Can ECOM perform tests on soft close actuators? Yes, it can, especially through specialized software that allows for comprehensive diagnostics and functionality checks. DTS-MONACO.EDU.VN provides access to advanced car coding knowledge and tools. Exploring options for advanced diagnostics, actuator testing and ECOM car coding opens up a wide range of possibilities, including enhanced vehicle diagnostics and performance monitoring.

Contents

- 1. Understanding ECOM and Soft Close Actuators

- 1.1. What is ECOM?

- 1.2. Soft Close Actuators: An Overview

- 1.3. The Role of Software in Actuator Testing

- 2. Capabilities of ECOM in Testing Soft Close Actuators

- 2.1. Diagnostic Functionality

- 2.2. Supported Tests and Procedures

- 2.3. Software Compatibility

- 3. Step-by-Step Guide: Testing Soft Close Actuators with ECOM and Software

- 3.1. Preparation and Setup

- 3.2. Connecting to the Vehicle’s System

- 3.3. Performing Diagnostic Tests

- 3.4. Analyzing Results and Troubleshooting

- 4. Common Issues and Solutions

- 4.1. Identifying Common Problems

- 4.2. Troubleshooting Techniques

- 4.3. Repair and Replacement Strategies

- 5. Advantages of Using ECOM for Actuator Testing

- 5.1. Precision and Accuracy

- 5.2. Time Savings

- 5.3. Cost-Effectiveness

- 6. Software Options for ECOM Actuator Testing

- 6.1. Overview of Popular Diagnostic Software

- 6.2. Key Features and Benefits

- 6.3. Choosing the Right Software for Your Needs

- 7. Case Studies: Real-World Applications

- 7.1. Example 1: Diagnosing a Faulty Soft Close Actuator in a Mercedes-Benz S-Class

- 7.2. Example 2: Troubleshooting a Non-Functional Soft Close Actuator in a BMW 7 Series

- 7.3. Lessons Learned

- 8. Advanced Techniques for ECOM and Software Usage

- 8.1. ECU Coding and Programming

- 8.2. Data Logging and Analysis

- 8.3. Remote Diagnostics and Support

- 9. Training and Resources for ECOM and Software

- 9.1. Formal Training Programs

- 9.2. Online Resources and Communities

- 9.3. DTS-MONACO.EDU.VN: Your Partner in Advanced Car Coding

- 10. The Future of Actuator Testing with ECOM and Software

- 10.1. Emerging Technologies

- 10.2. Industry Trends

- 10.3. Preparing for the Future

- 11. Optimizing Your Workflow with ECOM and Software

- 11.1. Creating a Streamlined Diagnostic Process

- 11.2. Managing Data and Documentation

- 11.3. Integrating ECOM and Software into Your Business

- 12. Safety Considerations When Using ECOM and Software

- 12.1. Electrical Safety

- 12.2. Software Safety

- 12.3. Vehicle Safety

- 13. Common Mistakes to Avoid

- 13.1. Incorrect Interface Selection

- 13.2. Outdated Software

- 13.3. Neglecting Basic Troubleshooting

- 13.4. Ignoring Warning Signs

- 14. Frequently Asked Questions (FAQs)

- 14.1. Can ECOM perform tests on soft close actuators?

- 14.2. What is an ECOM interface?

- 14.3. What software is compatible with ECOM for actuator testing?

- 14.4. What are some common issues with soft close actuators?

- 14.5. How can I troubleshoot a faulty soft close actuator?

- 14.6. What are the benefits of using ECOM for actuator testing?

- 14.7. Do I need special training to use ECOM and diagnostic software?

- 14.8. Can ECOM be used for ECU coding and programming?

- 14.9. What safety precautions should I take when using ECOM and software?

- 14.10. Where can I find more information about ECOM and diagnostic software?

- 15. Conclusion: Empowering Automotive Technicians with ECOM and Software

1. Understanding ECOM and Soft Close Actuators

1.1. What is ECOM?

ECOM stands for Electronic Communication. In automotive diagnostics, ECOM interfaces are crucial tools used for communication between a vehicle’s electronic control units (ECUs) and diagnostic software. These interfaces allow technicians to perform a variety of tasks, including reading diagnostic trouble codes (DTCs), monitoring live data, performing actuator tests, and reprogramming ECUs. According to Bosch Automotive Service Solutions, advanced diagnostic tools like ECOM interfaces are essential for modern vehicle maintenance and repair, enabling precise identification and resolution of complex electronic issues.

