Are you curious whether C4 or C6 interfaces can help diagnose issues with your BlueTEC diesel system? Yes, they can, offering powerful diagnostic capabilities for these advanced systems. At DTS-MONACO.EDU.VN, we provide the tools and knowledge you need to effectively diagnose and repair your Mercedes-Benz. Read on to discover how these interfaces, along with car coding techniques and advanced diagnostic software, can help keep your BlueTEC running smoothly.

Contents

- 1. Understanding BlueTEC Diesel Systems and Diagnostics

- 2. The Role of C4 and C6 Interfaces in BlueTEC Diagnostics

- 3. Key Features of C4 and C6 Interfaces

- 4. Step-by-Step Guide: Diagnosing BlueTEC Issues with C4/C6

- 5. Case Studies: Real-World BlueTEC Diagnostic Examples

- 6. Car Coding and BlueTEC Systems

- 7. Common Diagnostic Challenges with BlueTEC Systems

- 8. Choosing the Right Diagnostic Software

- 9. Training and Resources for BlueTEC Diagnostics

- 10. The Future of BlueTEC Diagnostics

- 11. Benefits of Investing in Advanced Diagnostic Tools

- 12. Maintaining and Updating Your Diagnostic Equipment

- 13. Diagnosing Common BlueTEC Error Codes

- 14. Optimizing Your Diagnostic Workflow

- 15. The Importance of Regular System Maintenance

- 16. Decoding VIN Information for Accurate Diagnostics

- 17. Utilizing Wiring Diagrams for Effective Troubleshooting

- 18. The Ethical Considerations in Car Coding

- 19. Future Innovations in Diesel Engine Technology

- 20. The Benefits of Using Genuine Parts in BlueTEC Repairs

- 21. How to Navigate Mercedes-Benz Diagnostic Forums

- 22. The Cost-Effectiveness of Preventative Maintenance

- 23. Understanding Diagnostic Trouble Code (DTC) Severity Levels

- 24. Advanced Techniques for DPF Regeneration

- 25. The Role of Aftermarket Diagnostic Tools

- 26. Utilizing Online Resources for Wiring Schematics

- 27. The Impact of Fuel Quality on BlueTEC System Performance

- 28. Understanding and Troubleshooting SCR Systems

- 29. How to Stay Updated on BlueTEC Technology

- 30. Maximizing the Lifespan of Your BlueTEC Engine

- FAQ About BlueTEC Diagnostics and C4/C6 Interfaces

1. Understanding BlueTEC Diesel Systems and Diagnostics

What exactly is a BlueTEC diesel system, and why is precise diagnostics so crucial?

BlueTEC is Mercedes-Benz’s name for a range of technologies designed to reduce emissions from diesel engines. These systems typically include diesel particulate filters (DPFs), selective catalytic reduction (SCR) converters, and other components to minimize nitrogen oxides (NOx) and particulate matter. Accurate diagnostics are essential because these systems are complex and sensitive. A minor issue in one component can affect the entire system’s performance and compliance with emission standards. Using the right diagnostic tools helps technicians pinpoint problems quickly, ensuring efficient and cost-effective repairs.

Think of it like this: your BlueTEC system is a finely tuned orchestra, and each component is an instrument. If one instrument is out of tune, the whole performance suffers. Diagnostic tools like the C4 and C6 interfaces are like the conductor’s ear, identifying the precise source of the dissonance.

2. The Role of C4 and C6 Interfaces in BlueTEC Diagnostics

How do C4 and C6 interfaces fit into the diagnostic process for BlueTEC systems?

The C4 and C6 interfaces are key components of Mercedes-Benz diagnostic systems, providing a crucial link between the vehicle’s electronic control units (ECUs) and diagnostic software. They allow technicians to read fault codes, access real-time data, perform guided tests, and even reprogram control units. The C4 interface is generally used for older vehicle models, while the C6 interface supports newer models with advanced communication protocols like Diagnostics over Internet Protocol (DoIP). Both interfaces are essential for diagnosing a wide range of issues within the BlueTEC system, from sensor malfunctions to problems with the SCR converter.

According to a study by the Automotive Management Institute (AMI), diagnostic tools that support advanced protocols like DoIP can reduce diagnostic time by up to 40%. This efficiency is particularly valuable for complex systems like BlueTEC.

3. Key Features of C4 and C6 Interfaces

What are the standout features of the C4 and C6 interfaces, and how do they aid in diagnostics?

Both the C4 and C6 interfaces are equipped with several features that make them indispensable for BlueTEC diagnostics:

- Comprehensive Fault Code Reading: Both interfaces can read and clear diagnostic trouble codes (DTCs) from all relevant control units within the BlueTEC system.

