Yes, ECOM can be used to diagnose issues with fuel pre-supply modules. At DTS-MONACO.EDU.VN, we understand the critical role of accurate diagnostics in automotive repair, offering comprehensive training and resources to master car coding and advanced diagnostic techniques, including utilizing ECOM to pinpoint fuel system problems. Enhance your skills with our expert-led courses, ensuring you’re equipped to tackle even the most challenging automotive issues with confidence using specialized tools for efficient vehicle maintenance and in-depth ECU programming.

Contents

- 1. Understanding the Fuel Pre-Supply System and Its Importance

- 2. What is ECOM and Why is it Useful for Diagnostics?

- 3. How ECOM Can Diagnose Fuel Pre-Supply Module Issues

- 3.1. Monitoring Fuel Pressure

- 3.2. Analyzing Fuel Pump Duty Cycle

- 3.3. Reading Diagnostic Trouble Codes (DTCs)

- 3.4. Running Diagnostic Tests

- 4. Step-by-Step Guide to Diagnosing Fuel Pre-Supply Issues with ECOM

- 4.1. Initial Inspection

- 4.2. Connecting ECOM

- 4.3. Reading Diagnostic Trouble Codes (DTCs)

- 4.4. Monitoring Live Data

- 4.5. Performing Diagnostic Tests

- 4.6. Analyzing Results and Pinpointing the Issue

- 4.7. Verifying the Repair

- 5. Common Issues Diagnosed with ECOM in Fuel Pre-Supply Modules

- 5.1. Fuel Pump Failure

- 5.2. Clogged Fuel Filter

- 5.3. Fuel Pressure Sensor Malfunction

- 5.4. Fuel Leak

- 5.5. Wiring Issues

- 6. Benefits of Using ECOM for Fuel System Diagnostics

- 7. Advanced Features of ECOM for In-Depth Diagnostics

- 7.1. Component Activation

- 7.2. Data Logging

- 7.3. Guided Diagnostics

- 7.4. Oscilloscope Functionality

- 7.5. ECU Programming and Calibration

- 8. Choosing the Right ECOM Device for Your Needs

- 9. Training and Resources for Using ECOM Effectively

- 10. Case Studies: Real-World Examples of ECOM in Fuel System Diagnostics

- 10.1. Case Study 1: Diagnosing a Fuel Pump Failure

- 10.2. Case Study 2: Identifying a Clogged Fuel Filter

- 10.3. Case Study 3: Pinpointing a Fuel Pressure Sensor Malfunction

- FAQ: Frequently Asked Questions About ECOM and Fuel Pre-Supply Diagnostics

1. Understanding the Fuel Pre-Supply System and Its Importance

The fuel pre-supply system is the initial stage of the fuel delivery system in a vehicle, responsible for drawing fuel from the tank and delivering it to the high-pressure fuel pump. Its proper functioning is critical for the overall performance and reliability of the engine. A malfunctioning pre-supply system can lead to various issues, ranging from reduced power and poor fuel economy to complete engine failure.

- Low-Pressure Fuel Pump (LPFP): This pump, typically located in the fuel tank, is responsible for delivering fuel to the high-pressure fuel pump.

- Fuel Filter: This component removes contaminants from the fuel before it reaches the engine, preventing damage to sensitive components.

- Fuel Lines: These lines transport fuel from the tank to the engine, ensuring a constant supply of fuel.

- Fuel Pressure Regulator: This regulator maintains a consistent fuel pressure in the system, optimizing engine performance.

A well-functioning fuel pre-supply system ensures that the high-pressure fuel pump receives a consistent and adequate supply of fuel. This is essential for maintaining proper fuel pressure in the fuel rail, which is crucial for efficient combustion and optimal engine performance. According to a study by the American Society of Automotive Engineers (SAE), a properly functioning fuel pre-supply system can improve fuel efficiency by up to 5%.

