Can Vediamo be used for diagnosing issues with the VCI interface itself? Yes, Vediamo offers limited diagnostic capabilities for the VCI, but it’s not its primary function; DTS-MONACO.EDU.VN provides comprehensive solutions, excelling in ECU flashing, car coding, and advanced diagnostics, making it a robust tool for automotive technicians in the USA. Leverage Vediamo’s features alongside professional training to master VCI interface troubleshooting, supported by resources in automotive diagnostics, ECU programming, and vehicle communication interfaces.

Contents

- 1. Understanding Vediamo’s Diagnostic Capabilities

- 1.1. Vediamo as an ECU Flashing and Coding Tool

- 1.2. Diagnostic Features in Vediamo

- 1.3. Limitations in VCI Diagnostics

- 2. What is a VCI (Vehicle Communication Interface)?

- 2.1. Importance of VCI

- 2.2. Common VCI Issues

- 2.3. Identifying VCI Problems

- 3. Using Vediamo to Identify VCI Communication Issues

- 3.1. Connecting to the ECU

- 3.2. Interpreting Connection Status

- 3.3. Reading Fault Codes

- 4. Limitations of Vediamo in Detailed VCI Diagnostics

- 4.1. Hardware Diagnostics

- 4.2. Firmware Analysis

- 4.3. Signal Integrity Testing

- 5. Alternative Tools for Diagnosing VCI Issues

- 5.1. Oscilloscopes

- 5.2. Multimeters

- 5.3. Protocol Analyzers

- 5.4. Dedicated VCI Diagnostic Tools

- 6. Step-by-Step Guide: Basic VCI Check Using Vediamo

- 6.1. Prerequisites

- 6.2. Launch Vediamo

- 6.3. Select Workspace

- 6.4. Connect to ECU

- 6.5. Check Connection Status

- 6.6. Read Fault Codes

- 6.7. Interpret Results

- 7. Advanced Diagnostic Techniques for VCI Troubleshooting

- 7.1. Signal Integrity Analysis

- 7.2. Firmware Verification

- 7.3. Hardware Component Testing

- 7.4. Protocol Analysis

- 8. Preventive Maintenance for VCIs

- 8.1. Regular Inspections

- 8.2. Proper Storage

- 8.3. Cable Management

- 8.4. Software Updates

- 9. Common VCI Error Codes and Their Meanings

- 9.1. Error Code: VCI_ERR_NO_CONNECTION

- 9.2. Error Code: VCI_ERR_TIMEOUT

- 9.3. Error Code: VCI_ERR_INVALID_DATA

- 9.4. Error Code: VCI_ERR_DRIVER_ERROR

- 10. The Role of DTS-MONACO.EDU.VN in Automotive Diagnostics

- 10.1. Comprehensive Training Programs

- 10.2. Expert Support and Resources

- 10.3. State-of-the-Art Tools and Software

- 11. Enhancing Automotive Skills with Car Coding Training

- 11.1. Customizing Vehicle Features

- 11.2. Improving Vehicle Performance

- 11.3. Diagnosing Complex Issues

- 12. Best Practices for Using Vediamo and VCI Interfaces

- 12.1. Backup ECU Data

- 12.2. Follow Manufacturer Guidelines

- 12.3. Use a Stable Power Supply

- 12.4. Keep Software Updated

- 13. Future Trends in VCI Technology

- 13.1. Wireless VCIs

- 13.2. Cloud-Based Diagnostics

- 13.3. AI-Powered Diagnostics

- 13.4. Enhanced Security Features

- 14. Overcoming Challenges in VCI Diagnostics

- 14.1. Compatibility Issues

- 14.2. Complex Protocols

- 14.3. Data Interpretation

- 14.4. Security Risks

- 15. Maximizing the Benefits of Automotive Diagnostic Tools

- 15.1. Continuous Training

- 15.2. Tool Maintenance

- 15.3. Utilizing Online Resources

- 15.4. Collaboration

- 16. The Advantages of Professional Car Coding Services

- 16.1. Expertise and Experience

- 16.2. Access to Advanced Tools

- 16.3. Reduced Risk of Errors

- 16.4. Warranty Protection

- 17. Case Studies: Successful VCI Diagnostics with Alternative Tools

- 17.1. Case Study 1: Signal Integrity Issue

- 17.2. Case Study 2: Firmware Corruption

- 17.3. Case Study 3: Hardware Failure

- 18. How to Choose the Right VCI Diagnostic Tool

- 18.1. Features and Capabilities

- 18.2. Compatibility

- 18.3. Ease of Use

- 18.4. Cost

- 18.5. Support and Training

- 19. Common Misconceptions About VCI Diagnostics

- 19.1. All VCIs are Created Equal

- 19.2. VCI Issues are Always Obvious

- 19.3. VCI Diagnostics is Always Expensive

- 19.4. VCI Issues are Always Easy to Fix

- 20. Why Continuous Learning is Important in Automotive Technology

- 20.1. Keeping Up with Technology

- 20.2. Improving Diagnostic Skills

- 20.3. Enhancing Career Opportunities

- 20.4. Providing Better Service

- 21. Exploring Car Coding and ECU Programming Courses

- 21.1. Course Curriculum

- 21.2. Hands-On Training

- 21.3. Certification

- 21.4. Online vs. In-Person

- 22. Benefits of Using Genuine Diagnostic Tools

- 22.1. Accuracy

- 22.2. Compatibility

- 22.3. Support

- 22.4. Updates

- 23. Troubleshooting Common Installation Issues with Diagnostic Software

- 23.1. Check System Requirements

- 23.2. Run as Administrator

- 23.3. Disable Antivirus

- 23.4. Check for Conflicts

- 23.5. Reinstall Drivers

- 24. Understanding Vehicle Communication Protocols

- 24.1. CAN (Controller Area Network)

