Replacing the secondary air injection check valve can seem daunting, but it’s a manageable task with the right guidance. At DTS-MONACO.EDU.VN, we offer expert insights and training to simplify complex automotive repairs like this one, ensuring you can confidently tackle the job. Learn how to replace secondary air injection, air injection system maintenance, and automotive repair tips with our comprehensive resources.

Contents

- 1. What is the Secondary Air Injection (SAI) System?

- 2. What is the Function of the Secondary Air Injection Check Valve?

- 3. What are the Symptoms of a Failing Secondary Air Injection Check Valve?

- 4. What are the Common Causes of Secondary Air Injection Check Valve Failure?

- 5. Can I Drive with a Faulty Secondary Air Injection Check Valve?

- 6. How to Diagnose a Secondary Air Injection Check Valve?

- 7. What Tools and Materials Do I Need to Replace the Secondary Air Injection Check Valve?

- 8. Step-by-Step Guide: How to Replace the Secondary Air Injection Check Valve?

- 9. What are the Benefits of Replacing the Secondary Air Injection Check Valve?

- 10. How Much Does It Cost to Replace the Secondary Air Injection Check Valve?

- 11. Can I Replace the Secondary Air Injection Check Valve Myself, or Should I Hire a Professional?

- 12. How Often Should the Secondary Air Injection Check Valve Be Replaced?

- 13. What are the Different Types of Secondary Air Injection Check Valves?

- 14. Are There Any Aftermarket Upgrades Available for the Secondary Air Injection System?

- 15. How Does the Secondary Air Injection System Impact My Vehicle’s Emissions?

- 16. What Diagnostic Trouble Codes (DTCs) are Associated with the Secondary Air Injection System?

- 17. How Does Temperature Affect the Secondary Air Injection System?

- 18. What Maintenance Tasks Should I Perform to Keep the Secondary Air Injection System in Good Condition?

- 19. How to Reset the Secondary Air Injection System After Replacement?

- 20. Where Can I Find More Information and Training on Automotive Repair and Diagnostics?

- FAQ: Secondary Air Injection Check Valve

- 1. What happens if the secondary air injection check valve fails?

- 2. How do I know if my secondary air injection check valve is bad?

- 3. Can I clean the secondary air injection check valve instead of replacing it?

- 4. Is it difficult to replace the secondary air injection check valve?

- 5. How long does it take to replace the secondary air injection check valve?

- 6. What is the purpose of the secondary air injection system?

- 7. How much does a new secondary air injection check valve cost?

- 8. Can a bad secondary air injection check valve affect fuel economy?

- 9. What tools do I need to replace the secondary air injection check valve?

- 10. How do I reset the Check Engine Light after replacing the secondary air injection check valve?

- Enhance Your Automotive Skills with DTS-MONACO.EDU.VN

1. What is the Secondary Air Injection (SAI) System?

The secondary air injection (SAI) system is an emissions control system designed to reduce hydrocarbon and carbon monoxide emissions during cold starts. It works by pumping fresh air into the exhaust system to help burn uncombusted fuel.

The secondary air injection system is an important component in reducing emissions during the initial startup phase of an engine, when it runs rich to ensure proper combustion. According to the Environmental Protection Agency (EPA), effective emissions control systems are crucial for meeting air quality standards and reducing the environmental impact of vehicles. Proper maintenance and repair of systems like the SAI are essential for maintaining environmental compliance and optimal vehicle performance.

2. What is the Function of the Secondary Air Injection Check Valve?

The secondary air injection check valve prevents exhaust gases from flowing back into the air pump and damaging it. This valve ensures that air flows in only one direction, which is from the air pump to the exhaust manifold.

The check valve is a critical component that ensures the SAI system operates efficiently. Its function is backed by engineering principles to prevent backflow, which could severely damage other components. According to a study by the Society of Automotive Engineers (SAE), check valves in emission control systems must meet stringent durability and performance standards to ensure long-term reliability. Understanding this function is vital for anyone looking to maintain or repair their vehicle’s emission system, making it a key topic in automotive training and education at institutions like DTS-MONACO.EDU.VN.

