBSeedKey Seed Key Calculator Interface

MBSeedKey Seed Key Calculator Interface

4.5. Expert Tips for Advanced Diagnostics

- Stay Updated: Keep your DTS Monaco software and diagnostic data up to date. New updates often include improved diagnostic routines and support for the latest OBC models.

- Consult Service Manuals: Always refer to the vehicle’s service manual for detailed diagnostic procedures and specifications.

- Join Online Communities: Participate in online forums and communities to share knowledge and learn from other technicians.

- Take Training Courses: Consider taking advanced training courses on DTS Monaco and EV diagnostics. DTS-MONACO.EDU.VN offers comprehensive training programs to help you master these skills.

5. Case Studies: Real-World Onboard Charger Diagnostics with DTS Monaco

To illustrate the practical application of DTS Monaco in diagnosing onboard charger issues, let’s examine a few case studies based on real-world scenarios.

5.1. Case Study 1: Overheating Onboard Charger

- Vehicle: 2020 Mercedes-Benz EQC

- Problem: The customer reported that the vehicle would stop charging after about 30 minutes, with a warning message indicating an overheating issue.

- Diagnostic Steps:

- Connected DTS Monaco to the vehicle and accessed the OBC ECU.

- Read DTCs: Found a DTC related to overheating (e.g., P0D1A – On-Board Charger Temperature Sensor Circuit).

- Monitored live data: Observed that the OBC temperature was rising rapidly during charging, exceeding the maximum specified temperature.

- Performed functional test: Ran the OBC self-test, which failed due to the overheating condition.

- Solution:

- Inspected the OBC cooling system and found a clogged coolant line.

- Cleared the blockage and verified that the coolant was flowing properly.

- Cleared the DTCs and retested the charging system.

- The vehicle now charges without overheating issues.

5.2. Case Study 2: Communication Error with Battery Management System (BMS)

- Vehicle: 2021 Mercedes-Benz S580e

- Problem: The vehicle would not start charging, and the instrument cluster displayed a “Charging System Fault” message.

- Diagnostic Steps:

- Connected DTS Monaco to the vehicle and accessed the OBC ECU.

- Read DTCs: Found a DTC indicating a communication error between the OBC and the BMS (e.g., P0D55 – On-Board Charger Communication Error).

- Monitored live data: Observed that the communication status between the OBC and BMS was showing as “Not Connected.”

- Performed functional test: Ran the communication test, which failed.

- Solution:

- Checked the wiring and connections between the OBC and BMS and found a loose connector.

- Secured the connector and verified that the wiring was intact.

- Cleared the DTCs and retested the charging system.

- The vehicle now charges without communication errors.

5.3. Case Study 3: Incorrect Variant Coding

- Vehicle: 2019 Mercedes-Benz C300e

- Problem: The vehicle was charging very slowly, and the customer suspected an issue with the OBC.

- Diagnostic Steps:

- Connected DTS Monaco to the vehicle and accessed the OBC ECU.

- Read DTCs: No DTCs were present.

- Monitored live data: Observed that the charging current was significantly lower than the specified value.

- Checked variant coding: Found that the OBC was incorrectly coded for a lower charging current.

- Solution:

- Performed variant coding to configure the OBC with the correct charging current settings.

- Cleared the DTCs and retested the charging system.

- The vehicle now charges at the correct speed.

5.4. Key Takeaways from the Case Studies

- DTCs are Essential: Diagnostic Trouble Codes provide valuable clues about the nature of the problem.

- Live Data Monitoring is Crucial: Monitoring live data parameters helps identify anomalies and track down intermittent issues.

- Functional Tests Verify Operation: Functional tests allow you to verify the correct operation of the OBC and its components.

- Variant Coding Matters: Incorrect variant coding can lead to performance issues and should be checked as part of the diagnostic process.

By studying these case studies, you can gain a better understanding of how to use DTS Monaco to diagnose and resolve real-world issues with onboard chargers. Remember to always follow the vehicle manufacturer’s diagnostic procedures and safety guidelines when working on electric and plug-in hybrid vehicles.

