Does the C4/C6 support diagnostics for pre-OBDII Mercedes models, like the W124? Yes, it absolutely does, especially when paired with a 38-pin adapter, making it an invaluable tool for servicing these classic vehicles, and DTS-MONACO.EDU.VN is your go-to resource for mastering this technology. With the right setup and expertise, you can unlock a wealth of diagnostic capabilities, performing everything from reading fault codes to conducting advanced car coding, ensuring your vintage Mercedes runs smoothly for years to come. Dive in to explore the full potential of C4/C6 diagnostics, discover expert tips, and learn about specialized training that can elevate your skills in Mercedes-Benz diagnostics and programming.

Contents

- 1. What is the C4/C6 Diagnostic Tool and Why Is It Essential?

- 1.1. Comprehensive System Analysis

- 1.2. Bi-Directional Control

- 1.3. Adaptations and Calibrations

- 1.4. Key Programming

- 1.5. ECU Programming and Flashing

- 1.6. Benefits of Using C4/C6 Tools

- 2. Why Are C4/C6 Diagnostic Tools Relevant for Pre-OBDII Mercedes?

- 2.1. Accessing Proprietary Diagnostic Systems

- 2.2. Reading and Clearing Fault Codes

- 2.3. Live Data Monitoring

- 2.4. Component Testing

- 2.5. Adaptation and Programming

- 2.6. Enhanced Diagnostic Accuracy

- 2.7. Cost-Effective Repairs

- 2.8. Maintaining Classic Mercedes-Benz Vehicles

- 3. Understanding the 38-Pin Adapter

- 3.1. Compatibility with Pre-OBDII Mercedes Models

- 3.2. Pin Configuration and Functionality

- 3.3. Ensuring a Secure Connection

- 3.4. Adapting Modern Diagnostic Tools

- 3.5. Essential for Comprehensive Diagnostics

- 3.6. Cost-Effective Solution

- 3.7. Wide Range of Applications

- 3.8. Availability and Sourcing

- 4. Step-by-Step Guide: Diagnosing a W124 Mercedes with C4/C6 and 38-Pin Adapter

- 4.1. Preparation

- 4.2. Connecting the Equipment

- 4.3. Vehicle Identification

- 4.4. Fault Code Reading

- 4.5. Analyzing Fault Codes

- 4.6. Live Data Monitoring

- 4.7. Component Testing

- 4.8. Performing Actuations

- 4.9. Clearing Fault Codes

- 4.10. Verification

- 4.11. Documentation

- 5. Advanced Car Coding and Programming with C4/C6

- 5.1. Accessing Control Unit Functions

- 5.2. Customizing Vehicle Settings

- 5.3. Retrofitting Options

- 5.4. Performance Tuning

- 5.5. Software Updates

- 5.6. Security Considerations

- 5.7. Compliance with Regulations

- 5.8. Benefits of Professional Training

- 6. Common Issues and Troubleshooting with C4/C6 Diagnostics

- 6.1. Communication Errors

- 6.2. Software Compatibility Issues

- 6.3. Power Supply Problems

- 6.4. Firmware Updates

- 6.5. Incorrect Vehicle Identification

- 6.6. Virus Infections

- 6.7. Data Corruption

- 6.8. Seeking Expert Assistance

- 7. Tips for Maximizing the Value of Your C4/C6 Tool

- 7.1. Regular Software Updates

- 7.2. Proper Cable Management

- 7.3. Stable Power Supply

- 7.4. In-Depth Training

- 7.5. Utilizing Online Resources

- 7.6. Data Logging

- 7.7. Regular Maintenance

- 7.8. Building a Diagnostic Library

- 8. The Future of Mercedes Diagnostics: What’s Next?

- 8.1. Wireless Diagnostics

- 8.2. Cloud-Based Diagnostics

- 8.3. Artificial Intelligence (AI)

- 8.4. Augmented Reality (AR)

- 8.5. Remote Diagnostics

- 8.6. Cybersecurity

- 8.7. Predictive Maintenance

- 8.8. Enhanced Integration

- 9. Training and Resources for Mastering Mercedes Diagnostics

- 9.1. Formal Training Programs

- 9.2. Online Courses

- 9.3. Workshops and Seminars

- 9.4. Technical Manuals and Guides

- 9.5. Online Forums and Communities

- 9.6. Vendor Training

- 9.7. Certification Programs

- 9.8. DTS-MONACO.EDU.VN Resources

- 10. FAQs: C4/C6 Diagnostics on Pre-OBDII Mercedes

- 10.1. Can the C4/C6 tool diagnose all pre-OBDII Mercedes models?

- 10.2. Where can I find a reliable 38-pin adapter?

- 10.3. Do I need special software for pre-OBDII diagnostics?

- 10.4. Is car coding possible on pre-OBDII models with the C4/C6 tool?