3. What are the Symptoms of a Failing Secondary Air Injection Check Valve?

A failing secondary air injection check valve can cause several symptoms:

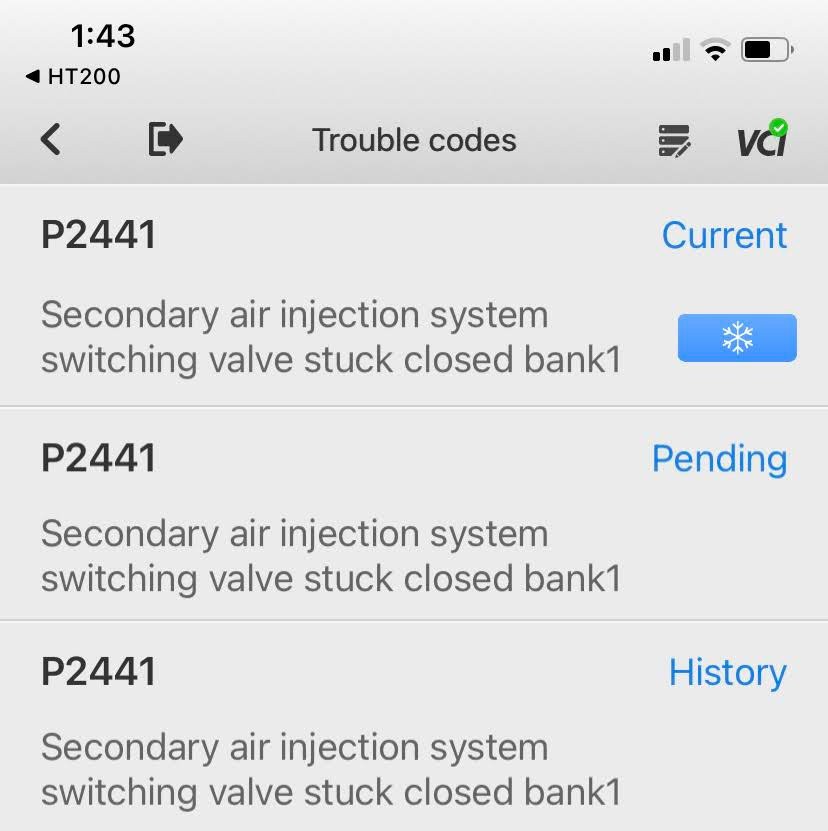

- Check Engine Light: This is often the first sign, with codes like P0410, P0412, or P2441.

- Rough Engine Start: The engine may struggle to start or run roughly during the initial cold start.

- Poor Fuel Economy: The engine may consume more fuel than usual.

- Failed Emissions Test: The vehicle may fail an emissions test due to increased emissions.

- Unusual Noises: You may hear unusual noises from the air pump, such as whining or rattling.

These symptoms can indicate that the valve is either stuck open or closed, disrupting the SAI system’s operation. A faulty valve can lead to increased emissions and potential damage to other components. The presence of a Check Engine Light, especially with the aforementioned codes, should prompt a diagnostic check of the SAI system. Ignoring these symptoms can lead to more severe issues and costly repairs, highlighting the importance of addressing them promptly. Regular diagnostic checks, especially when these symptoms arise, are essential for maintaining vehicle health.

4. What are the Common Causes of Secondary Air Injection Check Valve Failure?

Several factors can lead to the failure of the secondary air injection check valve:

- Moisture Intrusion: Water can enter the valve, causing corrosion and eventual failure.

- Debris: Debris from the exhaust system can clog the valve, preventing it from closing properly.

- Age and Wear: Over time, the valve can wear out due to normal use.

- Exhaust Back Pressure: High exhaust back pressure can damage the valve.