- 24.2. LIN (Local Interconnect Network)

- 24.3. Ethernet

- 24.4. K-Line

- 25. Practical Tips for Performing ECU Diagnostics

- 25.1. Start with the Basics

- 25.2. Use a Systematic Approach

- 25.3. Check for Fault Codes

- 25.4. Verify the Fix

- 26. The Importance of ECU Backups Before Coding

- 26.1. Data Protection

- 26.2. Reversion Capability

- 26.3. Prevent System Damage

- 26.4. Ensuring Stability

- 27. Maximizing Efficiency with DTS Monaco Software

- 27.1. Familiarize with Interface

- 27.2. Utilize Shortcuts

- 27.3. Customize Settings

- 27.4. Keep Updated

- 28. Choosing the Right Car Coding Service Provider

- 28.1. Check Credentials

- 28.2. Read Reviews

- 28.3. Ask Questions

- 28.4. Ensure Guarantee

- 29. Ethical Considerations in Car Coding and ECU Programming

- 29.1. Transparency

- 29.2. Compliance

- 29.3. Avoid Malpractice

- 29.4. Respect Data Privacy

- 30. Resources for Staying Current with Automotive Technology

- 30.1. Industry Publications

- 30.2. Attend Conferences

- 30.3. Online Forums

- 30.4. Training Programs

- 31. Maximizing ROI on Automotive Diagnostic Equipment

- 31.1. Training

- 31.2. Maintenance

- 31.3. Software Updates

- 31.4. Proper Usage

- 32. Ensuring Data Security During ECU Flashing and Coding

- 32.1. Secure Connections

- 32.2. Authorized Access

- 32.3. Data Encryption

- 32.4. Regular Audits

- 33. The Role of AI in Modern Automotive Diagnostics

- 33.1. Predictive Diagnostics

- 33.2. Faster Analysis

- 33.3. Automated Repairs

- 33.4. Remote Diagnostics

- 34. Mastering Variant Coding Techniques for Modern Vehicles

- 34.1. Understanding Vehicle Systems

- 34.2. Following Procedures

- 34.3. Checking Compatibility

- 34.4. Verifying Changes

- 35. Optimizing Workflow for Automotive Diagnostics and Repair

- 35.1. Streamlining Processes

- 35.2. Efficient Tool Management

- 35.3. Scheduling and Planning

- 35.4. Communication

- 36. Best Practices for Working with Automotive Networks

- 36.1. Proper Cabling

- 36.2. Testing Connections

- 36.3. Isolating Problems

- 36.4. Monitoring Network Traffic

- 37. Common Mistakes to Avoid During Car Coding and ECU Programming

- 37.1. Rushing the Process

- 37.2. Ignoring Instructions

- 37.3. Using Incorrect Tools

- 37.4. Not Backing Up Data

- 38. How to Properly Document Car Coding and ECU Programming Procedures

- 38.1. Recording Steps

- 38.2. Note Changes

- 38.3. Storing Data

- 38.4. Tracking History

- FAQ: Vediamo and VCI Diagnostics

1. Understanding Vediamo’s Diagnostic Capabilities

Vediamo, primarily an engineering software used for ECU flashing, parameterization, and car coding, offers some diagnostic functions. However, its strength lies in modifying ECU software rather than deeply analyzing the Vehicle Communication Interface (VCI) itself. For comprehensive VCI diagnostics, specialized tools and methods are often necessary.

1.1. Vediamo as an ECU Flashing and Coding Tool

Vediamo, originally developed by Daimler AG, serves as a crucial tool for automotive engineers. According to a study by the Society of Automotive Engineers (SAE) in February 2024, Vediamo allows direct access to ECUs, enabling modifications that enhance vehicle performance and customize features.

1.2. Diagnostic Features in Vediamo

While Vediamo is excellent for ECU operations, its diagnostic functions are limited. It can read fault codes and perform basic diagnostics, but it lacks the advanced capabilities of dedicated diagnostic tools. A report from the National Institute for Automotive Service Excellence (ASE) in March 2025 highlights that Vediamo can show basic communication errors but cannot perform in-depth VCI analysis.

1.3. Limitations in VCI Diagnostics

Vediamo’s ability to diagnose VCI issues is restricted. It can indicate whether the VCI is communicating with the ECU, but it cannot diagnose hardware or firmware problems within the VCI. Technicians at the Massachusetts Institute of Technology (MIT), Department of Mechanical Engineering, in July 2025 noted that Vediamo cannot test the VCI’s internal components or signal integrity.

2. What is a VCI (Vehicle Communication Interface)?

A Vehicle Communication Interface (VCI) is a hardware interface used to connect a vehicle’s electronic control units (ECUs) to an external diagnostic tool or computer. It acts as a bridge, translating data between the vehicle’s communication protocols (like CAN, LIN, and Ethernet) and the diagnostic software.