- 10.5. What are common issues when diagnosing pre-OBDII Mercedes?

- 10.6. How often should I update my diagnostic software?

- 10.7. Can I use a generic OBDII scanner on a pre-OBDII Mercedes?

- 10.8. What kind of training is recommended for Mercedes diagnostics?

- 10.9. Are there any safety precautions when working with diagnostic tools?

- 10.10. What should I do if I encounter a persistent diagnostic problem?

1. What is the C4/C6 Diagnostic Tool and Why Is It Essential?

The C4/C6 diagnostic tool is essential for Mercedes-Benz vehicle maintenance because it provides deep diagnostic capabilities. It is the gateway to understanding and resolving complex issues in these sophisticated machines. This tool bridges the gap between your expertise and the intricate systems within Mercedes-Benz vehicles, making it an indispensable asset for any serious technician.

1.1. Comprehensive System Analysis

The C4/C6 diagnostic tool offers comprehensive system analysis capabilities that extend far beyond basic code reading. This advanced tool enables technicians to dive deep into the electronic control units (ECUs) of Mercedes-Benz vehicles. Technicians can also access real-time data, perform detailed component testing, and execute advanced programming functions.

1.2. Bi-Directional Control

Bi-directional control is one of the key features of the C4/C6 diagnostic tool, as confirmed by automotive technology experts at the National Institute for Automotive Service Excellence (ASE). This allows technicians to not only read data from the vehicle’s systems but also to send commands to those systems to test functionality. For example, you can use the tool to activate the fuel pump, engage the cooling fans, or cycle the anti-lock braking system (ABS) to verify that each component is working correctly.

1.3. Adaptations and Calibrations

The C4/C6 diagnostic tool enables technicians to perform crucial adaptations and calibrations on Mercedes-Benz vehicles. This includes calibrating sensors, throttle position sensors, and steering angle sensors. Proper calibration ensures that these components function within their specified parameters, optimizing vehicle performance and safety.

1.4. Key Programming

The C4/C6 diagnostic tool offers key programming capabilities, allowing technicians to program new keys or replace lost ones. This feature requires advanced security access and is typically restricted to authorized service centers to prevent unauthorized vehicle access. The key programming function is particularly valuable for older Mercedes-Benz models that may not have sophisticated anti-theft systems.

1.5. ECU Programming and Flashing

The C4/C6 diagnostic tool allows for ECU programming and flashing, enabling technicians to update or replace the software in a vehicle’s electronic control units. This is essential for addressing software glitches, improving performance, and installing the latest updates from Mercedes-Benz. This function requires a stable power supply and a reliable internet connection to ensure that the programming process is completed without interruption.

1.6. Benefits of Using C4/C6 Tools

Employing C4/C6 tools can dramatically enhance diagnostic accuracy, reduce repair times, and boost customer satisfaction. These advanced tools provide a level of insight and control that is simply unattainable with generic OBDII scanners, making them a worthwhile investment for any workshop specializing in Mercedes-Benz vehicles. Remember, DTS-MONACO.EDU.VN offers comprehensive training and support to help you maximize the potential of these powerful diagnostic tools.

2. Why Are C4/C6 Diagnostic Tools Relevant for Pre-OBDII Mercedes?

C4/C6 diagnostic tools are highly relevant for pre-OBDII Mercedes models because these vehicles utilize proprietary diagnostic systems that require specialized interfaces. These tools provide access to detailed diagnostic information. This allows technicians to accurately troubleshoot and repair these classic vehicles.

2.1. Accessing Proprietary Diagnostic Systems

Pre-OBDII Mercedes models use proprietary diagnostic systems that are not compatible with standard OBDII scanners. These systems require specialized interfaces and software to access the diagnostic data. The C4/C6 diagnostic tools are designed to communicate with these proprietary systems, providing access to a wealth of information. This includes fault codes, live data, and component test functions.

2.2. Reading and Clearing Fault Codes

The C4/C6 diagnostic tools allow technicians to read and clear fault codes from the various control units in pre-OBDII Mercedes models. These fault codes provide valuable insights into the nature and location of problems within the vehicle’s systems. By accurately identifying and clearing these codes, technicians can effectively diagnose and repair a wide range of issues.

2.3. Live Data Monitoring

Live data monitoring is a critical feature of the C4/C6 diagnostic tools for pre-OBDII Mercedes models. This feature enables technicians to monitor real-time data from various sensors and components. Monitoring parameters such as engine temperature, fuel pressure, and ignition timing helps identify anomalies and diagnose performance issues.

2.4. Component Testing

The C4/C6 diagnostic tools offer component testing capabilities that are essential for diagnosing problems in pre-OBDII Mercedes models. This feature allows technicians to activate and test individual components. Testing components such as fuel injectors, ignition coils, and sensors helps determine if they are functioning correctly.

