Oil leaks from your Mercedes-Benz M272 or M273 engine can be frustrating, but identifying the source, particularly the oil cooler seals, is the first step to resolving the issue. At DTS-MONACO.EDU.VN, we are dedicated to empowering automotive technicians with the knowledge and resources necessary to diagnose and repair these common problems efficiently. Let’s explore the causes of oil leaks from the oil cooler seals in M272/M273 engines and guide you towards effective solutions and, ultimately, a leak-free engine.

Contents

- 1. What are the Common Causes of Oil Leaks in Mercedes-Benz M272/M273 Engines?

- 2. What Specific Role Do Oil Cooler Seals Play in Preventing Leaks?

- 3. What Causes Oil Cooler Seals to Fail in M272/M273 Engines?

- 4. How Can I Diagnose an Oil Leak From the Oil Cooler Seals?

- 5. Can I Replace the Oil Cooler Seals Myself, or Do I Need a Professional?

- 6. What Tools and Materials Are Needed for Replacing Oil Cooler Seals?

- 7. What is the Step-by-Step Process for Replacing Oil Cooler Seals on M272/M273 Engines?

- 8. What Are the Potential Risks of Not Addressing Oil Leaks Promptly?

- 9. How Can I Prevent Oil Cooler Seal Failures in the Future?

- 10. How Does DTS-MONACO.EDU.VN Support Automotive Technicians in Diagnosing and Repairing Oil Leaks?

- FAQ: Oil Leaks From Oil Cooler Seals (M272/M273)

1. What are the Common Causes of Oil Leaks in Mercedes-Benz M272/M273 Engines?

The common culprits behind oil leaks in Mercedes-Benz M272/M273 engines often include worn or deteriorated oil cooler seals, valve cover gaskets, camshaft plugs, oil filter housing gaskets, and the oil separator. Understanding these common leak points is essential for efficient diagnostics.

Oil leaks in Mercedes-Benz M272 and M273 engines can be a common headache for owners. These engines, found in various models from the mid-2000s to the early 2010s, are generally reliable but are prone to certain oil leak issues. Identifying the source of the leak is the first step in addressing the problem effectively. Here’s a more detailed breakdown of the common causes:

- Oil Cooler Seals: This is a very common source of leaks, especially as the vehicle ages. The oil cooler is typically mounted to the oil filter housing, and the seals between these components can harden and crack over time due to heat cycling.

- Valve Cover Gaskets: The valve cover gaskets seal the valve covers to the cylinder heads. These gaskets can become brittle and shrink with age and heat, leading to leaks.

- Camshaft Plugs: Located at the rear of the cylinder heads, these plugs seal off the camshaft bores. They are made of rubber and can dry out and leak over time.

- Oil Filter Housing Gaskets: The oil filter housing is another area prone to leaks. The gaskets between the housing and the engine block can fail due to heat and pressure.

- Oil Separator: Also known as the crankcase ventilation valve, the oil separator can leak if it becomes clogged or damaged.

- Timing Cover: The timing cover seals the front of the engine and can leak over time, especially where it joins the engine block and cylinder head.

- Rear Main Seal: Although less common than the other sources listed, the rear main seal can leak, which is located between the engine and transmission.

- Oil Pan Gasket: The oil pan gasket seals the oil pan to the engine block. It can leak due to age, damage, or improper installation.

Regular inspections and maintenance can help identify and address these leaks early, preventing more significant problems down the road. According to a study by the National Institute for Automotive Service Excellence (ASE), addressing minor oil leaks promptly can prevent more costly repairs later on.

2. What Specific Role Do Oil Cooler Seals Play in Preventing Leaks?

Oil cooler seals are vital for maintaining a leak-free engine by creating a tight seal between the oil cooler and the engine block. These seals prevent oil from escaping as it circulates through the cooler, ensuring efficient engine lubrication and cooling.

