The C6 VCI (Vehicle Communication Interface) adeptly manages communication with vehicles equipped with multiple CAN (Controller Area Network) gateways through intelligent routing and protocol handling. DTS-MONACO.EDU.VN provides comprehensive insights into this process. This involves identifying the target ECU (Electronic Control Unit), selecting the appropriate CAN bus, and ensuring seamless data transmission. Mastering these techniques allows technicians to effectively diagnose and reprogram modern vehicles, improving their overall expertise. Dive into advanced vehicle diagnostics and car coding techniques today!

Contents

- 1. What is a CAN Gateway and Why Do Modern Vehicles Need Them?

- 1.1 What Exactly is a CAN Bus?

- 1.2 What is the Role of ECUs in Vehicle Communication?

- 1.3 How Does a CAN Gateway Facilitate Communication Between Different CAN Buses?

- 2. Understanding The C6 VCI

- 2.1 What is the primary Function of the C6 VCI in Vehicle Diagnostics?

- 2.2 What Protocols Does the C6 VCI Support?

- 2.3 How Does the C6 VCI Connect to a Vehicle and a Diagnostic Computer?

- 3. Identifying CAN Gateways in a Vehicle

- 3.1 Where are CAN Gateways Typically Located in a Vehicle?

- 3.2 How Can Diagnostic Software Help Identify CAN Gateways?

- 3.3 What Role Do Wiring Diagrams Play in Locating CAN Gateways?

- 4. The Communication Process: C6 VCI and Multiple CAN Gateways

- 4.1 How Does the C6 VCI Identify the Target ECU and Its CAN Bus?

- 4.2 What Happens When a Message Needs to be Sent to an ECU on a Different CAN Bus?

- 4.3 How Does the CAN Gateway Ensure Messages Reach the Correct Destination ECU?

- 5. Key Features of the C6 VCI for Multi-CAN Communication

- 5.1 Multi-Bus Support: Communicating on Multiple CAN Networks

- 5.2 Intelligent Routing: Directing Messages to the Right ECU

- 5.3 Protocol Handling: Supporting Different Diagnostic Languages

- 6. Software and Firmware Considerations

- 6.1 How Does Firmware Affect the C6 VCI’s Communication Capabilities?

- 6.2 Why are Regular Software Updates Important for the C6 VCI?

- 6.3 How Do Diagnostic Software Settings Influence CAN Communication?

- 7. Practical Applications: Diagnostics and Car Coding

- 7.1 Diagnosing Complex Issues Across Multiple Vehicle Systems

- 7.2 Car Coding and Reprogramming ECUs in Modern Vehicles

- 7.3 Performing Module Replacement and Initialization

- 8. Common Challenges and Troubleshooting Tips

- 8.1 What are Some Common Communication Errors and How Can They Be Resolved?

- 8.2 What Steps Can Be Taken When an ECU is Not Responding?

- 8.3 How Can Data Corruption Issues Be Prevented and Addressed?

- 9. Best Practices for Using the C6 VCI with Multi-CAN Systems

- 9.1 The Importance of Using High-Quality Cables and Connectors

- 9.2 Verifying CAN Bus Settings for Accurate Communication

- 9.3 Staying Up-To-Date with C6 VCI Firmware and Software

- 10. Future Trends in Vehicle Communication and Diagnostics

- 10.1 The Rise of Automotive Ethernet and Its Impact on VCIs

- 10.2 The Role of Cloud-Based Diagnostics and Remote Vehicle Access

- 10.3 The Increasing Importance of Cybersecurity in Vehicle Communication

- 11. Training and Resources for Mastering C6 VCI Usage

- 11.1 The Benefits of Formal Training Courses on Vehicle Diagnostics

- 11.2 Online Resources and Communities for C6 VCI Users

- 11.3 How DTS-MONACO.EDU.VN Can Help You Become a Car Coding Expert

- 12. Case Studies: Real-World Examples of C6 VCI in Action

- 12.1 Case Study 1: Diagnosing an Intermittent Engine Stalling Issue

- 12.2 Case Study 2: Reprogramming an ECU After a Software Update Failure

- 12.3 Case Study 3: Performing a Module Replacement on a Modern Vehicle

- 13. Comparing the C6 VCI to Other Vehicle Communication Interfaces

- 13.1 What are the Key Differences Between the C6 VCI and Other VCIs?