1.2. Soft Close Actuators: An Overview

Soft close actuators are electromechanical devices used in modern vehicles to ensure doors and trunks close completely and securely with minimal effort. These systems enhance convenience and luxury by automatically pulling the door or trunk lid closed if it is not fully latched. The actuators typically consist of an electric motor, gears, sensors, and a control module that communicates with the vehicle’s central control system.

1.3. The Role of Software in Actuator Testing

Software plays a pivotal role in testing soft close actuators. Diagnostic software, such as that supported by ECOM interfaces, allows technicians to send commands to the actuator, monitor its performance, and diagnose any faults. These software applications can perform specific tests to check the actuator’s motor, sensors, and control module, ensuring that each component is functioning correctly.

Soft Close Actuator

Soft Close Actuator

Alt: Soft close actuator diagnostics using ECOM software for vehicle maintenance.

2. Capabilities of ECOM in Testing Soft Close Actuators

2.1. Diagnostic Functionality

ECOM interfaces, when paired with appropriate diagnostic software, offer extensive diagnostic capabilities for soft close actuators. Technicians can use these tools to:

- Read Diagnostic Trouble Codes (DTCs): Identify specific faults within the actuator system.

- Monitor Live Data: Observe real-time parameters such as voltage, current, and sensor readings.

- Perform Actuator Tests: Activate the actuator to check its mechanical and electrical operation.

- Access Control Module Information: Retrieve information about the actuator’s software version and configuration.

2.2. Supported Tests and Procedures

ECOM interfaces and diagnostic software support a range of tests tailored for soft close actuators. These may include:

- Motor Function Test: Checks the electrical motor’s ability to operate and deliver the necessary force.

- Sensor Calibration Test: Verifies the accuracy of the sensors that detect door or trunk lid position.

- Communication Test: Ensures proper communication between the actuator’s control module and the vehicle’s central system.

- Force Measurement Test: Measures the force applied by the actuator to ensure it meets specified standards.

2.3. Software Compatibility

The effectiveness of ECOM in testing soft close actuators depends heavily on the compatibility of the diagnostic software. Popular software platforms like Mercedes-Benz XENTRY/DAS, BMW ISTA, and VAG ODIS are designed to work seamlessly with ECOM interfaces, providing comprehensive diagnostic and testing capabilities.

3. Step-by-Step Guide: Testing Soft Close Actuators with ECOM and Software

3.1. Preparation and Setup

Before beginning the testing process, ensure that you have the necessary equipment and information.

- Gather Equipment: ECOM interface, diagnostic software, vehicle battery charger (to maintain voltage during testing), and the vehicle’s service manual.

- Software Installation: Install the diagnostic software on a computer and ensure it is properly configured to communicate with the ECOM interface.

- Vehicle Connection: Connect the ECOM interface to the vehicle’s OBD-II port and power on the diagnostic software.

3.2. Connecting to the Vehicle’s System

Establishing a stable connection between the ECOM interface and the vehicle’s system is crucial for accurate testing.

- Identify the Actuator: Use the diagnostic software to locate the soft close actuator within the vehicle’s control modules.

- Establish Communication: Initiate communication with the actuator’s control module to access diagnostic functions.

- Verify Connection: Confirm that the software displays the actuator’s status and available test options.

3.3. Performing Diagnostic Tests

Once connected, you can perform a variety of diagnostic tests to assess the actuator’s performance.

- Read DTCs: Check for any stored diagnostic trouble codes that indicate faults within the system.

- Run Actuator Tests: Use the software to activate the actuator and observe its operation.

- Monitor Live Data: View real-time parameters to identify any anomalies in voltage, current, or sensor readings.

3.4. Analyzing Results and Troubleshooting

After completing the tests, analyze the results to identify any issues and determine the necessary repairs.

- Interpret DTCs: Refer to the vehicle’s service manual or online resources to understand the meaning of any DTCs.

- Evaluate Actuator Performance: Compare the observed performance with the manufacturer’s specifications to identify deviations.