The oil cooler seals play a critical role in preventing oil leaks in the M272 and M273 engines. These seals are responsible for maintaining a tight, leak-free connection between the oil cooler and the engine block. Here’s a more in-depth look at their function and importance:

- Sealing the Connection: The oil cooler is typically mounted to the oil filter housing, and the seals are positioned between these two components. Their primary job is to prevent oil from leaking as it flows through the cooler.

- Maintaining Oil Pressure: A proper seal ensures that the oil pressure remains consistent. Leaks can cause a drop in oil pressure, which can lead to inadequate lubrication and potential engine damage.

- Preventing Contamination: The seals also help to keep contaminants out of the oil system. A compromised seal can allow dirt and debris to enter, which can accelerate wear and tear on engine components.

- Handling Heat and Pressure: Oil cooler seals are designed to withstand high temperatures and pressures. However, over time, the constant exposure to these conditions can cause the seals to harden, crack, and lose their elasticity, leading to leaks.

- Importance of Quality: Using high-quality oil cooler seals is crucial for ensuring long-lasting performance and reliability. Aftermarket seals may not meet the same standards as OEM (Original Equipment Manufacturer) parts and could fail prematurely.

- Regular Inspection: Regularly inspecting the oil cooler seals for signs of wear and tear is essential for preventing leaks. Early detection can save you from more extensive and costly repairs down the road.

In summary, the oil cooler seals are a small but vital component in the M272 and M273 engines. Their proper function is essential for maintaining oil pressure, preventing contamination, and ensuring the overall health and performance of the engine.

3. What Causes Oil Cooler Seals to Fail in M272/M273 Engines?

The primary causes of oil cooler seal failure include heat cycling, age-related degradation, and the use of incompatible or low-quality oil. Over time, these factors cause the seals to harden, crack, and lose their ability to maintain a tight seal.

Several factors can contribute to the failure of oil cooler seals in Mercedes-Benz M272 and M273 engines. Understanding these causes can help in preventing premature seal failure and maintaining the engine’s overall health. Here are the primary culprits:

- Heat Cycling: The constant heating and cooling of the engine cause the seals to expand and contract repeatedly. Over time, this thermal stress can lead to the seals hardening, cracking, and losing their elasticity.

- Age-Related Degradation: Like any rubber or elastomeric material, oil cooler seals degrade with age. The rubber compounds break down over time, leading to a loss of flexibility and sealing ability.

- Low-Quality Seals: Using inferior or non-OEM (Original Equipment Manufacturer) oil cooler seals can result in premature failure. These seals may not be made of the same high-quality materials as OEM parts and may not be able to withstand the same levels of heat and pressure.

- Improper Installation: Incorrect installation of the oil cooler seals can damage them or prevent them from sealing properly. This can occur if the seals are not seated correctly or if the mating surfaces are not clean and free of debris.

- Contaminated Oil: Contaminants in the engine oil, such as dirt, debris, and coolant, can accelerate the wear and tear on the oil cooler seals. These contaminants can cause the seals to become brittle and lose their sealing properties.

- Aggressive Driving: High-performance driving and frequent hard acceleration can increase the stress on the engine and its components, including the oil cooler seals. This can lead to premature seal failure.

By addressing these potential causes and implementing preventive measures, such as using high-quality seals, following proper installation procedures, and maintaining clean engine oil, you can extend the life of the oil cooler seals and prevent costly oil leaks. According to a technical bulletin from Mercedes-Benz, using genuine parts and following recommended maintenance schedules are crucial for ensuring the longevity of engine components.

