Can DTS Monaco Perform EPS Torque Sensor Calibrations Or Adaptations? Yes, DTS Monaco is a powerful tool used for diagnostics, coding, and programming of electronic control units (ECUs) in vehicles, and it often includes the capability to perform EPS (Electronic Power Steering) torque sensor calibrations and adaptations; for comprehensive training and support, consider DTS-MONACO.EDU.VN. This article will dive into the specifics of how DTS Monaco handles EPS systems, covering everything from basic diagnostics to advanced calibration procedures, ensuring you’re well-informed about its capabilities. By understanding these features, you’ll be better equipped to tackle various EPS-related tasks efficiently and effectively, enhancing your automotive diagnostic and repair skills. We’ll also discuss related concepts such as vehicle diagnostics, ECU programming, and automotive repair, providing you with a holistic view of the topic.

Contents

- 1. Understanding Electronic Power Steering (EPS) Systems

- 1.1. Key Components of an EPS System

- 1.2. Role of the Torque Sensor in EPS

- 2. What is DTS Monaco?

- 2.1. Key Features of DTS Monaco

- 2.2. DTS Monaco vs. Other Diagnostic Tools

- 3. EPS Torque Sensor Calibration: Why It Matters

- 3.1. Symptoms of a Miscalibrated Torque Sensor

- 3.2. Factors Requiring Torque Sensor Calibration

- 4. Using DTS Monaco for EPS Torque Sensor Calibration

- 4.1. Step-by-Step Guide to Calibration with DTS Monaco

- 4.2. Common Issues and Troubleshooting

- 5. Advantages of Using DTS Monaco for EPS Calibration

- 5.1. Enhanced Steering Accuracy

- 5.2. Streamlined Diagnostic Processes

- 6. Best Practices for EPS Torque Sensor Calibration

- 6.1. Ensuring Accurate Readings

- 6.2. Avoiding Common Mistakes

- 7. Training and Resources for DTS Monaco

- 7.1. DTS-MONACO.EDU.VN: Your Training Partner

1. Understanding Electronic Power Steering (EPS) Systems

What is Electronic Power Steering (EPS) and why is it important? Electronic Power Steering (EPS) is an advanced system in modern vehicles that provides power assistance to the steering mechanism using an electric motor, enhancing vehicle handling and fuel efficiency. It is important because it improves steering precision, reduces driver fatigue, and contributes to overall vehicle safety.

EPS systems offer several advantages over traditional hydraulic power steering, including:

- Improved Fuel Efficiency: EPS systems only consume power when steering assistance is needed, unlike hydraulic systems that constantly draw power from the engine. According to the U.S. Department of Energy, EPS can improve fuel economy by up to 3% compared to hydraulic systems.

- Enhanced Steering Feel: EPS systems can be programmed to provide variable steering assistance based on vehicle speed and driving conditions, offering a more responsive and natural steering feel.

- Reduced Maintenance: EPS systems eliminate the need for hydraulic fluids, hoses, and pumps, reducing the risk of leaks and the need for regular maintenance.

- Advanced Safety Features: EPS systems can be integrated with other safety systems, such as electronic stability control (ESC) and lane-keeping assist, to provide additional stability and control in challenging driving situations.

1.1. Key Components of an EPS System

What are the main components of an Electronic Power Steering (EPS) system? The main components of an EPS system include the torque sensor, electric motor, control module (ECU), and steering gear. Each component plays a crucial role in providing efficient and responsive steering assistance.

- Torque Sensor: This sensor measures the amount of force applied by the driver to the steering wheel. It sends this information to the EPS control module, which determines the appropriate amount of steering assistance to provide.

- Electric Motor: The electric motor provides the power assistance to the steering system. It is typically located on the steering column or steering rack and is controlled by the EPS control module.

- Control Module (ECU): The EPS control module receives data from the torque sensor, vehicle speed sensor, and other inputs. It uses this information to calculate the optimal amount of steering assistance and control the electric motor accordingly.

- Steering Gear: The steering gear converts the rotational motion of the steering wheel into the linear motion needed to turn the vehicle’s wheels. In an EPS system, the steering gear is often integrated with the electric motor to provide direct steering assistance.

1.2. Role of the Torque Sensor in EPS

What is the function of the torque sensor in an EPS system? The torque sensor in an EPS system measures the force applied by the driver to the steering wheel, providing crucial data to the control module for determining the level of steering assistance needed. This ensures the appropriate amount of power assist is applied, making steering easier and more responsive.

