Does ECOM support diagnostics involving reading ECU thermal sensor data? Absolutely, if the necessary parameter is available. This capability unlocks a deeper understanding of your vehicle’s health, providing valuable insights into engine performance and potential issues. At DTS-MONACO.EDU.VN, we empower automotive technicians with the knowledge and tools, including car coding and advanced diagnostics via software like DTS-Monaco, to master this vital skill. Embrace the power of data-driven diagnostics and unlock new levels of precision in your automotive repairs. Think of enhanced vehicle diagnostics, sensor data interpretation and automotive repair proficiency.

Contents

- 1. Understanding ECU Thermal Sensor Data and ECOM Diagnostics

- 1.1. What is ECU Thermal Sensor Data?

- 1.2. Why is Reading ECU Thermal Sensor Data Important?

- 1.3. What is ECOM and its Role in Diagnostics?

- 1.4. Does ECOM Support Reading ECU Thermal Sensor Data?

- 1.5. Accessing Enhanced Diagnostics with OBDLink® MX+ and the OBDLink App

- 2. Diving Deeper: Practical Applications of ECU Thermal Sensor Data

- 2.1. Diagnosing Overheating Issues with ECU Thermal Sensor Data

- 2.2. Evaluating Catalytic Converter Efficiency

- 2.3. Transmission Temperature Monitoring

- 2.4. Intake Air Temperature and Engine Performance

- 2.5. Utilizing Freeze Frame Data for Comprehensive Analysis

- 3. Essential Tools and Techniques for Reading ECU Thermal Sensor Data

- 3.1. Selecting the Right ECOM Interface

- 3.2. Choosing the Appropriate Diagnostic Software

- 3.3. Establishing a Reliable Connection

- 3.4. Understanding PID Data Formats and Units

- 3.5. Interpreting Live Data and Freeze Frame Data

- 3.6. Utilizing Graphing and Data Logging

- 3.7. Navigating Enhanced Diagnostics on the OBDLink App

- 4. Advanced Diagnostic Techniques Using DTS-Monaco

- 4.1. What is DTS-Monaco?

- 4.2. Advantages of Using DTS-Monaco

- 4.3. Reading ECU Thermal Sensor Data with DTS-Monaco

- 4.4. Performing Car Coding with DTS-Monaco

- 4.5. ECU Flashing with DTS-Monaco

- 4.6. Training and Certification at DTS-MONACO.EDU.VN

- 5. Troubleshooting Common Issues When Reading Thermal Sensor Data

- 5.1. No Data Available for Specific PIDs

- 5.2. Inaccurate or Unrealistic Readings

- 5.3. Intermittent Data Loss or Communication Errors

- 5.4. Compatibility Challenges with Specific Vehicle Models

- 5.5. Disconnection Issues During Data Download

- 6. Keeping Up with Industry Advances

- 6.1. Continuous Learning and Training

- 6.2. Staying Informed about New Technologies

- 6.3. Leveraging Online Resources and Communities

- 6.4. Embracing New Diagnostic Tools and Techniques

- 7. Frequently Asked Questions (FAQ)

- 8. Conclusion: Empowering Automotive Technicians with Knowledge and Tools

1. Understanding ECU Thermal Sensor Data and ECOM Diagnostics

ECU thermal sensor data plays a critical role in modern vehicle diagnostics, and ECOM diagnostic tools can be instrumental in accessing and interpreting this information. Let’s delve into the specifics:

1.1. What is ECU Thermal Sensor Data?

The Electronic Control Unit (ECU) in a vehicle relies on a network of sensors to monitor various parameters, including temperature. Thermal sensors are strategically placed to measure temperatures of critical components like:

- Engine Coolant: Monitors the engine’s operating temperature, preventing overheating.

- Engine Oil: Ensures proper lubrication and prevents oil breakdown due to excessive heat.

- Intake Air: Optimizes fuel combustion based on air temperature.

- Exhaust Gas: Crucial for catalytic converter efficiency and emissions control.

- Transmission Fluid: Maintains optimal transmission performance and prevents damage.

This thermal data is used by the ECU to make real-time adjustments to engine operation, ensuring optimal performance, fuel efficiency, and emissions control.

1.2. Why is Reading ECU Thermal Sensor Data Important?

Accessing and analyzing ECU thermal sensor data is invaluable for:

- Identifying Overheating Issues: Early detection of potential engine or transmission overheating.

- Diagnosing Sensor Malfunctions: Determining if a specific temperature sensor is faulty.

- Evaluating System Performance: Assessing the efficiency of cooling and lubrication systems.

- Troubleshooting Emissions Problems: Identifying issues related to exhaust gas temperature.

- Optimizing Engine Tuning: Fine-tuning engine parameters for optimal performance and fuel economy.

1.3. What is ECOM and its Role in Diagnostics?

ECOM (likely referring to a specific diagnostic interface or protocol) serves as a communication bridge between a diagnostic tool (like a laptop running diagnostic software) and the vehicle’s ECU. It enables the transfer of data, including the crucial thermal sensor readings, allowing technicians to:

- Access Live Data Streams: View real-time temperature readings from various sensors.

- Read Diagnostic Trouble Codes (DTCs): Identify temperature-related fault codes stored in the ECU.