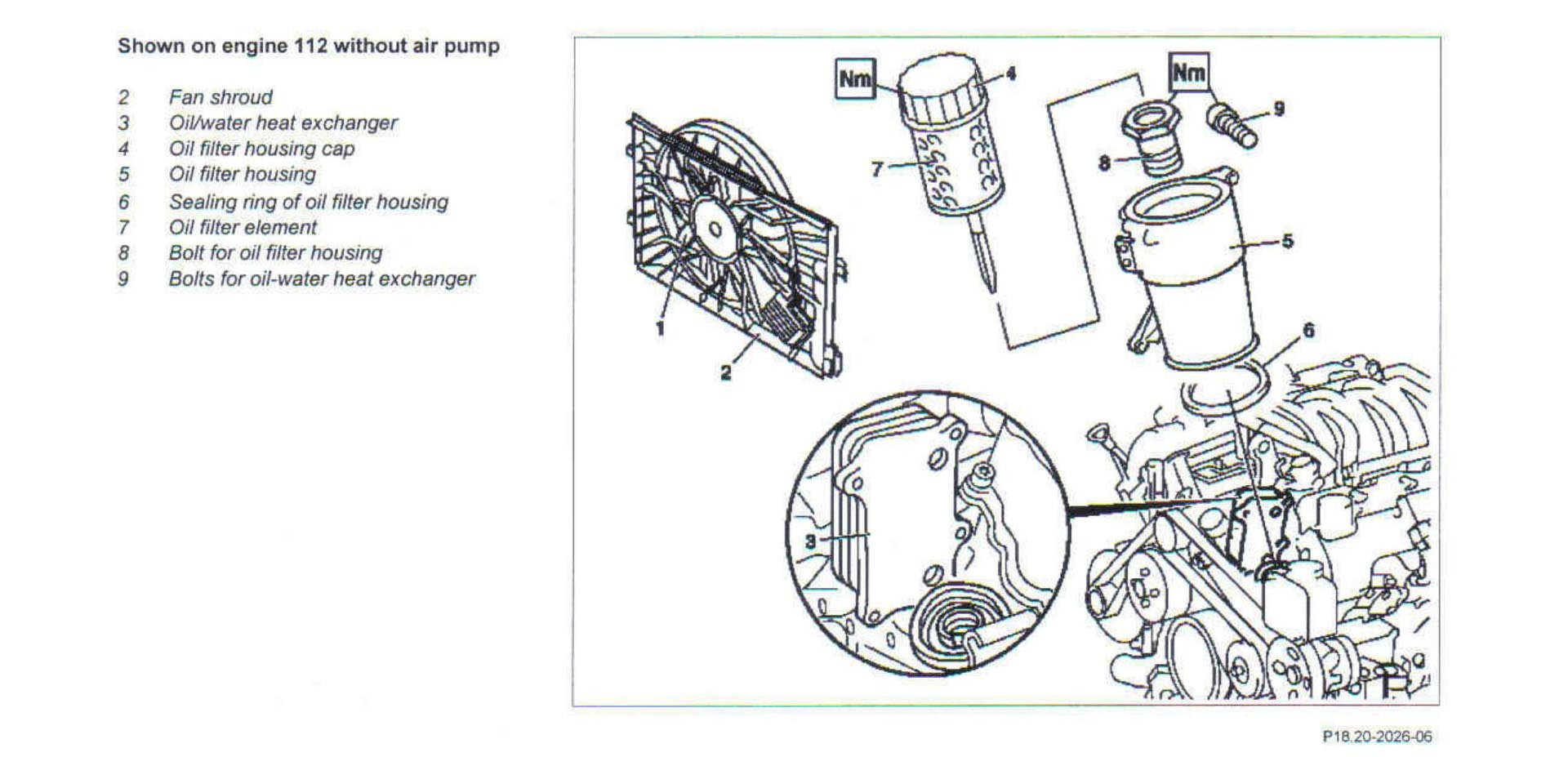

Mercedes-Benz M112 Oil Filter Housing Diagram

Mercedes-Benz M112 Oil Filter Housing Diagram

Mercedes-Benz M112 Oil Filter Housing Diagram

4. How Can I Diagnose an Oil Leak From the Oil Cooler Seals?

Diagnosing an oil leak from the oil cooler seals involves a visual inspection for oil residue around the oil cooler and filter housing, checking for oil drips, and potentially using dye to pinpoint the leak’s exact location.