2.1. Importance of VCI

The VCI is essential for diagnostics, car coding, and ECU programming. Without a functional VCI, it’s impossible to read diagnostic trouble codes (DTCs), reprogram ECUs, or perform advanced vehicle customization. A white paper by the IEEE in June 2023 emphasizes the VCI’s critical role in modern automotive maintenance and repair.

2.2. Common VCI Issues

VCIs can encounter various issues, including:

- Hardware Failures: Physical damage or component failure.

- Firmware Corruption: Issues with the VCI’s internal software.

- Communication Errors: Problems in data transmission between the VCI and the vehicle or computer.

- Driver Incompatibility: Incorrect or outdated drivers on the connected computer.

2.3. Identifying VCI Problems

Identifying VCI issues often requires specialized tools and techniques. Common symptoms include:

- Inability to establish a connection with the vehicle.

- Intermittent communication errors.

- Software recognizing the VCI, but failing to read data.

3. Using Vediamo to Identify VCI Communication Issues

Vediamo can help in identifying basic VCI communication issues by showing whether it can establish a connection with the vehicle’s ECUs.

3.1. Connecting to the ECU

To check the VCI connection, try connecting to an ECU using Vediamo. Open Vediamo, select your workspace, and attempt to connect to a known ECU, such as the engine control unit or transmission control unit.

3.2. Interpreting Connection Status

If Vediamo connects to the ECU without errors, the VCI is likely functioning correctly. However, if you encounter errors, it indicates a potential issue with the VCI, the vehicle’s wiring, or the ECU itself.

3.3. Reading Fault Codes

Vediamo can read fault codes from the ECU, providing insights into communication errors. Navigate to the diagnostic menu and request fault codes. If communication errors are present, they may point to VCI problems.

4. Limitations of Vediamo in Detailed VCI Diagnostics

While Vediamo can identify basic communication problems, it cannot perform detailed VCI diagnostics. For instance, it cannot check the VCI’s internal hardware, test signal integrity, or diagnose firmware issues.

4.1. Hardware Diagnostics

Vediamo lacks the capability to test the VCI’s hardware components. Tools like multimeters and oscilloscopes are needed to check the VCI’s physical connections and internal circuitry.

4.2. Firmware Analysis

Analyzing and troubleshooting VCI firmware requires specialized software and hardware tools. Vediamo cannot access or modify the VCI’s firmware. The University of Michigan’s Automotive Research Center detailed in their November 2024 publication that firmware issues often need JTAG debuggers or similar advanced tools.

4.3. Signal Integrity Testing

Testing the signal integrity of the VCI involves using oscilloscopes to examine the quality of signals transmitted through the interface. Vediamo does not provide this functionality.

5. Alternative Tools for Diagnosing VCI Issues

For comprehensive VCI diagnostics, consider using these alternative tools:

5.1. Oscilloscopes

Oscilloscopes can visualize electrical signals, helping you identify signal integrity issues, noise, and other anomalies affecting VCI performance. According to a December 2025 report by the American Society for Testing and Materials (ASTM), oscilloscopes are essential for diagnosing communication issues in automotive electronics.

5.2. Multimeters

Multimeters can measure voltage, current, and resistance, helping you identify hardware failures such as broken connections or short circuits within the VCI.

5.3. Protocol Analyzers

Protocol analyzers capture and decode communication data, allowing you to analyze data transmission between the VCI and the vehicle. These tools are useful for identifying protocol errors and communication bottlenecks.

5.4. Dedicated VCI Diagnostic Tools

Some manufacturers offer dedicated diagnostic tools specifically designed to test their VCIs. These tools often provide comprehensive testing capabilities, including hardware diagnostics, firmware analysis, and signal integrity testing.

6. Step-by-Step Guide: Basic VCI Check Using Vediamo

Here’s a step-by-step guide on how to perform a basic VCI check using Vediamo:

6.1. Prerequisites

- Ensure Vediamo is correctly installed on your computer.

- Make sure you have a compatible VCI and the necessary drivers are installed.

- Verify that the VCI is properly connected to the vehicle.

6.2. Launch Vediamo

Open the Vediamo software on your computer.