The torque sensor is a critical component because it directly influences the steering feel and responsiveness. A properly functioning torque sensor ensures that the EPS system provides the right amount of assistance based on the driver’s input. If the torque sensor is faulty or miscalibrated, it can lead to various issues, such as:

- Erratic Steering Assistance: The EPS system may provide too much or too little assistance, making it difficult to control the vehicle.

- Steering Wheel Vibration: A faulty torque sensor can cause vibrations in the steering wheel, especially at low speeds.

- EPS Warning Light: The EPS warning light on the dashboard may illuminate, indicating a problem with the system.

- Loss of Steering Assistance: In some cases, a faulty torque sensor can cause the complete loss of steering assistance, making it very difficult to steer the vehicle.

Due to the importance of torque sensors, it’s important to understand the different types available and their function. According to a study done by the Bosch Automotive Handbook in 2021, understanding the intricacies of torque sensors will allow technicians to perform successful calibrations and adaptations.

2. What is DTS Monaco?

What is DTS Monaco and what is it used for? DTS Monaco is a diagnostic, testing, and engineering software used primarily for Mercedes-Benz vehicles, allowing advanced ECU programming, diagnostics, and vehicle modifications. It is used by automotive professionals for tasks such as flashing, coding, and module programming.

DTS Monaco is a powerful tool used by automotive technicians and engineers for advanced diagnostics and programming tasks. It offers a wide range of capabilities, including:

- ECU Flashing: Updating the software on electronic control units (ECUs) to the latest versions, which can improve performance, fix bugs, and add new features.

- ECU Coding: Configuring ECUs to match the vehicle’s specifications and enable or disable certain features.

- Diagnostics: Reading and clearing diagnostic trouble codes (DTCs), viewing live data, and performing actuator tests to diagnose vehicle problems.

- Module Programming: Programming new or replacement ECUs to function correctly in the vehicle.

- Variant Coding: Changing the vehicle’s configuration to enable or disable specific options or features.

2.1. Key Features of DTS Monaco

What are the key features of DTS Monaco that make it a valuable tool for automotive diagnostics and programming? DTS Monaco offers several key features, including advanced ECU programming, comprehensive diagnostic capabilities, user-friendly interface, and extensive vehicle coverage, making it a valuable tool for automotive professionals.

Key features of DTS Monaco:

- Advanced ECU Programming: DTS Monaco allows users to perform complex programming tasks, such as flashing, coding, and module programming, on a wide range of ECUs.

- Comprehensive Diagnostics: The software provides extensive diagnostic capabilities, including reading and clearing DTCs, viewing live data, and performing actuator tests.

- User-Friendly Interface: DTS Monaco features an intuitive and easy-to-use interface, making it accessible to both experienced and novice users.

- Extensive Vehicle Coverage: The software supports a wide range of Mercedes-Benz vehicles, including passenger cars, trucks, and buses.

- Offline Programming: DTS Monaco allows users to perform programming tasks offline, without the need for an internet connection.

- Automation Capabilities: The software supports automation scripting, allowing users to automate repetitive tasks and improve efficiency.

2.2. DTS Monaco vs. Other Diagnostic Tools

How does DTS Monaco compare to other diagnostic tools in the market? DTS Monaco stands out with its advanced capabilities in ECU programming and modifications, while other tools may focus more on basic diagnostics and code reading. DTS Monaco is generally more suited for advanced users familiar with ECU architecture.

While many diagnostic tools offer similar basic functionalities, DTS Monaco distinguishes itself through its specialized features and capabilities. Here’s a comparison of DTS Monaco with other diagnostic tools:

| Feature | DTS Monaco | Standard Diagnostic Tools |

|---|---|---|

| ECU Programming | Offers advanced ECU programming, flashing, coding, and module programming. | Limited ECU programming capabilities, primarily focused on basic coding and adaptations. |

| Diagnostics | Provides comprehensive diagnostics, including reading/clearing DTCs, live data streaming, and advanced actuator tests. | Offers standard diagnostic functions such as reading/clearing DTCs and basic live data. |

| User Interface | Designed for advanced users with a steeper learning curve; offers extensive customization options. | Generally more user-friendly and intuitive for a broader range of users. |

| Vehicle Coverage | Primarily focused on Mercedes-Benz vehicles, with extensive support for various models and systems. | Broader vehicle coverage across multiple manufacturers, but may lack depth for specific brands. |

| Special Functions | Includes advanced functions like variant coding, SCN coding, and detailed ECU configuration. | Typically includes common special functions such as oil reset, EPB reset, and battery registration. |

| Automation | Supports automation scripting for repetitive tasks, enhancing efficiency for complex procedures. | Limited or no support for automation scripting. |

| Offline Capabilities | Can perform programming tasks offline, providing flexibility and convenience in various working conditions. | May require an internet connection for certain functions, limiting offline capabilities. |

| Cost | Generally more expensive due to its advanced features and specialized capabilities. | Typically more affordable, making them accessible to a wider range of users. |