Diagnosing an oil leak from the oil cooler seals in Mercedes-Benz M272 and M273 engines requires a systematic approach to accurately identify the source of the leak. Here are the steps to effectively diagnose this issue:

- Visual Inspection: Begin by visually inspecting the area around the oil cooler and oil filter housing. Look for signs of fresh oil, such as wet spots, drips, or residue. Pay close attention to the seams where the oil cooler connects to the engine block or oil filter housing.

- Check for Oil Drips: Place a clean piece of cardboard or paper under the engine overnight to check for oil drips. This can help you determine the severity of the leak and pinpoint the general area from which it is originating.

- Clean the Area: Clean the area around the oil cooler and oil filter housing with a degreaser or brake cleaner to remove any existing oil residue. This will make it easier to spot fresh leaks.

- UV Dye Test: Add UV dye to the engine oil and run the engine for a short period. Then, use a UV light to inspect the area around the oil cooler and oil filter housing. The dye will make it easier to spot even small leaks.

- Pressure Test: Perform a pressure test on the cooling system to check for leaks. A drop in pressure can indicate a leak in the oil cooler or its seals.

- Check Oil Level and Condition: Monitor the engine oil level regularly. A rapid drop in oil level can indicate a significant leak. Also, check the condition of the oil for signs of contamination, such as coolant or debris.

- Inspect Other Potential Leak Sources: Rule out other potential sources of oil leaks, such as the valve cover gaskets, camshaft plugs, and oil filter housing gaskets. These components are also common leak points in M272 and M273 engines.

- Professional Inspection: If you are unable to locate the leak yourself, consider taking your vehicle to a trusted mechanic or Mercedes-Benz dealership for a professional inspection. They have the expertise and tools to accurately diagnose and repair oil leaks.

By following these steps, you can effectively diagnose an oil leak from the oil cooler seals in your Mercedes-Benz M272 or M273 engine and take the necessary steps to repair it. According to the experts at Mercedes-Benz of North America, accurate diagnosis is key to preventing further damage and ensuring the longevity of your engine.

5. Can I Replace the Oil Cooler Seals Myself, or Do I Need a Professional?

Replacing oil cooler seals can be a DIY project if you have experience with automotive repairs. However, if you’re unfamiliar with engine mechanics, it’s best to seek a professional to avoid potential complications. At DTS-MONACO.EDU.VN, we offer resources to help DIYers and professionals alike.

Deciding whether to replace the oil cooler seals yourself or hire a professional depends on your mechanical skills, experience, and comfort level. Here’s a breakdown of the factors to consider:

Replacing Oil Cooler Seals Yourself (DIY):

-

Pros:

- Cost Savings: DIY repairs can save you money on labor costs.

- Personal Satisfaction: Some people enjoy working on their cars and find it rewarding to complete repairs themselves.

- Learning Experience: DIY repairs can be a great way to learn more about your car and how it works.

-

Cons:

- Time Commitment: DIY repairs can take a significant amount of time, especially if you are not experienced.

- Potential for Mistakes: If you are not careful, you could make mistakes that could damage your car or cause further problems.

- Tool Investment: You may need to purchase special tools to complete the repair, which can add to the cost.

- Warranty Issues: DIY repairs may void your car’s warranty if not performed correctly.

-

When to Consider DIY:

- You have experience with automotive repairs, particularly engine work.

- You have the necessary tools and equipment.

- You are comfortable working on your car and following instructions.

- You have access to reliable repair information and resources.

Hiring a Professional Mechanic:

-

Pros:

- Expertise and Experience: Professional mechanics have the knowledge and experience to diagnose and repair oil leaks quickly and accurately.