- Real-Time Data Streaming: Technicians can monitor live data parameters, such as sensor readings, actuator positions, and system pressures, to identify anomalies.

- Actuator Testing: This feature allows technicians to activate individual components within the BlueTEC system, such as the SCR dosing valve, to verify their functionality.

- ECU Programming and Coding: Both interfaces support ECU programming and coding, enabling technicians to update software, calibrate sensors, and adapt control units to new components.

While both interfaces share these core features, the C6 interface offers several advantages, including faster communication speeds, support for the latest communication protocols, and compatibility with newer vehicle models.

4. Step-by-Step Guide: Diagnosing BlueTEC Issues with C4/C6

How can you effectively use C4 or C6 interfaces to troubleshoot BlueTEC system problems?

Here’s a step-by-step guide to diagnosing BlueTEC issues using a C4 or C6 interface, along with diagnostic software like Xentry or DTS-Monaco:

- Connect the Interface: Connect the C4 or C6 interface to the vehicle’s OBD-II port and your diagnostic computer.

- Launch Diagnostic Software: Open Xentry or DTS-Monaco on your computer and select the appropriate vehicle model and year.

- Read Fault Codes: Use the software to scan all control units for fault codes. Record any codes related to the BlueTEC system.

- Analyze Fault Codes: Research the fault codes to understand the potential causes of the problem. Consult the Mercedes-Benz WIS (Workshop Information System) for detailed information.

- Monitor Real-Time Data: Use the software to monitor real-time data parameters, such as NOx sensor readings, DPF pressure, and SCR catalyst temperature. Compare the readings to expected values.

- Perform Actuator Tests: Use the software to perform actuator tests on relevant components, such as the SCR dosing valve and DPF regeneration system. Verify that each component responds correctly.

- Perform Guided Tests: Follow the guided diagnostic routines in Xentry to pinpoint the root cause of the problem.

- Repair or Replace Components: Based on your findings, repair or replace any faulty components.

- Clear Fault Codes: After completing the repairs, clear the fault codes and retest the system to ensure the problem is resolved.

This structured approach helps ensure no stone is left unturned when diagnosing BlueTEC issues.

5. Case Studies: Real-World BlueTEC Diagnostic Examples

Can you share some real-world examples of how C4 and C6 interfaces have helped diagnose BlueTEC issues?

Here are a couple of case studies illustrating the power of C4 and C6 interfaces in diagnosing BlueTEC problems:

-

Case Study 1: NOx Sensor Failure

- Vehicle: 2015 Mercedes-Benz GL350 BlueTEC

- Symptoms: Check engine light, reduced engine power, increased emissions

- Diagnostic Steps:

- Connected C4 interface and launched Xentry software.

- Read fault codes and found a code indicating a faulty NOx sensor.

- Monitored real-time data and confirmed that the NOx sensor reading was out of range.

- Performed actuator test on the SCR dosing valve to ensure it was functioning correctly.

- Replaced the faulty NOx sensor and cleared the fault codes.

- Outcome: The check engine light was cleared, engine power was restored, and emissions returned to normal.

-

Case Study 2: DPF Clogging

- Vehicle: 2018 Mercedes-Benz E300d

- Symptoms: Reduced fuel economy, frequent DPF regeneration cycles, black smoke from exhaust

- Diagnostic Steps:

- Connected C6 interface and launched DTS-Monaco software.

- Read fault codes and found a code indicating excessive DPF pressure.

- Monitored real-time data and confirmed that the DPF pressure was above the specified limit.

- Performed a forced DPF regeneration using the software.

- Inspected the DPF for damage or blockages and found excessive soot buildup.

- Cleaned the DPF and reset the DPF adaptation values using the software.

- Outcome: Fuel economy improved, DPF regeneration cycles became less frequent, and black smoke from the exhaust disappeared.

These case studies demonstrate how C4 and C6 interfaces, combined with the right software and expertise, can effectively diagnose and resolve a wide range of BlueTEC issues.

6. Car Coding and BlueTEC Systems

How does car coding factor into the diagnostics and maintenance of BlueTEC systems?

Car coding, also known as ECU programming or software calibration, is an essential aspect of maintaining and repairing BlueTEC systems. Coding allows technicians to adapt control units to new components, update software, and enable or disable certain features. For example, after replacing a faulty NOx sensor, you may need to code the ECU to recognize the new sensor and calibrate its readings. Similarly, after cleaning or replacing a DPF, you may need to reset the DPF adaptation values to ensure proper regeneration.

According to a report by the Equipment and Tool Institute (ETI), car coding is becoming increasingly important as vehicles become more complex and rely more heavily on software. Proper coding ensures that all systems function correctly and comply with emission standards.