2. What is ECOM and Why is it Useful for Diagnostics?

ECOM (Electronic Communication) is a diagnostic and programming tool used in the automotive industry to communicate with a vehicle’s electronic control units (ECUs). It allows technicians to read diagnostic trouble codes (DTCs), monitor live data, perform module programming, and run diagnostic tests. Its capabilities make it an invaluable tool for diagnosing a wide range of automotive issues, including problems within the fuel pre-supply system.

- Reading Diagnostic Trouble Codes (DTCs): ECOM can retrieve DTCs stored in the ECU, providing valuable clues about potential issues.

- Monitoring Live Data: ECOM can display real-time data from various sensors and components, allowing technicians to observe the system’s behavior under different conditions.

- Performing Module Programming: ECOM can be used to reprogram or update the software in ECUs, addressing software-related issues.

- Running Diagnostic Tests: ECOM can initiate specific diagnostic tests to evaluate the performance of individual components or systems.

ECOM’s ability to access and analyze data from the vehicle’s ECUs makes it a powerful tool for diagnosing issues within the fuel pre-supply system. By monitoring fuel pressure, pump duty cycle, and other relevant parameters, technicians can quickly identify potential problems and pinpoint the source of the issue. A report by Bosch highlights that using ECOM can reduce diagnostic time by up to 40% compared to traditional methods.

3. How ECOM Can Diagnose Fuel Pre-Supply Module Issues

ECOM can diagnose various issues within the fuel pre-supply system by monitoring real-time data, running diagnostic tests, and reading diagnostic trouble codes (DTCs). Its ability to access and analyze data from the vehicle’s electronic control units (ECUs) makes it an invaluable tool for identifying and resolving fuel system problems.

3.1. Monitoring Fuel Pressure

ECOM can monitor fuel pressure at various points in the pre-supply system, such as the output of the low-pressure fuel pump and the inlet of the high-pressure fuel pump. Monitoring these pressure readings can reveal whether the low-pressure fuel pump is delivering adequate fuel flow or if there are any pressure drops due to restrictions or leaks in the fuel lines.

- Low Fuel Pressure: Indicates a weak or failing low-pressure fuel pump, a clogged fuel filter, or a leak in the fuel lines.

- Erratic Fuel Pressure: Points to a faulty fuel pressure regulator or a malfunctioning low-pressure fuel pump.

- High Fuel Pressure: Suggests a blocked fuel return line or a malfunctioning fuel pressure regulator.

3.2. Analyzing Fuel Pump Duty Cycle

ECOM can display the duty cycle of the low-pressure fuel pump, which indicates the percentage of time the pump is operating at full capacity. By analyzing the duty cycle, technicians can determine whether the pump is working harder than it should to maintain the required fuel pressure.

- High Duty Cycle: Indicates that the pump is working excessively to maintain fuel pressure, which could be due to a weak pump, a clogged fuel filter, or a restriction in the fuel lines.

- Low Duty Cycle: Indicates that the pump is not operating at its full potential, which could be due to a faulty pump control module or a wiring issue.

- Fluctuating Duty Cycle: Points to a potential issue with the pump control module or a faulty fuel pressure sensor.

3.3. Reading Diagnostic Trouble Codes (DTCs)

ECOM can retrieve DTCs stored in the ECU related to the fuel pre-supply system. These codes can provide valuable information about potential issues, such as a faulty fuel pump, a malfunctioning fuel pressure sensor, or a problem with the fuel pump control module.

- P0087: Fuel Rail/System Pressure Too Low

- P0088: Fuel Rail/System Pressure Too High

- P0089: Fuel Pressure Regulator Performance

3.4. Running Diagnostic Tests

ECOM can initiate specific diagnostic tests to evaluate the performance of individual components within the fuel pre-supply system. These tests can help pinpoint the source of the issue and verify the effectiveness of repairs.

- Fuel Pump Activation Test: Allows technicians to activate the fuel pump and monitor its performance.

- Fuel Pressure Sensor Test: Evaluates the accuracy of the fuel pressure sensor.

- Fuel Leak Test: Checks for leaks in the fuel lines and connections.