- Proper Tools and Equipment: Mechanics have access to specialized tools and equipment that can make the repair easier and more efficient.

- Warranty Protection: Repairs performed by a professional mechanic are typically covered by a warranty, giving you peace of mind.

- Time Savings: Hiring a mechanic can save you a significant amount of time and effort.

-

Cons:

- Higher Cost: Professional repairs can be more expensive than DIY repairs due to labor costs.

-

When to Consider a Professional:

- You lack experience with automotive repairs.

- You are not comfortable working on your car.

- You do not have the necessary tools and equipment.

- You want the peace of mind that comes with having a professional perform the repair.

According to a survey by the American Automobile Association (AAA), most car owners prefer to have major repairs performed by a professional mechanic due to the complexity of modern vehicles. Ultimately, the decision of whether to replace the oil cooler seals yourself or hire a professional depends on your individual circumstances and abilities.

6. What Tools and Materials Are Needed for Replacing Oil Cooler Seals?

To replace oil cooler seals, you’ll typically need a socket set, torque wrench, new oil cooler seals, replacement coolant (if necessary), and possibly a new oil filter. It’s also helpful to have a repair manual for your specific Mercedes-Benz model.

Replacing oil cooler seals on Mercedes-Benz M272 and M273 engines requires a specific set of tools and materials to ensure the job is done correctly and efficiently. Here’s a comprehensive list:

Tools:

- Socket Set: A comprehensive socket set with various sizes is essential for removing and installing bolts and nuts.

- Torque Wrench: A torque wrench is crucial for tightening bolts to the manufacturer’s specified torque settings.

- Wrenches: A set of wrenches, including open-end, box-end, and combination wrenches, will be needed for various tasks.

- Screwdrivers: Both flathead and Phillips head screwdrivers will be necessary for removing various components.

- Pliers: Pliers, including needle-nose and regular pliers, can be helpful for removing hoses and clips.

- Pick Set: A pick set is useful for removing old seals and gaskets without damaging the surrounding surfaces.

- Oil Filter Wrench: An oil filter wrench is needed to remove and install the oil filter.

- Drain Pan: A drain pan is essential for catching the oil and coolant that will be drained from the engine.

- Cleaning Supplies: Brake cleaner, degreaser, and rags are needed to clean the area around the oil cooler and oil filter housing.

- UV Light (Optional): If you used UV dye to locate the leak, a UV light will be needed to inspect the area after the repair.

Materials:

- New Oil Cooler Seals: Purchase high-quality OEM (Original Equipment Manufacturer) oil cooler seals specifically designed for your Mercedes-Benz M272 or M273 engine.

- New Oil Filter: Replace the oil filter when you replace the oil cooler seals to ensure optimal performance.

- Engine Oil: Use the correct type and grade of engine oil recommended by Mercedes-Benz for your engine.

- Coolant: If you need to remove the coolant lines, have the correct type of coolant on hand to refill the system.

- Distilled Water: Use distilled water to mix with the coolant if necessary.

- Gasket Scraper: A gasket scraper is helpful for removing old gasket material from the mating surfaces.

- Shop Towels: Keep plenty of shop towels on hand for cleaning up spills and wiping down parts.

- Gloves: Wear gloves to protect your hands from oil, coolant, and other fluids.

According to a technical service bulletin from Mercedes-Benz, using the correct tools and materials is essential for ensuring a successful oil cooler seal replacement. Investing in quality tools and OEM parts will help you complete the job efficiently and prevent future leaks.

7. What is the Step-by-Step Process for Replacing Oil Cooler Seals on M272/M273 Engines?

The process generally involves draining the engine oil and coolant, removing the oil filter and cooler, replacing the seals, and reassembling everything. Always consult a repair manual for your specific model to ensure accuracy.