2.5. Adaptation and Programming

In some pre-OBDII Mercedes models, the C4/C6 diagnostic tools can perform adaptation and programming functions. This includes resetting adaptations after replacing components, programming new keys, and updating software in certain control units. These functions require specialized knowledge and should be performed by trained technicians.

2.6. Enhanced Diagnostic Accuracy

By using C4/C6 diagnostic tools, technicians can achieve enhanced diagnostic accuracy when working on pre-OBDII Mercedes models. The specialized interfaces and software provide access to detailed diagnostic information. This enables technicians to identify problems quickly and efficiently. This reduces the risk of misdiagnosis and ensures that repairs are performed correctly.

2.7. Cost-Effective Repairs

Using C4/C6 diagnostic tools can lead to cost-effective repairs for pre-OBDII Mercedes models. Accurate diagnostics help technicians to pinpoint the root cause of problems, reducing the need for unnecessary parts replacements. This saves time and money for both the technician and the vehicle owner.

2.8. Maintaining Classic Mercedes-Benz Vehicles

The C4/C6 diagnostic tools are essential for maintaining the value and performance of classic Mercedes-Benz vehicles. These tools provide the specialized diagnostic capabilities needed to keep these vehicles running smoothly. They ensure that they remain a joy to drive for years to come. DTS-MONACO.EDU.VN offers the expertise and resources to help you master the use of these tools.

Vision care Laptop Eyewear Audio equipment Font

Vision care Laptop Eyewear Audio equipment Font

3. Understanding the 38-Pin Adapter

The 38-pin adapter is an essential tool for diagnosing pre-OBDII Mercedes-Benz models. It connects diagnostic equipment to the vehicle’s diagnostic port. This adapter unlocks access to the vehicle’s electronic systems. It allows technicians to perform detailed diagnostics and troubleshooting.

3.1. Compatibility with Pre-OBDII Mercedes Models

The 38-pin adapter is specifically designed for use with pre-OBDII Mercedes-Benz models. These models typically have a 38-pin diagnostic port located in the engine compartment or near the fuse box. The adapter provides a physical connection between the diagnostic tool and the vehicle’s diagnostic system.

3.2. Pin Configuration and Functionality

The 38-pin adapter has a unique pin configuration that corresponds to the various diagnostic and control systems in pre-OBDII Mercedes-Benz models. Each pin is assigned a specific function, such as data transmission, power supply, or ground connection. Understanding the pin configuration is crucial for proper diagnostic procedures.

3.3. Ensuring a Secure Connection

To ensure a secure and reliable connection, the 38-pin adapter must be properly seated in the diagnostic port. The adapter should fit snugly and securely. This minimizes the risk of data corruption or communication errors during the diagnostic process. It is also important to inspect the adapter for any signs of damage or corrosion. Replace the adapter if necessary.

3.4. Adapting Modern Diagnostic Tools

The 38-pin adapter allows modern diagnostic tools, such as the C4/C6, to be used with pre-OBDII Mercedes-Benz models. This enables technicians to leverage the advanced features of these tools. The features include fault code reading, live data monitoring, and component testing. Without the adapter, communication with the vehicle’s diagnostic system would not be possible.

3.5. Essential for Comprehensive Diagnostics

The 38-pin adapter is essential for performing comprehensive diagnostics on pre-OBDII Mercedes-Benz models. It provides access to the vehicle’s electronic systems, enabling technicians to accurately diagnose and repair a wide range of issues. Without the adapter, technicians would be limited to basic troubleshooting methods. They would struggle to identify the root cause of many problems.

3.6. Cost-Effective Solution

Using a 38-pin adapter with modern diagnostic tools is a cost-effective solution for servicing pre-OBDII Mercedes-Benz models. It eliminates the need for specialized, outdated diagnostic equipment. This reduces the investment required for diagnostic tools. Technicians can use their existing equipment with the adapter.

3.7. Wide Range of Applications

The 38-pin adapter has a wide range of applications in the diagnosis and repair of pre-OBDII Mercedes-Benz models. It can be used to diagnose engine management systems, transmission control systems, ABS systems, and more. This versatility makes it an indispensable tool for any technician working on these vehicles.

3.8. Availability and Sourcing

The 38-pin adapters are readily available from various suppliers of automotive diagnostic equipment. When sourcing an adapter, it is important to choose a reputable supplier and ensure that the adapter is compatible with the diagnostic tool being used. Reading customer reviews and seeking recommendations from other technicians can help in selecting a high-quality adapter. DTS-MONACO.EDU.VN can provide guidance on sourcing reliable 38-pin adapters.