Moisture intrusion is a common culprit, particularly in regions with high humidity or frequent temperature changes. Debris accumulation can occur due to the valve’s proximity to the exhaust system. Age and wear are inevitable, but regular maintenance can extend the valve’s lifespan. Excessive exhaust back pressure, often caused by exhaust system restrictions, can accelerate wear and tear. Understanding these causes is crucial for preventing failures and maintaining the SAI system’s health. Regular inspections and timely replacements can mitigate these issues, ensuring the system operates efficiently and prolonging the life of the check valve.

5. Can I Drive with a Faulty Secondary Air Injection Check Valve?

Driving with a faulty secondary air injection check valve is not recommended. While the vehicle may still be drivable, it can lead to:

- Increased Emissions: The vehicle will emit higher levels of pollutants.

- Damage to Air Pump: Exhaust gases can damage the air pump, leading to costly repairs.

- Poor Engine Performance: The engine may experience rough starts and poor fuel economy.

- Potential for Further Damage: Other components of the SAI system could be affected.

Continuing to drive with a faulty valve can exacerbate the problem and potentially cause more extensive damage. The increased emissions contribute to environmental pollution, and the risk of damaging the air pump can lead to significant repair costs. The engine’s performance can also suffer, resulting in a less efficient and less enjoyable driving experience. Addressing the issue promptly can prevent these negative consequences and maintain the vehicle’s overall health and performance. It’s best to have the valve replaced as soon as possible to avoid further complications.

6. How to Diagnose a Secondary Air Injection Check Valve?

Diagnosing a secondary air injection check valve involves several steps:

- Visual Inspection: Check the valve for any visible signs of damage or corrosion.

- OBD2 Scanner: Use an OBD2 scanner to check for diagnostic trouble codes (DTCs) related to the SAI system.

- Vacuum Test: Use a vacuum gauge to test the valve’s ability to hold vacuum.

- Air Pump Test: Check the air pump for proper operation.

- Resistance Test: Use a multimeter to check the valve’s electrical resistance.

A visual inspection can often reveal obvious issues, such as cracks or corrosion. An OBD2 scanner provides valuable information through DTCs, guiding further diagnostics. A vacuum test assesses the valve’s sealing capability, while an air pump test ensures the pump is functioning correctly. A resistance test checks the electrical components of the valve. Combining these methods provides a comprehensive assessment of the valve’s condition, enabling accurate diagnosis and appropriate repairs.

7. What Tools and Materials Do I Need to Replace the Secondary Air Injection Check Valve?

To replace the secondary air injection check valve, you will need:

- New Secondary Air Injection Check Valve: Ensure it is compatible with your vehicle.

- Socket Set: For removing and installing bolts and nuts.

- Wrench Set: For tightening and loosening fasteners.

- Screwdrivers: Both flathead and Phillips head.

- OBD2 Scanner: To clear any diagnostic trouble codes after the replacement.

- Vacuum Gauge: For testing the new valve.

- Multimeter: For electrical testing.

- Safety Glasses: To protect your eyes.

- Gloves: To protect your hands.

Having the right tools and materials on hand is essential for a smooth and successful replacement. A compatible new valve ensures proper fit and function. Socket and wrench sets are necessary for removing and installing fasteners. Screwdrivers assist with various tasks, while an OBD2 scanner helps clear any stored codes. A vacuum gauge and multimeter are useful for testing the new valve’s performance. Safety glasses and gloves protect you from potential hazards during the process.

8. Step-by-Step Guide: How to Replace the Secondary Air Injection Check Valve?

Here’s a step-by-step guide on how to replace the secondary air injection check valve:

- Preparation:

- Gather all necessary tools and materials.

- Park the vehicle on a level surface and turn off the engine.

- Disconnect the negative battery terminal.

- Locate the Secondary Air Injection Check Valve:

- Refer to your vehicle’s service manual to find the valve’s location. It is typically located near the air pump or exhaust manifold.

- Remove the Old Valve:

- Disconnect any electrical connectors or hoses attached to the valve.

- Use a socket or wrench to remove the bolts or nuts holding the valve in place.

- Carefully remove the old valve.

- Install the New Valve:

- Ensure the mounting surface is clean.