Understanding these differences helps automotive professionals choose the tool that best fits their specific needs and skill level. For advanced diagnostics and ECU modifications on Mercedes-Benz vehicles, DTS Monaco is often the preferred choice.

3. EPS Torque Sensor Calibration: Why It Matters

Why is EPS torque sensor calibration important for vehicle performance and safety? EPS torque sensor calibration is essential for ensuring accurate steering assistance, optimal vehicle handling, and overall safety, as it directly affects the responsiveness and stability of the vehicle.

Accurate calibration of the EPS torque sensor is crucial for several reasons:

- Optimal Steering Performance: Proper calibration ensures that the EPS system provides the correct amount of assistance based on the driver’s input, resulting in smooth and predictable steering.

- Enhanced Vehicle Handling: A well-calibrated EPS system contributes to improved vehicle handling and stability, especially during cornering and emergency maneuvers.

- Driver Comfort: Accurate calibration reduces driver fatigue by minimizing the effort required to steer the vehicle.

- Safety: A properly functioning EPS system enhances safety by providing consistent and reliable steering assistance in various driving conditions.

- Prevention of Fault Codes: Incorrect calibration can trigger fault codes and warning lights, indicating a problem with the EPS system.

3.1. Symptoms of a Miscalibrated Torque Sensor

What are the common symptoms indicating a miscalibrated EPS torque sensor? Common symptoms of a miscalibrated torque sensor include erratic steering assistance, steering wheel vibration, EPS warning light illumination, and a general feeling of instability while driving.

When the EPS torque sensor is not calibrated correctly, it can lead to a variety of noticeable symptoms that affect the vehicle’s handling and the driver’s experience. Here are some common signs of a miscalibrated torque sensor:

- Erratic Steering Assistance: The steering may feel inconsistent, with moments of too much or too little assistance. This can make it challenging to maintain a steady course, especially at highway speeds.

- Steering Wheel Vibration: Unusual vibrations in the steering wheel, particularly at low speeds, can indicate that the torque sensor is not accurately measuring the driver’s input.

- EPS Warning Light: The EPS warning light on the dashboard may illuminate, signaling a problem with the system. This light is a clear indication that the EPS system has detected an issue that needs attention.

- Difficulty Maintaining a Straight Line: The vehicle may tend to wander or pull to one side, requiring constant corrections to keep it moving straight.

- Increased Steering Effort: The steering may feel heavier than usual, requiring more effort from the driver to turn the wheel.

- Uneven Steering Feel: The steering may feel different when turning in one direction compared to the other.

- Loss of Steering Assistance: In severe cases, the EPS system may completely shut down, resulting in a loss of power steering.

- Fault Codes: Diagnostic scans may reveal fault codes related to the torque sensor or EPS system.

3.2. Factors Requiring Torque Sensor Calibration

When is it necessary to perform an EPS torque sensor calibration? EPS torque sensor calibration is typically required after replacing the torque sensor, EPS control module, or steering rack, as well as after performing wheel alignments or any repairs affecting the steering system geometry.

Several factors may necessitate the calibration of the EPS torque sensor. Knowing these factors can help technicians identify when calibration is needed, ensuring the EPS system operates correctly.

- Replacement of Torque Sensor: Anytime the torque sensor is replaced, calibration is essential to ensure the new sensor is accurately reading steering inputs.

- Replacement of EPS Control Module: If the EPS control module (ECU) is replaced, it needs to be calibrated to match the vehicle’s specific steering characteristics and torque sensor.

- Steering Rack Replacement: Replacing the steering rack can alter the alignment and mechanical properties of the steering system, requiring a recalibration of the torque sensor.

- Wheel Alignment: Performing a wheel alignment can affect the steering angle and torque sensor readings, necessitating a calibration to ensure accurate EPS assistance.

- Steering System Repairs: Any repairs or adjustments to the steering system components, such as tie rod ends or ball joints, can impact the torque sensor’s calibration.

- Collision Repair: After a collision, the steering system may be misaligned or damaged, requiring a thorough inspection and calibration of the EPS torque sensor.