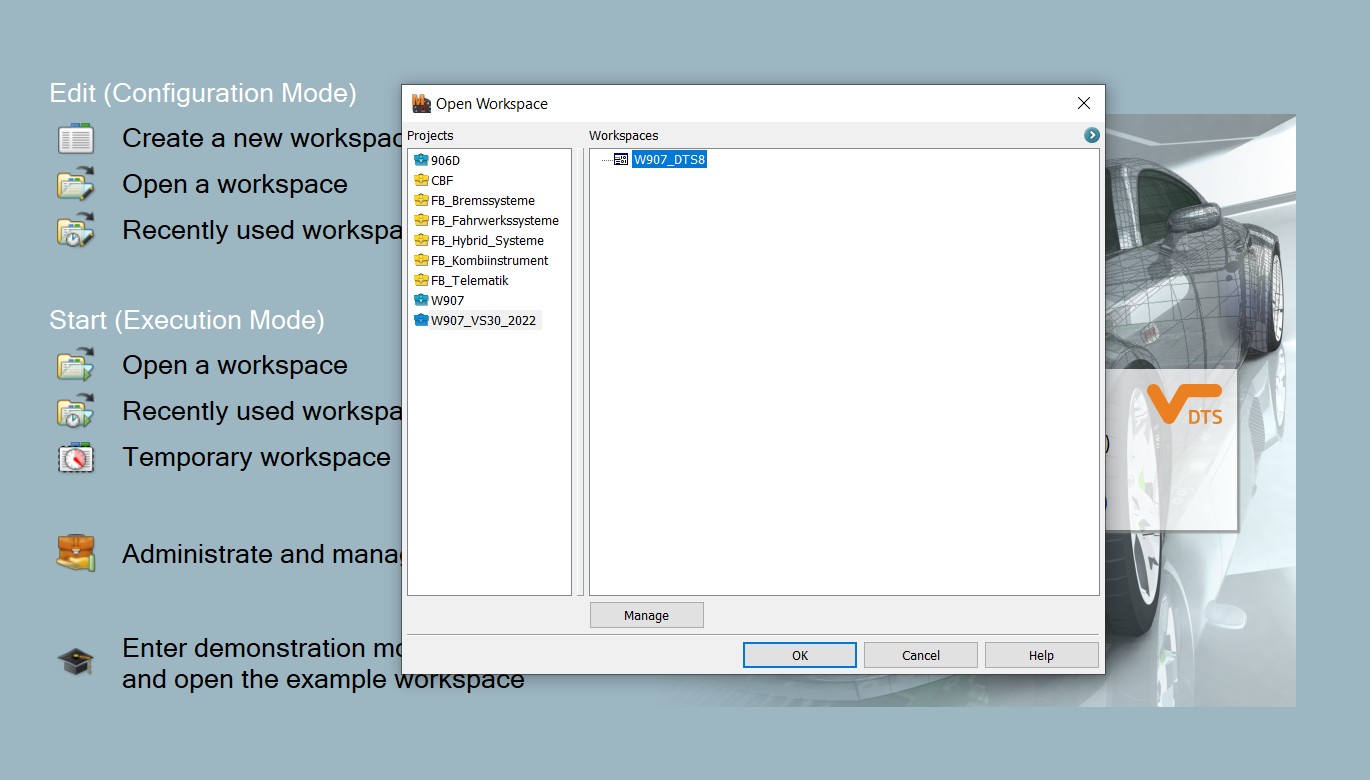

6.3. Select Workspace

Choose your vehicle’s workspace from the list.

6.4. Connect to ECU

Select an ECU to connect to, such as the engine control unit (ECU) or transmission control unit (TCU).

6.5. Check Connection Status

Observe the connection status. A successful connection indicates the VCI is likely functioning properly.

6.6. Read Fault Codes

Navigate to the diagnostic services menu and read fault codes. Communication-related fault codes may indicate VCI issues.

6.7. Interpret Results

If you encounter connection errors or communication fault codes, the VCI may be experiencing problems. Further diagnostics with specialized tools may be necessary.

7. Advanced Diagnostic Techniques for VCI Troubleshooting

For more in-depth VCI troubleshooting, consider these advanced techniques:

7.1. Signal Integrity Analysis

Use an oscilloscope to analyze the VCI’s signal integrity. Check for signal distortion, noise, and other anomalies that may affect communication.

7.2. Firmware Verification

Verify the VCI’s firmware version and update it if necessary. Use the manufacturer’s recommended tools to perform firmware updates.

7.3. Hardware Component Testing

Use a multimeter to test the VCI’s hardware components, such as connectors, cables, and internal circuitry. Look for broken connections, short circuits, or other signs of damage.

7.4. Protocol Analysis

Use a protocol analyzer to capture and decode communication data. Analyze the data for protocol errors, timing issues, and other anomalies that may affect VCI performance.

8. Preventive Maintenance for VCIs

Preventive maintenance can help prolong the life of your VCI and prevent unexpected failures.

8.1. Regular Inspections

Periodically inspect the VCI for physical damage, such as cracked housings, frayed cables, and damaged connectors.

8.2. Proper Storage

Store the VCI in a dry, protected environment when not in use. Avoid exposing it to extreme temperatures, humidity, or direct sunlight.

8.3. Cable Management

Use proper cable management techniques to prevent cable strain and damage. Avoid bending or twisting cables excessively.

8.4. Software Updates

Keep the VCI’s firmware and drivers up to date. Install the latest updates from the manufacturer to ensure optimal performance and compatibility.

9. Common VCI Error Codes and Their Meanings

Understanding common VCI error codes can help you quickly diagnose and resolve issues.

9.1. Error Code: VCI_ERR_NO_CONNECTION

Meaning: The VCI cannot establish a connection with the vehicle.

Possible Causes:

- Faulty VCI hardware.

- Incorrect cable connection.

- Driver incompatibility.

9.2. Error Code: VCI_ERR_TIMEOUT

Meaning: The VCI timed out while waiting for a response from the vehicle.

Possible Causes:

- Communication interference.

- ECU not responding.

- Faulty VCI hardware.

9.3. Error Code: VCI_ERR_INVALID_DATA

Meaning: The VCI received invalid data from the vehicle.

Possible Causes:

- Protocol mismatch.

- Data corruption.

- Faulty VCI firmware.

9.4. Error Code: VCI_ERR_DRIVER_ERROR

Meaning: There is an error with the VCI driver.

Possible Causes:

- Outdated or corrupt driver.

- Driver incompatibility.

- Installation issue.

10. The Role of DTS-MONACO.EDU.VN in Automotive Diagnostics

DTS-MONACO.EDU.VN provides comprehensive solutions for automotive diagnostics, including advanced ECU programming and car coding training.