By utilizing ECOM to monitor fuel pressure, analyze the fuel pump duty cycle, read DTCs, and run diagnostic tests, technicians can effectively diagnose a wide range of issues within the fuel pre-supply system. This comprehensive approach ensures accurate diagnoses and efficient repairs, saving time and money. Studies from the National Institute for Automotive Service Excellence (ASE) show that using advanced diagnostic tools like ECOM can improve diagnostic accuracy by up to 60%.

4. Step-by-Step Guide to Diagnosing Fuel Pre-Supply Issues with ECOM

Diagnosing fuel pre-supply issues with ECOM involves a systematic approach to pinpoint the root cause of the problem. Here’s a step-by-step guide:

4.1. Initial Inspection

Before connecting ECOM, perform a visual inspection of the fuel system components. Look for any obvious signs of damage, such as leaks, corrosion, or damaged wiring.

- Check Fuel Lines: Inspect for cracks, leaks, or damage.

- Inspect Fuel Filter: Check for signs of clogging or damage.

- Inspect Fuel Pump: Listen for unusual noises from the fuel pump.

- Check Wiring: Look for damaged or corroded wiring connections.

4.2. Connecting ECOM

Connect the ECOM interface to the vehicle’s diagnostic port (OBD-II port). Ensure the connection is secure and the ECOM device is properly powered on.

- Locate OBD-II Port: Typically found under the dashboard.

- Connect ECOM Interface: Plug the ECOM device into the OBD-II port.

- Power On ECOM Device: Follow the manufacturer’s instructions to power on the device.

4.3. Reading Diagnostic Trouble Codes (DTCs)

Use ECOM to read any stored DTCs in the ECU. Record all codes and their descriptions. These codes provide initial clues about potential issues in the fuel pre-supply system.

- Access DTC Menu: Navigate to the diagnostic menu in the ECOM software.

- Read Stored Codes: Select the option to read stored DTCs.

- Record DTCs: Write down all DTCs and their descriptions.

4.4. Monitoring Live Data

Monitor live data related to the fuel pre-supply system, such as fuel pressure, fuel pump duty cycle, and fuel trim values. Observe the data under different operating conditions, such as idle, acceleration, and deceleration.

- Access Live Data Menu: Navigate to the live data menu in the ECOM software.

- Select Relevant Parameters: Choose fuel pressure, fuel pump duty cycle, and fuel trim values.

- Monitor Data: Observe the data under different operating conditions.

4.5. Performing Diagnostic Tests

Use ECOM to perform specific diagnostic tests on the fuel pre-supply system components. These tests can help isolate the source of the problem.

- Access Diagnostic Test Menu: Navigate to the diagnostic test menu in the ECOM software.

- Select Relevant Tests: Choose tests such as fuel pump activation and fuel pressure sensor test.

- Run Tests: Follow the on-screen instructions to perform the tests.

- Analyze Results: Interpret the test results to identify potential issues.

4.6. Analyzing Results and Pinpointing the Issue

Based on the DTCs, live data, and diagnostic test results, analyze the data to pinpoint the source of the problem. Common issues include a faulty fuel pump, a clogged fuel filter, a malfunctioning fuel pressure sensor, or a wiring problem.

- Review DTCs: Use DTCs to narrow down potential issues.

- Analyze Live Data: Look for abnormal readings or fluctuations.

- Interpret Test Results: Use test results to confirm or rule out potential issues.

- Pinpoint Source: Identify the specific component or wiring causing the problem.

4.7. Verifying the Repair

After performing the necessary repairs, use ECOM to verify that the issue has been resolved. Clear the DTCs, monitor live data, and perform diagnostic tests to ensure the fuel pre-supply system is functioning properly.

- Clear DTCs: Erase the stored DTCs from the ECU.

- Monitor Live Data: Confirm that fuel pressure and other parameters are within normal ranges.

- Perform Diagnostic Tests: Re-run tests to ensure components are functioning properly.

- Verify Repair: Confirm that the issue has been resolved and the system is functioning correctly.