- Software Updates: Some software updates to the EPS control module may require a recalibration of the torque sensor to ensure compatibility and proper function.

- EPS Warning Light: If the EPS warning light is illuminated and diagnostic scans reveal a torque sensor calibration issue, calibration is necessary.

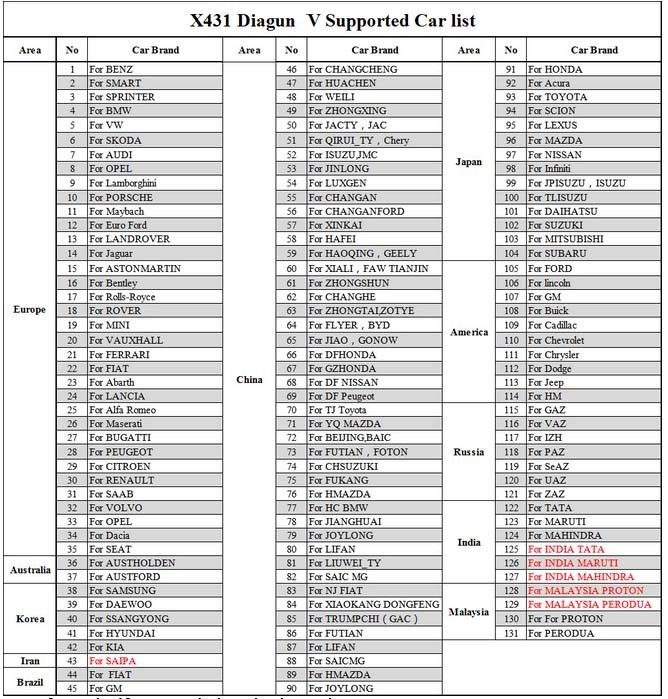

Launch X431 Diagun V Display D1A

Launch X431 Diagun V Display D1A

4. Using DTS Monaco for EPS Torque Sensor Calibration

Can DTS Monaco be used to calibrate EPS torque sensors? Yes, DTS Monaco offers specific functions for calibrating EPS torque sensors, allowing technicians to perform the necessary adaptations and adjustments to ensure accurate steering assistance.

DTS Monaco is equipped with the necessary tools and functions to perform EPS torque sensor calibrations on compatible vehicles. The process generally involves the following steps:

- Connect DTS Monaco to the Vehicle: Establish a connection between the DTS Monaco software and the vehicle’s diagnostic port using the appropriate interface cable.

- Identify the EPS Control Module: Use DTS Monaco to identify and select the EPS control module (ECU) from the list of available modules.

- Access Calibration Functions: Navigate to the calibration or adaptation functions within the EPS control module menu.

- Follow On-Screen Instructions: Follow the on-screen instructions provided by DTS Monaco to perform the torque sensor calibration procedure. This may involve specific steps, such as centering the steering wheel, performing a steering angle sweep, or entering specific values.

- Verify Calibration: After completing the calibration procedure, verify that the torque sensor readings are within the specified range and that the EPS system is functioning correctly.

4.1. Step-by-Step Guide to Calibration with DTS Monaco

What are the detailed steps for performing EPS torque sensor calibration using DTS Monaco? Calibrating the EPS torque sensor with DTS Monaco involves connecting to the vehicle, accessing the EPS module, selecting the calibration function, following on-screen prompts, and verifying the calibration results.

Here is a more detailed step-by-step guide to performing EPS torque sensor calibration using DTS Monaco:

-

Preparation:

- Ensure that you have the DTS Monaco software installed on your laptop or computer.

- Verify that you have the correct interface cable and that it is properly connected to your computer.

- Make sure the vehicle’s battery is fully charged to prevent interruptions during the calibration process.

- Park the vehicle on a level surface and ensure the steering wheel is centered.

-

Connect to the Vehicle:

- Connect the interface cable to the vehicle’s diagnostic port (OBD-II port).

- Turn on the vehicle’s ignition but do not start the engine.

- Launch the DTS Monaco software on your computer.

-

Identify the EPS Control Module:

- In DTS Monaco, select the appropriate vehicle model and year.

- Navigate to the control unit selection menu and identify the EPS control module (ECU). The module may be labeled as “Electronic Power Steering,” “Steering Assist,” or similar.

- Select the EPS control module to establish a connection.

-

Access Calibration Functions:

- Once connected to the EPS control module, navigate to the function menu.