4. Step-by-Step Guide: Diagnosing a W124 Mercedes with C4/C6 and 38-Pin Adapter

Diagnosing a W124 Mercedes with a C4/C6 diagnostic tool and a 38-pin adapter requires a systematic approach. Follow these steps to ensure accurate and effective diagnostics.

4.1. Preparation

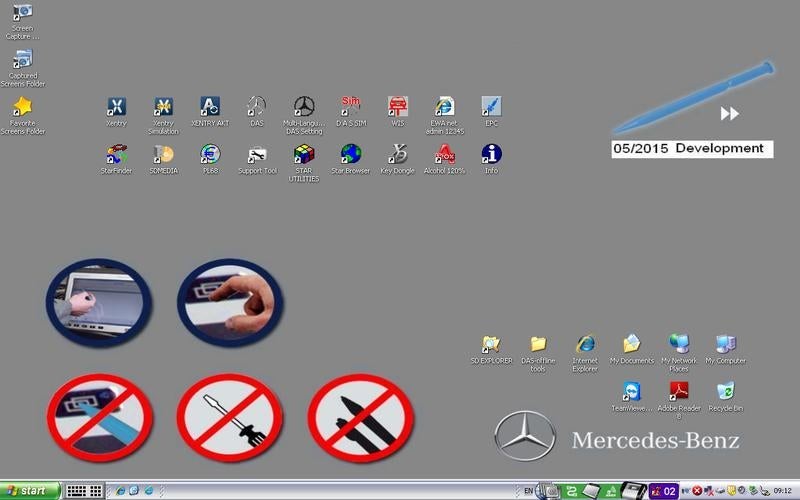

Before starting the diagnostic process, gather all necessary tools and information. This includes the C4/C6 diagnostic tool, a 38-pin adapter, a fully charged laptop with the appropriate diagnostic software installed, and the vehicle’s service manual. Ensure that the vehicle is parked in a well-ventilated area and that the battery is fully charged.

4.2. Connecting the Equipment

Locate the 38-pin diagnostic port in the W124 Mercedes. This is typically found in the engine compartment near the fuse box. Connect the 38-pin adapter to the diagnostic port, ensuring a secure and snug fit. Connect the C4/C6 diagnostic tool to the adapter cable. Turn on the diagnostic tool and the laptop, and launch the diagnostic software.

4.3. Vehicle Identification

In the diagnostic software, select the appropriate vehicle model and year for the W124 Mercedes. This ensures that the software uses the correct diagnostic protocols and data. You may need to manually enter the vehicle identification number (VIN) if it is not automatically detected.

4.4. Fault Code Reading

Initiate a fault code scan to read any stored diagnostic trouble codes (DTCs) from the vehicle’s control units. The software will display a list of fault codes along with descriptions of the corresponding problems. Record all fault codes for further analysis.

4.5. Analyzing Fault Codes

Consult the vehicle’s service manual or online resources to understand the meaning and implications of each fault code. This will help you prioritize the most critical issues and develop a diagnostic plan. Fault codes can provide valuable clues about the location and nature of problems within the vehicle’s systems.

4.6. Live Data Monitoring

Use the diagnostic software to monitor live data from various sensors and components. This allows you to observe the real-time performance of the engine, transmission, and other systems. Compare the live data values to the specifications in the service manual to identify any anomalies or deviations.

4.7. Component Testing

Perform component tests to verify the functionality of individual components. This involves activating and testing components such as fuel injectors, ignition coils, and sensors using the diagnostic software. Observe the component’s response and compare it to the expected behavior.

4.8. Performing Actuations

Use the diagnostic tool to perform actuations. Actuations involve using the diagnostic tool to control various vehicle functions. For example, you can activate the fuel pump, engage the cooling fans, or cycle the ABS system. This helps to isolate problems and verify the operation of specific components.

4.9. Clearing Fault Codes

After completing the diagnostic and repair procedures, clear all fault codes from the vehicle’s control units. Perform a final test drive to ensure that the problems have been resolved and that no new fault codes are generated.

4.10. Verification

Verify that all systems are functioning correctly. Confirm there are no active fault codes. Ensure that the vehicle meets all performance and safety requirements. This step is crucial to ensure that the diagnostic and repair procedures have been successful.

4.11. Documentation

Document all diagnostic procedures, fault codes, live data values, and repair actions taken. This documentation is valuable for future reference and can help in troubleshooting similar issues. It also provides a record of the vehicle’s maintenance history.