- Perform Actuator Tests: Control cooling fans or other components to verify their functionality.

- Flash ECU Software: Update the ECU software to address temperature-related issues or improve performance (requires advanced knowledge and caution).

1.4. Does ECOM Support Reading ECU Thermal Sensor Data?

The key question is whether ECOM supports reading this valuable data. The answer is yes, but it depends on the specific ECOM implementation and the vehicle’s communication protocol.

- Availability of the Parameter (PID): The ECU must make the thermal sensor data available as a Parameter ID (PID). Not all ECUs expose every possible sensor reading.

- ECOM Compatibility: The ECOM interface and diagnostic software must be compatible with the vehicle’s communication protocol (e.g., CAN, K-Line) and the specific PIDs used for thermal sensors.

- Software Capabilities: The diagnostic software used with the ECOM interface needs to be capable of requesting and displaying the thermal sensor data in a user-friendly format.

Therefore, before assuming ECOM can access thermal sensor data, it’s essential to:

- Consult the ECOM interface documentation: Verify compatibility with the vehicle’s communication protocol.

- Check the diagnostic software’s PID library: Confirm that the desired thermal sensor PIDs are supported.

- Perform a vehicle scan: Use the diagnostic software to scan the ECU and identify available PIDs.

1.5. Accessing Enhanced Diagnostics with OBDLink® MX+ and the OBDLink App

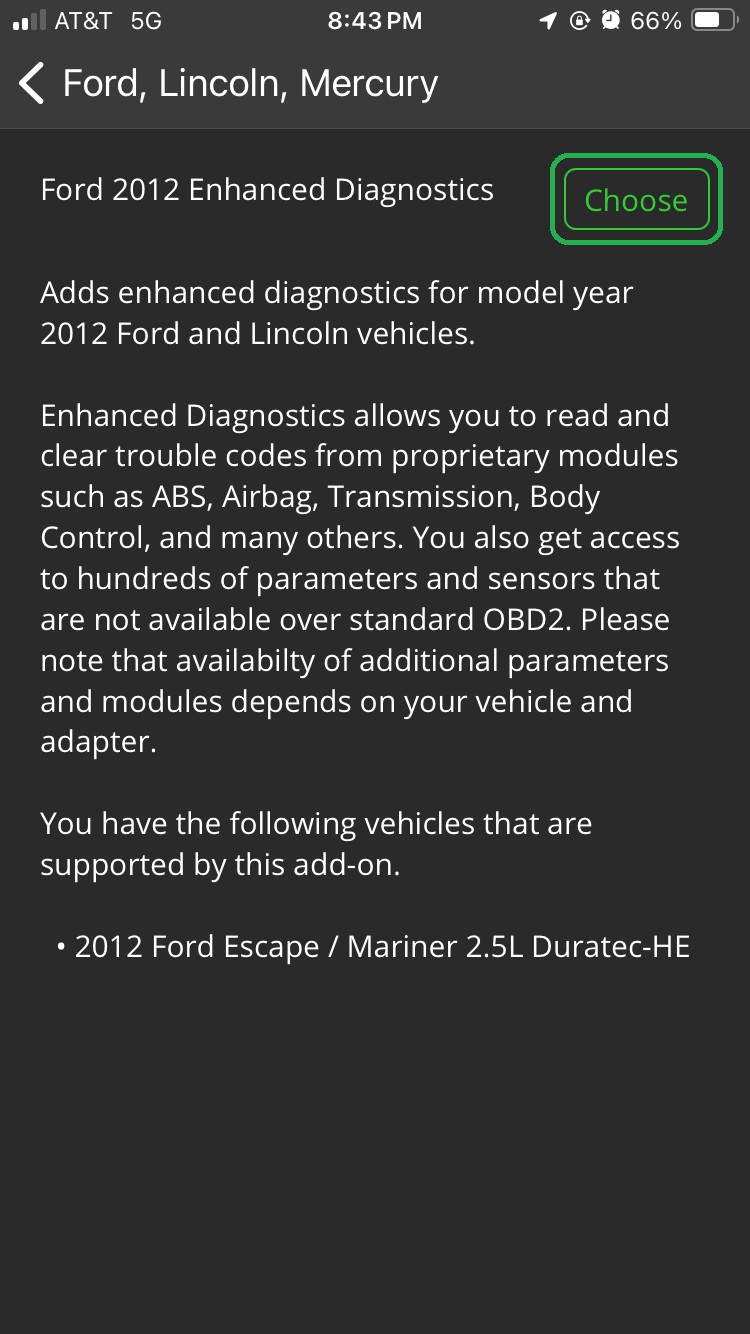

The OBDLink® MX+ adapter, when paired with the OBDLink app, provides enhanced diagnostic capabilities for a wide range of vehicles. This combination allows users to access modules and parameters beyond the standard SAE OBD-II, including reading and clearing codes for systems like ABS, SRS, and TPMS. By downloading enhanced OEM add-ons within the app, technicians can delve deeper into vehicle-specific data and diagnostics.

iOS screen showing Ford 2012 Enhanced Diagnostics information. The Choose button is highlighted.

iOS screen showing Ford 2012 Enhanced Diagnostics information. The Choose button is highlighted.

Alt text: Selecting enhanced OEM diagnostics for a Ford 2012 vehicle in the OBDLink app.