- Troubleshoot Issues: Use the diagnostic software and service manual to guide troubleshooting steps, such as checking wiring connections, replacing faulty sensors, or reprogramming the control module.

4. Common Issues and Solutions

4.1. Identifying Common Problems

Soft close actuators can experience several common issues that may require diagnosis and repair.

- Motor Failure: The electric motor may fail due to wear, corrosion, or electrical faults.

- Sensor Malfunctions: Sensors that detect door or trunk lid position can become inaccurate or fail completely.

- Wiring Issues: Damaged or corroded wiring can disrupt communication between the actuator and the vehicle’s control system.

- Control Module Problems: The actuator’s control module may experience software glitches or hardware failures.

4.2. Troubleshooting Techniques

Effective troubleshooting techniques can help identify the root cause of the problem and guide the repair process.

- Visual Inspection: Check for any visible signs of damage, such as broken wires, corrosion, or physical damage to the actuator.

- Electrical Testing: Use a multimeter to check voltage, current, and resistance in the actuator’s wiring and components.

- Software Diagnostics: Utilize the diagnostic software to perform detailed tests and monitor live data.

4.3. Repair and Replacement Strategies

Depending on the nature of the problem, various repair and replacement strategies can be employed.

- Component Replacement: Replace faulty components such as the motor, sensors, or control module.

- Wiring Repair: Repair or replace damaged wiring and connectors.

- Software Reprogramming: Reprogram the actuator’s control module with updated software to resolve glitches or compatibility issues.

5. Advantages of Using ECOM for Actuator Testing

5.1. Precision and Accuracy

ECOM interfaces, combined with specialized diagnostic software, provide a high level of precision and accuracy in actuator testing. These tools can detect subtle issues that may not be apparent through visual inspection or basic testing methods.

5.2. Time Savings

Using ECOM for actuator testing can significantly reduce diagnostic time. The software-guided tests and real-time data monitoring capabilities allow technicians to quickly identify faults and pinpoint the source of the problem.

5.3. Cost-Effectiveness

While the initial investment in ECOM and diagnostic software may seem significant, the long-term cost savings can be substantial. By accurately diagnosing and repairing issues, technicians can avoid unnecessary component replacements and reduce the risk of repeat repairs.

6. Software Options for ECOM Actuator Testing

6.1. Overview of Popular Diagnostic Software

Several diagnostic software platforms are compatible with ECOM interfaces, each offering unique features and capabilities.

- Mercedes-Benz XENTRY/DAS: Comprehensive diagnostic software for Mercedes-Benz vehicles, providing detailed actuator testing and programming functions.

- BMW ISTA: Advanced diagnostic software for BMW vehicles, offering extensive diagnostic and troubleshooting capabilities.

- VAG ODIS: Diagnostic software for Volkswagen, Audi, Skoda, and SEAT vehicles, providing detailed actuator testing and adaptation functions.

- DTS-Monaco: A versatile diagnostic and engineering tool used for ECU flashing, coding, and advanced diagnostics in various vehicle brands.

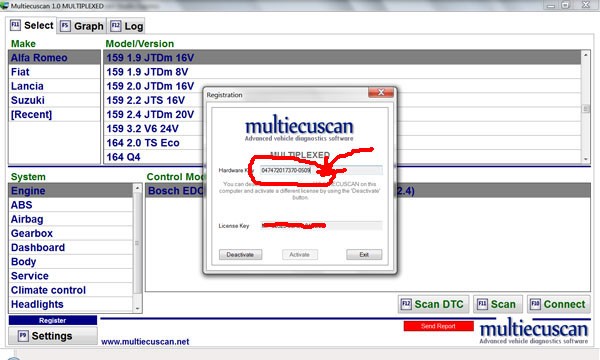

- Multiecuscan: Software for diagnostic work for the Alfa Romeo Giulia/Stelvio and 4C.

6.2. Key Features and Benefits

Each software option offers specific advantages for actuator testing.

- XENTRY/DAS and ISTA: Known for their comprehensive diagnostic coverage and detailed troubleshooting guides.

- ODIS: Offers advanced adaptation and programming functions for VAG vehicles.

- DTS-Monaco: Provides flexibility and customization options for advanced users.

- Multiecuscan: Compatible with ELM327 / CAN327 min. V1.3, FIAT-KKL Interface, OBDProtect Interface, OBDKey Interface, Bluetooth interface CAN327, OBDLink interface, ELM327 and CAN327 WIFI interface.