7. Common Diagnostic Challenges with BlueTEC Systems

What are the typical hurdles technicians face when diagnosing BlueTEC systems, and how can they be overcome?

Diagnosing BlueTEC systems can be challenging due to their complexity and sensitivity. Here are some common diagnostic challenges and how to overcome them:

- Intermittent Faults: Intermittent faults can be difficult to diagnose because they don’t always trigger fault codes. To overcome this challenge, use real-time data monitoring to look for anomalies and perform thorough visual inspections of wiring and connectors.

- Multiple Fault Codes: Multiple fault codes can make it difficult to pinpoint the root cause of the problem. Prioritize the fault codes based on their severity and relevance to the symptoms. Use guided diagnostic routines to systematically troubleshoot each code.

- Software Glitches: Software glitches can cause false fault codes or erratic system behavior. Ensure that your diagnostic software is up-to-date and that the vehicle’s ECUs have the latest software versions.

- Lack of Knowledge: BlueTEC systems are constantly evolving, and technicians need to stay up-to-date on the latest technologies and diagnostic techniques. Invest in training and resources to improve your knowledge and skills.

Addressing these challenges requires a combination of technical expertise, advanced diagnostic tools, and a systematic approach to troubleshooting.

8. Choosing the Right Diagnostic Software

Which diagnostic software is best suited for working with BlueTEC systems and C4/C6 interfaces?

Several diagnostic software options are available for working with BlueTEC systems and C4/C6 interfaces, but the two most popular choices are Xentry and DTS-Monaco:

- Xentry: Xentry is the official diagnostic software used by Mercedes-Benz dealerships. It provides comprehensive diagnostic capabilities, including fault code reading, real-time data monitoring, actuator testing, guided diagnostics, and ECU programming. Xentry is user-friendly and well-suited for both novice and experienced technicians.

- DTS-Monaco: DTS-Monaco is a more advanced diagnostic software that offers greater flexibility and customization options. It is commonly used for ECU programming, coding, and calibration. DTS-Monaco requires more technical expertise than Xentry but provides access to a wider range of functions and parameters.

The choice between Xentry and DTS-Monaco depends on your specific needs and skill level. Xentry is a good choice for general diagnostic work, while DTS-Monaco is better suited for advanced programming and coding tasks.

9. Training and Resources for BlueTEC Diagnostics

Where can technicians find quality training and resources to enhance their BlueTEC diagnostic skills?

Several resources are available to help technicians improve their BlueTEC diagnostic skills:

- Mercedes-Benz Training: Mercedes-Benz offers a range of training courses on BlueTEC systems, including online modules, classroom sessions, and hands-on workshops.

- Automotive Training Centers: Many automotive training centers offer courses on diesel engine diagnostics and emissions control systems. Look for courses that specifically cover BlueTEC technology.

- Online Forums and Communities: Online forums and communities, such as the iATN (International Automotive Technicians Network), provide a platform for technicians to share knowledge, ask questions, and discuss diagnostic challenges.

- DTS-MONACO.EDU.VN: At DTS-MONACO.EDU.VN, we offer specialized training and resources for using DTS-Monaco software for BlueTEC diagnostics and car coding. Our courses cover everything from basic diagnostics to advanced programming techniques.

Investing in training and resources is essential for staying ahead of the curve and providing high-quality diagnostic services for BlueTEC systems. Our address is 275 N Harrison St, Chandler, AZ 85225, United States. You can contact us via Whatsapp at +1 (641) 206-8880. Visit our website at DTS-MONACO.EDU.VN for more information.

10. The Future of BlueTEC Diagnostics

What trends and innovations are shaping the future of BlueTEC diagnostics?

The field of BlueTEC diagnostics is constantly evolving, with several trends and innovations shaping its future:

- Remote Diagnostics: Remote diagnostics allows technicians to diagnose and repair vehicles remotely using telematics data and remote access tools. This technology can reduce downtime and improve efficiency.

- Artificial Intelligence (AI): AI is being used to analyze diagnostic data, identify patterns, and predict potential problems. AI-powered diagnostic tools can help technicians troubleshoot complex issues more quickly and accurately.

- Augmented Reality (AR): AR is being used to overlay diagnostic information onto the real-world view of the vehicle, providing technicians with step-by-step instructions and visual aids.

- Data Analytics: Data analytics is being used to analyze large volumes of diagnostic data to identify trends, improve system performance, and optimize maintenance schedules.

These innovations promise to make BlueTEC diagnostics more efficient, accurate, and accessible in the years to come.

11. Benefits of Investing in Advanced Diagnostic Tools

Why is it a smart move to invest in advanced diagnostic tools for BlueTEC systems?