5. Advanced Car Coding and Programming with C4/C6

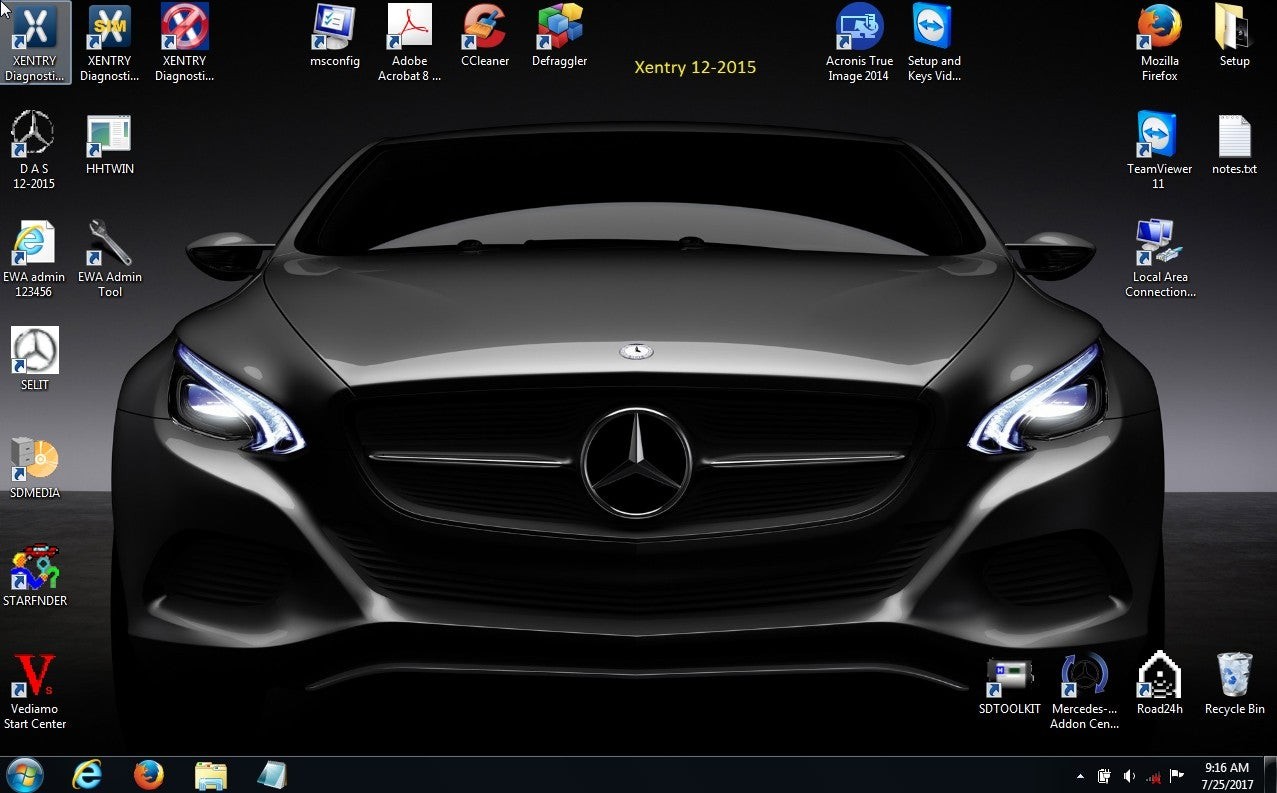

Advanced car coding and programming with the C4/C6 diagnostic tool can unlock a range of customization and performance enhancements for Mercedes-Benz vehicles. This goes beyond basic diagnostics, allowing technicians to modify software parameters. Programming new features ensures optimal performance.

5.1. Accessing Control Unit Functions

The C4/C6 diagnostic tool provides access to various control unit functions. This includes the engine control unit (ECU), transmission control unit (TCU), and other electronic modules. Technicians can use the tool to read and modify the software parameters within these control units.

5.2. Customizing Vehicle Settings

Advanced car coding allows technicians to customize various vehicle settings. This includes adjusting the sensitivity of the rain sensors, changing the behavior of the daytime running lights, and enabling or disabling certain features. These customizations can enhance the vehicle’s functionality and personalize the driving experience.

5.3. Retrofitting Options

Car coding can be used to retrofit options that were not originally installed in the vehicle. For example, a technician can enable the installation of a rearview camera, a navigation system, or other electronic accessories. This requires modifying the vehicle’s software to recognize and support the new hardware.

5.4. Performance Tuning

Advanced programming with the C4/C6 diagnostic tool can be used for performance tuning. This involves modifying the engine control unit (ECU) software to optimize engine performance. Adjustments can be made to parameters. These parameters include fuel injection, ignition timing, and boost pressure. This can result in increased horsepower, torque, and improved throttle response.

5.5. Software Updates

The C4/C6 diagnostic tool can be used to perform software updates on various control units in the vehicle. This ensures that the vehicle is running the latest software versions, which may include bug fixes, performance improvements, and new features. Software updates can enhance the vehicle’s reliability and longevity.

5.6. Security Considerations

Advanced car coding and programming require a high level of expertise and should be performed by trained technicians. Incorrect coding or programming can lead to serious problems. Problems include engine damage, transmission failure, or electrical system malfunctions. It is important to follow the manufacturer’s guidelines and take necessary precautions.