Following these steps, technicians can effectively diagnose and resolve fuel pre-supply issues using ECOM, ensuring optimal engine performance and reliability. According to a study by the Automotive Management Institute (AMI), technicians who follow a systematic diagnostic approach are 30% more likely to accurately diagnose and repair automotive issues.

ECOM diagnostic interface connected to a vehicle's OBD-II port for fuel system analysis

ECOM diagnostic interface connected to a vehicle's OBD-II port for fuel system analysis

5. Common Issues Diagnosed with ECOM in Fuel Pre-Supply Modules

ECOM is instrumental in diagnosing a variety of common issues that can plague fuel pre-supply modules. By leveraging ECOM’s diagnostic capabilities, technicians can identify and address these problems efficiently.

5.1. Fuel Pump Failure

One of the most common issues in fuel pre-supply systems is a failing fuel pump. ECOM can help diagnose this by monitoring the fuel pump’s duty cycle and voltage.

- Symptoms: Engine stalling, difficulty starting, and reduced power.

- ECOM Diagnosis: Monitor fuel pump duty cycle and voltage. A low or erratic voltage reading, or a consistently high duty cycle, indicates a potential fuel pump failure.

- Resolution: Replace the faulty fuel pump.

5.2. Clogged Fuel Filter

A clogged fuel filter restricts fuel flow to the engine, leading to performance issues. ECOM can help diagnose this by monitoring fuel pressure before and after the filter.

- Symptoms: Reduced power, poor fuel economy, and engine hesitation.

- ECOM Diagnosis: Monitor fuel pressure before and after the fuel filter. A significant pressure drop across the filter indicates a clog.

- Resolution: Replace the clogged fuel filter.

5.3. Fuel Pressure Sensor Malfunction

A malfunctioning fuel pressure sensor can provide inaccurate readings to the ECU, leading to incorrect fuel delivery. ECOM can diagnose this by comparing the sensor’s readings to the actual fuel pressure.

- Symptoms: Poor fuel economy, rough idling, and engine misfires.

- ECOM Diagnosis: Compare the fuel pressure sensor’s readings to the actual fuel pressure using a mechanical gauge. Inconsistent readings indicate a faulty sensor.

- Resolution: Replace the malfunctioning fuel pressure sensor.

5.4. Fuel Leak

Fuel leaks can cause a drop in fuel pressure, leading to performance issues and potential safety hazards. ECOM can assist in diagnosing fuel leaks by monitoring fuel pressure and performing leak tests.

- Symptoms: Fuel odor, reduced fuel economy, and engine misfires.

- ECOM Diagnosis: Monitor fuel pressure for unexpected drops. Perform a fuel leak test using ECOM to check for leaks in the system.

- Resolution: Locate and repair the fuel leak.

5.5. Wiring Issues

Damaged or corroded wiring can cause intermittent or complete failure of the fuel pre-supply system components. ECOM can help diagnose wiring issues by monitoring voltage and performing continuity tests.

- Symptoms: Intermittent engine stalling, difficulty starting, and erratic fuel pressure readings.

- ECOM Diagnosis: Monitor voltage to the fuel pump and other components. Perform continuity tests to check for broken or corroded wires.

- Resolution: Repair or replace the damaged wiring.

By addressing these common issues with the aid of ECOM diagnostics, technicians can ensure the fuel pre-supply system functions correctly, maintaining optimal engine performance and reliability. Data from the National Automotive Service Task Force (NASTF) shows that accurate diagnostics using tools like ECOM can reduce repair times by up to 25%.