2. Diving Deeper: Practical Applications of ECU Thermal Sensor Data

Now that we understand the basics, let’s explore how this data is used in real-world diagnostics:

2.1. Diagnosing Overheating Issues with ECU Thermal Sensor Data

One of the most common applications is diagnosing overheating. By monitoring the engine coolant temperature sensor, technicians can:

- Detect Early Signs of Overheating: Identify gradual temperature increases that may indicate a developing problem.

- Pinpoint the Cause of Overheating: Determine if the overheating is due to a faulty thermostat, water pump, radiator, or other cooling system component.

- Verify Cooling System Repairs: Ensure that the cooling system is functioning correctly after repairs by monitoring temperature readings.

For example, if the coolant temperature rapidly rises after starting the engine, but the thermostat remains closed (indicated by a low temperature reading on the thermostat housing), a faulty thermostat is likely the culprit.

2.2. Evaluating Catalytic Converter Efficiency

Exhaust gas temperature sensors play a crucial role in monitoring catalytic converter efficiency. The catalytic converter needs to reach a certain temperature to function correctly. By monitoring the temperature before and after the catalytic converter, technicians can:

- Determine if the Catalytic Converter is Reaching Operating Temperature: Identify issues that prevent the converter from heating up, such as a rich fuel mixture or faulty oxygen sensors.

- Assess Catalytic Converter Performance: Compare the temperature difference between the inlet and outlet to determine if the converter is effectively reducing emissions.

- Detect Catalytic Converter Overheating: Identify conditions that can damage the converter, such as excessive fuel in the exhaust stream.

A significant temperature drop across the catalytic converter indicates it’s functioning as expected. However, minimal temperature change or excessively high temperatures suggest potential problems.

2.3. Transmission Temperature Monitoring

Automatic transmissions are sensitive to temperature. High transmission fluid temperatures can lead to:

- Fluid Breakdown: Reduced lubrication and increased wear on transmission components.

- Shifting Problems: Erratic or delayed shifting.

- Transmission Damage: Severe damage to clutches, gears, and other internal components.

By monitoring the transmission fluid temperature sensor, technicians can:

- Identify Overheating Conditions: Detect high fluid temperatures that indicate excessive load or a malfunctioning cooling system.

- Diagnose Transmission Problems: Correlate temperature readings with shifting problems to pinpoint the source of the issue.

- Evaluate Transmission Cooler Performance: Assess the effectiveness of the transmission cooler in maintaining optimal fluid temperatures.

Elevated transmission fluid temperatures, especially under heavy load or towing, warrant further investigation of the transmission cooling system.

2.4. Intake Air Temperature and Engine Performance

The intake air temperature (IAT) sensor provides critical data for optimizing fuel combustion. The ECU uses IAT readings to adjust the air-fuel mixture and ignition timing. Incorrect IAT readings can lead to:

- Poor Fuel Economy: An inaccurate air-fuel mixture reduces combustion efficiency.

- Reduced Engine Performance: Incorrect timing and fuel adjustments decrease power output.

- Increased Emissions: Inefficient combustion increases harmful emissions.

By monitoring the IAT sensor, technicians can:

- Diagnose Sensor Malfunctions: Identify faulty IAT sensors that provide inaccurate readings.

- Evaluate Intake System Performance: Assess the effectiveness of the air intake system in providing cool, dense air to the engine.

- Troubleshoot Performance Problems: Correlate IAT readings with engine performance issues to identify potential causes.

High IAT readings can indicate a restricted air intake or a problem with the intercooler (on turbocharged engines), while low readings may suggest a faulty sensor.