- Look for options such as “Calibration,” “Adaptation,” “Torque Sensor Calibration,” or “Steering Angle Sensor Calibration.”

- Select the appropriate calibration function to begin the process.

-

Follow On-Screen Instructions:

- DTS Monaco will provide on-screen instructions for performing the calibration procedure.

- These instructions may include steps such as:

- Centering the steering wheel: Ensure the steering wheel is in the straight-ahead position and remains stable throughout the calibration.

- Steering angle sweep: Slowly turn the steering wheel from lock to lock (full left to full right) as instructed by the software. This helps the system learn the steering angle range.

- Entering specific values: In some cases, you may need to enter specific values or parameters as prompted by the software.

- Waiting for the calibration to complete: Allow the calibration process to run without interruption.

-

Verify Calibration:

- After the calibration procedure is complete, DTS Monaco will typically display a confirmation message or report.

- Check the torque sensor readings to ensure they are within the specified range.

- Clear any diagnostic trouble codes (DTCs) that may have been generated during the calibration process.

- Test drive the vehicle to ensure the EPS system is functioning correctly and providing the appropriate level of steering assistance.

-

Troubleshooting:

- If the calibration fails or the EPS system is not functioning correctly after calibration, review the on-screen instructions and repeat the procedure.

- Check for any diagnostic trouble codes (DTCs) that may provide clues about the problem.

- Consult the vehicle’s service manual or contact technical support for further assistance if needed.

4.2. Common Issues and Troubleshooting

What are some common issues encountered during EPS torque sensor calibration and how can they be resolved? Common issues include connection problems, incorrect data input, and software errors. Resolutions involve checking connections, verifying data, and updating or reinstalling the software.

Even with the right tools and procedures, you may encounter issues during EPS torque sensor calibration. Here are some common problems and troubleshooting tips:

-

Connection Problems:

- Issue: DTS Monaco fails to connect to the vehicle’s EPS control module.

- Troubleshooting:

- Check the interface cable connection at both the computer and the vehicle’s diagnostic port.

- Ensure the vehicle’s ignition is turned on but the engine is not running.

- Verify that the correct vehicle model and year are selected in DTS Monaco.

- Try using a different interface cable to rule out a faulty cable.

- Check the vehicle’s diagnostic port for any damage or corrosion.

-

Incorrect Data Input:

- Issue: The calibration procedure requires specific values or parameters, and incorrect data is entered.

- Troubleshooting:

- Double-check the vehicle’s service manual or repair information for the correct data values.

- Ensure that the data is entered accurately and in the correct format.

- If unsure, consult with a more experienced technician or contact technical support for assistance.

-

Software Errors:

- Issue: DTS Monaco displays error messages or crashes during the calibration process.

- Troubleshooting:

- Restart the DTS Monaco software and try the calibration procedure again.

- Ensure that you are using the latest version of DTS Monaco and that all software updates are installed.

- Check your computer’s system requirements to ensure they meet the minimum specifications for DTS Monaco.

- Reinstall DTS Monaco to rule out corrupted software files.

- Contact DTS Monaco technical support for assistance with software-related issues.

-

Calibration Failure:

- Issue: The calibration procedure fails to complete successfully, and an error message is displayed.

- Troubleshooting:

- Review the on-screen instructions and ensure that all steps were followed correctly.

- Check for any diagnostic trouble codes (DTCs) that may provide clues about the problem.

- Verify that the vehicle is parked on a level surface and the steering wheel is centered.

- Ensure that the vehicle’s battery is fully charged to prevent interruptions during the calibration process.

- If the problem persists, consult the vehicle’s service manual or contact technical support for further assistance.

-

EPS Warning Light Remains On:

- Issue: The EPS warning light remains illuminated after performing the calibration procedure.

- Troubleshooting:

- Use DTS Monaco to read and clear any diagnostic trouble codes (DTCs) related to the EPS system.

- Test drive the vehicle to see if the EPS warning light turns off after driving for a short distance.

- If the EPS warning light persists, there may be an underlying issue with the EPS system that requires further diagnosis and repair.

By addressing these common issues methodically, technicians can effectively troubleshoot and resolve problems encountered during EPS torque sensor calibration, ensuring accurate and reliable steering performance.

5. Advantages of Using DTS Monaco for EPS Calibration

What are the benefits of using DTS Monaco for EPS torque sensor calibration compared to other methods? DTS Monaco offers advanced, precise calibration, comprehensive diagnostics, and integration with other ECU functions, resulting in improved steering accuracy and system performance.