Replacing the oil cooler seals on Mercedes-Benz M272 and M273 engines can be a straightforward process if you follow the correct steps. Here’s a detailed, step-by-step guide to help you through the procedure:

Step 1: Preparation

- Gather Tools and Materials: Ensure you have all the necessary tools and materials listed in the previous section.

- Safety First: Wear safety glasses and gloves to protect yourself from fluids and sharp objects.

- Park the Vehicle: Park your Mercedes-Benz on a level surface and engage the parking brake.

- Disconnect the Battery: Disconnect the negative terminal of the battery to prevent electrical shorts.

Step 2: Drain the Engine Oil and Coolant

- Drain the Engine Oil: Locate the oil drain plug on the oil pan and place a drain pan underneath. Remove the drain plug and allow the oil to drain completely.

- Drain the Coolant: Locate the coolant drain plug on the radiator or engine block and place a drain pan underneath. Remove the drain plug and allow the coolant to drain completely.

Step 3: Remove the Oil Filter and Oil Cooler

- Remove the Oil Filter: Use an oil filter wrench to remove the oil filter from the oil filter housing.

- Disconnect Oil Cooler Lines: Carefully disconnect the oil cooler lines from the oil cooler. Be prepared for some residual oil to spill.

- Remove the Oil Cooler: Remove the bolts or nuts that secure the oil cooler to the oil filter housing or engine block. Carefully remove the oil cooler.

Step 4: Replace the Oil Cooler Seals

- Remove the Old Seals: Use a pick set to carefully remove the old oil cooler seals from the oil cooler and oil filter housing. Be sure to clean the sealing surfaces thoroughly.

- Install the New Seals: Lubricate the new oil cooler seals with fresh engine oil and install them into the grooves on the oil cooler and oil filter housing.

Step 5: Reassemble the Components

- Reinstall the Oil Cooler: Carefully reinstall the oil cooler onto the oil filter housing or engine block. Tighten the bolts or nuts to the manufacturer’s specified torque settings.

- Reconnect Oil Cooler Lines: Reconnect the oil cooler lines to the oil cooler. Make sure they are securely fastened.

- Install New Oil Filter: Install a new oil filter onto the oil filter housing. Tighten it to the manufacturer’s specified torque settings.

Step 6: Refill the Engine Oil and Coolant

- Reinstall Oil Drain Plug: Reinstall the oil drain plug onto the oil pan and tighten it to the manufacturer’s specified torque settings.

- Refill Engine Oil: Refill the engine with the correct type and grade of engine oil recommended by Mercedes-Benz.

- Reinstall Coolant Drain Plug: Reinstall the coolant drain plug onto the radiator or engine block and tighten it securely.

- Refill Coolant: Refill the cooling system with the correct type of coolant recommended by Mercedes-Benz. Mix the coolant with distilled water if necessary.

Step 7: Final Checks and Start-Up

- Check for Leaks: Inspect the area around the oil cooler and oil filter housing for any signs of leaks.

- Reconnect the Battery: Reconnect the negative terminal of the battery.

- Start the Engine: Start the engine and let it run for a few minutes. Monitor the oil pressure and coolant temperature gauges.

- Inspect Again for Leaks: After the engine has warmed up, inspect the area around the oil cooler and oil filter housing again for any signs of leaks.

- Top Off Fluids: If necessary, top off the engine oil and coolant levels.

According to a repair manual for Mercedes-Benz M272 and M273 engines, following these steps carefully will ensure a successful oil cooler seal replacement. If you encounter any difficulties or are unsure about any of the steps, seek assistance from a qualified mechanic.

8. What Are the Potential Risks of Not Addressing Oil Leaks Promptly?

Ignoring oil leaks can lead to engine damage due to inadequate lubrication, increased oil consumption, and potential environmental hazards. Addressing leaks promptly prevents costly repairs and maintains your vehicle’s performance.