- Position the new valve in place and secure it with the bolts or nuts.

- Tighten the fasteners to the manufacturer’s specified torque.

- Reconnect any electrical connectors or hoses.

- Testing:

- Reconnect the negative battery terminal.

- Start the engine and check for any leaks or unusual noises.

- Use an OBD2 scanner to clear any diagnostic trouble codes.

- Perform a vacuum test to ensure the valve is functioning correctly.

- Final Inspection:

- Verify that all connections are secure and that the valve is properly installed.

- Take the vehicle for a test drive to ensure everything is working as expected.

Following these steps carefully will help ensure a successful replacement. Preparation is key, so make sure to have everything ready before you begin. Refer to your vehicle’s service manual for specific instructions and torque specifications. Cleaning the mounting surface ensures a good seal, and proper tightening of fasteners prevents leaks. Testing the new valve is essential to verify its functionality. A final inspection ensures everything is secure and working correctly.

9. What are the Benefits of Replacing the Secondary Air Injection Check Valve?

Replacing the secondary air injection check valve offers several benefits:

- Reduced Emissions: The vehicle will emit lower levels of pollutants, helping it pass emissions tests.

- Improved Engine Performance: The engine will start more smoothly and run more efficiently.

- Prevention of Further Damage: Replacing the valve can prevent damage to the air pump and other components.

- Better Fuel Economy: The engine will consume less fuel, saving you money.

- Compliance with Regulations: Ensuring the SAI system is functioning correctly helps comply with environmental regulations.

These benefits make replacing the valve a worthwhile investment. Reduced emissions contribute to cleaner air, while improved engine performance enhances the driving experience. Preventing further damage can save you from costly repairs down the road. Better fuel economy translates to savings at the pump, and compliance with regulations avoids potential fines.

10. How Much Does It Cost to Replace the Secondary Air Injection Check Valve?

The cost to replace the secondary air injection check valve can vary depending on several factors:

- Valve Cost: The cost of the valve itself can range from $50 to $300, depending on the vehicle make and model.

- Labor Cost: If you choose to have a professional mechanic replace the valve, labor costs can range from $100 to $500, depending on the shop’s hourly rate and the complexity of the job.

- Additional Parts: You may need to replace other parts, such as hoses or gaskets, which can add to the overall cost.

Overall, the total cost can range from $150 to $800. Doing the job yourself can save on labor costs, but it requires the right tools and knowledge. Getting quotes from multiple mechanics can help you find the best price if you opt for professional installation.

11. Can I Replace the Secondary Air Injection Check Valve Myself, or Should I Hire a Professional?

Whether you should replace the secondary air injection check valve yourself or hire a professional depends on your mechanical skills and experience:

- DIY: If you have experience working on cars and are comfortable using tools, you may be able to replace the valve yourself. Follow the steps outlined in this guide and consult your vehicle’s service manual.

- Professional: If you are not comfortable working on cars or lack the necessary tools, it is best to hire a professional mechanic. They have the expertise and equipment to do the job correctly.

If you choose the DIY route, be sure to prioritize safety and take your time. If you opt for professional installation, research local mechanics and read reviews to find a reputable shop.

12. How Often Should the Secondary Air Injection Check Valve Be Replaced?

The secondary air injection check valve should be replaced when it fails or shows signs of wear. There is no specific replacement interval, but regular inspections can help identify potential issues.

Check the valve during routine maintenance, such as oil changes or tune-ups. Look for signs of corrosion, damage, or leaks. If you notice any issues, replace the valve promptly to prevent further damage and maintain the SAI system’s efficiency.

13. What are the Different Types of Secondary Air Injection Check Valves?

There are several types of secondary air injection check valves:

- Mechanical Check Valves: These valves use a spring-loaded poppet to control airflow.

- Electrical Check Valves: These valves use an electric solenoid to control airflow.

- Combination Valves: These valves combine mechanical and electrical components.

The type of valve used in your vehicle depends on the make, model, and year. Refer to your vehicle’s service manual or consult a professional mechanic to determine the correct type of valve for your vehicle.