- 13.2 How Does the C6 VCI Stack Up in Terms of Performance and Reliability?

- 13.3 What are the Cost Considerations When Choosing a VCI?

- 14. Investing in the Right Tools for Efficient Diagnostics

- 14.1 How Does the C6 VCI Improve Diagnostic Efficiency?

- 14.2 What is the Return on Investment (ROI) of a High-Quality VCI?

- 14.3 Why is Ongoing Investment in Diagnostic Tools Important?

- 15. Conclusion: Embracing the Power of the C6 VCI for Modern Vehicle Diagnostics

- FAQ: Frequently Asked Questions About C6 VCI and Multi-CAN Communication

- 1. What is the C6 VCI and what does it do?

- 2. Why are CAN gateways necessary in modern vehicles?

- 3. How does the C6 VCI handle communication with multiple CAN gateways?

- 4. What are the key features of the C6 VCI for multi-CAN communication?

- 5. How do software and firmware updates affect the C6 VCI’s performance?

- 6. What are common challenges when using the C6 VCI and how can they be resolved?

- 7. What are the best practices for using the C6 VCI with multi-CAN systems?

- 8. How is Automotive Ethernet impacting vehicle communication?

- 9. What role does cybersecurity play in vehicle communication and diagnostics?

- 10. How can DTS-MONACO.EDU.VN help me become a car coding expert?

1. What is a CAN Gateway and Why Do Modern Vehicles Need Them?

A CAN gateway serves as a bridge between different CAN buses within a vehicle, and modern vehicles need them to manage the increasing complexity of their electronic systems. Vehicles today are packed with numerous ECUs (Electronic Control Units) that control everything from the engine and transmission to the brakes, airbags, and infotainment system. These ECUs communicate with each other over CAN buses. As the number of ECUs and the amount of data they exchange has grown, it has become necessary to divide these systems into multiple CAN buses for efficiency and bandwidth management. This is also according to research from the Society of Automotive Engineers (SAE) in February 2024, which states, modern vehicles often utilize multiple CAN buses operating at different speeds to optimize performance and communication efficiency. A CAN gateway allows these different buses to communicate with each other, enabling data exchange and coordinated operation of vehicle systems.

1.1 What Exactly is a CAN Bus?

A CAN bus is a robust and reliable communication protocol used in vehicles to allow different electronic control units (ECUs) to communicate with each other. Developed by Bosch in the 1980s, it’s designed to operate in harsh electrical environments, making it perfect for automotive applications.

1.2 What is the Role of ECUs in Vehicle Communication?

ECUs are essentially mini-computers that control specific functions within a vehicle. They use sensors to gather data, process it, and then send commands to actuators to control various systems.

1.3 How Does a CAN Gateway Facilitate Communication Between Different CAN Buses?

A CAN gateway acts as a translator and router, receiving messages from one CAN bus and forwarding them to another, ensuring that data gets to the right destination. It handles differences in communication speeds, protocols, and message formats between the buses.

2. Understanding The C6 VCI

The C6 VCI is a vehicle communication interface designed for advanced diagnostics, programming, and car coding tasks, and it is vital for interacting with complex vehicle networks. A VCI like the C6 serves as a bridge between a diagnostic tool (such as a laptop running diagnostic software) and the vehicle’s electronic systems. It translates communication protocols, allowing the diagnostic tool to send commands to and receive data from the vehicle’s ECUs.

2.1 What is the primary Function of the C6 VCI in Vehicle Diagnostics?

The C6 VCI enables technicians to read diagnostic trouble codes (DTCs), access live data, perform actuation tests, and reprogram ECUs, facilitating comprehensive vehicle diagnostics and repair.

2.2 What Protocols Does the C6 VCI Support?

The C6 VCI typically supports a wide range of communication protocols, including CAN, K-Line, L-Line, and J1850, making it compatible with various vehicle makes and models.