Investing in advanced diagnostic tools like the C4 and C6 interfaces offers numerous benefits:

- Faster Diagnostics: Advanced tools can quickly pinpoint the root cause of problems, reducing diagnostic time and labor costs.

- Accurate Repairs: Accurate diagnostics lead to effective repairs, reducing the risk of repeat visits and customer dissatisfaction.

- Improved Efficiency: Advanced tools can automate many diagnostic tasks, freeing up technicians to focus on more complex repairs.

- Increased Revenue: By offering a wider range of diagnostic and repair services, you can attract more customers and increase revenue.

- Enhanced Customer Satisfaction: Customers appreciate quick, accurate, and reliable service. Investing in advanced diagnostic tools can help you deliver a superior customer experience.

The initial investment in advanced diagnostic tools may seem significant, but the long-term benefits far outweigh the costs.

12. Maintaining and Updating Your Diagnostic Equipment

How can you ensure your C4 and C6 interfaces and diagnostic software remain in top working condition?

Proper maintenance and regular updates are essential for keeping your diagnostic equipment in top working condition:

- Keep Software Up-to-Date: Regularly update your diagnostic software to ensure compatibility with the latest vehicle models and access to the latest diagnostic routines.

- Protect Your Hardware: Store your C4 and C6 interfaces in a safe, dry place to prevent damage. Avoid exposing them to extreme temperatures or humidity.

- Clean Your Equipment: Regularly clean your diagnostic equipment to remove dirt, dust, and debris. Use a soft cloth and mild cleaning solution.

- Calibrate Your Tools: Calibrate your diagnostic tools regularly to ensure accurate readings. Follow the manufacturer’s instructions for calibration.

- Seek Professional Service: If you encounter any problems with your diagnostic equipment, seek professional service from a qualified technician.

By following these maintenance tips, you can extend the life of your diagnostic equipment and ensure it performs reliably for years to come.

13. Diagnosing Common BlueTEC Error Codes

What are some common error codes encountered in BlueTEC systems, and what do they indicate?

Here are some common error codes encountered in BlueTEC systems and their potential causes:

| Error Code | Description | Potential Causes |

|---|---|---|

| P20EE | SCR Catalyst Efficiency Below Threshold | Faulty NOx sensor, contaminated SCR catalyst, malfunctioning SCR dosing valve |

| P2033 | Exhaust Gas Temperature Sensor Circuit High | Faulty exhaust gas temperature sensor, wiring issue, ECU problem |

| P2463 | Diesel Particulate Filter Restriction | Clogged DPF, faulty DPF pressure sensor, malfunctioning DPF regeneration system |

| P2002 | Diesel Particulate Filter Efficiency Below Threshold | Damaged DPF, faulty DPF pressure sensor, excessive soot buildup |

| P0401 | Exhaust Gas Recirculation Flow Insufficient | Faulty EGR valve, clogged EGR passages, vacuum leak |

| P229F | NOx Sensor Circuit Range/Performance Bank 1 | Faulty NOx sensor, wiring issue, ECU problem |

| P20BA | Reductant Heater “A” Control Circuit Performance | Faulty reductant heater, wiring issue, ECU problem |

Understanding these common error codes and their potential causes can help you quickly narrow down the source of the problem and perform effective repairs.

14. Optimizing Your Diagnostic Workflow

How can technicians streamline their diagnostic workflow to improve efficiency and accuracy?

Here are some tips for optimizing your diagnostic workflow:

- Gather Information: Before starting the diagnostic process, gather as much information as possible about the problem, including the vehicle’s history, symptoms, and any recent repairs.

- Use a Checklist: Use a diagnostic checklist to ensure that you follow a systematic approach and don’t miss any important steps.

- Prioritize Fault Codes: Prioritize fault codes based on their severity and relevance to the symptoms. Start with the most likely causes and work your way down the list.

- Use Real-Time Data Monitoring: Use real-time data monitoring to identify anomalies and confirm your suspicions.

- Document Your Findings: Document your findings throughout the diagnostic process, including fault codes, real-time data readings, actuator test results, and any repairs performed.

- Learn from Your Mistakes: Analyze your diagnostic successes and failures to identify areas for improvement.

By following these tips, you can improve your diagnostic efficiency and accuracy, leading to faster repairs and happier customers.

15. The Importance of Regular System Maintenance

Why is routine maintenance crucial for the longevity and performance of BlueTEC systems?

Regular system maintenance is essential for the longevity and performance of BlueTEC systems. Here are some key maintenance tasks:

- Oil Changes: Regular oil changes are essential for maintaining engine health and preventing damage to the DPF.