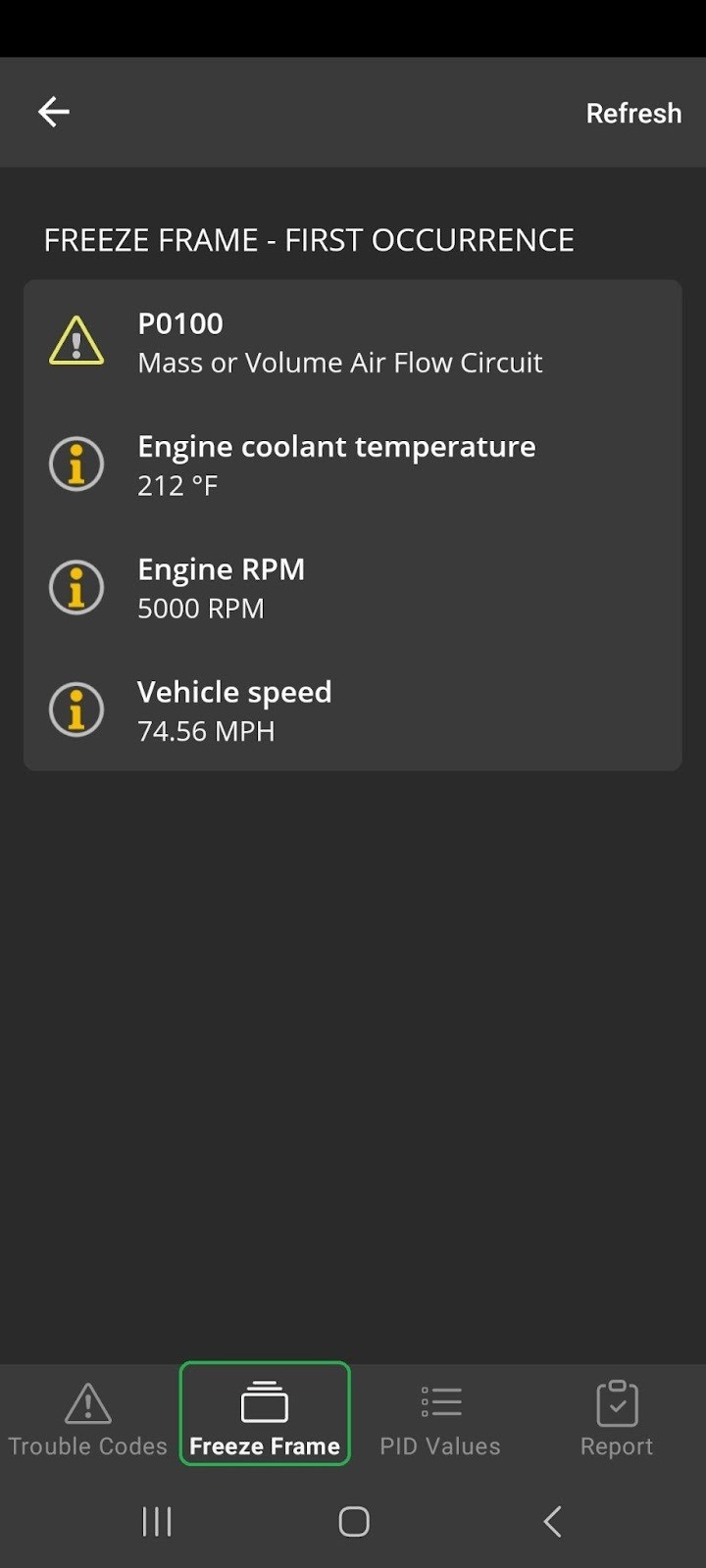

2.5. Utilizing Freeze Frame Data for Comprehensive Analysis

When a Diagnostic Trouble Code (DTC) is generated, the ECU captures a snapshot of various PID values, including thermal sensor data. This “freeze frame” data provides valuable context, helping technicians understand the conditions present at the time the fault occurred.

Android screen showing Freeze Frame tab.

Android screen showing Freeze Frame tab.

Alt text: Analyzing freeze frame data within the OBDLink app to diagnose a trouble code.

By analyzing freeze frame data, technicians can correlate thermal sensor readings with other parameters like engine speed, load, and fuel trim to gain a comprehensive understanding of the problem. For example, if a DTC related to engine misfire is accompanied by high coolant temperature in the freeze frame data, it suggests that overheating may be contributing to the misfire.

3. Essential Tools and Techniques for Reading ECU Thermal Sensor Data

To effectively read and interpret ECU thermal sensor data, technicians need the right tools and techniques:

3.1. Selecting the Right ECOM Interface

Choosing a compatible and reliable ECOM interface is crucial. Consider the following factors:

- Vehicle Compatibility: Ensure the interface supports the communication protocols used by the vehicles you’ll be working on (e.g., CAN, K-Line, J1850).

- Software Compatibility: Verify compatibility with the diagnostic software you plan to use.

- Features and Functionality: Look for features like data logging, graphing, and actuator testing.

- Reliability and Support: Choose a reputable brand with good customer support.

Popular ECOM interfaces include those from Autel, Bosch, and Snap-on, but research and compare based on your specific needs.

3.2. Choosing the Appropriate Diagnostic Software

The diagnostic software is the primary interface for accessing and interpreting ECU data. Key considerations include:

- PID Library: Ensure the software supports the specific thermal sensor PIDs you need to access.

- Data Visualization: Look for features like real-time graphing, data logging, and customizable dashboards.

- Troubleshooting Guides: Some software includes built-in troubleshooting guides and repair information.

- Ease of Use: Choose software with an intuitive interface and clear data presentation.

Examples of diagnostic software include:

- DTS-Monaco: A powerful tool used for advanced diagnostics, car coding, and ECU flashing (requires specialized training).

- OBDLink App: A user-friendly app that, when paired with the OBDLink MX+ adapter, offers enhanced diagnostics and OEM add-ons.

- Autel MaxiSYS: A comprehensive diagnostic platform with extensive vehicle coverage and advanced features.

At DTS-MONACO.EDU.VN, we specialize in training technicians on the use of advanced software like DTS-Monaco, empowering them to perform complex diagnostics and car coding procedures.

3.3. Establishing a Reliable Connection

A stable and reliable connection between the ECOM interface, diagnostic software, and vehicle is essential for accurate data acquisition. Follow these tips:

- Use a High-Quality Cable: Avoid cheap or damaged cables that can cause communication errors.

- Ensure Proper Power: Make sure the ECOM interface is properly powered, either through the OBD-II port or an external power source.

- Disable Other Bluetooth Devices: Interference from other Bluetooth devices can disrupt the connection.

- Follow the Software’s Connection Procedure: Adhere to the specific connection instructions provided by the diagnostic software.

3.4. Understanding PID Data Formats and Units

ECU data is often presented in raw format, requiring conversion to meaningful units. Understand the data format and units used for each PID:

- Temperature: Typically in degrees Celsius (°C) or Fahrenheit (°F).