6.3. Choosing the Right Software for Your Needs

Selecting the appropriate software depends on the vehicle brands you service, your diagnostic needs, and your budget. Consider the following factors when making your decision:

- Vehicle Compatibility: Ensure the software supports the vehicle brands and models you work with.

- Diagnostic Capabilities: Evaluate the software’s diagnostic functions, including DTC reading, live data monitoring, and actuator testing.

- User Interface: Choose software with an intuitive and user-friendly interface.

- Support and Updates: Consider the availability of technical support and software updates.

7. Case Studies: Real-World Applications

7.1. Example 1: Diagnosing a Faulty Soft Close Actuator in a Mercedes-Benz S-Class

A Mercedes-Benz S-Class was brought into the shop with a complaint that the driver’s side door was not closing properly. The soft close actuator would attempt to pull the door closed, but it would not fully latch. Using Mercedes-Benz XENTRY/DAS software and an ECOM interface, the technician connected to the vehicle’s diagnostic system and performed the following steps:

- Read DTCs: The software revealed a DTC indicating a fault in the driver’s side door soft close actuator.

- Performed Actuator Test: The technician ran an actuator test to observe the motor’s operation. The test showed that the motor was struggling to generate enough force to fully close the door.

- Monitored Live Data: The live data stream indicated that the voltage to the motor was within the specified range, but the current was lower than expected.

Based on these findings, the technician concluded that the motor in the soft close actuator was failing. The actuator was replaced, and the system was retested using XENTRY/DAS to ensure proper operation. The door now closed smoothly and securely.

7.2. Example 2: Troubleshooting a Non-Functional Soft Close Actuator in a BMW 7 Series

A BMW 7 Series had a non-functional soft close actuator in the trunk lid. The trunk would close manually, but the soft close feature was not engaging. Using BMW ISTA software and an ECOM interface, the technician performed the following steps:

- Read DTCs: The software showed a DTC indicating a communication fault with the trunk lid soft close actuator.

- Performed Actuator Test: Attempting to run an actuator test resulted in an error message, indicating that the control module was not responding.

- Checked Wiring and Connections: A visual inspection revealed a damaged wiring harness near the trunk hinge.

The technician repaired the damaged wiring harness and reconnected the system. After clearing the DTCs and running the actuator test, the trunk lid soft close function returned to normal operation.

7.3. Lessons Learned

These case studies highlight the importance of using ECOM interfaces and diagnostic software for accurate and efficient actuator testing. By following a systematic diagnostic process and utilizing the capabilities of these tools, technicians can quickly identify and resolve complex issues in soft close actuator systems.

8. Advanced Techniques for ECOM and Software Usage

8.1. ECU Coding and Programming

In some cases, soft close actuator issues may require ECU coding or programming. ECOM interfaces and diagnostic software can be used to:

- Reprogram Control Modules: Update the software in the actuator’s control module to resolve glitches or compatibility issues.

- Code New Actuators: Configure the vehicle’s system to recognize and communicate with a newly installed actuator.

- Customize System Settings: Adjust parameters such as the closing speed or force applied by the actuator.

8.2. Data Logging and Analysis

ECOM interfaces and diagnostic software can log real-time data during actuator operation. This data can be analyzed to identify intermittent issues or performance deviations that may not be apparent during static testing.

8.3. Remote Diagnostics and Support

Advanced diagnostic software platforms offer remote diagnostic and support capabilities. Technicians can use these tools to access vehicle data and perform tests from a remote location, providing assistance to other technicians or diagnosing issues without being physically present.

9. Training and Resources for ECOM and Software

9.1. Formal Training Programs

Several organizations offer formal training programs on the use of ECOM interfaces and diagnostic software. These programs provide in-depth instruction on diagnostic techniques, troubleshooting procedures, and ECU coding and programming.

- Bosch Training: Bosch offers a range of training programs on automotive diagnostics, including courses on the use of diagnostic tools and software.

- Delphi Training: Delphi provides training on vehicle diagnostics and repair, including courses on the use of diagnostic software and ECOM interfaces.

- Snap-on Training: Snap-on offers training programs on automotive diagnostics, including courses on the use of their diagnostic tools and software.