- Filter Replacements: Replace air filters, fuel filters, and cabin filters according to the manufacturer’s recommendations.

- Fluid Checks: Check and top off all fluids, including coolant, brake fluid, power steering fluid, and transmission fluid.

- DPF Regeneration: Ensure that the DPF regenerates properly to prevent clogging.

- SCR System Maintenance: Inspect the SCR system for leaks, damage, and proper operation.

- Sensor Inspections: Inspect all sensors for damage, corrosion, and proper function.

Following a regular maintenance schedule can help prevent problems before they occur, extending the life of your BlueTEC system and ensuring optimal performance.

16. Decoding VIN Information for Accurate Diagnostics

How does VIN (Vehicle Identification Number) decoding aid in ensuring precise BlueTEC diagnostics?

Decoding the VIN is a critical first step in any diagnostic procedure. It provides essential information about the vehicle’s make, model, year, engine type, and factory-installed options. This information helps technicians:

- Identify the Correct Diagnostic Procedures: Different BlueTEC models may require different diagnostic procedures. VIN decoding ensures that you use the correct procedures for the specific vehicle.

- Access the Correct Technical Information: VIN decoding allows you to access the correct wiring diagrams, component locations, and technical specifications.

- Ensure Parts Compatibility: VIN decoding ensures that you order the correct replacement parts for the vehicle.

Many diagnostic software programs include built-in VIN decoding features. You can also use online VIN decoding tools to obtain this information.

17. Utilizing Wiring Diagrams for Effective Troubleshooting

How do wiring diagrams facilitate more effective troubleshooting of BlueTEC systems?

Wiring diagrams are essential for troubleshooting electrical problems in BlueTEC systems. They show the connections between all electrical components, including sensors, actuators, and control units. Wiring diagrams help technicians:

- Trace Circuits: Wiring diagrams allow you to trace circuits to identify shorts, opens, and other electrical faults.

- Locate Components: Wiring diagrams show the physical location of electrical components within the vehicle.

- Verify Connections: Wiring diagrams allow you to verify that all electrical connections are correct.

Mercedes-Benz WIS (Workshop Information System) provides detailed wiring diagrams for all vehicle models. You can also find wiring diagrams in some aftermarket repair manuals and online databases.

18. The Ethical Considerations in Car Coding

What ethical considerations should technicians keep in mind when performing car coding on BlueTEC systems?

Car coding can be a powerful tool, but it also raises some ethical considerations:

- Compliance with Regulations: Ensure that any coding changes comply with all applicable emissions regulations and safety standards.

- Transparency with Customers: Be transparent with customers about any coding changes you make to their vehicles. Explain the purpose of the changes and any potential consequences.

- Protecting Vehicle Security: Take steps to protect vehicle security when performing coding. Use secure diagnostic tools and follow best practices for data protection.

- Avoiding Malicious Intent: Never use car coding to disable safety features, manipulate emissions controls, or engage in other malicious activities.

Technicians have a responsibility to use car coding ethically and responsibly.

19. Future Innovations in Diesel Engine Technology

What future innovations can we anticipate in diesel engine technology, and how will these impact diagnostics?

Diesel engine technology is continuing to evolve, with several innovations on the horizon:

- Advanced Combustion Strategies: New combustion strategies, such as gasoline direct injection (GDI) and homogeneous charge compression ignition (HCCI), promise to improve fuel efficiency and reduce emissions.

- Electrification: Hybrid and plug-in hybrid diesel engines are becoming more common, offering improved fuel economy and reduced emissions.

- Alternative Fuels: Alternative fuels, such as biodiesel and renewable diesel, offer a sustainable alternative to conventional diesel fuel.

- Advanced Emissions Control Systems: New emissions control systems, such as close-coupled catalytic converters and advanced particulate filters, promise to further reduce emissions.

These innovations will require new diagnostic tools and techniques. Technicians will need to stay up-to-date on the latest technologies to effectively diagnose and repair future diesel engines.

20. The Benefits of Using Genuine Parts in BlueTEC Repairs

Why is using genuine Mercedes-Benz parts in BlueTEC repairs often the best approach?

Using genuine Mercedes-Benz parts in BlueTEC repairs offers several advantages:

- Guaranteed Compatibility: Genuine parts are designed to fit and function correctly in Mercedes-Benz vehicles.

- Superior Quality: Genuine parts are made from high-quality materials and are built to last.

- Warranty Protection: Genuine parts are typically backed by a warranty, providing added peace of mind.

- Optimal Performance: Genuine parts are designed to optimize the performance of your BlueTEC system.

- Compliance with Standards: Genuine parts meet all applicable emissions regulations and safety standards.