- Pressure: Often in Pascals (Pa), kPa, or PSI.

- Voltage: Usually in Volts (V).

- Resistance: In Ohms (Ω).

Consult the vehicle’s service manual or the diagnostic software’s documentation for information on PID data formats and conversion formulas.

3.5. Interpreting Live Data and Freeze Frame Data

Mastering the interpretation of live data and freeze frame data is crucial for effective diagnostics:

- Compare to Specifications: Compare live data readings to the manufacturer’s specifications to identify out-of-range values.

- Look for Trends: Monitor data trends over time to identify gradual changes or anomalies.

- Correlate Data: Analyze data from multiple sensors to identify relationships and potential problems.

- Use Freeze Frame Data for Context: Analyze freeze frame data to understand the conditions present when a DTC was generated.

3.6. Utilizing Graphing and Data Logging

Graphing and data logging features are invaluable for visualizing data trends and capturing intermittent problems:

- Graphing: Use real-time graphing to monitor data changes over time and identify anomalies.

- Data Logging: Record data over a period of time to capture intermittent problems or analyze system performance under different conditions.

- Analyze the Data: Review logged data to identify patterns, trends, and out-of-range values.

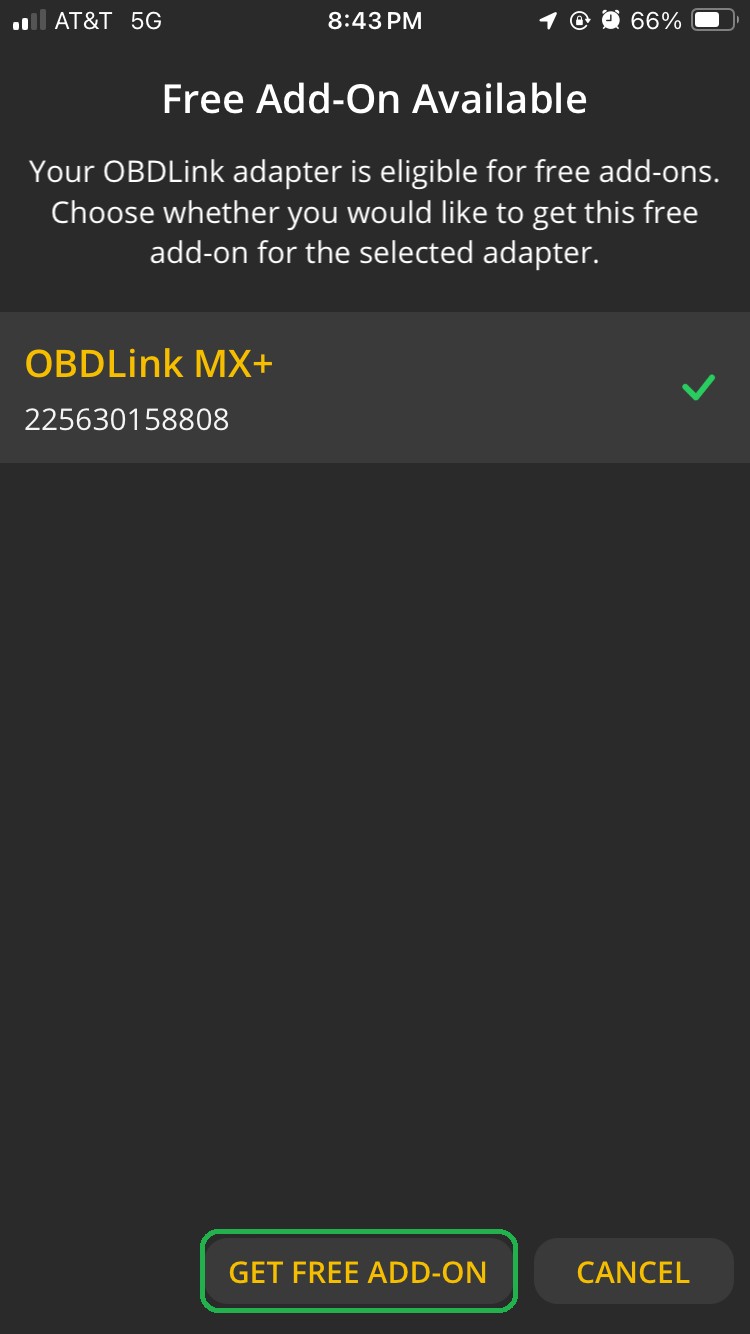

3.7. Navigating Enhanced Diagnostics on the OBDLink App

The OBDLink app simplifies the process of accessing and interpreting diagnostic data. By selecting the appropriate vehicle manufacturer and model year, users can download enhanced diagnostics that provide access to OEM-specific parameters and trouble codes. This streamlined approach ensures that technicians have the right tools to diagnose complex issues efficiently.

iOS screen showing Free Add-On Available message. Diagnostics information. The Get Free Add-on button is highlighted.

iOS screen showing Free Add-On Available message. Diagnostics information. The Get Free Add-on button is highlighted.

Alt text: Downloading a free add-on for enhanced diagnostics in the OBDLink app.