Failing to address oil leaks promptly in your Mercedes-Benz M272 or M273 engine can lead to a variety of potential risks and costly consequences. Here’s a detailed look at what can happen if you ignore these leaks:

- Engine Damage: One of the most significant risks of ignoring oil leaks is engine damage due to inadequate lubrication. Oil leaks can cause a drop in oil pressure, which means that critical engine components, such as the crankshaft, connecting rods, and camshaft, may not receive enough lubrication. This can lead to increased friction, wear, and ultimately, engine failure.

- Increased Oil Consumption: Oil leaks can lead to increased oil consumption, as the engine is constantly losing oil. This means you will need to add oil more frequently to maintain the proper oil level. Over time, this can become costly and inconvenient.

- Overheating: Oil leaks can also contribute to engine overheating. Oil helps to dissipate heat from the engine, and a loss of oil can reduce its ability to cool effectively. Overheating can cause significant damage to engine components, such as the cylinder head and pistons.

- Environmental Damage: Oil leaks can cause environmental damage by contaminating soil and water sources. Leaking oil can seep into the ground and pollute the soil, and it can also wash into storm drains and contaminate waterways.

- Fire Hazard: In some cases, oil leaks can create a fire hazard. If oil leaks onto hot engine components, such as the exhaust manifold, it can ignite and cause a fire.

- Failed Emissions Test: Oil leaks can cause your vehicle to fail an emissions test. Leaking oil can contaminate the catalytic converter, which is responsible for reducing harmful emissions.

- Costly Repairs: Ignoring oil leaks can lead to more extensive and costly repairs down the road. What starts as a simple oil leak can quickly escalate into major engine damage, requiring expensive repairs or even engine replacement.

According to the Environmental Protection Agency (EPA), properly maintaining your vehicle and addressing oil leaks promptly can help protect the environment and prevent costly repairs.

9. How Can I Prevent Oil Cooler Seal Failures in the Future?

Preventive measures include regular oil changes with high-quality oil, monitoring engine temperatures, and replacing seals at recommended intervals. These practices help extend the life of your engine and prevent future leaks.

Preventing oil cooler seal failures in your Mercedes-Benz M272 and M273 engines involves proactive maintenance and care. Here are several effective strategies to help extend the life of your oil cooler seals and prevent future leaks:

- Regular Oil Changes: One of the most important things you can do to prevent oil cooler seal failures is to perform regular oil changes using high-quality engine oil. Clean oil helps to keep the seals lubricated and prevents the buildup of contaminants that can cause them to degrade. Follow the manufacturer’s recommended oil change intervals.

- Use High-Quality Oil Filters: Use high-quality oil filters that are designed to trap contaminants and prevent them from circulating through the engine. A good oil filter will help to keep the oil clean and protect the oil cooler seals.

- Monitor Engine Temperatures: Keep an eye on your engine’s temperature gauge. Overheating can cause the oil cooler seals to degrade more quickly. If you notice your engine running hotter than usual, investigate the cause and address it promptly.

- Avoid Aggressive Driving: High-performance driving and frequent hard acceleration can put extra stress on the engine and its components, including the oil cooler seals. Avoid aggressive driving habits to help prolong the life of the seals.

- Inspect Regularly: Periodically inspect the area around the oil cooler and oil filter housing for any signs of oil leaks. Catching leaks early can prevent them from escalating into more significant problems.

- Replace Seals at Recommended Intervals: Consider replacing the oil cooler seals at the manufacturer’s recommended intervals, even if they are not currently leaking. This can help to prevent future leaks and ensure the continued health of your engine.

- Use OEM Parts: When replacing oil cooler seals, use OEM (Original Equipment Manufacturer) parts or high-quality aftermarket parts that meet or exceed OEM specifications. These parts are designed to withstand the high temperatures and pressures of the engine and will provide a more reliable seal.

By following these preventive measures, you can significantly reduce the risk of oil cooler seal failures in your Mercedes-Benz M272 and M273 engines and help keep your engine running smoothly for years to come. According to a report by Consumer Reports, regular maintenance and the use of quality parts are key to preventing automotive problems.