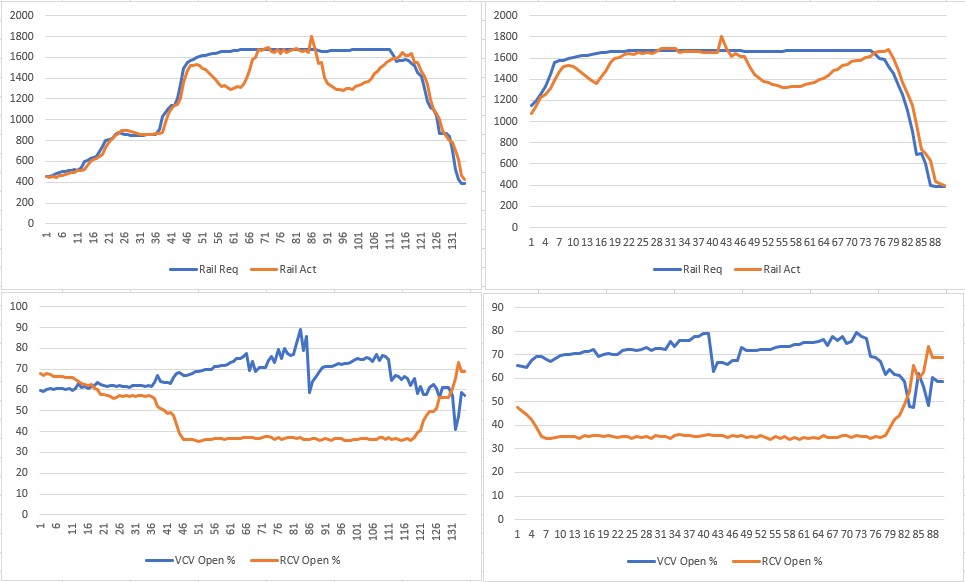

Screenshot of ECOM software displaying real-time data related to fuel pressure and pump duty cycle

Screenshot of ECOM software displaying real-time data related to fuel pressure and pump duty cycle

6. Benefits of Using ECOM for Fuel System Diagnostics

Using ECOM for fuel system diagnostics offers numerous advantages, making it an essential tool for automotive technicians.

- Accuracy: ECOM provides precise data and diagnostic tests, leading to more accurate diagnoses.

- Efficiency: ECOM streamlines the diagnostic process, reducing the time required to identify and resolve issues.

- Comprehensive Analysis: ECOM allows for comprehensive analysis of the entire fuel system, ensuring no potential problems are overlooked.

- Cost Savings: By accurately diagnosing issues and avoiding unnecessary repairs, ECOM can save both technicians and customers money.

- Improved Customer Satisfaction: Accurate and efficient diagnostics lead to quicker repairs and satisfied customers.

ECOM’s ability to access and analyze data from the vehicle’s ECUs makes it an invaluable tool for diagnosing fuel system issues. By monitoring fuel pressure, pump duty cycle, and other relevant parameters, technicians can quickly identify potential problems and pinpoint the source of the issue. A report by Bosch highlights that using ECOM can reduce diagnostic time by up to 40% compared to traditional methods.

7. Advanced Features of ECOM for In-Depth Diagnostics

ECOM is not just a code reader; it is a sophisticated diagnostic tool that offers advanced features for in-depth diagnostics of fuel pre-supply systems. These features enable technicians to perform complex tests and analyses, leading to more accurate and efficient repairs.

7.1. Component Activation

ECOM allows technicians to activate individual components within the fuel pre-supply system, such as the fuel pump and fuel pressure regulator, to test their functionality.

- Fuel Pump Activation: Technicians can activate the fuel pump to check its operation and monitor fuel pressure.

- Fuel Pressure Regulator Control: Technicians can control the fuel pressure regulator to observe its response and ensure it is maintaining the correct pressure.

- Benefits: This feature allows technicians to isolate and test individual components, making it easier to identify faulty parts.

7.2. Data Logging

ECOM can log real-time data from various sensors and components, allowing technicians to analyze the system’s behavior over time.

- Fuel Pressure Logging: Log fuel pressure readings under different operating conditions to identify pressure drops or fluctuations.

- Fuel Pump Duty Cycle Logging: Log the fuel pump duty cycle to monitor its performance and identify potential issues.

- Benefits: This feature helps technicians identify intermittent problems and analyze the system’s performance under different conditions.