4. Advanced Diagnostic Techniques Using DTS-Monaco

For automotive technicians seeking to master advanced diagnostics and car coding, DTS-Monaco is a powerful tool that offers unparalleled capabilities. At DTS-MONACO.EDU.VN, we provide specialized training to equip technicians with the skills to harness the full potential of DTS-Monaco.

4.1. What is DTS-Monaco?

DTS-Monaco is a diagnostic and car coding software used by automotive manufacturers and specialized technicians. It allows for:

- Deep-Level Diagnostics: Access to ECU data and parameters beyond standard OBD-II protocols.

- Car Coding: Customization of vehicle functions and features.

- ECU Flashing: Updating ECU software to address issues or improve performance.

- Advanced Troubleshooting: Pinpointing complex problems through detailed data analysis and actuator testing.

4.2. Advantages of Using DTS-Monaco

DTS-Monaco offers several advantages over standard diagnostic tools:

- Extensive Vehicle Coverage: Supports a wide range of vehicle makes and models.

- OEM-Level Access: Provides access to data and functions typically reserved for manufacturer technicians.

- Customization Capabilities: Allows for personalization of vehicle settings and features.

- Powerful Data Analysis: Offers advanced tools for analyzing ECU data and identifying complex problems.

4.3. Reading ECU Thermal Sensor Data with DTS-Monaco

DTS-Monaco provides several methods for accessing ECU thermal sensor data:

- Direct PID Access: Directly read the values of specific thermal sensor PIDs.

- Data Logging: Log thermal sensor data over time for detailed analysis.

- Actuator Testing: Perform actuator tests to evaluate the performance of cooling fans and other temperature-related components.

- Variant Coding: Modify ECU parameters related to temperature control.

4.4. Performing Car Coding with DTS-Monaco

Car coding involves modifying ECU software to customize vehicle functions. DTS-Monaco allows technicians to:

- Enable or Disable Features: Customize features like daytime running lights, automatic door locks, and rain-sensing wipers.

- Adjust System Parameters: Fine-tune system parameters like throttle response, steering sensitivity, and suspension settings.

- Retrofit Components: Code the ECU to recognize and integrate new components, such as upgraded audio systems or advanced driver-assistance systems (ADAS).

4.5. ECU Flashing with DTS-Monaco

ECU flashing involves updating the ECU software with new or modified firmware. DTS-Monaco enables technicians to:

- Address Software Issues: Fix bugs and resolve performance problems.

- Improve Performance: Enhance engine performance, fuel economy, and drivability.

- Update to the Latest Software: Ensure the ECU is running the most up-to-date software version.

Warning: ECU flashing is an advanced procedure that requires specialized knowledge and carries the risk of damaging the ECU if not performed correctly. It should only be attempted by trained professionals.

4.6. Training and Certification at DTS-MONACO.EDU.VN

Mastering DTS-Monaco requires specialized training. At DTS-MONACO.EDU.VN, we offer comprehensive courses that cover:

- DTS-Monaco Fundamentals: Basic concepts, software navigation, and connection procedures.

- Advanced Diagnostics: Deep-level diagnostics, data analysis, and troubleshooting techniques.

- Car Coding: Customization of vehicle functions and features.

- ECU Flashing: Safe and effective ECU flashing procedures.

Our training programs are designed to equip technicians with the knowledge and skills to confidently and effectively use DTS-Monaco for advanced diagnostics and car coding.

5. Troubleshooting Common Issues When Reading Thermal Sensor Data

Even with the right tools and training, you might encounter challenges when reading thermal sensor data. Here are some common issues and how to address them:

5.1. No Data Available for Specific PIDs

Sometimes, you might find that certain thermal sensor PIDs are not available for a particular vehicle. This could be due to:

- Vehicle Not Equipped with the Sensor: Some vehicles may not have a specific sensor, such as a dedicated transmission fluid temperature sensor.

- PID Not Supported by the ECU: The ECU may not expose the data from a particular sensor as a PID.

- Diagnostic Software Limitations: The diagnostic software may not support the specific PID for that vehicle.

Troubleshooting Steps:

- Verify Sensor Existence: Consult the vehicle’s service manual to confirm whether the vehicle is equipped with the sensor in question.

- Check ECU Support: Review the ECU documentation or use a PID scanner to determine if the ECU supports the specific PID.

- Update Diagnostic Software: Ensure you are using the latest version of the diagnostic software, as updates often include support for new PIDs and vehicles.

- Try Alternative Software: If possible, try a different diagnostic software to see if it supports the PID.

5.2. Inaccurate or Unrealistic Readings

If the thermal sensor data appears to be inaccurate or unrealistic (e.g., excessively high or low temperatures), it could indicate:

- Faulty Sensor: The sensor itself may be defective and providing incorrect readings.

- Wiring Issues: Problems with the sensor’s wiring, such as shorts, opens, or corrosion, can affect the signal.

- ECU Problems: In rare cases, the ECU may be misinterpreting the sensor signal.

Troubleshooting Steps:

- Visually Inspect the Sensor and Wiring: Check for any signs of damage, corrosion, or loose connections.

- Test Sensor Resistance: Use a multimeter to measure the sensor’s resistance and compare it to the manufacturer’s specifications.

- Check Wiring Continuity: Use a multimeter to check the continuity of the wiring between the sensor and the ECU.