Using DTS Monaco for EPS calibration offers several advantages:

- Precision and Accuracy: DTS Monaco provides precise control over the calibration process, ensuring accurate torque sensor readings and optimal steering performance.

- Comprehensive Diagnostics: DTS Monaco offers comprehensive diagnostic capabilities, allowing technicians to identify and resolve any underlying issues that may be affecting the EPS system.

- Integration with Other ECU Functions: DTS Monaco can be used to perform other ECU programming and coding tasks, allowing technicians to address multiple issues in a single session.

- User-Friendly Interface: DTS Monaco features an intuitive interface that makes it easy to navigate and perform calibration procedures.

- Extensive Vehicle Coverage: DTS Monaco supports a wide range of Mercedes-Benz vehicles, ensuring compatibility with various models and systems.

- Automation Capabilities: DTS Monaco supports automation scripting, allowing technicians to automate repetitive tasks and improve efficiency.

5.1. Enhanced Steering Accuracy

How does DTS Monaco improve steering accuracy through its calibration functions? DTS Monaco ensures precise torque sensor readings and adjustments, leading to more accurate steering assistance and improved vehicle handling.

DTS Monaco enhances steering accuracy through its advanced calibration functions, which allow technicians to fine-tune the EPS system for optimal performance. Here’s how DTS Monaco improves steering accuracy:

- Precise Torque Sensor Readings: DTS Monaco provides accurate and reliable torque sensor readings, ensuring that the EPS system receives precise data about the driver’s steering input.

- Fine-Tuned Adjustments: DTS Monaco allows technicians to make fine-tuned adjustments to the EPS system parameters, such as the amount of steering assistance provided at different speeds and steering angles.

- Compensation for Component Wear: DTS Monaco can compensate for wear and tear on steering system components, such as the steering rack and tie rod ends, by adjusting the calibration parameters accordingly.

- Customized Steering Feel: DTS Monaco allows technicians to customize the steering feel to match the driver’s preferences, providing a more comfortable and enjoyable driving experience.

- Improved Vehicle Stability: By ensuring accurate steering assistance, DTS Monaco improves vehicle stability and handling, especially during cornering and emergency maneuvers.

- Reduced Driver Fatigue: Accurate steering assistance reduces the effort required to steer the vehicle, which can help reduce driver fatigue on long trips.

5.2. Streamlined Diagnostic Processes

In what ways does DTS Monaco streamline the diagnostic process for EPS systems? DTS Monaco offers quick access to diagnostic data, automated testing procedures, and clear error reporting, saving time and improving diagnostic accuracy for EPS issues.

DTS Monaco streamlines the diagnostic process for EPS systems in several ways:

- Quick Access to Diagnostic Data: DTS Monaco provides quick access to diagnostic data, such as diagnostic trouble codes (DTCs), live data streams, and freeze frame data, allowing technicians to quickly identify potential issues with the EPS system.

- Automated Testing Procedures: DTS Monaco offers automated testing procedures that can quickly evaluate the performance of the EPS system components, such as the torque sensor, electric motor, and control module.

- Clear Error Reporting: DTS Monaco provides clear and concise error reporting, making it easy for technicians to understand the nature of the problem and take appropriate action.

- Integrated Repair Information: DTS Monaco integrates with repair information databases, providing technicians with access to wiring diagrams, component locations, and repair procedures.

- Remote Diagnostics: DTS Monaco supports remote diagnostics, allowing technicians to diagnose and troubleshoot EPS system problems from a remote location.

- Data Logging: DTS Monaco can log diagnostic data over time, allowing technicians to analyze intermittent problems and identify trends.

LAUNCH X431 Diagun V Display D2A

LAUNCH X431 Diagun V Display D2A

6. Best Practices for EPS Torque Sensor Calibration

What are the recommended best practices for performing EPS torque sensor calibration? Best practices include using a stable power supply, following OEM procedures, ensuring proper vehicle alignment, and verifying calibration results with a test drive.

Following best practices is crucial for ensuring accurate and reliable EPS torque sensor calibration. Here are some recommended guidelines:

-

Use a Stable Power Supply:

- Ensure that the vehicle’s battery is fully charged and in good condition before starting the calibration procedure.

- Use a stable power supply or battery maintainer to prevent voltage fluctuations during the calibration process.

-

Follow OEM Procedures:

- Always follow the OEM (Original Equipment Manufacturer) procedures for EPS torque sensor calibration.

- Refer to the vehicle’s service manual or repair information for specific instructions and data values.