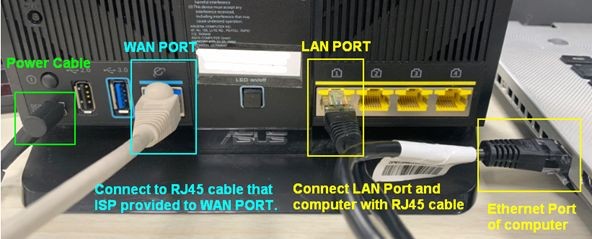

2.3 How Does the C6 VCI Connect to a Vehicle and a Diagnostic Computer?

The C6 VCI connects to the vehicle via the OBD-II port (or other diagnostic port) and to the diagnostic computer via USB, Bluetooth, or Wi-Fi, providing a seamless communication link.

3. Identifying CAN Gateways in a Vehicle

Identifying CAN gateways is crucial for effective vehicle diagnostics and car coding, and it involves recognizing their location, function, and the buses they connect. Typically, a vehicle’s CAN gateway is a dedicated ECU or module that handles communication between different CAN buses. It can often be identified by its central location in the vehicle’s network architecture and its connections to multiple CAN buses. Diagnostic software and wiring diagrams can also help pinpoint the CAN gateway.

3.1 Where are CAN Gateways Typically Located in a Vehicle?

CAN gateways are often located in the central console, under the dashboard, or within the engine compartment, depending on the vehicle’s design.

3.2 How Can Diagnostic Software Help Identify CAN Gateways?

Diagnostic software can display the vehicle’s network topology, showing the CAN gateway and the ECUs connected to it. It can also provide information about the gateway’s function and the buses it connects.

3.3 What Role Do Wiring Diagrams Play in Locating CAN Gateways?

Wiring diagrams provide detailed information about the vehicle’s electrical system, including the location of the CAN gateway, its connections to other ECUs, and the CAN bus wiring.

4. The Communication Process: C6 VCI and Multiple CAN Gateways

The C6 VCI handles communication with vehicles having multiple CAN gateways by intelligently routing messages to the correct CAN bus and ECU. When a diagnostic tool sends a request, the C6 VCI identifies the target ECU and determines which CAN bus it is connected to. It then transmits the message to the appropriate CAN gateway, which forwards it to the target ECU. The response from the ECU is routed back through the CAN gateway and the C6 VCI to the diagnostic tool.

4.1 How Does the C6 VCI Identify the Target ECU and Its CAN Bus?

The C6 VCI uses diagnostic protocols and ECU addressing schemes to identify the target ECU and its CAN bus. This information is often stored in the VCI’s firmware or obtained from the diagnostic software.

4.2 What Happens When a Message Needs to be Sent to an ECU on a Different CAN Bus?

When a message needs to be sent to an ECU on a different CAN bus, the C6 VCI transmits the message to the CAN gateway, which then forwards it to the appropriate bus.

4.3 How Does the CAN Gateway Ensure Messages Reach the Correct Destination ECU?

The CAN gateway uses routing tables and message filtering to ensure that messages reach the correct destination ECU. It examines the message ID and other parameters to determine the appropriate destination and CAN bus.

5. Key Features of the C6 VCI for Multi-CAN Communication

The C6 VCI boasts several key features that enhance its ability to handle multi-CAN communication. These include:

- Multi-Bus Support: The ability to connect to and communicate with multiple CAN buses simultaneously.

- Intelligent Routing: Software and hardware capabilities that enable the VCI to route messages to the correct CAN bus and ECU.

- Protocol Handling: Support for various diagnostic protocols and the ability to translate between them.

- High-Speed Communication: Fast data transfer rates to handle the increasing volume of data exchanged in modern vehicles.

5.1 Multi-Bus Support: Communicating on Multiple CAN Networks

The C6 VCI’s multi-bus support allows it to simultaneously monitor and transmit data on different CAN buses, providing a comprehensive view of the vehicle’s network activity.

5.2 Intelligent Routing: Directing Messages to the Right ECU

Intelligent routing ensures that diagnostic requests and commands are accurately delivered to the intended ECU, minimizing errors and improving diagnostic efficiency.

5.3 Protocol Handling: Supporting Different Diagnostic Languages

The C6 VCI’s protocol handling capabilities enable it to communicate with ECUs that use different diagnostic protocols, ensuring compatibility with a wide range of vehicle makes and models.