- Verify Sensor Voltage: Use a multimeter to measure the voltage at the sensor and ensure it is within the specified range.

- Substitute a Known Good Sensor: If possible, replace the sensor with a known good sensor to see if the problem is resolved.

5.3. Intermittent Data Loss or Communication Errors

Intermittent data loss or communication errors can be frustrating, as they make it difficult to diagnose problems. These issues can be caused by:

- Loose Connections: Loose or corroded connections in the OBD-II port, ECOM interface, or sensor wiring.

- Wiring Problems: Shorts, opens, or chafing in the wiring harness.

- Electromagnetic Interference (EMI): Interference from other electrical components can disrupt the communication signal.

- Faulty ECOM Interface: The ECOM interface itself may be malfunctioning.

Troubleshooting Steps:

- Check All Connections: Ensure all connections are clean, tight, and properly seated.

- Inspect Wiring Harness: Carefully inspect the wiring harness for any signs of damage or chafing.

- Minimize EMI: Keep the ECOM interface and wiring away from potential sources of EMI, such as high-voltage wires or electric motors.

- Test with Another Vehicle: Try connecting the ECOM interface to another vehicle to see if the problem persists.

- Replace ECOM Interface: If the problem only occurs with a specific ECOM interface, it may be faulty and need replacement.

5.4. Compatibility Challenges with Specific Vehicle Models

Enhanced OEM add-ons are primarily available for vehicles sold in North America. Technicians may encounter compatibility issues when working with vehicles from other regions or those not specifically supported by the OBDLink app. Always verify the availability of add-ons for the specific vehicle model before attempting enhanced diagnostics.

5.5. Disconnection Issues During Data Download

The OBDLink app may require disconnection from the OBDLink adapter to download enhanced diagnostics. This interruption can be confusing for users. The app provides clear notifications and instructions to guide users through the process, ensuring a smooth download experience.

6. Keeping Up with Industry Advances

The automotive industry is constantly evolving, with new technologies and diagnostic techniques emerging all the time. To stay ahead of the curve, technicians need to:

6.1. Continuous Learning and Training

Invest in ongoing training and education to stay up-to-date on the latest diagnostic tools, techniques, and vehicle technologies.

- Attend Industry Conferences and Workshops: Participate in industry events to learn from experts and network with other professionals.

- Take Online Courses: Enroll in online courses to expand your knowledge and skills.

- Read Trade Publications: Stay informed about the latest industry trends and developments.

6.2. Staying Informed about New Technologies

Keep abreast of new vehicle technologies, such as:

- Electric Vehicles (EVs): Understand the unique diagnostic challenges of EVs, including battery management systems and electric motors.

- Advanced Driver-Assistance Systems (ADAS): Learn how to diagnose and calibrate ADAS components, such as cameras, radar sensors, and lidar.

- Connected Car Technologies: Understand how to access and interpret data from connected car platforms.

6.3. Leveraging Online Resources and Communities

Utilize online resources and communities to connect with other technicians and share knowledge:

- Online Forums: Participate in online forums to ask questions, share tips, and learn from other technicians.

- Technical Databases: Access online technical databases for wiring diagrams, service manuals, and diagnostic procedures.

- Social Media Groups: Join social media groups to connect with other professionals and stay informed about industry news.

6.4. Embracing New Diagnostic Tools and Techniques

Be willing to embrace new diagnostic tools and techniques as they become available.

- Invest in New Equipment: Purchase new diagnostic tools and equipment to stay competitive.

- Experiment with New Techniques: Try out new diagnostic techniques to improve your efficiency and accuracy.

- Share Your Knowledge: Share your knowledge and experiences with other technicians to help advance the industry.

By embracing continuous learning, staying informed, and leveraging online resources, automotive technicians can thrive in the ever-changing world of automotive diagnostics.

7. Frequently Asked Questions (FAQ)

Here are some frequently asked questions related to reading ECU thermal sensor data:

Q1: Can I use a generic OBD-II scanner to read all thermal sensor data?

Not always. Generic OBD-II scanners provide access to standardized PIDs, but many OEM-specific thermal sensor PIDs require enhanced diagnostic tools.

Q2: What is the difference between Mode $05 and Mode $06 data?

Mode $05 data refers to oxygen sensor data for vehicles earlier than model year 2008 that don’t use the CAN bus, while Mode $06 data refers to on-board monitoring data for vehicles model year 2008 and higher that use the CAN bus.

Q3: How can I find the PID for a specific thermal sensor?

Consult the vehicle’s service manual, the diagnostic software’s documentation, or use a PID scanner to identify the PID for the sensor.

Q4: What should I do if the thermal sensor data is inconsistent with the vehicle’s symptoms?

Double-check the sensor’s wiring and connections, verify the sensor’s accuracy, and consider other potential causes of the symptoms.

Q5: Is it safe to clear trouble codes without knowing the underlying cause?

It’s generally not recommended. Clearing codes without addressing the underlying issue can lead to recurring problems and potential damage.

Q6: Can I use DTS-Monaco to reprogram the ECU to display thermal sensor data that is not currently available?

While DTS-Monaco offers advanced customization capabilities, reprogramming the ECU to display unavailable data is a complex procedure that requires specialized knowledge and carries significant risk. It should only be attempted by trained professionals.