10. How Does DTS-MONACO.EDU.VN Support Automotive Technicians in Diagnosing and Repairing Oil Leaks?

DTS-MONACO.EDU.VN provides comprehensive training and resources for automotive technicians, including detailed guides on using diagnostic software and performing repairs. Our goal is to equip technicians with the expertise needed to efficiently address issues like oil leaks in Mercedes-Benz vehicles.

At DTS-MONACO.EDU.VN, we are committed to providing automotive technicians with the knowledge, tools, and resources they need to excel in their field. Here’s how we support technicians in diagnosing and repairing oil leaks, particularly in Mercedes-Benz vehicles:

- Comprehensive Training Programs: We offer comprehensive training programs that cover a wide range of automotive topics, including engine diagnostics and repair. Our courses are designed to provide technicians with the theoretical knowledge and practical skills they need to diagnose and repair oil leaks effectively.

- Detailed Diagnostic Guides: We provide detailed diagnostic guides that walk technicians through the process of diagnosing oil leaks step-by-step. These guides include information on common leak points, diagnostic procedures, and troubleshooting tips.

- Access to Technical Information: We offer access to a vast library of technical information, including repair manuals, wiring diagrams, and technical service bulletins. This information can help technicians to accurately diagnose and repair oil leaks in a variety of vehicles.

- Hands-On Training: Our training programs include hands-on training sessions where technicians can practice their skills on real vehicles. This hands-on experience is invaluable for developing the confidence and expertise needed to tackle complex repairs.

- Support and Mentorship: We provide ongoing support and mentorship to our students and graduates. Our team of experienced instructors and technicians is available to answer questions, provide guidance, and offer assistance with difficult repairs.

- Partnerships with Industry Leaders: We partner with leading automotive manufacturers and suppliers to ensure that our training programs are up-to-date and relevant to the needs of the industry.

By providing comprehensive training, detailed diagnostic guides, access to technical information, hands-on training, and ongoing support, DTS-MONACO.EDU.VN is helping to empower automotive technicians to diagnose and repair oil leaks effectively and efficiently.

Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880. Website: DTS-MONACO.EDU.VN.

Ready to master car coding and diagnostics? Visit DTS-MONACO.EDU.VN today to explore our software, training courses, and support services!

FAQ: Oil Leaks From Oil Cooler Seals (M272/M273)

- What are the symptoms of an oil cooler seal leak?

- Oil drips under the car, low oil level, and visible oil residue around the oil filter housing are common symptoms.

- How often should I replace my oil cooler seals?

- It is generally recommended to replace them every 75,000 to 100,000 miles, or sooner if you notice any leaks.

- Can I drive with an oil cooler seal leak?

- Driving with a leak can cause significant engine damage due to low oil levels. It’s best to address the leak as soon as possible.

- Are OEM oil cooler seals better than aftermarket?

- OEM seals are typically of higher quality and offer a better fit and longer lifespan compared to aftermarket options.

- How much does it cost to replace oil cooler seals?

- The cost can vary, but typically ranges from $300 to $600, depending on labor rates and parts costs.

- What is the purpose of the oil cooler?

- The oil cooler helps regulate engine oil temperature, preventing it from overheating and maintaining optimal lubrication.

- How do I check my engine oil level?

- Use the dipstick located in the engine bay to check the oil level. Ensure the level is between the minimum and maximum marks.

- What type of oil should I use in my M272/M273 engine?

- Refer to your vehicle’s owner’s manual for the recommended oil type and viscosity.

- Can an oil leak cause my engine to overheat?

- Yes, an oil leak can lead to overheating due to reduced oil levels and decreased cooling efficiency.

- Where is the oil cooler located in my Mercedes-Benz?

- The oil cooler is typically located near the oil filter housing, on the front or side of the engine block.