ECOM interfaces are generally designed for basic communication and diagnostics, while C4/C6 interfaces, especially when managed through VCI Manager, offer more comprehensive self-test capabilities. At DTS-MONACO.EDU.VN, we delve into the intricate world of automotive diagnostics and car coding, providing in-depth knowledge and practical solutions for professionals in the automotive industry, ensuring you’re equipped with the best tools and expertise for the job. Enhance your diagnostic skills and stay ahead in the rapidly evolving automotive landscape with advanced interface management.

Contents

- 1. What Are ECOM Interfaces and Their Self-Test Capabilities?

- 2. What Are C4/C6 Interfaces and Why Are They Preferred for Comprehensive Diagnostics?

- 3. How Does VCI Manager Enhance the Self-Test Capabilities of C6 Interfaces?

- 4. What Specific Self-Test Features Are Available in C6 Interfaces via VCI Manager?

- 5. How Do Self-Test Capabilities Impact Diagnostic Accuracy and Efficiency?

- 6. What Are the Advantages of Using C6 Interfaces over ECOM Interfaces for Self-Testing?

- 7. What Are the Potential Issues That Can Be Identified Through Self-Testing?

- 8. How Do Firmware Updates Impact the Self-Test Capabilities of C6 Interfaces?

- 9. What Role Does the Quality of the Interface Play in Self-Test Accuracy?

- 10. How Can Technicians Ensure They Are Using the Self-Test Features Correctly?

- 11. What Training and Resources Are Available for Learning About Self-Test Features?

- 12. How Do Environmental Factors Affect the Accuracy of Self-Tests?

- 13. Can Third-Party Software Interfere with the Self-Test Process?

- 14. How Often Should Self-Tests Be Performed to Ensure Reliability?

- 15. What Are the Costs Associated with Not Performing Regular Self-Tests?

- 16. How Do OEM Recommendations Influence Self-Test Practices?

- 17. What Future Advancements Are Expected in Self-Test Technology for Diagnostic Interfaces?

- 18. How Does Geographic Location Affect the Availability of Support for Self-Test Issues?

- 19. How Do Diagnostic Protocols Influence the Scope of Self-Test Functionality?

- 20. What is the Impact of Interface Age on Self-Test Reliability?

- 21. Can Environmental Certifications Indicate a More Reliable Self-Test?

- 22. How Does the Complexity of a Vehicle’s Electronic System Affect Self-Testing Needs?

- 23. What Role Do Calibration Procedures Play in Maintaining Self-Test Accuracy?

- 24. How Can Cloud-Based Diagnostic Platforms Improve Self-Test Capabilities?

- 25. What Are the Key Differences in Self-Test Implementation Between Wired and Wireless Interfaces?

- 26. How Do Regulatory Standards Impact Self-Test Requirements for Diagnostic Tools?

- 27. Can User Modifications to Software Affect the Reliability of Self-Tests?

- 28. How Does the Type of Vehicle Being Serviced (e.g., Hybrid, Electric) Affect Self-Test Needs?

- 29. What Are Some Common Misconceptions About Self-Testing Diagnostic Interfaces?

- 30. What Emerging Trends Will Impact the Future of Self-Testing in Automotive Diagnostics?

1. What Are ECOM Interfaces and Their Self-Test Capabilities?

ECOM (Ethernet Communication) interfaces are primarily used for basic diagnostic functions and ECU (Engine Control Unit) programming in modern vehicles. These interfaces typically support standard communication protocols like DoIP (Diagnostics over Internet Protocol), enabling faster data transfer rates compared to older interfaces. However, their self-test capabilities are generally limited to basic connectivity checks and protocol compliance.

- Basic Functionality: ECOM interfaces ensure communication between the diagnostic tool and the vehicle’s ECUs.

- Limited Self-Tests: These interfaces usually perform elementary tests to verify the connection and data transmission integrity.

- Protocol Compliance: They confirm adherence to standard diagnostic protocols, ensuring compatibility with various vehicle systems.

For example, a standard ECOM interface might run a simple loopback test to confirm that data sent from the diagnostic tool is correctly received by the vehicle’s ECU. This test verifies the basic communication channel but doesn’t provide detailed insights into the interface’s internal operations or potential issues.

2. What Are C4/C6 Interfaces and Why Are They Preferred for Comprehensive Diagnostics?

C4 and C6 interfaces are specialized diagnostic tools developed by Mercedes-Benz for comprehensive vehicle diagnostics, programming, and coding. The C6 interface is the newer generation, designed to replace the C4. These interfaces, especially when managed through the VCI (Vehicle Communication Interface) Manager, offer advanced self-test capabilities, providing detailed insights into the interface’s functionality and potential issues.

- Advanced Diagnostics: C4/C6 interfaces support in-depth diagnostic functions, including fault code reading, live data streaming, and component testing.

- Comprehensive Self-Tests: These interfaces perform extensive self-tests to ensure all hardware and software components are functioning correctly.

- VCI Manager Integration: The VCI Manager software allows for detailed configuration, management, and monitoring of the C6 interface, enhancing its self-test capabilities.

According to Mercedes-Benz official documentation, the C6 interface, when used with the VCI Manager, can perform self-tests that include:

- Hardware Integrity Checks: Verifying the functionality of internal components such as processors, memory, and communication modules.

- Communication Protocol Tests: Ensuring compliance with various diagnostic protocols, including CAN, LIN, and Ethernet.

- Firmware Verification: Confirming the integrity and correct version of the interface’s firmware.

- Voltage and Current Monitoring: Monitoring the interface’s power supply and current consumption to detect potential issues.