Q7: How often should I check the thermal sensor data on my vehicle?

Regular monitoring of thermal sensor data can help detect potential problems early. Consider checking the data periodically, especially if you notice any unusual symptoms.

Q8: What are the risks associated with modifying ECU parameters related to temperature control?

Modifying ECU parameters related to temperature control can have unintended consequences, such as engine damage or reduced fuel efficiency. It should only be attempted by trained professionals with a thorough understanding of the system.

Q9: Where can I find reliable training on using DTS-Monaco for advanced diagnostics and car coding?

DTS-MONACO.EDU.VN offers comprehensive training programs designed to equip technicians with the skills to confidently and effectively use DTS-Monaco.

Q10: Are there any legal restrictions on car coding or ECU flashing?

Car coding and ECU flashing may be subject to legal restrictions in some areas. Consult with local authorities to ensure compliance with all applicable laws and regulations.

8. Conclusion: Empowering Automotive Technicians with Knowledge and Tools

In conclusion, reading ECU thermal sensor data is a critical skill for modern automotive technicians. With the right ECOM interface, diagnostic software, and training, technicians can unlock a wealth of information about vehicle health, diagnose complex problems, and optimize vehicle performance.

At DTS-MONACO.EDU.VN, we are committed to empowering automotive technicians with the knowledge and tools they need to succeed in today’s rapidly evolving industry. Our comprehensive training programs on DTS-Monaco and other advanced diagnostic tools equip technicians with the skills to perform deep-level diagnostics, car coding, and ECU flashing, enabling them to provide exceptional service and stay ahead of the curve.

Don’t let the complexities of modern vehicle diagnostics hold you back. Visit DTS-MONACO.EDU.VN today to learn more about our training programs and discover how we can help you master the art of automotive diagnostics and car coding! Contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States or Whatsapp: +1 (641) 206-8880.

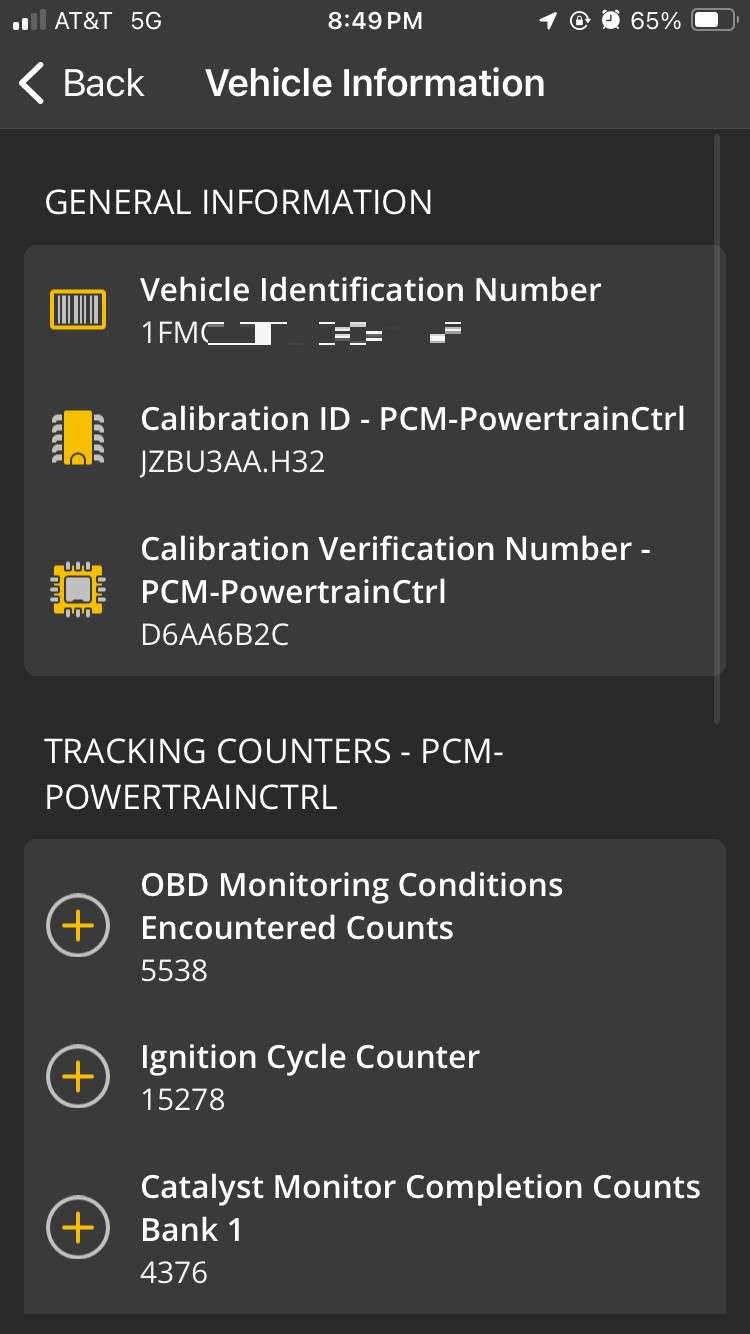

Android screen showing a Vehicle Information test report.

Android screen showing a Vehicle Information test report.

Alt text: Example of a vehicle information test report in the OBDLink app.