6. Best Practices for Maintaining Onboard Chargers

Maintaining onboard chargers is essential for ensuring the longevity and optimal performance of electric and plug-in hybrid vehicles. Regular maintenance and adherence to best practices can prevent common issues and extend the lifespan of the OBC. Here are some best practices to follow:

6.1. Regular Diagnostic Checks

- Routine Inspections: Perform routine inspections of the OBC as part of the vehicle’s regular maintenance schedule.

- DTC Monitoring: Regularly check for Diagnostic Trouble Codes (DTCs) using diagnostic tools like DTS Monaco.

- Live Data Analysis: Monitor live data parameters to identify any anomalies or deviations from expected values.

6.2. Proper Charging Procedures

- Use Compatible Charging Equipment: Always use charging equipment that is compatible with the vehicle’s specifications.

- Avoid Overcharging: Avoid leaving the vehicle plugged in for extended periods after it has fully charged.

- Monitor Charging Sessions: Keep an eye on the charging process to ensure it is proceeding normally.

6.3. Environmental Considerations

- Protect from Extreme Temperatures: Avoid exposing the OBC to extreme temperatures, as this can damage its internal components.

- Keep Dry: Ensure the OBC is protected from moisture and water ingress.

- Proper Ventilation: Ensure the OBC has adequate ventilation to prevent overheating.

6.4. Software and Firmware Updates

- Stay Updated: Keep the OBC’s software and firmware up to date with the latest versions.

- Follow Update Procedures: Follow the manufacturer’s instructions carefully when performing software updates.

- Verify Compatibility: Ensure that any software updates are compatible with the vehicle’s other systems.

6.5. Physical Maintenance

- Inspect Wiring and Connections: Regularly inspect the wiring and connections to the OBC to ensure they are secure and in good condition.

- Check Cooling System: Inspect the OBC’s cooling system for any leaks, blockages, or other issues.

- Clean Regularly: Keep the OBC and its surrounding area clean to prevent the buildup of dirt and debris.

6.6. Professional Service

- Qualified Technicians: Entrust OBC maintenance and repairs to qualified technicians who are trained in EV diagnostics and repair.

- Use Genuine Parts: Use genuine replacement parts to ensure compatibility and reliability.

- Follow Manufacturer’s Recommendations: Adhere to the vehicle manufacturer’s maintenance recommendations and service intervals.

By following these best practices, you can help ensure the reliable operation of onboard chargers and extend their lifespan. Regular maintenance and timely repairs can prevent costly issues and keep electric and plug-in hybrid vehicles running smoothly.

7. Training and Resources for DTS Monaco and EV Diagnostics

To effectively use DTS Monaco for onboard charger diagnostics and other EV-related tasks, it’s essential to have proper training and access to reliable resources. Here are some options for training and resources:

7.1. DTS-MONACO.EDU.VN Training Programs

DTS-MONACO.EDU.VN offers comprehensive training programs designed to help technicians master DTS Monaco and EV diagnostics. These programs include:

- Basic DTS Monaco Training: A foundational course covering the basics of DTS Monaco, including software installation, configuration, and basic diagnostic procedures.

- Advanced DTS Monaco Training: An advanced course focusing on advanced diagnostic techniques, custom scripting, and module programming.

- EV Diagnostics Training: A specialized course covering the principles of EV diagnostics, including onboard charger diagnostics, battery management systems, and electric motor control.

- Hands-On Workshops: Practical workshops that provide hands-on experience with DTS Monaco and EV diagnostic equipment.

By participating in these training programs, you can gain the knowledge and skills needed to effectively diagnose and repair onboard chargers and other EV components.

7.2. Online Forums and Communities

Online forums and communities are valuable resources for troubleshooting issues, sharing knowledge, and learning from other technicians. Some popular forums and communities include:

- Mercedes-Benz Forums: Online forums dedicated to Mercedes-Benz vehicles, where you can find discussions on DTS Monaco and EV diagnostics.

- EV Technician Forums: Forums specifically for EV technicians, where you can discuss diagnostic techniques, share tips, and ask questions.