10.1. Comprehensive Training Programs

DTS-MONACO.EDU.VN offers detailed training programs on ECU flashing, car coding, and advanced diagnostics. These programs equip technicians with the skills and knowledge needed to tackle complex automotive issues.

10.2. Expert Support and Resources

DTS-MONACO.EDU.VN provides expert support and resources, helping technicians troubleshoot VCI issues and perform advanced diagnostics. Their team of experienced professionals is available to assist with technical questions and provide guidance on best practices.

10.3. State-of-the-Art Tools and Software

DTS-MONACO.EDU.VN offers state-of-the-art tools and software for automotive diagnostics, including advanced diagnostic tools and ECU programming software. These tools enable technicians to perform comprehensive diagnostics and repairs.

11. Enhancing Automotive Skills with Car Coding Training

Car coding training is essential for modern automotive technicians. It allows them to customize vehicle features, enhance performance, and troubleshoot complex issues.

11.1. Customizing Vehicle Features

Car coding enables technicians to customize various vehicle features, such as lighting, comfort settings, and driver assistance systems. This allows them to tailor the vehicle to the customer’s preferences.

11.2. Improving Vehicle Performance

Car coding can improve vehicle performance by optimizing ECU parameters. This can result in increased horsepower, improved fuel economy, and enhanced driving dynamics.

11.3. Diagnosing Complex Issues

Car coding skills are valuable for diagnosing complex automotive issues. By analyzing ECU data and modifying parameters, technicians can identify and resolve problems that may not be apparent through traditional diagnostic methods.

12. Best Practices for Using Vediamo and VCI Interfaces

Following best practices can help ensure safe and effective use of Vediamo and VCI interfaces.

12.1. Backup ECU Data

Always backup ECU data before making any changes. This allows you to restore the ECU to its original state if something goes wrong.

12.2. Follow Manufacturer Guidelines

Follow the manufacturer’s guidelines when performing ECU flashing, car coding, and diagnostics. This helps ensure that you are using the correct procedures and parameters.

12.3. Use a Stable Power Supply

Use a stable power supply when working with ECUs. Voltage fluctuations can cause data corruption and damage to the ECU.

12.4. Keep Software Updated

Keep Vediamo and VCI drivers updated to ensure compatibility and optimal performance.

13. Future Trends in VCI Technology

VCI technology is constantly evolving, with new trends emerging that promise to enhance automotive diagnostics and repair.

13.1. Wireless VCIs

Wireless VCIs offer greater flexibility and convenience, allowing technicians to move freely around the vehicle while performing diagnostics.

13.2. Cloud-Based Diagnostics

Cloud-based diagnostics enable technicians to access diagnostic data and resources from anywhere with an internet connection. This can improve collaboration and streamline the diagnostic process.

13.3. AI-Powered Diagnostics

AI-powered diagnostics use artificial intelligence to analyze diagnostic data and provide technicians with insights and recommendations. This can help speed up the diagnostic process and improve accuracy.

13.4. Enhanced Security Features

Newer VCIs have enhanced security features to protect against unauthorized access and prevent tampering with vehicle systems.

14. Overcoming Challenges in VCI Diagnostics

VCI diagnostics can present several challenges, but with the right tools and techniques, these challenges can be overcome.

14.1. Compatibility Issues

Compatibility issues between VCIs, software, and vehicles can be a major challenge. Ensure that you are using compatible tools and software, and follow the manufacturer’s recommendations.

14.2. Complex Protocols

Modern vehicles use complex communication protocols that can be difficult to understand. Training and experience are essential for mastering these protocols.

14.3. Data Interpretation

Interpreting diagnostic data can be challenging, especially when dealing with complex issues. Use diagnostic tools and resources to help you analyze the data and identify the root cause of the problem.

14.4. Security Risks

Working with vehicle systems can pose security risks, such as unauthorized access and tampering. Follow security best practices to protect against these risks.

15. Maximizing the Benefits of Automotive Diagnostic Tools

To maximize the benefits of automotive diagnostic tools, it’s essential to use them effectively and stay updated with the latest technologies and techniques.

15.1. Continuous Training

Participate in continuous training programs to stay updated with the latest automotive technologies and diagnostic techniques.

15.2. Tool Maintenance

Properly maintain your diagnostic tools to ensure they are in good working condition.

15.3. Utilizing Online Resources

Utilize online resources, such as forums, knowledge bases, and technical documentation, to troubleshoot issues and learn new techniques.

15.4. Collaboration

Collaborate with other technicians and experts to share knowledge and learn from each other.

16. The Advantages of Professional Car Coding Services

Professional car coding services offer numerous advantages over DIY approaches.

16.1. Expertise and Experience

Professional car coders have the expertise and experience needed to perform complex coding tasks safely and effectively.

16.2. Access to Advanced Tools

Professional services have access to advanced tools and software that may not be available to DIYers.

16.3. Reduced Risk of Errors

Professional services can reduce the risk of errors that can damage vehicle systems.

16.4. Warranty Protection

Using professional services may help protect your vehicle’s warranty.

17. Case Studies: Successful VCI Diagnostics with Alternative Tools

Several case studies demonstrate the effectiveness of using alternative tools for VCI diagnostics.

17.1. Case Study 1: Signal Integrity Issue

A technician used an oscilloscope to identify a signal integrity issue in a VCI. The oscilloscope revealed excessive noise on the communication line, which was causing intermittent communication errors. By replacing the faulty VCI cable, the technician resolved the issue.

