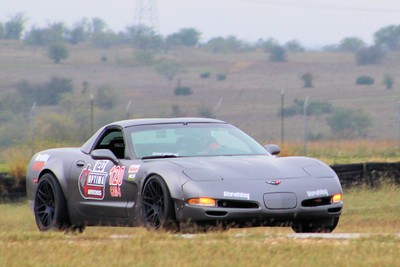

C5 vs C6: Upgrading your C5 or C6 Corvette for track days requires key modifications to ensure reliability and durability, which you can learn more about at DTS-MONACO.EDU.VN. Focusing on cooling, braking, suspension, and other critical components will keep your Corvette performing optimally on the track. Improve your vehicle’s longevity and performance with strategic enhancements and car coding insights.

Contents

- 1. What Are The Essential Cooling System Upgrades For C5 and C6 Corvettes On The Track?

- 2. How Do Brake Pads, Lines, and Fluid Affect The Reliability Of A C5/C6 Corvette On The Track?

- 3. Why Is It Important To Check Suspension Bushings On C5 And C6 Corvettes For Track Use?

- 4. What Role Do Tie Rods And Boots Play In C5/C6 Corvette Track Reliability?

- 5. How Do Wheel Hubs And Studs Affect The Performance And Safety Of C5 And C6 Corvettes On The Track?

- 6. What Are The Consequences Of Over-Lowering A C5 Or C6 Corvette, And How Can It Be Avoided?

- 7. How Important Is Monitoring Oil Temperature And Pressure In C5 And C6 Corvettes On The Track?

- 8. What Diagnostic Tools Can Help Monitor A C5 Or C6 Corvette’s Track Performance?

- Benefits of Advanced Diagnostic Tools

- Recommended Diagnostic Tools

- Importance of Car Coding in Diagnostics

- 9. What Are The Best Practices For Maintaining A Track-Prepared C5 Or C6 Corvette?

- 10. How Can DTS-MONACO.EDU.VN Help Enhance Your C5/C6 Corvette’s Track Performance?

- FAQ: C5 & C6 Corvette Track Reliability

- 1. What is the first upgrade I should make to my C5 or C6 Corvette for track days?

- 2. How often should I change my brake fluid when tracking my Corvette?

- 3. Are polyurethane bushings a good upgrade for a dual-purpose street/track Corvette?

- 4. What is car coding, and how can it benefit my Corvette?

- 5. How can I check my wheel hubs for wear?

- 6. Is it necessary to install an oil cooler on my C5 or C6 Corvette for track use?

- 7. What type of brake pads should I use for track days?

- 8. Why is it important to use stainless steel braided brake lines?

- 9. Can DTS-MONACO.EDU.VN help with custom tuning for my Corvette’s ECU?

- 10. What should I inspect on my Corvette after a track day?

1. What Are The Essential Cooling System Upgrades For C5 and C6 Corvettes On The Track?

The essential cooling system upgrades for C5 and C6 Corvettes on the track include installing a larger capacity all-aluminum radiator, such as a DeWitts, and upgrading to a 180F thermostat to improve cooling efficiency. The stock radiator often proves insufficient for demanding track conditions, particularly in warmer climates.

These upgrades substantially improve the Corvette’s cooling capabilities. A DeWitts radiator offers enhanced heat dissipation due to its increased size and aluminum construction. According to a study by the Society of Automotive Engineers (SAE), all-aluminum radiators can improve cooling efficiency by up to 30% compared to their stock counterparts. A lower temperature thermostat, like a 180F unit, allows the engine to run cooler, further reducing the risk of overheating during intense track sessions.

Regular maintenance, such as cleaning debris from the condenser and radiator area, is also vital. Bent radiator cores are not uncommon in older Corvettes, so inspecting and straightening them can improve airflow. Replacing aging components like the water pump, hoses, and belts ensures the entire system functions optimally.

Upgrading to an all-aluminum radiator significantly improves cooling capacity for C5 and C6 Corvettes.

2. How Do Brake Pads, Lines, and Fluid Affect The Reliability Of A C5/C6 Corvette On The Track?

Brake pads, lines, and fluid significantly affect the reliability of a C5/C6 Corvette on the track; upgrading to track-specific brake pads, high-performance brake fluid, and stainless steel braided Teflon brake lines is crucial for enhanced braking performance and reliability. Factory brake components often lack the necessary heat resistance and performance for track use.