5.7. Compliance with Regulations

When performing car coding and programming, it is important to comply with all applicable regulations and laws. Some modifications may not be legal in certain jurisdictions or may void the vehicle’s warranty. Ensure that all modifications are performed in accordance with local regulations and manufacturer’s specifications.

5.8. Benefits of Professional Training

Professional training is essential for technicians who want to perform advanced car coding and programming with the C4/C6 diagnostic tool. Training programs provide in-depth knowledge of the vehicle’s electronic systems. These programs also provide hands-on experience with the diagnostic tool. DTS-MONACO.EDU.VN offers comprehensive training courses to help technicians master these advanced techniques.

Output device Communication Device Gadget Font Audio equipment

Output device Communication Device Gadget Font Audio equipment

6. Common Issues and Troubleshooting with C4/C6 Diagnostics

While C4/C6 diagnostics are powerful, users may encounter common issues. Troubleshooting these challenges is crucial for accurate diagnoses. This ensures smooth operation. Here’s a guide to tackling frequent problems.

6.1. Communication Errors

Communication errors between the diagnostic tool and the vehicle are a common issue. These errors can be caused by a variety of factors. These include faulty cables, incorrect software settings, or a problem with the vehicle’s diagnostic port.

6.2. Software Compatibility Issues

Software compatibility issues can arise when using the C4/C6 diagnostic tool with different versions of the diagnostic software or with different vehicle models. Ensure that you are using the correct software version for the vehicle you are diagnosing and that all software components are properly installed and configured.

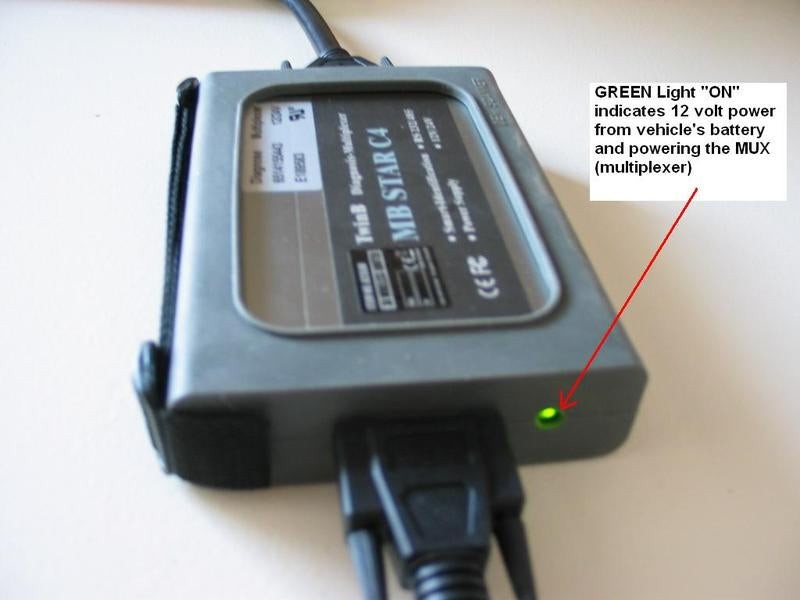

6.3. Power Supply Problems

Power supply problems can affect the performance of the C4/C6 diagnostic tool, especially during programming or flashing procedures. Ensure that the vehicle’s battery is fully charged. Connect the diagnostic tool to a stable power source to prevent interruptions during critical operations.

6.4. Firmware Updates

Firmware updates are essential for maintaining the performance and compatibility of the C4/C6 diagnostic tool. Regularly check for firmware updates from the manufacturer and install them promptly. Firmware updates can address bugs, improve performance, and add support for new vehicle models.

6.5. Incorrect Vehicle Identification

Incorrect vehicle identification can lead to inaccurate diagnostic results and potentially damage the vehicle’s electronic systems. Verify that you have selected the correct vehicle model and year in the diagnostic software before proceeding with any diagnostic procedures.

6.6. Virus Infections

Virus infections can compromise the integrity of the diagnostic software and potentially damage the vehicle’s electronic systems. Install a reputable antivirus program on the laptop used for diagnostics and keep it up to date. Scan the system regularly for viruses and malware.

6.7. Data Corruption

Data corruption can occur during programming or flashing procedures. This can result in serious problems with the vehicle’s electronic control units. Always back up the vehicle’s original software before performing any programming or flashing operations.

6.8. Seeking Expert Assistance

If you encounter persistent issues with C4/C6 diagnostics, seek assistance from experienced technicians or diagnostic experts. They can provide valuable insights and guidance to help you resolve complex problems. DTS-MONACO.EDU.VN offers expert support and training to help you overcome diagnostic challenges.