9.2. Online Resources and Communities

Numerous online resources and communities offer valuable information and support for technicians using ECOM interfaces and diagnostic software.

- Automotive Forums: Online forums dedicated to automotive diagnostics and repair can provide valuable insights and troubleshooting tips.

- YouTube Channels: Several YouTube channels offer tutorials and demonstrations on the use of ECOM interfaces and diagnostic software.

- Manufacturer Websites: Vehicle manufacturers often provide technical resources and support information on their websites.

9.3. DTS-MONACO.EDU.VN: Your Partner in Advanced Car Coding

DTS-MONACO.EDU.VN offers comprehensive resources, training, and software solutions for advanced car coding and diagnostics. Whether you’re looking to enhance your skills or need support with complex diagnostic procedures, DTS-MONACO.EDU.VN is your trusted partner.

10. The Future of Actuator Testing with ECOM and Software

10.1. Emerging Technologies

The field of automotive diagnostics is constantly evolving, with new technologies and techniques emerging regularly.

- Artificial Intelligence (AI): AI-powered diagnostic tools can analyze vehicle data and identify potential issues with greater accuracy and efficiency.

- Cloud-Based Diagnostics: Cloud-based diagnostic platforms allow technicians to access vehicle data and perform tests from anywhere with an internet connection.

- Augmented Reality (AR): AR technology can overlay diagnostic information onto the technician’s view of the vehicle, providing real-time guidance and assistance.

10.2. Industry Trends

Several key trends are shaping the future of actuator testing and automotive diagnostics.

- Increased Complexity: Modern vehicles are becoming increasingly complex, with more electronic systems and actuators than ever before.

- Remote Diagnostics: Remote diagnostics are becoming more prevalent, allowing technicians to diagnose and repair vehicles from a distance.

- Data-Driven Diagnostics: Data-driven diagnostics are using vehicle data to identify trends, predict failures, and improve maintenance schedules.

10.3. Preparing for the Future

To stay ahead in the rapidly evolving field of automotive diagnostics, technicians must continuously update their skills and knowledge. This includes:

- Staying Informed: Keep up-to-date with the latest technologies, techniques, and industry trends.

- Investing in Training: Participate in formal training programs and online courses to enhance your diagnostic skills.

- Embracing New Tools: Adopt new diagnostic tools and software platforms to improve your efficiency and accuracy.

11. Optimizing Your Workflow with ECOM and Software

11.1. Creating a Streamlined Diagnostic Process

To maximize the benefits of using ECOM and diagnostic software, it’s essential to establish a streamlined diagnostic process. This includes:

- Gathering Information: Collect as much information as possible about the vehicle’s symptoms and history.

- Performing a Visual Inspection: Conduct a thorough visual inspection to identify any obvious issues.

- Connecting to the Vehicle: Connect the ECOM interface to the vehicle’s OBD-II port and launch the diagnostic software.

- Reading DTCs: Check for any stored diagnostic trouble codes.

- Performing Actuator Tests: Run relevant actuator tests to assess the performance of the system.

- Monitoring Live Data: Observe real-time parameters to identify any anomalies.

- Analyzing Results: Analyze the test results and data to pinpoint the root cause of the problem.

- Troubleshooting Issues: Follow a systematic troubleshooting process to identify and resolve the issue.

- Verifying Repairs: After completing the repairs, retest the system to ensure proper operation.

11.2. Managing Data and Documentation

Proper data management and documentation are crucial for efficient diagnostics and future reference. This includes:

- Saving Diagnostic Reports: Save diagnostic reports generated by the software for future reference.

- Documenting Troubleshooting Steps: Keep a detailed record of the troubleshooting steps you took and the results you obtained.

- Organizing Data: Organize your data in a logical and easily accessible manner.

11.3. Integrating ECOM and Software into Your Business

Integrating ECOM and diagnostic software into your business can provide numerous benefits, including:

- Improved Efficiency: Reduce diagnostic time and improve overall efficiency.

- Enhanced Customer Satisfaction: Provide accurate and reliable diagnoses, leading to increased customer satisfaction.

- Increased Revenue: Offer advanced diagnostic services and attract new customers.

12. Safety Considerations When Using ECOM and Software

12.1. Electrical Safety

When working with electrical systems, it’s essential to follow proper safety precautions to avoid injury.