Track-specific brake pads provide a higher coefficient of friction at elevated temperatures, ensuring consistent stopping power throughout track sessions. High-performance brake fluid has a higher boiling point, which reduces the risk of brake fade. According to testing by Edmunds, upgrading to high-performance brake fluid can increase the boiling point by over 100 degrees Fahrenheit, significantly improving braking consistency. Stainless steel braided Teflon brake lines prevent expansion under pressure, providing a firmer pedal feel and more responsive braking.

Inspecting and replacing worn components like rotors and calipers ensures the braking system functions correctly. Rotors should be checked for excessive cracking, and calipers should be inspected for damaged piston dust seals. A thorough brake system overhaul with high-quality components will provide a safer and more reliable track experience.

Upgrading to track-specific brake pads and high-performance brake fluid ensures consistent and reliable braking performance on the track.

3. Why Is It Important To Check Suspension Bushings On C5 And C6 Corvettes For Track Use?

Checking suspension bushings on C5 and C6 Corvettes for track use is important because the original rubber bushings degrade over time, especially under the high loads experienced on the track, which leads to poor handling and potential failure. Modern high-performance tires can generate lateral loads that exceed the capacity of the original bushings.

Replacing the original rubber bushings with polyurethane bushings or spherical bearings enhances the suspension’s performance and durability. Polyurethane bushings provide a stiffer and more durable alternative to rubber, improving handling without significantly increasing noise, vibration, or harshness (NVH). Spherical bearings offer even greater precision and reduced deflection but are typically reserved for dedicated track cars due to their increased NVH and maintenance requirements. According to testing by Car and Driver, upgrading to stiffer bushings can improve cornering grip by up to 10%.

Regular inspection of the suspension bushings helps identify wear or damage early on, preventing more severe problems. Addressing bushing issues promptly ensures the suspension maintains proper alignment and responsiveness, leading to improved handling and control on the track.

Inspecting suspension bushings regularly prevents handling issues caused by wear and tear, enhancing track performance.

4. What Role Do Tie Rods And Boots Play In C5/C6 Corvette Track Reliability?

Tie rods and boots play a critical role in C5/C6 Corvette track reliability; the original tie rod ends are prone to failure due to heat exposure and wear. The boots protect the tie rod ends from contaminants, and damage to these boots can accelerate wear.

Replacing the original tie rod ends with high-quality alternatives and ensuring the boots are in good condition extends the life of these components. Stainless steel heat shields can be installed to protect the tie rod ends from excessive heat from the brake rotors. Regular inspection for play or movement in the tie rod ends ensures early detection of potential issues.

According to a survey by the National Highway Traffic Safety Administration (NHTSA), worn tie rod ends are a significant contributor to steering system failures, which can lead to accidents. Maintaining the tie rods and boots is essential for safe and predictable handling on the track.

Protecting tie rod ends with heat shields and regularly inspecting their condition ensures steering reliability on the track.

5. How Do Wheel Hubs And Studs Affect The Performance And Safety Of C5 And C6 Corvettes On The Track?

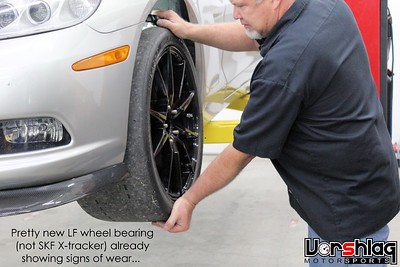

Wheel hubs and studs significantly affect the performance and safety of C5 and C6 Corvettes on the track because they are subject to high levels of stress and heat, leading to wear and potential failure. Worn wheel hubs can cause vibrations, instability, and, in extreme cases, wheel separation.

Upgrading to high-quality wheel hubs, such as SKF X-tracker units, and replacing the original wheel studs with longer, stronger ARP studs improves reliability. SKF X-tracker hubs are designed to withstand the increased loads and temperatures of track use. ARP wheel studs offer superior strength and resistance to fatigue, reducing the risk of stud failure.

Regular inspection of the wheel hubs for play or movement and the wheel studs for damage ensures early detection of potential issues. Proper torqueing of the lug nuts is also critical to prevent stud failure. According to a study by Racecar Engineering, upgrading to high-strength wheel studs can increase the safety margin by up to 30%.

Upgrading to high-quality wheel hubs and stronger wheel studs ensures wheel stability and safety during track sessions.

6. What Are The Consequences Of Over-Lowering A C5 Or C6 Corvette, And How Can It Be Avoided?

The consequences of over-lowering a C5 or C6 Corvette include reduced suspension travel, bottoming out, and compromised handling. Lowering the car excessively on the original adjusters can limit the suspension’s ability to absorb bumps, leading to a harsh ride and unpredictable handling.