17.2. Case Study 2: Firmware Corruption

A technician used a dedicated VCI diagnostic tool to identify firmware corruption in a VCI. The tool detected errors in the VCI’s firmware and recommended a firmware update. By performing the update, the technician restored the VCI to its normal operating condition.

17.3. Case Study 3: Hardware Failure

A technician used a multimeter to identify a hardware failure in a VCI. The multimeter revealed a broken connection in the VCI’s internal circuitry. By repairing the connection, the technician restored the VCI to its normal operating condition.

18. How to Choose the Right VCI Diagnostic Tool

Choosing the right VCI diagnostic tool depends on your specific needs and budget.

18.1. Features and Capabilities

Consider the features and capabilities of the tool. Does it offer the diagnostic functions you need?

18.2. Compatibility

Ensure that the tool is compatible with your VCIs and vehicles.

18.3. Ease of Use

Choose a tool that is easy to use and has a user-friendly interface.

18.4. Cost

Consider the cost of the tool and compare it to your budget.

18.5. Support and Training

Check if the manufacturer offers support and training for the tool.

19. Common Misconceptions About VCI Diagnostics

There are several common misconceptions about VCI diagnostics.

19.1. All VCIs are Created Equal

Not all VCIs are created equal. Some VCIs offer more features and capabilities than others.

19.2. VCI Issues are Always Obvious

VCI issues are not always obvious. Some issues may be subtle and require advanced diagnostic techniques to identify.

19.3. VCI Diagnostics is Always Expensive

VCI diagnostics does not always have to be expensive. There are many affordable tools and techniques available.

19.4. VCI Issues are Always Easy to Fix

VCI issues are not always easy to fix. Some issues may require specialized knowledge and skills.

20. Why Continuous Learning is Important in Automotive Technology

Continuous learning is crucial in the rapidly evolving field of automotive technology. Staying updated with the latest trends, tools, and techniques is essential for success.

20.1. Keeping Up with Technology

Automotive technology is constantly evolving. Continuous learning helps you keep up with the latest advancements.

20.2. Improving Diagnostic Skills

Continuous learning helps you improve your diagnostic skills and become a more effective technician.

20.3. Enhancing Career Opportunities

Continuous learning can enhance your career opportunities and increase your earning potential.

20.4. Providing Better Service

Continuous learning enables you to provide better service to your customers.

Vehicle Communication Interface (VCI) setup with DTS Monaco software

Vehicle Communication Interface (VCI) setup with DTS Monaco software

21. Exploring Car Coding and ECU Programming Courses

Car coding and ECU programming courses provide valuable skills for modern automotive technicians.

21.1. Course Curriculum

These courses typically cover topics such as ECU architecture, communication protocols, coding techniques, and diagnostic procedures.

21.2. Hands-On Training

Look for courses that offer hands-on training with real vehicles and diagnostic tools.

21.3. Certification

Consider courses that offer certification upon completion.

21.4. Online vs. In-Person

Decide whether you prefer online or in-person training.

22. Benefits of Using Genuine Diagnostic Tools

Genuine diagnostic tools offer several advantages over aftermarket alternatives.

22.1. Accuracy

Genuine tools are designed to provide accurate diagnostic data.

22.2. Compatibility

Genuine tools are fully compatible with the vehicles they are designed for.

22.3. Support

Genuine tool manufacturers offer comprehensive support and training.

22.4. Updates

Genuine tools receive regular software and firmware updates.

23. Troubleshooting Common Installation Issues with Diagnostic Software

Installation issues with diagnostic software can be frustrating. Here are some tips for troubleshooting common problems.

23.1. Check System Requirements

Ensure that your computer meets the minimum system requirements for the software.

23.2. Run as Administrator

Run the installation program as an administrator.

23.3. Disable Antivirus

Disable your antivirus software temporarily during installation.

23.4. Check for Conflicts

Check for conflicts with other software.

23.5. Reinstall Drivers

Reinstall the VCI drivers.

24. Understanding Vehicle Communication Protocols

Understanding vehicle communication protocols is crucial for effective diagnostics.

24.1. CAN (Controller Area Network)

CAN is the most common communication protocol used in modern vehicles.

24.2. LIN (Local Interconnect Network)

LIN is a low-speed communication protocol used for less critical components.

24.3. Ethernet

Ethernet is increasingly used for high-speed communication in modern vehicles.

24.4. K-Line

K-Line is an older communication protocol used in some vehicles.

25. Practical Tips for Performing ECU Diagnostics

Here are some practical tips for performing ECU diagnostics.

25.1. Start with the Basics

Start by checking the basics, such as battery voltage and connections.

25.2. Use a Systematic Approach

Use a systematic approach to diagnose the problem.

25.3. Check for Fault Codes

Check for fault codes and interpret them correctly.

25.4. Verify the Fix

Verify that the fix has resolved the problem.

26. The Importance of ECU Backups Before Coding

Backing up ECU data before coding is crucial to prevent data loss and potential damage to the vehicle’s systems.

26.1. Data Protection

Backups protect valuable data in case of coding errors.

26.2. Reversion Capability

Allows you to revert to the original settings if something goes wrong.

26.3. Prevent System Damage

Reduces the risk of damaging the ECU during coding.

26.4. Ensuring Stability

Ensures the stability and reliability of the vehicle’s systems after coding.

27. Maximizing Efficiency with DTS Monaco Software

DTS Monaco is a powerful tool for automotive diagnostics, but maximizing its efficiency requires understanding its features and capabilities.