6. Software and Firmware Considerations

Software and firmware play a critical role in the C6 VCI’s ability to handle multi-CAN communication. The VCI’s firmware contains the necessary drivers, communication protocols, and routing tables to interact with different CAN buses and ECUs. Diagnostic software uses this firmware to send commands to the VCI and interpret the data it receives. Regular firmware updates are essential to maintain compatibility with new vehicle models and diagnostic protocols.

6.1 How Does Firmware Affect the C6 VCI’s Communication Capabilities?

Firmware dictates the communication protocols, routing algorithms, and diagnostic functions that the C6 VCI can perform, directly impacting its ability to interact with different vehicle networks.

6.2 Why are Regular Software Updates Important for the C6 VCI?

Regular software updates ensure that the C6 VCI remains compatible with the latest vehicle models, diagnostic protocols, and software features, maximizing its diagnostic capabilities.

6.3 How Do Diagnostic Software Settings Influence CAN Communication?

Diagnostic software settings allow technicians to configure the C6 VCI’s communication parameters, such as CAN bus speed, addressing schemes, and diagnostic protocols, optimizing performance for specific vehicle models and diagnostic tasks.

7. Practical Applications: Diagnostics and Car Coding

The ability of the C6 VCI to handle multi-CAN communication is essential for various practical applications in vehicle diagnostics and car coding.

7.1 Diagnosing Complex Issues Across Multiple Vehicle Systems

By connecting to multiple CAN buses, the C6 VCI allows technicians to diagnose complex issues that span multiple vehicle systems, such as engine and transmission problems, braking and stability control issues, and electrical system faults.

7.2 Car Coding and Reprogramming ECUs in Modern Vehicles

The C6 VCI enables technicians to reprogram ECUs with updated software, customize vehicle settings, and add new features, enhancing vehicle performance and functionality.

7.3 Performing Module Replacement and Initialization

When replacing a faulty ECU, the C6 VCI can be used to initialize the new module, configure its settings, and integrate it into the vehicle’s network, ensuring proper operation.

8. Common Challenges and Troubleshooting Tips

While the C6 VCI is a powerful tool, technicians may encounter challenges when working with multi-CAN communication. These can include:

- Communication Errors: Caused by incorrect CAN bus settings, faulty wiring, or incompatible protocols.

- ECU Not Responding: Due to incorrect addressing, power supply issues, or a faulty ECU.

- Data Corruption: Resulting from electrical noise, interference, or faulty hardware.

8.1 What are Some Common Communication Errors and How Can They Be Resolved?

Common communication errors include incorrect CAN bus speeds, mismatched protocols, and faulty wiring. Solutions include verifying CAN bus settings, checking wiring connections, and using the correct diagnostic protocols.

8.2 What Steps Can Be Taken When an ECU is Not Responding?

When an ECU is not responding, check the power supply to the ECU, verify the CAN bus connection, and ensure that the correct addressing scheme is being used. If the problem persists, the ECU may be faulty.

8.3 How Can Data Corruption Issues Be Prevented and Addressed?

Data corruption can be prevented by using high-quality cables, ensuring proper grounding, and avoiding electrical interference. If data corruption occurs, try re-sending the command or replacing the communication hardware.

9. Best Practices for Using the C6 VCI with Multi-CAN Systems

To maximize the effectiveness and reliability of the C6 VCI when working with multi-CAN systems, technicians should follow these best practices:

- Use High-Quality Cables and Connectors: To ensure reliable communication and minimize data corruption.

- Verify CAN Bus Settings: To ensure the correct communication speed and protocol are used.

- Keep the C6 VCI Firmware Updated: To maintain compatibility with new vehicle models and diagnostic protocols.

- Follow Diagnostic Procedures: To ensure accurate and safe operation.

9.1 The Importance of Using High-Quality Cables and Connectors

High-quality cables and connectors minimize signal loss, reduce electrical noise, and ensure reliable communication between the C6 VCI and the vehicle’s ECUs.

9.2 Verifying CAN Bus Settings for Accurate Communication

Verifying CAN bus settings, such as communication speed and protocol, ensures that the C6 VCI is communicating with the ECUs using the correct parameters, preventing communication errors.

9.3 Staying Up-To-Date with C6 VCI Firmware and Software

Keeping the C6 VCI firmware and software updated ensures compatibility with the latest vehicle models, diagnostic protocols, and software features, maximizing its diagnostic capabilities.