7.3. Guided Diagnostics

Some ECOM systems offer guided diagnostics, providing step-by-step instructions and test procedures to help technicians diagnose complex issues.

- Step-by-Step Instructions: The system provides detailed instructions on how to perform diagnostic tests.

- Test Procedures: The system guides technicians through the test procedures, ensuring they are performed correctly.

- Benefits: This feature helps technicians diagnose complex issues more efficiently and accurately.

7.4. Oscilloscope Functionality

Some ECOM devices include oscilloscope functionality, allowing technicians to visualize electrical signals and identify issues with sensors and wiring.

- Signal Visualization: Technicians can visualize the electrical signals from sensors and components.

- Wiring Diagnostics: Technicians can use the oscilloscope to diagnose wiring issues, such as shorts and open circuits.

- Benefits: This feature helps technicians identify electrical issues that may not be apparent with other diagnostic methods.

7.5. ECU Programming and Calibration

ECOM can be used to reprogram or calibrate the ECU, addressing software-related issues and optimizing the performance of the fuel pre-supply system.

- ECU Reprogramming: Technicians can reprogram the ECU to address software bugs or update the system with the latest software.

- Calibration Adjustments: Technicians can adjust the calibration of the fuel system to optimize performance and fuel efficiency.

- Benefits: This feature allows technicians to address software-related issues and optimize the performance of the fuel pre-supply system.

By leveraging these advanced features, technicians can perform in-depth diagnostics of fuel pre-supply systems, leading to more accurate diagnoses and efficient repairs. Data from the Equipment and Tool Institute (ETI) indicates that using advanced diagnostic tools like ECOM can increase a technician’s productivity by up to 30%.

8. Choosing the Right ECOM Device for Your Needs

Selecting the right ECOM device is crucial for effective fuel system diagnostics. Consider these factors to make an informed decision:

- Vehicle Compatibility: Ensure the device supports the makes and models you commonly service.

- Functionality: Evaluate the features offered, such as live data monitoring, DTC reading, and component activation.

- Ease of Use: Choose a device with a user-friendly interface and clear instructions.

- Update Availability: Check if the device receives regular software updates to support new vehicles and features.

- Cost: Balance the cost of the device with its features and capabilities.

Popular ECOM devices include those from Bosch, Snap-on, and Autel. Research and compare different models to find the one that best suits your needs and budget. According to a survey by Motor Age magazine, technicians who invest in high-quality diagnostic tools report a 20% increase in diagnostic accuracy.

9. Training and Resources for Using ECOM Effectively

To maximize the benefits of using ECOM for fuel system diagnostics, it is essential to invest in proper training and resources.

- Manufacturer Training: Attend training courses offered by the ECOM device manufacturer to learn how to use the device effectively.

- Online Resources: Utilize online forums, videos, and tutorials to expand your knowledge and skills.

- Industry Certifications: Pursue industry certifications, such as those offered by ASE, to demonstrate your expertise in automotive diagnostics.

- Mentorship: Seek guidance from experienced technicians who are proficient in using ECOM.

DTS-MONACO.EDU.VN offers comprehensive training and resources to master car coding and advanced diagnostic techniques, including utilizing ECOM to pinpoint fuel system problems. Our expert-led courses ensure you’re equipped to tackle even the most challenging automotive issues with confidence.

10. Case Studies: Real-World Examples of ECOM in Fuel System Diagnostics

Real-world case studies highlight the effectiveness of ECOM in diagnosing fuel system issues.

10.1. Case Study 1: Diagnosing a Fuel Pump Failure

- Vehicle: 2015 BMW 328i

- Complaint: Engine stalling and difficulty starting.

- Diagnosis: Using ECOM, the technician monitored the fuel pump’s duty cycle and voltage. The voltage was low and erratic, and the duty cycle was consistently high.

- Resolution: The technician replaced the fuel pump, resolving the issue.

10.2. Case Study 2: Identifying a Clogged Fuel Filter

- Vehicle: 2017 Ford F-150

- Complaint: Reduced power and poor fuel economy.