14. Are There Any Aftermarket Upgrades Available for the Secondary Air Injection System?

Yes, there are aftermarket upgrades available for the secondary air injection system:

- Bypass Kits: These kits allow you to bypass the SAI system completely, which can be useful for off-road vehicles or vehicles used in racing applications.

- Performance Valves: These valves are designed to improve airflow and enhance the performance of the SAI system.

Before installing any aftermarket upgrades, be sure to check local regulations to ensure they are legal in your area. Also, consider the potential impact on your vehicle’s emissions and performance.

15. How Does the Secondary Air Injection System Impact My Vehicle’s Emissions?

The secondary air injection system plays a crucial role in reducing your vehicle’s emissions:

- Reduces Hydrocarbons: The SAI system helps burn uncombusted hydrocarbons during cold starts.

- Reduces Carbon Monoxide: The SAI system helps convert carbon monoxide into carbon dioxide.

- Improves Catalytic Converter Efficiency: By reducing emissions, the SAI system helps the catalytic converter function more efficiently.

By ensuring the SAI system is functioning correctly, you can help reduce your vehicle’s environmental impact and comply with emissions regulations.

16. What Diagnostic Trouble Codes (DTCs) are Associated with the Secondary Air Injection System?

Several diagnostic trouble codes (DTCs) are associated with the secondary air injection system:

- P0410: Secondary Air Injection System Malfunction

- P0411: Secondary Air Injection System Incorrect Flow Detected

- P0412: Secondary Air Injection System Switching Valve A Circuit Malfunction

- P0413: Secondary Air Injection System Switching Valve A Circuit Open

- P0414: Secondary Air Injection System Switching Valve A Circuit Shorted

- P0415: Secondary Air Injection System Switching Valve B Circuit Malfunction

- P0416: Secondary Air Injection System Switching Valve B Circuit Open

- P0417: Secondary Air Injection System Switching Valve B Circuit Shorted

- P2440: Secondary Air Injection System Switching Valve Stuck Open Bank 1

- P2441: Secondary Air Injection System Switching Valve Stuck Closed Bank 1

- P2442: Secondary Air Injection System Switching Valve Stuck Open Bank 2

- P2443: Secondary Air Injection System Switching Valve Stuck Closed Bank 2

These codes can help you diagnose specific issues with the SAI system. Use an OBD2 scanner to retrieve the codes and consult your vehicle’s service manual for troubleshooting steps.

17. How Does Temperature Affect the Secondary Air Injection System?

Temperature can affect the secondary air injection system in several ways:

- Cold Starts: The SAI system is most active during cold starts when the engine is running rich.

- Extreme Temperatures: Extreme temperatures can affect the performance of the valve and other components.

- Moisture: Temperature fluctuations can lead to moisture buildup in the valve, causing corrosion and failure.

To mitigate these effects, ensure the valve is properly sealed and protected from the elements. Regular inspections can help identify potential issues caused by temperature fluctuations.

18. What Maintenance Tasks Should I Perform to Keep the Secondary Air Injection System in Good Condition?

To keep the secondary air injection system in good condition, perform the following maintenance tasks:

- Regular Inspections: Check the valve, hoses, and air pump for any signs of damage or wear.

- Clean the Valve: Periodically clean the valve to remove any debris or corrosion.

- Replace Air Filter: Replace the air filter regularly to prevent debris from entering the SAI system.

- Check Electrical Connections: Ensure all electrical connections are secure and free from corrosion.

Performing these maintenance tasks can help extend the life of the SAI system and prevent costly repairs.

19. How to Reset the Secondary Air Injection System After Replacement?

After replacing the secondary air injection check valve, you may need to reset the system:

- Clear Diagnostic Trouble Codes: Use an OBD2 scanner to clear any diagnostic trouble codes (DTCs) related to the SAI system.

- Perform a Reset Procedure: Some vehicles require a specific reset procedure to recalibrate the SAI system. Consult your vehicle’s service manual for instructions.