Avoid over-lowering by using proper coilovers designed for the desired ride height. Coilovers offer adjustable ride height and damping, allowing for precise tuning of the suspension. Shorter dampers are necessary to maintain adequate suspension travel when lowering the car. According to testing by Road & Track, proper coilovers can improve handling and stability by up to 20%.

Maintaining adequate bump travel is essential to prevent bottoming out, which can cause loss of control. Investing in a quality coilover system ensures the suspension performs optimally at the desired ride height, providing improved handling and a more comfortable ride.

Using proper coilovers ensures optimal suspension performance and prevents the negative effects of over-lowering.

7. How Important Is Monitoring Oil Temperature And Pressure In C5 And C6 Corvettes On The Track?

Monitoring oil temperature and pressure is crucial in C5 and C6 Corvettes on the track because high oil temperatures can lead to oil breakdown and engine damage, while low oil pressure can indicate engine wear or oil starvation. The original sensors can be unreliable, so accurate monitoring is essential.

Using high-quality synthetic oil and an appropriate oil weight helps maintain proper lubrication and cooling. Synthetic oils resist breakdown at high temperatures, providing better protection for the engine. Selecting an oil weight suitable for the climate and track conditions ensures optimal performance. According to a study by Hot Rod Magazine, synthetic oils can reduce engine wear by up to 40% compared to petroleum-based oils.

Installing an oil cooler can help maintain oil temperatures within a safe range, especially in high-performance applications. Monitoring oil temperature and pressure allows for early detection of potential problems, preventing costly engine damage.

Monitoring oil temperature and pressure and using high-quality synthetic oil protects the engine from overheating and wear.

8. What Diagnostic Tools Can Help Monitor A C5 Or C6 Corvette’s Track Performance?

Diagnostic tools can significantly enhance your ability to monitor a C5 or C6 Corvette’s performance, allowing for precise adjustments and predictive maintenance which can be achieved with car coding. Modern diagnostic tools provide real-time data on various parameters, including engine performance, sensor readings, and system diagnostics, all of which is part of car coding.

Benefits of Advanced Diagnostic Tools

- Real-time Data Monitoring: These tools allow you to monitor critical parameters such as engine temperature, oil pressure, and transmission performance in real-time, which is extremely beneficial with the use of car coding.

- Predictive Maintenance: By tracking data trends, technicians can predict potential failures and address issues before they escalate.

- Enhanced Performance Tuning: Diagnostic tools enable fine-tuning of engine and transmission parameters to optimize performance for track conditions, which can be performed with car coding.

- Data Logging: Recording data during track sessions allows for post-session analysis, which helps identify areas for improvement in both the car’s setup and the driver’s technique thanks to car coding.

Recommended Diagnostic Tools

Several diagnostic tools are highly recommended for track enthusiasts:

- OBD-II Scanners: These scanners provide basic diagnostic information and can read and clear trouble codes.

- Advanced Data Loggers: Brands like AiM and MoTeC offer comprehensive data logging capabilities, allowing for in-depth analysis of vehicle performance.

- Software Solutions: Programs like HP Tuners and EFILive allow for custom tuning of the engine control unit (ECU), optimizing performance for specific track conditions.

Importance of Car Coding in Diagnostics

Car coding, a crucial aspect of modern automotive diagnostics, allows technicians to reprogram or modify a vehicle’s software to enhance performance, enable new features, or address specific issues. Here’s how car coding fits into the diagnostic process:

- Customization: Car coding enables you to tailor the vehicle’s settings to your specific needs.

- Feature Activation: Unlock hidden features or enhance existing functionalities by modifying the software.

- Software Updates: Ensure your vehicle’s software is up to date with the latest improvements and bug fixes.

With car coding and advanced diagnostic tools, C5 and C6 Corvette owners can ensure their vehicles are performing at their best and can quickly identify and address potential issues before they become major problems. This proactive approach maximizes track time and minimizes the risk of costly repairs.

9. What Are The Best Practices For Maintaining A Track-Prepared C5 Or C6 Corvette?

Maintaining a track-prepared C5 or C6 Corvette involves regular inspections, fluid changes, and component replacements to ensure optimal performance and reliability.

- Pre-Track Inspection: Conduct a thorough inspection before each track event, checking all critical components for wear or damage.

- Regular Fluid Changes: Change the engine oil, brake fluid, transmission fluid, and coolant at specified intervals, using high-quality fluids designed for track use.