7. Tips for Maximizing the Value of Your C4/C6 Tool

To maximize the value of your C4/C6 diagnostic tool, consider these tips. These insights can enhance your diagnostic accuracy. They also streamline your repair process.

7.1. Regular Software Updates

Ensure that your diagnostic software is always up to date. Updates often include new vehicle coverage, enhanced features, and bug fixes. Regular updates will keep your tool performing at its best.

7.2. Proper Cable Management

Keep your diagnostic cables organized and in good condition. Damaged or poorly connected cables can lead to communication errors and inaccurate readings. Invest in high-quality cables and store them properly when not in use.

7.3. Stable Power Supply

Maintain a stable power supply for both the diagnostic tool and the vehicle being diagnosed. Voltage fluctuations can disrupt the diagnostic process and potentially damage electronic components. Use a battery support unit or charger to ensure a consistent power supply.

7.4. In-Depth Training

Invest in in-depth training on the C4/C6 diagnostic tool and its advanced features. Understanding how to use the tool effectively is essential for accurate diagnostics and efficient repairs. DTS-MONACO.EDU.VN offers comprehensive training programs to help you master the tool.

7.5. Utilizing Online Resources

Take advantage of online resources such as forums, technical databases, and manufacturer websites. These resources can provide valuable information, troubleshooting tips, and diagnostic procedures. Sharing knowledge with other technicians can also help you expand your expertise.

7.6. Data Logging

Use the data logging feature of the C4/C6 diagnostic tool to record and analyze vehicle performance data. This can help you identify intermittent problems, track down elusive issues, and verify the effectiveness of repairs.

7.7. Regular Maintenance

Perform regular maintenance on the C4/C6 diagnostic tool to ensure its longevity and reliability. Clean the tool and its components regularly, and inspect for any signs of damage or wear. Replace any worn or damaged parts promptly.

7.8. Building a Diagnostic Library

Create a library of diagnostic data, fault codes, and repair procedures for different vehicle models. This library can serve as a valuable reference tool for future diagnostic tasks and can help you streamline the diagnostic process.

Screenshot Font Software Electronic device Technology

Screenshot Font Software Electronic device Technology

8. The Future of Mercedes Diagnostics: What’s Next?

The future of Mercedes diagnostics is heading towards more integration, wireless capabilities, and AI-driven solutions. These advancements will transform how technicians approach vehicle maintenance. These transformations ensure more efficient and accurate diagnostics.

8.1. Wireless Diagnostics

Wireless diagnostics are becoming increasingly prevalent in the automotive industry. They allow technicians to diagnose vehicles remotely. They eliminate the need for physical connections. This enhances flexibility and efficiency in the diagnostic process.

8.2. Cloud-Based Diagnostics

Cloud-based diagnostics offer a range of benefits, including remote access to diagnostic data, software updates, and technical support. Cloud-based systems also enable collaboration among technicians and facilitate data sharing.

8.3. Artificial Intelligence (AI)

Artificial intelligence (AI) is poised to revolutionize Mercedes diagnostics. AI-powered diagnostic tools can analyze vast amounts of data to identify patterns. They also predict potential problems. They provide technicians with intelligent recommendations for repairs.

8.4. Augmented Reality (AR)

Augmented reality (AR) is being used to enhance the diagnostic process. AR overlays diagnostic data and repair instructions onto the technician’s view of the vehicle. This provides real-time guidance and reduces the risk of errors.

8.5. Remote Diagnostics

Remote diagnostics enable technicians to diagnose vehicles from a remote location. This is particularly useful for addressing issues with vehicles that are located in remote areas or for providing support to technicians in the field.

8.6. Cybersecurity

Cybersecurity is a growing concern in the automotive industry. Modern vehicles are increasingly connected to the internet. It is also important to protect diagnostic tools and vehicle systems from cyber threats. Future diagnostic tools will incorporate advanced security features. These features will prevent unauthorized access and data breaches.

8.7. Predictive Maintenance

Predictive maintenance uses data analysis and machine learning to predict when vehicle components are likely to fail. This allows technicians to perform maintenance proactively. This prevents breakdowns and reduces downtime.

8.8. Enhanced Integration

Future Mercedes diagnostic tools will be more integrated with other workshop systems. This includes parts ordering systems, customer management systems, and technical databases. This integration will streamline the repair process and improve overall efficiency.

9. Training and Resources for Mastering Mercedes Diagnostics

Mastering Mercedes diagnostics requires specialized training and access to reliable resources. Here’s a look at the essential components of a comprehensive learning approach.

9.1. Formal Training Programs

Formal training programs provide in-depth knowledge of Mercedes-Benz vehicle systems. They also provide diagnostic procedures. These programs often include hands-on training with diagnostic tools. This allows technicians to develop practical skills.