10. Future Trends in Vehicle Communication and Diagnostics

The field of vehicle communication and diagnostics is constantly evolving, with new technologies and protocols emerging to meet the demands of increasingly complex vehicle systems.

10.1 The Rise of Automotive Ethernet and Its Impact on VCIs

Automotive Ethernet is a high-speed communication protocol that is becoming increasingly popular in vehicles. VCIs will need to support Automotive Ethernet to communicate with ECUs that use this protocol.

10.2 The Role of Cloud-Based Diagnostics and Remote Vehicle Access

Cloud-based diagnostics and remote vehicle access are enabling technicians to diagnose and repair vehicles remotely, improving efficiency and reducing downtime.

10.3 The Increasing Importance of Cybersecurity in Vehicle Communication

As vehicles become more connected, cybersecurity is becoming increasingly important. VCIs will need to incorporate security features to protect against unauthorized access and data breaches.

11. Training and Resources for Mastering C6 VCI Usage

To effectively use the C6 VCI and master multi-CAN communication, technicians need access to quality training and resources. DTS-MONACO.EDU.VN offers comprehensive training courses, detailed documentation, and expert support to help technicians develop the necessary skills and knowledge.

11.1 The Benefits of Formal Training Courses on Vehicle Diagnostics

Formal training courses provide technicians with a structured learning environment, hands-on experience, and expert guidance, accelerating their skill development and improving their diagnostic capabilities.

11.2 Online Resources and Communities for C6 VCI Users

Online resources and communities provide C6 VCI users with access to troubleshooting tips, best practices, and peer support, helping them overcome challenges and stay up-to-date with the latest developments.

11.3 How DTS-MONACO.EDU.VN Can Help You Become a Car Coding Expert

DTS-MONACO.EDU.VN offers comprehensive training programs and resources specifically designed to help technicians become car coding experts, mastering the skills and knowledge needed to reprogram ECUs, customize vehicle settings, and add new features. With our expert guidance, you’ll confidently tackle any car coding challenge!

12. Case Studies: Real-World Examples of C6 VCI in Action

Examining real-world case studies can illustrate how the C6 VCI is used to diagnose and repair vehicles with multi-CAN systems.

12.1 Case Study 1: Diagnosing an Intermittent Engine Stalling Issue

A technician used the C6 VCI to connect to multiple CAN buses and monitor live data from the engine control unit (ECU), transmission control unit (TCU), and other relevant modules. By analyzing the data, the technician identified a faulty sensor that was causing the engine to stall intermittently.

12.2 Case Study 2: Reprogramming an ECU After a Software Update Failure

A technician used the C6 VCI to reprogram an ECU after a software update failed, causing the vehicle to malfunction. The technician downloaded the correct software from the manufacturer’s website and used the C6 VCI to flash the ECU, restoring the vehicle to proper operation.

12.3 Case Study 3: Performing a Module Replacement on a Modern Vehicle

A technician used the C6 VCI to replace a faulty ECU on a modern vehicle. The technician used the C6 VCI to initialize the new module, configure its settings, and integrate it into the vehicle’s network, ensuring proper operation.

13. Comparing the C6 VCI to Other Vehicle Communication Interfaces

While the C6 VCI is a popular choice for vehicle diagnostics and car coding, there are other VCIs available on the market. Comparing the C6 VCI to these alternatives can help technicians make informed decisions about which tool is best suited for their needs.

13.1 What are the Key Differences Between the C6 VCI and Other VCIs?

Key differences between the C6 VCI and other VCIs include communication speed, protocol support, multi-bus capabilities, and software features.

13.2 How Does the C6 VCI Stack Up in Terms of Performance and Reliability?

The C6 VCI is known for its high performance, reliability, and compatibility with a wide range of vehicle makes and models.

13.3 What are the Cost Considerations When Choosing a VCI?

Cost considerations when choosing a VCI include the initial purchase price, software update fees, and subscription costs. The C6 VCI offers a balance of performance, features, and cost, making it a popular choice for many technicians.