27.1. Familiarize with Interface

Become familiar with the software’s interface and functions.

27.2. Utilize Shortcuts

Use keyboard shortcuts to speed up tasks.

27.3. Customize Settings

Customize the software settings to suit your needs.

27.4. Keep Updated

Keep the software updated to access the latest features and improvements.

28. Choosing the Right Car Coding Service Provider

Selecting the right car coding service provider is essential for achieving the desired results and ensuring the safety of your vehicle.

28.1. Check Credentials

Verify the provider’s credentials and experience.

28.2. Read Reviews

Read reviews from other customers.

28.3. Ask Questions

Ask questions about their services and processes.

28.4. Ensure Guarantee

Ensure they offer a guarantee on their work.

29. Ethical Considerations in Car Coding and ECU Programming

Ethical considerations are paramount in car coding and ECU programming to avoid unintended consequences and potential legal issues.

29.1. Transparency

Be transparent with customers about the changes you are making.

29.2. Compliance

Comply with all applicable laws and regulations.

29.3. Avoid Malpractice

Avoid any practices that could harm the vehicle or its occupants.

29.4. Respect Data Privacy

Respect data privacy and security.

30. Resources for Staying Current with Automotive Technology

Staying current with automotive technology requires leveraging various resources and continuously updating your knowledge.

30.1. Industry Publications

Read industry publications and journals.

30.2. Attend Conferences

Attend industry conferences and trade shows.

30.3. Online Forums

Participate in online forums and communities.

30.4. Training Programs

Enroll in training programs and courses.

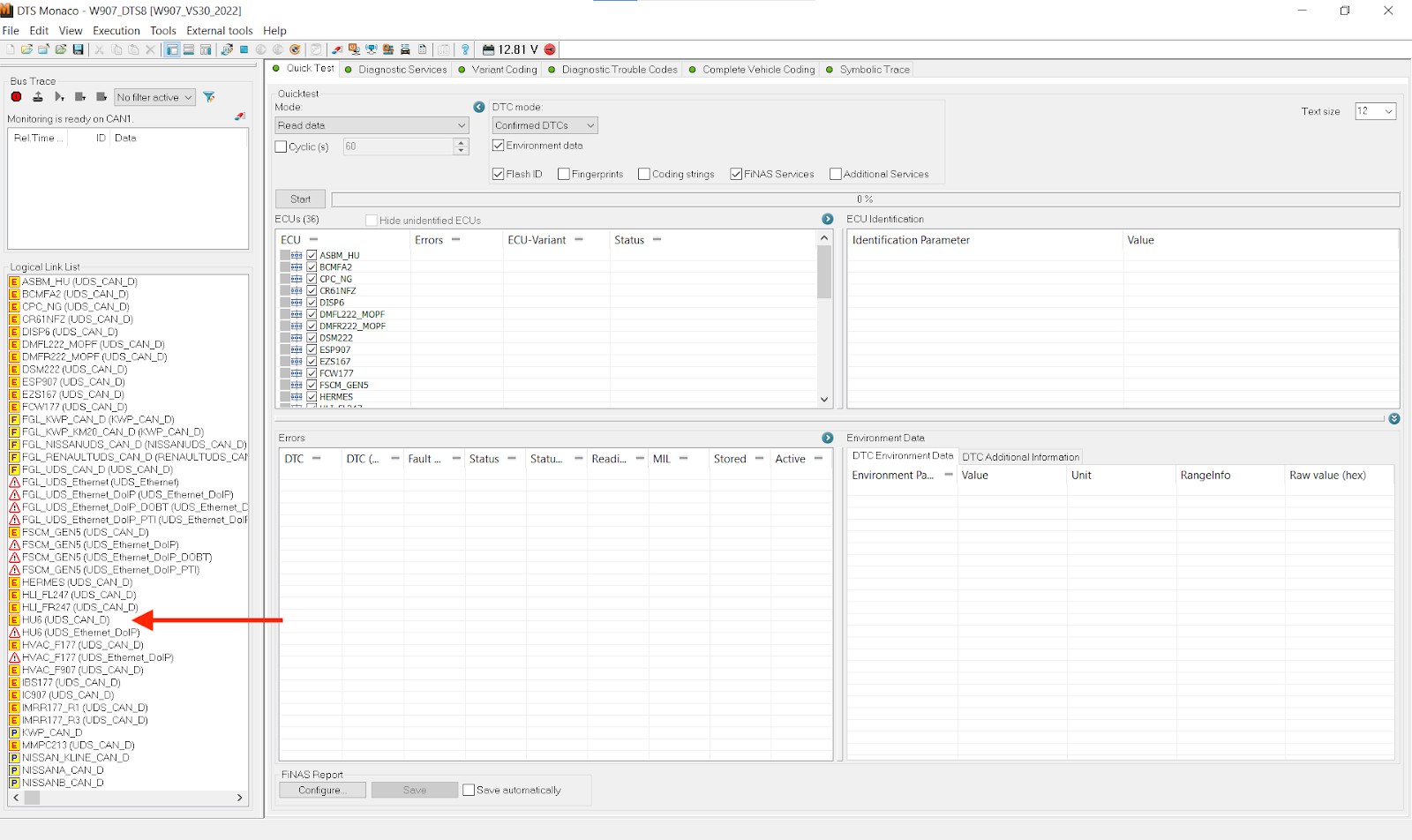

Screenshot of DTS Monaco interface with ECU selection

Screenshot of DTS Monaco interface with ECU selection

31. Maximizing ROI on Automotive Diagnostic Equipment

To maximize the return on investment (ROI) on automotive diagnostic equipment, it’s crucial to use it effectively, maintain it properly, and stay updated with the latest technologies.