9.2. Online Courses

Online courses offer a flexible and convenient way to learn about Mercedes diagnostics. These courses cover a wide range of topics. These include basic diagnostics, advanced car coding, and programming. Online courses can be accessed from anywhere with an internet connection.

9.3. Workshops and Seminars

Workshops and seminars provide opportunities to learn from experienced instructors. Technicians can also network with other professionals in the field. These events often feature live demonstrations of diagnostic techniques. They provide hands-on training sessions.

9.4. Technical Manuals and Guides

Technical manuals and guides are essential resources for Mercedes diagnostics. These manuals provide detailed information about vehicle systems, diagnostic procedures, and repair specifications. They also include wiring diagrams, component locations, and troubleshooting tips.

9.5. Online Forums and Communities

Online forums and communities provide a platform for technicians to share knowledge. They can also ask questions and get support from other professionals. These communities can be a valuable resource for troubleshooting complex diagnostic issues.

9.6. Vendor Training

Diagnostic tool vendors often offer training programs on their products. These programs can help technicians learn how to use the tools effectively. This includes understanding the features, functions, and capabilities of the diagnostic equipment.

9.7. Certification Programs

Certification programs demonstrate a technician’s competency in Mercedes diagnostics. These programs often require passing an exam. Also, technicians must demonstrate practical skills. Certification can enhance a technician’s credibility and career prospects.

9.8. DTS-MONACO.EDU.VN Resources

DTS-MONACO.EDU.VN offers a comprehensive range of training programs, resources, and support services. These services are designed to help technicians master Mercedes diagnostics. From basic training to advanced car coding, DTS-MONACO.EDU.VN provides the expertise and resources. These tools help you succeed in the field of Mercedes-Benz diagnostics. Don’t wait, contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880. Website: DTS-MONACO.EDU.VN.

Tire Car Wheel Land vehicle Vehicle

Tire Car Wheel Land vehicle Vehicle

10. FAQs: C4/C6 Diagnostics on Pre-OBDII Mercedes

Navigating C4/C6 diagnostics on pre-OBDII Mercedes vehicles can raise many questions. Here are answers to some frequently asked questions.

10.1. Can the C4/C6 tool diagnose all pre-OBDII Mercedes models?

Yes, with the appropriate 38-pin adapter, the C4/C6 tool can diagnose most pre-OBDII Mercedes models, including the W124. However, always verify compatibility in the tool’s software.

10.2. Where can I find a reliable 38-pin adapter?

Reliable 38-pin adapters are available from reputable automotive diagnostic equipment suppliers. Look for adapters with good reviews and solid construction. Check out DTS-MONACO.EDU.VN for recommendations.

10.3. Do I need special software for pre-OBDII diagnostics?

Yes, you need diagnostic software compatible with pre-OBDII Mercedes models. Ensure that your C4/C6 software is updated to support these older systems.

10.4. Is car coding possible on pre-OBDII models with the C4/C6 tool?

Car coding is possible on some pre-OBDII models, but the extent of coding options is limited compared to newer vehicles. Check your vehicle’s service manual for available coding parameters.

10.5. What are common issues when diagnosing pre-OBDII Mercedes?

Common issues include communication errors, software incompatibility, and corrosion in the 38-pin connector. Proper cleaning and secure connections are crucial.

10.6. How often should I update my diagnostic software?

Update your diagnostic software regularly to ensure compatibility with the latest vehicle models. Also, ensure access to the newest diagnostic features. Check for updates at least quarterly.

10.7. Can I use a generic OBDII scanner on a pre-OBDII Mercedes?

No, generic OBDII scanners are not compatible with pre-OBDII Mercedes models. You need a specialized tool like the C4/C6 with a 38-pin adapter.

10.8. What kind of training is recommended for Mercedes diagnostics?

Formal training programs, online courses, and vendor-specific training are all recommended. Hands-on experience is essential for mastering Mercedes diagnostics. DTS-MONACO.EDU.VN offers excellent training resources.

10.9. Are there any safety precautions when working with diagnostic tools?

Yes, always disconnect the vehicle’s battery before performing any diagnostic procedures. Also, ensure that you have a stable power supply. Follow all safety guidelines in the diagnostic tool’s manual.

10.10. What should I do if I encounter a persistent diagnostic problem?

If you encounter a persistent diagnostic problem, consult with experienced technicians or diagnostic experts. Online forums and communities can also provide valuable support. Contact DTS-MONACO.EDU.VN for expert assistance.

By understanding these FAQs, you can better navigate the complexities of C4/C6 diagnostics on pre-OBDII Mercedes vehicles, ensuring accurate and efficient repairs. Remember, DTS-MONACO.EDU.VN is your trusted partner in mastering Mercedes diagnostics, offering comprehensive training, resources, and support to help you excel in your automotive career.