14. Investing in the Right Tools for Efficient Diagnostics

Investing in the right tools, such as the C6 VCI, is essential for efficient vehicle diagnostics and car coding. The C6 VCI enables technicians to quickly and accurately diagnose complex issues, reprogram ECUs, and perform module replacements, saving time and improving customer satisfaction.

14.1 How Does the C6 VCI Improve Diagnostic Efficiency?

The C6 VCI improves diagnostic efficiency by providing technicians with access to comprehensive vehicle data, advanced diagnostic functions, and multi-bus capabilities.

14.2 What is the Return on Investment (ROI) of a High-Quality VCI?

The ROI of a high-quality VCI, such as the C6 VCI, can be significant, as it enables technicians to perform more repairs in less time, increasing revenue and improving customer satisfaction.

14.3 Why is Ongoing Investment in Diagnostic Tools Important?

Ongoing investment in diagnostic tools is important to keep up with the latest vehicle technologies, diagnostic protocols, and software features, ensuring that technicians can continue to provide high-quality service.

15. Conclusion: Embracing the Power of the C6 VCI for Modern Vehicle Diagnostics

In conclusion, the C6 VCI is a powerful tool that enables technicians to effectively diagnose and repair modern vehicles with multi-CAN systems. By understanding how the C6 VCI handles communication with multiple CAN gateways, technicians can unlock its full potential and provide high-quality service to their customers. Embrace the power of the C6 VCI and stay ahead in the ever-evolving world of vehicle diagnostics! Remember, for top-tier car coding training and in-depth knowledge, visit DTS-MONACO.EDU.VN, your ultimate resource for mastering vehicle diagnostics and car coding. Gain expertise in vehicle network, car software, and electronic control!

Automotive network topology displaying multiple CAN buses

Automotive network topology displaying multiple CAN buses

FAQ: Frequently Asked Questions About C6 VCI and Multi-CAN Communication

1. What is the C6 VCI and what does it do?

The C6 VCI (Vehicle Communication Interface) is a diagnostic tool that enables communication between a diagnostic computer and a vehicle’s electronic systems, facilitating tasks like reading DTCs, accessing live data, and reprogramming ECUs.

2. Why are CAN gateways necessary in modern vehicles?

CAN gateways are necessary to manage the increasing complexity of vehicle electronic systems by bridging different CAN buses, enabling data exchange, and ensuring coordinated operation.

3. How does the C6 VCI handle communication with multiple CAN gateways?

The C6 VCI intelligently routes messages to the correct CAN bus and ECU by identifying the target ECU, determining its CAN bus, and transmitting messages through the appropriate CAN gateway.

4. What are the key features of the C6 VCI for multi-CAN communication?

Key features include multi-bus support, intelligent routing, protocol handling, and high-speed communication, which enable the VCI to effectively interact with various vehicle networks.

5. How do software and firmware updates affect the C6 VCI’s performance?

Regular software and firmware updates ensure the C6 VCI remains compatible with the latest vehicle models, diagnostic protocols, and software features, maximizing its diagnostic capabilities.

6. What are common challenges when using the C6 VCI and how can they be resolved?

Common challenges include communication errors, non-responding ECUs, and data corruption. These can be resolved by verifying CAN bus settings, checking wiring, and ensuring proper grounding.

7. What are the best practices for using the C6 VCI with multi-CAN systems?

Best practices include using high-quality cables, verifying CAN bus settings, keeping the firmware updated, and following diagnostic procedures.

8. How is Automotive Ethernet impacting vehicle communication?

Automotive Ethernet is a high-speed communication protocol that is becoming increasingly popular in vehicles, requiring VCIs to support this protocol for effective communication.

9. What role does cybersecurity play in vehicle communication and diagnostics?

Cybersecurity is crucial to protect against unauthorized access and data breaches as vehicles become more connected, requiring VCIs to incorporate security features.

10. How can DTS-MONACO.EDU.VN help me become a car coding expert?

DTS-MONACO.EDU.VN offers comprehensive training programs and resources designed to help technicians become car coding experts, mastering the skills and knowledge needed to reprogram ECUs and customize vehicle settings.

Visit DTS-MONACO.EDU.VN today and take the first step toward becoming a master of vehicle diagnostics and car coding. Contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States or Whatsapp: +1 (641) 206-8880 to learn more about our training programs and services.