While aftermarket parts may be less expensive, they may not offer the same level of quality, compatibility, and performance as genuine parts. In many cases, using genuine parts is the best way to ensure a long-lasting and reliable repair.

21. How to Navigate Mercedes-Benz Diagnostic Forums

What’s the best way to engage with Mercedes-Benz diagnostic forums to get your questions answered?

Engaging with online forums can be a great way to get help with diagnostic challenges. Here are some tips for navigating Mercedes-Benz diagnostic forums:

- Search Before Posting: Before posting a question, search the forum to see if someone has already asked and answered it.

- Be Specific: When posting a question, be as specific as possible about the problem you are experiencing, the vehicle model, and any diagnostic steps you have already taken.

- Provide Details: Provide as much detail as possible about the symptoms, fault codes, and any relevant data readings.

- Be Polite: Be polite and respectful when interacting with other forum members.

- Follow the Rules: Follow the forum rules and guidelines.

- Give Back: Once you have gained some experience, contribute to the forum by answering questions and sharing your knowledge.

By following these tips, you can make the most of Mercedes-Benz diagnostic forums and get the help you need to diagnose and repair BlueTEC systems.

22. The Cost-Effectiveness of Preventative Maintenance

How does preventative maintenance save money on BlueTEC systems in the long run?

Preventative maintenance is a cost-effective way to extend the life of your BlueTEC system and avoid costly repairs. By following a regular maintenance schedule, you can:

- Prevent Problems: Preventative maintenance can identify and address potential problems before they become major issues.

- Improve Fuel Economy: Regular maintenance can help improve fuel economy, saving you money at the pump.

- Reduce Emissions: Regular maintenance can help reduce emissions, ensuring that your vehicle complies with environmental regulations.

- Extend Component Life: Preventative maintenance can extend the life of critical components, such as the DPF and SCR catalyst.

- Avoid Downtime: Preventative maintenance can help avoid unexpected breakdowns and downtime.

The cost of preventative maintenance is typically much lower than the cost of repairing a major problem.

23. Understanding Diagnostic Trouble Code (DTC) Severity Levels

How do technicians use the severity levels of Diagnostic Trouble Codes (DTCs) to prioritize repairs?

Diagnostic Trouble Codes (DTCs) are not all created equal. They come in different severity levels, indicating the seriousness of the problem and the urgency of the repair. Understanding these severity levels can help technicians prioritize their work.

- Informational Codes: These codes indicate a minor issue that does not affect vehicle performance or safety. They may not require immediate attention.

- Warning Codes: These codes indicate a more serious issue that could affect vehicle performance or safety. They should be investigated and repaired as soon as possible.

- Severe Codes: These codes indicate a critical issue that could cause significant damage to the vehicle or pose a safety hazard. They require immediate attention.

When diagnosing a BlueTEC system, prioritize the DTCs based on their severity level. Address the most severe codes first to prevent further damage or safety risks.

24. Advanced Techniques for DPF Regeneration

What advanced techniques can be employed to ensure effective DPF regeneration in BlueTEC systems?

Diesel Particulate Filters (DPFs) require regular regeneration to prevent clogging. Here are some advanced techniques for ensuring effective DPF regeneration:

- Forced Regeneration: Use a diagnostic tool to initiate a forced DPF regeneration cycle. This can be helpful if the DPF is severely clogged.

- Adaptation Reset: Reset the DPF adaptation values after cleaning or replacing the DPF. This ensures that the ECU accurately monitors DPF pressure and soot levels.

- Additive Use: Use a DPF regeneration additive to lower the DPF regeneration temperature and improve regeneration efficiency.

- Driving Habits: Encourage customers to adopt driving habits that promote DPF regeneration, such as driving at highway speeds for extended periods.

These techniques can help ensure that the DPF regenerates effectively and prevent costly repairs.

25. The Role of Aftermarket Diagnostic Tools

What role do aftermarket diagnostic tools play in servicing BlueTEC systems?

While genuine Mercedes-Benz diagnostic tools like Xentry are the gold standard, aftermarket diagnostic tools can also play a valuable role in servicing BlueTEC systems. Aftermarket tools offer several advantages:

- Cost-Effectiveness: Aftermarket tools are typically less expensive than genuine tools.

- Versatility: Many aftermarket tools support multiple vehicle brands and models.

- Ease of Use: Some aftermarket tools have a more user-friendly interface than genuine tools.

However, it’s important to choose aftermarket tools carefully. Look for tools that offer comprehensive coverage of Mercedes-Benz vehicles and support all the necessary diagnostic functions.

26. Utilizing Online Resources for Wiring Schematics

How can technicians leverage online resources to find accurate wiring schematics for BlueTEC systems?