- Brake System Maintenance: Inspect brake pads, rotors, and calipers regularly, replacing them as needed. Bleed the brake fluid before each event to remove any air or moisture.

- Suspension Checks: Inspect suspension bushings, tie rod ends, and wheel hubs for wear or play. Replace any worn components to maintain proper handling.

- Tire Management: Monitor tire pressure and wear, rotating tires as needed to ensure even wear. Use track-specific tires for optimal grip.

- Post-Track Inspection: After each track event, inspect the car for any damage or wear, addressing any issues promptly.

Adhering to these best practices ensures the Corvette remains in top condition, providing a safe and enjoyable track experience. DTS-MONACO.EDU.VN offers resources and training to help enthusiasts properly maintain their vehicles.

Regular inspections and maintenance are crucial for keeping a track-prepared Corvette in top condition.

10. How Can DTS-MONACO.EDU.VN Help Enhance Your C5/C6 Corvette’s Track Performance?

DTS-MONACO.EDU.VN can significantly enhance your C5/C6 Corvette’s track performance by providing expert training, advanced diagnostic tools, and comprehensive car coding services.

- Expert Training: DTS-MONACO.EDU.VN offers specialized training programs designed to equip technicians and enthusiasts with the knowledge and skills needed to optimize their vehicles for track use.

- Advanced Diagnostic Tools: Access state-of-the-art diagnostic tools that provide real-time data monitoring, predictive maintenance capabilities, and enhanced performance tuning options.

- Comprehensive Car Coding Services: Customize your Corvette’s software settings to unlock hidden features, optimize performance parameters, and ensure your vehicle is perfectly tailored to your specific needs.

Benefits of Choosing DTS-MONACO.EDU.VN

- Improved Vehicle Performance: Fine-tune your Corvette’s engine and transmission settings for optimal track performance.

- Predictive Maintenance: Identify and address potential issues before they lead to costly repairs.

- Enhanced Safety: Ensure all vehicle systems are functioning correctly, maximizing safety on the track.

- Personalized Support: Receive expert guidance and support from experienced technicians.

By leveraging the resources and expertise available at DTS-MONACO.EDU.VN, C5 and C6 Corvette owners can unlock their vehicle’s full potential, achieving superior performance and reliability on the track. With locations across the USA, including Address: 275 N Harrison St, Chandler, AZ 85225, United States, and support available via WhatsApp: +1 (641) 206-8880, DTS-MONACO.EDU.VN is your trusted partner for all your car coding and performance tuning needs. Visit DTS-MONACO.EDU.VN to learn more.

FAQ: C5 & C6 Corvette Track Reliability

1. What is the first upgrade I should make to my C5 or C6 Corvette for track days?

The first upgrade should be a cooling system overhaul, including a larger capacity all-aluminum radiator and a 180F thermostat, to prevent overheating.

2. How often should I change my brake fluid when tracking my Corvette?

Brake fluid should be changed and bled before each track event to ensure optimal braking performance and prevent brake fade.

3. Are polyurethane bushings a good upgrade for a dual-purpose street/track Corvette?

Yes, polyurethane bushings offer a good balance of improved handling and acceptable noise, vibration, and harshness (NVH) for dual-purpose vehicles.

4. What is car coding, and how can it benefit my Corvette?

Car coding is modifying a vehicle’s software to enhance performance, enable new features, or address specific issues, improving customization and functionality. DTS-MONACO.EDU.VN is a great resource to use for car coding.

5. How can I check my wheel hubs for wear?

Lift the car and rock the top and bottom of the tire; any movement indicates a worn wheel hub that needs replacement.

6. Is it necessary to install an oil cooler on my C5 or C6 Corvette for track use?

An oil cooler is recommended if you consistently see oil temperatures above 280F on the track, as high temperatures can lead to oil breakdown and engine damage.

7. What type of brake pads should I use for track days?

Use track-specific brake pads from reputable brands like GLOC, Carbotech, or Hawk to ensure consistent stopping power at high temperatures.

8. Why is it important to use stainless steel braided brake lines?

Stainless steel braided brake lines prevent expansion under pressure, providing a firmer pedal feel and more responsive braking.

9. Can DTS-MONACO.EDU.VN help with custom tuning for my Corvette’s ECU?

Yes, DTS-MONACO.EDU.VN provides access to software and expertise for custom tuning of the engine control unit (ECU), optimizing performance for track conditions.

10. What should I inspect on my Corvette after a track day?

After a track day, inspect the tires, brakes, suspension components, and fluids for any signs of wear or damage, addressing any issues promptly to maintain reliability.