-

Ensure Proper Vehicle Alignment:

- Verify that the vehicle’s wheel alignment is within the specified range before performing the calibration procedure.

- Correct any alignment issues before proceeding with the calibration.

-

Center the Steering Wheel:

- Ensure that the steering wheel is centered and in the straight-ahead position before starting the calibration procedure.

- Use a steering wheel centering tool if necessary.

-

Follow On-Screen Instructions Carefully:

- Read and follow the on-screen instructions provided by DTS Monaco carefully.

- Pay attention to any specific steps or data values that are required.

-

Avoid Interruptions:

- Avoid interruptions during the calibration procedure.

- Do not turn off the ignition or disconnect the interface cable until the calibration is complete.

-

Verify Calibration Results:

- After completing the calibration procedure, verify that the torque sensor readings are within the specified range.

- Clear any diagnostic trouble codes (DTCs) that may have been generated during the calibration process.

-

Test Drive the Vehicle:

- Test drive the vehicle to ensure that the EPS system is functioning correctly and providing the appropriate level of steering assistance.

- Check for any unusual steering behavior, such as erratic assistance or vibrations.

6.1. Ensuring Accurate Readings

How can you ensure accurate torque sensor readings during the calibration process? Accurate readings can be ensured by using a stable power supply, verifying sensor connections, and following the calibration steps precisely as outlined in the service manual.

Ensuring accurate torque sensor readings during the calibration process is crucial for achieving optimal EPS system performance. Here are some tips to help you achieve accurate readings:

-

Stable Power Supply:

- Use a stable power supply or battery maintainer to prevent voltage fluctuations during the calibration process.

- Voltage fluctuations can affect the accuracy of the torque sensor readings.

-

Verify Sensor Connections:

- Check the torque sensor connections to ensure they are clean, secure, and free from corrosion.

- Loose or corroded connections can cause inaccurate readings.

-

Proper Vehicle Alignment:

- Ensure that the vehicle’s wheel alignment is within the specified range before performing the calibration procedure.

- Misalignment can affect the torque sensor readings and lead to inaccurate calibration.

-

Calibrate on a Level Surface:

- Perform the calibration procedure on a level surface to ensure accurate torque sensor readings.

- An uneven surface can affect the sensor readings and lead to inaccurate calibration.

-

Follow Calibration Steps Precisely:

- Follow the calibration steps precisely as outlined in the vehicle’s service manual or repair information.

- Skipping steps or deviating from the procedure can lead to inaccurate readings.

-

Use the Correct Tools:

- Use the correct tools and equipment for the calibration procedure.

- Using the wrong tools can damage the sensor or lead to inaccurate readings.

-

Avoid External Interference:

- Avoid external interference, such as radio frequencies or magnetic fields, during the calibration process.

- External interference can affect the accuracy of the torque sensor readings.

-

Verify Calibration Results:

- After completing the calibration procedure, verify that the torque sensor readings are within the specified range.

- If the readings are not within the specified range, repeat the calibration procedure or troubleshoot the sensor.

6.2. Avoiding Common Mistakes

What are some common mistakes to avoid during EPS torque sensor calibration? Common mistakes include neglecting vehicle alignment, skipping steps in the calibration process, using an unstable power supply, and failing to verify the calibration results.

Avoiding common mistakes during EPS torque sensor calibration is essential for achieving accurate and reliable results. Here are some mistakes to avoid:

-

Neglecting Vehicle Alignment:

- Mistake: Failing to check and correct the vehicle’s wheel alignment before performing the calibration procedure.

- Consequence: Misalignment can affect the torque sensor readings and lead to inaccurate calibration.

- Solution: Ensure that the vehicle’s wheel alignment is within the specified range before proceeding with the calibration.

-

Skipping Steps in the Calibration Process:

- Mistake: Skipping steps or deviating from the calibration procedure outlined in the vehicle’s service manual.

- Consequence: Skipping steps can lead to incomplete or inaccurate calibration.

- Solution: Follow the calibration steps precisely as outlined in the vehicle’s service manual or repair information.

-

Using an Unstable Power Supply:

- Mistake: Performing the calibration procedure with an unstable power supply or a weak battery.

- Consequence: Voltage fluctuations can affect the accuracy of the torque sensor readings.

- Solution: Use a stable power supply or battery maintainer to prevent voltage fluctuations during the calibration process.

-

Failing to Center the Steering Wheel:

- Mistake: Failing to ensure that the steering wheel is centered and in the straight-ahead position before starting the calibration procedure.