- Test the System: After resetting the system, test it to ensure it is functioning correctly.

Resetting the system ensures that the vehicle’s computer recognizes the new valve and that the SAI system is operating properly.

20. Where Can I Find More Information and Training on Automotive Repair and Diagnostics?

You can find more information and training on automotive repair and diagnostics at DTS-MONACO.EDU.VN. We offer comprehensive resources, including:

- Detailed Guides: Step-by-step guides on various automotive repair topics.

- Training Courses: Hands-on training courses on automotive diagnostics and repair.

- Online Resources: Articles, videos, and forums where you can learn from experts and other enthusiasts.

At DTS-MONACO.EDU.VN, we are dedicated to providing the highest quality automotive education and resources. Visit our website to learn more and start your journey to becoming a skilled automotive technician. Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880. Website: DTS-MONACO.EDU.VN.

FAQ: Secondary Air Injection Check Valve

1. What happens if the secondary air injection check valve fails?

If the secondary air injection check valve fails, it can lead to increased emissions, damage to the air pump, poor engine performance, and potential failure of emissions tests.

2. How do I know if my secondary air injection check valve is bad?

Symptoms of a bad secondary air injection check valve include a Check Engine Light, rough engine start, poor fuel economy, failed emissions test, and unusual noises from the air pump.

3. Can I clean the secondary air injection check valve instead of replacing it?

Cleaning the secondary air injection check valve may temporarily resolve the issue, but it is generally recommended to replace it for a more reliable and long-term solution.

4. Is it difficult to replace the secondary air injection check valve?

The difficulty of replacing the secondary air injection check valve depends on your mechanical skills and experience. If you are comfortable working on cars and have the necessary tools, you may be able to do it yourself. Otherwise, it is best to hire a professional mechanic.

5. How long does it take to replace the secondary air injection check valve?

Replacing the secondary air injection check valve can take anywhere from 1 to 3 hours, depending on the vehicle and the mechanic’s experience.

6. What is the purpose of the secondary air injection system?

The purpose of the secondary air injection system is to reduce hydrocarbon and carbon monoxide emissions during cold starts by pumping fresh air into the exhaust system to help burn uncombusted fuel.

7. How much does a new secondary air injection check valve cost?

The cost of a new secondary air injection check valve can range from $50 to $300, depending on the vehicle make and model.

8. Can a bad secondary air injection check valve affect fuel economy?

Yes, a bad secondary air injection check valve can affect fuel economy by causing the engine to run less efficiently.

9. What tools do I need to replace the secondary air injection check valve?

To replace the secondary air injection check valve, you will need a socket set, wrench set, screwdrivers, OBD2 scanner, vacuum gauge, multimeter, safety glasses, and gloves.

10. How do I reset the Check Engine Light after replacing the secondary air injection check valve?

After replacing the secondary air injection check valve, use an OBD2 scanner to clear any diagnostic trouble codes (DTCs) related to the SAI system.

Enhance Your Automotive Skills with DTS-MONACO.EDU.VN

Ready to take your automotive repair skills to the next level? At DTS-MONACO.EDU.VN, we provide the training and resources you need to master complex tasks like replacing the secondary air injection check valve. Explore our comprehensive guides, hands-on training courses, and expert support to confidently tackle any automotive challenge.

Don’t let complicated repairs hold you back. Visit DTS-MONACO.EDU.VN today to discover how our expert training can transform your automotive career. Whether you’re a seasoned mechanic or just starting out, we have the tools and knowledge to help you succeed. Contact us now to learn more about our training programs and unlock your full potential in automotive repair and diagnostics. Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880. Website: DTS-MONACO.EDU.VN.

Secondary Air Injection Check Valve

Dorman 911-643 Secondary Air Injection Check Valve

Air Intake Manifold

Wiring Harness Clips

Wiring Harness Clip Tab

Throttle Body

Air Intake Manifold Removed

Engine After Manifold Removal

Secondary Air Intake Valves

Old Secondary Air Injection Valves

Disassembled Secondary Air Injection Valve