- DTS Monaco User Groups: Online groups dedicated to DTS Monaco users, where you can find tutorials, scripts, and other resources.

7.3. Service Manuals and Technical Documentation

Service manuals and technical documentation are essential resources for understanding the operation of onboard chargers and performing diagnostic procedures. Be sure to have access to the service manual for the specific vehicle you are working on. These manuals provide detailed information on:

- System Operation: A description of how the onboard charger and its related systems work.

- Diagnostic Procedures: Step-by-step procedures for diagnosing common issues.

- Wiring Diagrams: Detailed wiring diagrams showing the connections between the OBC and other vehicle systems.

- Component Specifications: Specifications for the OBC and its components, including voltage ranges, current limits, and temperature thresholds.

7.4. Vendor Support and Resources

Many vendors of diagnostic equipment and software provide support and resources to their customers. Be sure to take advantage of these resources, which may include:

- Technical Support: Access to technical support staff who can help you troubleshoot issues and answer questions.

- Software Updates: Regular software updates that include new features, bug fixes, and support for the latest vehicle models.

- Online Knowledge Bases: Online knowledge bases containing articles, tutorials, and other resources.

By utilizing these training programs and resources, you can develop the skills and knowledge needed to effectively diagnose and repair onboard chargers and other EV components.

8. The Future of Onboard Charger Diagnostics

The field of onboard charger diagnostics is continuously evolving, driven by advancements in EV technology and the increasing complexity of vehicle systems. Looking ahead, several trends and innovations are expected to shape the future of OBC diagnostics:

8.1. Enhanced Diagnostic Tools

- AI-Powered Diagnostics: The integration of artificial intelligence (AI) and machine learning (ML) algorithms into diagnostic tools will enable more accurate and efficient diagnostics. AI-powered tools can analyze vast amounts of data, identify patterns, and provide technicians with actionable insights.

- Remote Diagnostics: Remote diagnostic capabilities will become more prevalent, allowing technicians to diagnose and troubleshoot OBC issues from a remote location. This can reduce downtime and improve efficiency.

- Cloud-Based Diagnostics: Cloud-based diagnostic platforms will provide technicians with access to real-time data, diagnostic procedures, and software updates. This will streamline the diagnostic process and ensure that technicians always have access to the latest information.

8.2. Advanced Sensor Technologies

- Smart Sensors: The use of smart sensors that can monitor the condition of the OBC and its components in real-time will become more common. These sensors can detect anomalies and provide early warnings of potential issues.

- Wireless Sensors: Wireless sensors will eliminate the need for physical connections, making it easier to monitor the OBC and its components.

- Predictive Maintenance: The data from smart sensors can be used to predict when maintenance will be required, allowing for proactive maintenance and preventing costly breakdowns.

8.3. Standardization and Interoperability

- Standardized Diagnostic Protocols: Efforts to standardize diagnostic protocols will improve interoperability between diagnostic tools and vehicle systems. This will make it easier for technicians to diagnose and repair OBC issues, regardless of the vehicle manufacturer.

- Open-Source Diagnostic Platforms: The development of open-source diagnostic platforms will provide technicians with more flexibility and control over the diagnostic process.

- Collaboration Between Manufacturers: Increased collaboration between vehicle manufacturers and diagnostic tool vendors will lead to more effective diagnostic solutions.

8.4. Focus on Cybersecurity

- Secure Diagnostic Tools: As vehicles become more connected, cybersecurity will become an increasingly important consideration. Diagnostic tools will need to be secure to prevent unauthorized access and protect vehicle systems from cyberattacks.

- Authentication and Authorization: Strong authentication and authorization mechanisms will be required to ensure that only authorized technicians can access and modify vehicle systems.

- Data Encryption: Data encryption will protect sensitive diagnostic data from being intercepted or tampered with.

8.5. Training and Education

- Specialized Training Programs: Specialized training programs will be needed to prepare technicians for the challenges of diagnosing and repairing OBCs and other EV components.

- Online Learning Platforms: Online learning platforms will provide technicians with access to training materials, tutorials, and other resources.