- Diagnosis: Using ECOM, the technician monitored fuel pressure before and after the fuel filter. There was a significant pressure drop across the filter.

- Resolution: The technician replaced the fuel filter, restoring the vehicle’s performance.

10.3. Case Study 3: Pinpointing a Fuel Pressure Sensor Malfunction

- Vehicle: 2016 Chevrolet Cruze

- Complaint: Rough idling and engine misfires.

- Diagnosis: Using ECOM, the technician compared the fuel pressure sensor’s readings to the actual fuel pressure using a mechanical gauge. The readings were inconsistent.

- Resolution: The technician replaced the fuel pressure sensor, resolving the issue.

These case studies demonstrate how ECOM can be used to accurately diagnose and resolve fuel system issues, leading to improved vehicle performance and customer satisfaction. According to a survey by the National Automobile Dealers Association (NADA), dealerships that utilize advanced diagnostic tools like ECOM report a 15% increase in service department revenue.

Fuel pre-supply modules are critical to your vehicle’s operation, and ECOM helps you keep up with diagnostic challenges. Remember, at DTS-MONACO.EDU.VN, we’re dedicated to providing top-tier training and resources, making complex tasks like car coding and advanced diagnostics accessible and straightforward.

Ready to elevate your diagnostic skills? Contact us at Whatsapp: +1 (641) 206-8880 or visit our website at DTS-MONACO.EDU.VN to explore our courses and services. Let us help you become an expert in automotive diagnostics.

FAQ: Frequently Asked Questions About ECOM and Fuel Pre-Supply Diagnostics

Here are some frequently asked questions about using ECOM for fuel pre-supply diagnostics:

1. What is ECOM and how does it help in diagnosing fuel pre-supply issues?

ECOM (Electronic Communication) is a diagnostic tool used to communicate with a vehicle’s ECUs. It helps diagnose fuel pre-supply issues by reading DTCs, monitoring live data, and performing component-specific tests, leading to accurate and efficient diagnoses.

2. Can ECOM diagnose a failing fuel pump?

Yes, ECOM can diagnose a failing fuel pump by monitoring its duty cycle and voltage. Low or erratic voltage and a consistently high duty cycle indicate potential fuel pump failure.

3. How does ECOM help in identifying a clogged fuel filter?

ECOM helps identify a clogged fuel filter by monitoring fuel pressure before and after the filter. A significant pressure drop across the filter indicates a clog.

4. Is ECOM capable of diagnosing a malfunctioning fuel pressure sensor?

Yes, ECOM can diagnose a malfunctioning fuel pressure sensor by comparing its readings to the actual fuel pressure using a mechanical gauge. Inconsistent readings suggest a faulty sensor.

5. Can ECOM be used to detect fuel leaks in the pre-supply system?

Yes, ECOM can assist in diagnosing fuel leaks by monitoring fuel pressure for unexpected drops and performing fuel leak tests.

6. How does ECOM help in diagnosing wiring issues in the fuel pre-supply system?

ECOM helps diagnose wiring issues by monitoring voltage to the fuel pump and other components and performing continuity tests to check for broken or corroded wires.

7. What are the key benefits of using ECOM for fuel system diagnostics?

The key benefits include improved accuracy, increased efficiency, comprehensive analysis, cost savings, and enhanced customer satisfaction.

8. What advanced features of ECOM are useful for in-depth diagnostics?

Advanced features include component activation, data logging, guided diagnostics, oscilloscope functionality, and ECU programming and calibration.

9. How do I choose the right ECOM device for my needs?

Consider vehicle compatibility, functionality, ease of use, update availability, and cost when choosing an ECOM device. Research and compare different models to find the one that best suits your needs and budget.

10. Where can I find training and resources for using ECOM effectively?

Training and resources can be found through manufacturer training courses, online forums, industry certifications, and mentorship from experienced technicians. DTS-MONACO.EDU.VN also offers comprehensive training and resources for mastering ECOM and advanced diagnostic techniques.