- Disconnect the Battery: Disconnect the vehicle’s battery before working on electrical components.

- Use Insulated Tools: Use insulated tools to prevent electrical shocks.

- Avoid Water: Avoid working in wet or damp conditions.

12.2. Software Safety

When using diagnostic software, it’s important to follow safety guidelines to prevent damage to the vehicle’s systems.

- Use Reliable Software: Use only reliable and reputable diagnostic software.

- Follow Instructions: Follow the software’s instructions carefully.

- Avoid Interruptions: Avoid interrupting the software during critical operations such as ECU programming.

12.3. Vehicle Safety

When performing actuator tests, it’s important to ensure the safety of the vehicle and its occupants.

- Clear the Area: Ensure that the area around the vehicle is clear of obstacles and personnel.

- Use Caution: Use caution when activating actuators, as they may move suddenly or forcefully.

- Follow Procedures: Follow the vehicle manufacturer’s recommended procedures for actuator testing.

13. Common Mistakes to Avoid

13.1. Incorrect Interface Selection

Using the wrong ECOM interface for a particular vehicle or software can lead to communication errors or even damage to the vehicle’s systems.

13.2. Outdated Software

Using outdated diagnostic software can result in inaccurate diagnoses or incompatibility issues with newer vehicles.

13.3. Neglecting Basic Troubleshooting

Relying solely on diagnostic software without performing basic troubleshooting steps such as visual inspection and electrical testing can lead to misdiagnosis and unnecessary repairs.

13.4. Ignoring Warning Signs

Ignoring warning signs such as unusual noises, vibrations, or error messages can lead to further damage to the vehicle.

14. Frequently Asked Questions (FAQs)

14.1. Can ECOM perform tests on soft close actuators?

Yes, ECOM can perform tests on soft close actuators through specialized diagnostic software, allowing for comprehensive diagnostics and functionality checks.

14.2. What is an ECOM interface?

An ECOM interface is an electronic communication interface used for communication between a vehicle’s ECUs and diagnostic software.

14.3. What software is compatible with ECOM for actuator testing?

Popular software platforms include Mercedes-Benz XENTRY/DAS, BMW ISTA, VAG ODIS, DTS-Monaco, and Multiecuscan.

14.4. What are some common issues with soft close actuators?

Common issues include motor failure, sensor malfunctions, wiring problems, and control module failures.

14.5. How can I troubleshoot a faulty soft close actuator?

Troubleshooting techniques include visual inspection, electrical testing, and software diagnostics.

14.6. What are the benefits of using ECOM for actuator testing?

Benefits include precision and accuracy, time savings, and cost-effectiveness.

14.7. Do I need special training to use ECOM and diagnostic software?

Yes, formal training programs and online resources are available to help technicians learn how to use ECOM interfaces and diagnostic software effectively.

14.8. Can ECOM be used for ECU coding and programming?

Yes, ECOM interfaces and diagnostic software can be used to reprogram control modules, code new actuators, and customize system settings.

14.9. What safety precautions should I take when using ECOM and software?

Safety precautions include disconnecting the battery, using insulated tools, and following software instructions carefully.

14.10. Where can I find more information about ECOM and diagnostic software?

You can find more information on automotive forums, YouTube channels, manufacturer websites, and DTS-MONACO.EDU.VN.

15. Conclusion: Empowering Automotive Technicians with ECOM and Software

In conclusion, ECOM interfaces and diagnostic software are essential tools for automotive technicians working on modern vehicles. By providing precise diagnostics, efficient testing, and advanced programming capabilities, these tools empower technicians to accurately diagnose and repair complex electronic systems such as soft close actuators. As the automotive industry continues to evolve, staying up-to-date with the latest technologies and techniques is crucial for success. Embrace the power of ECOM and software to elevate your diagnostic skills and provide exceptional service to your customers.

Ready to take your automotive diagnostic skills to the next level? Visit DTS-MONACO.EDU.VN today to explore our comprehensive range of software solutions, training programs, and expert support. Unlock the full potential of your diagnostic capabilities and stay ahead in the rapidly evolving world of automotive technology. Contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States, Whatsapp: +1 (641) 206-8880, or visit our Website: DTS-MONACO.EDU.VN to learn more.