Access to accurate wiring schematics is essential for troubleshooting electrical problems in BlueTEC systems. Here are some online resources for finding wiring schematics:

- Mercedes-Benz WIS (Workshop Information System): The official Mercedes-Benz resource for wiring schematics.

- Alldata: A subscription-based service that provides access to wiring schematics and other repair information.

- Mitchell 1: Another subscription-based service that offers wiring schematics and repair information.

- Online Forums: Online forums can be a valuable source of wiring schematics, but be sure to verify the accuracy of the information.

When using online resources for wiring schematics, be sure to verify that the information is accurate and up-to-date.

27. The Impact of Fuel Quality on BlueTEC System Performance

How does the quality of diesel fuel affect the overall performance and longevity of BlueTEC systems?

The quality of diesel fuel has a significant impact on the performance and longevity of BlueTEC systems. Poor-quality fuel can cause a variety of problems:

- Clogged Fuel Filters: Contaminated fuel can clog fuel filters, reducing engine performance and potentially damaging the fuel pump.

- Injector Problems: Poor-quality fuel can damage fuel injectors, leading to reduced fuel economy and increased emissions.

- DPF Problems: Fuel additives and contaminants can clog the DPF, reducing its efficiency and lifespan.

- SCR Catalyst Problems: Fuel contaminants can poison the SCR catalyst, reducing its ability to remove NOx from the exhaust.

To protect your BlueTEC system, use high-quality diesel fuel from reputable sources. Avoid using fuel that is contaminated or has been stored for long periods.

28. Understanding and Troubleshooting SCR Systems

How can technicians effectively troubleshoot Selective Catalytic Reduction (SCR) systems in BlueTEC vehicles?

Selective Catalytic Reduction (SCR) systems are a key component of BlueTEC technology. They use a catalyst to convert NOx into harmless nitrogen and water. Here are some tips for troubleshooting SCR systems:

- Check for Leaks: Inspect the SCR system for leaks of diesel exhaust fluid (DEF).

- Verify DEF Quality: Ensure that the DEF is of the correct quality and concentration.

- Test the NOx Sensors: Test the NOx sensors to ensure they are functioning correctly.

- Inspect the SCR Catalyst: Inspect the SCR catalyst for damage or contamination.

- Check the DEF Injector: Check the DEF injector for proper operation.

Proper maintenance and troubleshooting of the SCR system are essential for maintaining the performance and emissions of your BlueTEC vehicle.

29. How to Stay Updated on BlueTEC Technology

What are the best strategies for technicians to stay informed about the latest advancements in BlueTEC technology?

BlueTEC technology is constantly evolving. Here are some strategies for staying informed about the latest advancements:

- Attend Training Courses: Attend training courses offered by Mercedes-Benz and other automotive training providers.

- Read Technical Publications: Read technical publications from Mercedes-Benz and other industry sources.

- Attend Industry Events: Attend industry events, such as trade shows and conferences.

- Join Online Forums: Join online forums and communities to connect with other technicians and share knowledge.

- Follow Industry News: Follow industry news websites and publications to stay up-to-date on the latest developments.

Staying informed about the latest advancements in BlueTEC technology is essential for providing high-quality diagnostic and repair services.

30. Maximizing the Lifespan of Your BlueTEC Engine

What key practices will ensure the longest possible lifespan for a BlueTEC diesel engine?

To maximize the lifespan of your BlueTEC diesel engine, follow these key practices:

- Regular Maintenance: Follow the manufacturer’s recommended maintenance schedule.

- High-Quality Fuel: Use high-quality diesel fuel from reputable sources.

- Genuine Parts: Use genuine Mercedes-Benz parts for repairs.

- Proper Driving Habits: Avoid aggressive driving and excessive idling.

- Timely Repairs: Address any problems promptly to prevent further damage.

- Professional Service: Have your vehicle serviced by a qualified technician who is familiar with BlueTEC systems.

By following these practices, you can extend the life of your BlueTEC engine and enjoy years of reliable performance.

We hope this comprehensive guide has equipped you with the knowledge and resources you need to effectively diagnose and maintain your BlueTEC system using C4 and C6 interfaces. At DTS-MONACO.EDU.VN, we are committed to providing you with the tools, training, and support you need to succeed. Contact us today to learn more about our services and how we can help you keep your Mercedes-Benz running smoothly. Visit our website at DTS-MONACO.EDU.VN, call us, or visit us at Address: 275 N Harrison St, Chandler, AZ 85225, United States and contact us via Whatsapp at +1 (641) 206-8880. Let’s work together to keep your BlueTEC performing at its best!