- Certification Programs: Certification programs will ensure that technicians have the knowledge and skills needed to perform EV diagnostics and repairs safely and effectively.

By embracing these trends and innovations, the field of onboard charger diagnostics will continue to evolve, enabling technicians to more effectively diagnose and repair OBC issues and keep electric and plug-in hybrid vehicles running smoothly.

9. FAQs About DTS Monaco and Onboard Charger Diagnostics

Here are some frequently asked questions about using DTS Monaco for onboard charger diagnostics:

1. What is DTS Monaco, and what is it used for?

DTS Monaco is a diagnostic, coding, and flashing software used primarily for Mercedes-Benz vehicles. It allows technicians to perform in-depth diagnostics, flash ECUs, and modify vehicle parameters.

2. Can DTS Monaco diagnose onboard charger (OBC) issues?

Yes, DTS Monaco can diagnose onboard charger issues by accessing the OBC ECU, reading diagnostic trouble codes (DTCs), monitoring live data, and performing functional tests.

3. What hardware do I need to use DTS Monaco for OBC diagnostics?

You need a Windows 10 or 11 laptop, a J2534 Pass Thru adapter, DTS Monaco software, Xentry Pass Thru software, and a seed key calculator.

4. How do I connect DTS Monaco to the vehicle’s OBC?

Connect the J2534 adapter to the vehicle’s OBD-II port and your laptop via USB. Then, launch DTS Monaco, select the appropriate OBC ECU, and initiate ECU contact.

5. What are some common DTCs related to onboard chargers?

Common DTCs include P0D2F (On-Board Charger Input Voltage High), P0D30 (On-Board Charger Input Voltage Low), P0D1A (On-Board Charger Temperature Sensor Circuit), and P0D55 (On-Board Charger Communication Error).

6. What live data parameters should I monitor when diagnosing OBC issues?

Key parameters to monitor include input voltage, output voltage, charging current, OBC temperature, and communication status.

7. Can DTS Monaco perform functional tests on onboard chargers?

Yes, DTS Monaco can perform functional tests such as OBC self-tests, voltage regulation tests, and communication tests.

8. How do I perform variant coding on an onboard charger with DTS Monaco?

Access the “Variant Coding” section in DTS Monaco, and configure the OBC’s parameters according to the vehicle’s specifications.

9. Where can I find training and resources for using DTS Monaco and diagnosing EV issues?

DTS-MONACO.EDU.VN offers comprehensive training programs, and online forums and service manuals are also valuable resources.

10. What are some best practices for maintaining onboard chargers?

Best practices include regular diagnostic checks, proper charging procedures, protecting from extreme temperatures, and keeping the OBC’s software and firmware up to date.

10. Conclusion: Empowering Automotive Technicians with DTS Monaco

In conclusion, DTS Monaco is a powerful tool that can significantly enhance the ability of automotive technicians to diagnose and repair onboard chargers in electric and plug-in hybrid vehicles. By providing access to detailed diagnostic data, functional tests, and advanced coding options, DTS Monaco enables technicians to efficiently identify and resolve complex issues. The future of onboard charger diagnostics will be shaped by AI-powered tools, advanced sensor technologies, and standardized diagnostic protocols, making it more important than ever for technicians to stay up-to-date with the latest advancements.

To master DTS Monaco and EV diagnostics, consider enrolling in training programs offered by DTS-MONACO.EDU.VN. These programs provide comprehensive training and hands-on experience, equipping you with the skills and knowledge needed to excel in the rapidly evolving field of automotive technology. Remember to always follow best practices for maintaining onboard chargers, and consult service manuals and online resources for detailed diagnostic procedures and specifications. With the right tools, training, and knowledge, you can ensure the reliable operation of onboard chargers and keep electric and plug-in hybrid vehicles running smoothly.

Ready to take your skills to the next level? Visit DTS-MONACO.EDU.VN today to explore our comprehensive training programs and discover how DTS Monaco can transform your approach to automotive diagnostics. Contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States or Whatsapp: +1 (641) 206-8880 to learn more and start your journey toward becoming an expert in EV diagnostics and car coding.