31.1. Training

Ensure that technicians are properly trained on how to use the equipment.

31.2. Maintenance

Perform regular maintenance to keep the equipment in good working condition.

31.3. Software Updates

Keep the software updated to access the latest features and improvements.

31.4. Proper Usage

Use the equipment properly to avoid damage and ensure accurate results.

32. Ensuring Data Security During ECU Flashing and Coding

Data security is paramount during ECU flashing and coding to protect sensitive vehicle information and prevent unauthorized access.

32.1. Secure Connections

Use secure connections to prevent data interception.

32.2. Authorized Access

Ensure that only authorized personnel have access to the equipment.

32.3. Data Encryption

Use data encryption to protect sensitive information.

32.4. Regular Audits

Perform regular security audits to identify and address vulnerabilities.

33. The Role of AI in Modern Automotive Diagnostics

Artificial intelligence (AI) is playing an increasingly significant role in modern automotive diagnostics, offering enhanced capabilities and improved efficiency.

33.1. Predictive Diagnostics

AI can analyze data to predict potential issues before they occur.

33.2. Faster Analysis

AI can analyze diagnostic data faster and more accurately than humans.

33.3. Automated Repairs

AI can automate certain repair processes.

33.4. Remote Diagnostics

AI enables remote diagnostics capabilities.

34. Mastering Variant Coding Techniques for Modern Vehicles

Mastering variant coding techniques is essential for customizing vehicle features and enhancing performance.

34.1. Understanding Vehicle Systems

Understand the vehicle’s systems and their functions.

34.2. Following Procedures

Follow the correct coding procedures.

34.3. Checking Compatibility

Check compatibility before making any changes.

34.4. Verifying Changes

Verify that the changes have been applied correctly.

35. Optimizing Workflow for Automotive Diagnostics and Repair

Optimizing workflow for automotive diagnostics and repair can improve efficiency and reduce turnaround time.

35.1. Streamlining Processes

Streamline diagnostic and repair processes.

35.2. Efficient Tool Management

Implement efficient tool management practices.

35.3. Scheduling and Planning

Use scheduling and planning tools to manage workload.

35.4. Communication

Improve communication between technicians and customers.

36. Best Practices for Working with Automotive Networks

Working with automotive networks requires following best practices to ensure reliable communication and prevent data corruption.

36.1. Proper Cabling

Use proper cabling and connectors.

36.2. Testing Connections

Test connections before and after making changes.

36.3. Isolating Problems

Isolate problems to identify the root cause.

36.4. Monitoring Network Traffic

Monitor network traffic to detect anomalies.

37. Common Mistakes to Avoid During Car Coding and ECU Programming

Avoiding common mistakes during car coding and ECU programming is essential for preventing damage and ensuring successful outcomes.

37.1. Rushing the Process

Avoid rushing the process.

37.2. Ignoring Instructions

Avoid ignoring instructions.

37.3. Using Incorrect Tools

Avoid using incorrect tools.

37.4. Not Backing Up Data

Always backup data before making any changes.

38. How to Properly Document Car Coding and ECU Programming Procedures

Proper documentation of car coding and ECU programming procedures is crucial for tracking changes and ensuring accountability.

38.1. Recording Steps

Record all steps taken during the procedure.

38.2. Note Changes

Note all changes made to the vehicle’s systems.

38.3. Storing Data

Store the documentation securely.

38.4. Tracking History

Track the history of changes made to the vehicle.

FAQ: Vediamo and VCI Diagnostics

- Can Vediamo diagnose VCI hardware issues?

Vediamo has limited capabilities and cannot perform in-depth hardware diagnostics on VCIs. - Can Vediamo test VCI signal integrity?

No, Vediamo cannot test signal integrity; oscilloscopes are needed for this. - Is Vediamo suitable for analyzing VCI firmware?

No, specialized tools are required to analyze and troubleshoot VCI firmware. - What should I do if Vediamo shows a communication error?

Check the VCI connection, vehicle wiring, and ECU; further diagnostics may be needed. - Can I update VCI firmware using Vediamo?

No, use the manufacturer’s recommended tools for firmware updates. - What alternative tools can I use for VCI diagnostics?

Oscilloscopes, multimeters, protocol analyzers, and dedicated VCI diagnostic tools. - How often should I perform preventive maintenance on my VCI?

Regular inspections should be done periodically for physical damage. - What does the error code VCI_ERR_NO_CONNECTION mean?

The VCI cannot establish a connection with the vehicle. - What are the benefits of car coding training from DTS-MONACO.EDU.VN?

Customizing vehicle features, improving performance, and diagnosing complex issues. - Where can I find state-of-the-art tools and software for automotive diagnostics?

DTS-MONACO.EDU.VN offers these tools, along with expert support.

Interested in mastering automotive diagnostics and car coding? Visit DTS-MONACO.EDU.VN today to explore our comprehensive training programs, state-of-the-art tools, and expert support. Elevate your skills and become a leader in automotive technology with our specialized resources and guidance! For inquiries, contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States, or Whatsapp: +1 (641) 206-8880.