Benz diagnostic tool mb star c3 with newest PCB

Benz diagnostic tool mb star c3 with newest PCB

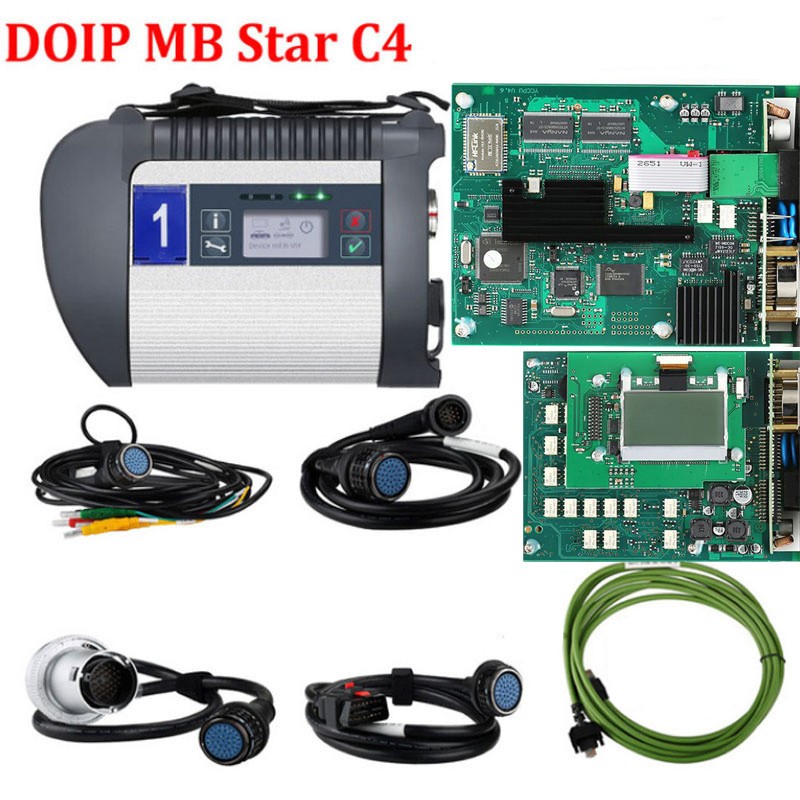

benz diagnostic tool mb star c4 support doip

benz diagnostic tool mb star c4 support doip

benz diagnostic tool mb star c5 doip with newest software

benz diagnostic tool mb star c5 doip with newest software

benz diagnostic tool mb star c6 with G1 laptop

benz diagnostic tool mb star c6 with G1 laptop

FAQ About BlueTEC Diagnostics and C4/C6 Interfaces

1. What is BlueTEC technology?

BlueTEC is Mercedes-Benz’s term for a suite of technologies designed to minimize diesel engine emissions, reducing nitrogen oxides (NOx) and particulate matter through systems like diesel particulate filters (DPF) and selective catalytic reduction (SCR).

2. Can C4 and C6 interfaces be used for all Mercedes-Benz models?

The C4 interface is generally used for older models, while the C6 interface supports newer models with advanced communication protocols.

3. What is car coding, and why is it important for BlueTEC systems?

Car coding involves adapting control units to new components, updating software, and enabling or disabling features, ensuring all systems function correctly and comply with emission standards.

4. What are some common challenges in diagnosing BlueTEC systems?

Common challenges include intermittent faults, multiple fault codes, software glitches, and the need for up-to-date knowledge of evolving BlueTEC technologies.

5. Which diagnostic software is recommended for BlueTEC systems?

Xentry is the official software used by Mercedes-Benz, while DTS-Monaco offers greater flexibility and customization for advanced programming and coding tasks.

6. Where can technicians find training for BlueTEC diagnostics?

Training resources include Mercedes-Benz training courses, automotive training centers, online forums, and specialized courses at DTS-MONACO.EDU.VN.

7. How does remote diagnostics help in BlueTEC servicing?

Remote diagnostics allows technicians to diagnose and repair vehicles remotely using telematics data and access tools, reducing downtime and improving efficiency.

8. What are the benefits of using genuine parts in BlueTEC repairs?

Genuine Mercedes-Benz parts ensure guaranteed compatibility, superior quality, warranty protection, optimal performance, and compliance with emission standards.

9. How does the quality of diesel fuel affect BlueTEC system performance?

Poor-quality fuel can clog filters, damage injectors, and harm the DPF and SCR catalyst, so high-quality fuel from reputable sources is essential.

10. What are the key practices to maximize the lifespan of a BlueTEC engine?

Key practices include regular maintenance, high-quality fuel, genuine parts, proper driving habits, timely repairs, and professional service from technicians familiar with BlueTEC systems.