- Consequence: Inaccurate torque sensor readings and incorrect calibration.

- Solution: Center the steering wheel and use a steering wheel centering tool if necessary.

-

Ignoring Error Messages:

- Mistake: Ignoring error messages or warnings displayed by the diagnostic tool during the calibration process.

- Consequence: Error messages can indicate underlying issues that need to be addressed before proceeding with the calibration.

- Solution: Pay attention to any error messages and troubleshoot the underlying issues before continuing with the calibration.

-

Failing to Verify Calibration Results:

- Mistake: Failing to verify that the torque sensor readings are within the specified range after completing the calibration procedure.

- Consequence: The EPS system may not function correctly, leading to handling issues or safety concerns.

- Solution: Verify the torque sensor readings and test drive the vehicle to ensure that the EPS system is functioning correctly.

-

Using Incorrect Data Values:

- Mistake: Entering incorrect data values or parameters during the calibration procedure.

- Consequence: Inaccurate calibration and potential damage to the EPS system.

- Solution: Double-check the vehicle’s service manual or repair information for the correct data values and ensure that they are entered accurately.

-

Overlooking Sensor Connections:

- Mistake: Neglecting to check the torque sensor connections for cleanliness, security, and corrosion.

- Consequence: Loose or corroded connections can cause inaccurate readings.

- Solution: Verify that the torque sensor connections are clean, secure, and free from corrosion.

By avoiding these common mistakes, technicians can improve the accuracy and reliability of EPS torque sensor calibration, ensuring optimal steering performance and vehicle safety.

LAUNCH X431 Diagun V Display D3A

LAUNCH X431 Diagun V Display D3A

7. Training and Resources for DTS Monaco

Where can automotive technicians find training and resources for using DTS Monaco effectively? Automotive technicians can find training and resources for using DTS Monaco effectively through online courses, vendor-provided training, and automotive forums. In particular, DTS-MONACO.EDU.VN offers comprehensive training and support for mastering DTS Monaco.

To effectively use DTS Monaco, automotive technicians can benefit from various training and resources. Here are some options:

-

Online Courses:

- Platforms: Websites like Udemy, Coursera, and Skillshare offer courses on automotive diagnostics and ECU programming, some of which may include specific modules on DTS Monaco.

- Benefits: Flexible learning schedules, access to a wide range of topics, and often more affordable than in-person training.

-

Vendor-Provided Training:

- Source: Check with the vendor or distributor from whom you purchased DTS Monaco. They often provide training sessions or resources specifically tailored to their products.

- Benefits: Direct instruction from experts, hands-on experience with the software, and answers to specific questions.

-

Automotive Forums:

- Platforms: Websites like iATN (International Automotive Technicians Network) and other automotive-specific forums have dedicated sections for diagnostics and programming.

- Benefits: Access to a community of experienced technicians, opportunities to ask questions, and real-world case studies.

-

Technical Documentation:

- Source: The official DTS Monaco documentation provides detailed information on the software’s features, functions, and procedures.

- Benefits: Comprehensive and accurate information, step-by-step instructions, and troubleshooting tips.

-

YouTube Tutorials:

- Platforms: YouTube is a great resource for visual learners. Search for tutorials on DTS Monaco to see demonstrations of various procedures.

- Benefits: Free access to visual guides, real-time demonstrations, and tips from experienced users.

-

DTS-MONACO.EDU.VN:

- Offerings: This website specializes in DTS Monaco training and support. They offer comprehensive courses, tutorials, and resources designed to help technicians master the software.

- Benefits: Tailored training programs, expert support, and a focus on practical application.

7.1. DTS-MONACO.EDU.VN: Your Training Partner

What specific training programs and resources does DTS-MONACO.EDU.VN offer for DTS Monaco users? DTS-MONACO.EDU.VN offers specialized training programs, tutorials, and support tailored for DTS Monaco users, ensuring comprehensive understanding and effective application of the software.

DTS-MONACO.EDU.VN stands out as a premier training partner for automotive technicians looking to master DTS Monaco. Here’s what they offer:

-

Comprehensive Training Programs:

- Curriculum: Structured courses that cover everything from basic diagnostics to advanced ECU programming with DTS Monaco.

- Content: Includes detailed explanations, hands-on exercises, and real-world case studies.

-

Tutorials and Guides:

- Format: Step-by-step tutorials and guides that walk you through various DTS Monaco procedures.

- Topics: Covers EPS torque sensor calibration, ECU flashing, coding, and module