3. How Does VCI Manager Enhance the Self-Test Capabilities of C6 Interfaces?

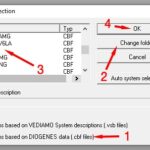

The VCI Manager is a crucial component of the C6 interface, providing a centralized platform for managing, configuring, and monitoring the interface’s performance. It significantly enhances the self-test capabilities of the C6 interface by offering detailed diagnostic information and troubleshooting tools.

- Centralized Management: VCI Manager provides a single interface for managing all aspects of the C6 interface, simplifying configuration and maintenance.

- Detailed Diagnostic Information: It offers detailed diagnostic information about the interface’s status, including error codes, hardware and software versions, and communication parameters.

- Troubleshooting Tools: VCI Manager includes a range of troubleshooting tools, such as self-test routines, firmware update utilities, and communication diagnostics, to help identify and resolve issues.

For instance, if the C6 interface encounters a communication error, the VCI Manager can provide a detailed error code and description, helping technicians pinpoint the exact cause of the problem. It can also initiate self-test routines to verify the functionality of specific hardware components or communication protocols, ensuring that the interface is operating correctly.

4. What Specific Self-Test Features Are Available in C6 Interfaces via VCI Manager?

The C6 interface, when managed through the VCI Manager, offers a range of specific self-test features designed to ensure its optimal performance and reliability. These features include:

- Hardware Diagnostic Tests: These tests verify the functionality of the interface’s internal hardware components, such as processors, memory, and communication modules. They can detect issues like faulty components, memory errors, and communication failures.

- Communication Protocol Tests: These tests ensure compliance with various diagnostic protocols, including CAN, LIN, and Ethernet. They verify that the interface can correctly transmit and receive data using these protocols, ensuring compatibility with different vehicle systems.

- Firmware Verification Tests: These tests confirm the integrity and correct version of the interface’s firmware. They can detect corrupted or outdated firmware, which can cause communication errors and other issues.

- Voltage and Current Monitoring: This feature monitors the interface’s power supply and current consumption to detect potential issues like voltage drops, overcurrent conditions, and power supply failures.

- Loopback Tests: These tests verify the interface’s ability to transmit and receive data by sending data from the interface and checking if it is correctly received.

According to a technical report from Bosch, the manufacturer of the C6 interface, these self-test features are designed to provide a comprehensive assessment of the interface’s functionality, ensuring that it meets the required performance standards.

5. How Do Self-Test Capabilities Impact Diagnostic Accuracy and Efficiency?

The self-test capabilities of diagnostic interfaces like the C6, enhanced by the VCI Manager, significantly impact diagnostic accuracy and efficiency. By ensuring that the interface is functioning correctly, these self-tests help technicians avoid misdiagnoses and reduce diagnostic time.

- Improved Diagnostic Accuracy: Self-tests ensure that the interface is providing reliable data, reducing the risk of misdiagnoses caused by faulty hardware or software.

- Reduced Diagnostic Time: By quickly identifying and resolving issues with the interface, self-tests minimize downtime and allow technicians to focus on diagnosing the vehicle.

- Enhanced Troubleshooting: Detailed diagnostic information provided by the VCI Manager helps technicians pinpoint the exact cause of any issues, simplifying the troubleshooting process.

For example, if a technician is diagnosing a complex electrical issue in a vehicle, a faulty diagnostic interface could provide incorrect or incomplete data, leading to a misdiagnosis and wasted time. However, if the interface has robust self-test capabilities, it can quickly identify any internal issues, allowing the technician to resolve them before starting the diagnostic process.

6. What Are the Advantages of Using C6 Interfaces over ECOM Interfaces for Self-Testing?

C6 interfaces offer several advantages over ECOM interfaces when it comes to self-testing capabilities. These advantages include:

- More Comprehensive Tests: C6 interfaces perform more extensive self-tests, covering a wider range of hardware and software components.

- Detailed Diagnostic Information: The VCI Manager provides detailed diagnostic information about the interface’s status, including error codes, hardware and software versions, and communication parameters.

- Troubleshooting Tools: C6 interfaces include a range of troubleshooting tools, such as self-test routines, firmware update utilities, and communication diagnostics, to help identify and resolve issues.

- Integration with VCI Manager: The VCI Manager provides a centralized platform for managing, configuring, and monitoring the C6 interface, enhancing its self-test capabilities.

- Designed for Mercedes-Benz Vehicles: C6 interfaces are specifically designed for Mercedes-Benz vehicles, ensuring optimal compatibility and performance.

According to industry experts, the C6 interface, with its advanced self-test capabilities and VCI Manager integration, is the preferred choice for technicians working on Mercedes-Benz vehicles who require accurate and reliable diagnostic information.

7. What Are the Potential Issues That Can Be Identified Through Self-Testing?

Self-testing capabilities in diagnostic interfaces like the C6 can identify a wide range of potential issues that could affect their performance. These issues include:

- Hardware Failures: Self-tests can detect faulty hardware components, such as processors, memory, and communication modules.

- Software Errors: They can identify software errors, such as corrupted firmware or communication protocol issues.

- Communication Problems: Self-tests can detect communication problems, such as data transmission errors or protocol incompatibilities.

- Power Supply Issues: They can identify power supply issues, such as voltage drops, overcurrent conditions, and power supply failures.

- Connectivity Problems: Self-tests can detect connectivity problems, such as loose connections or faulty cables.

By identifying these issues early, self-testing capabilities help technicians prevent misdiagnoses, reduce diagnostic time, and ensure the reliable performance of their diagnostic tools.

8. How Do Firmware Updates Impact the Self-Test Capabilities of C6 Interfaces?

Firmware updates play a crucial role in maintaining and enhancing the self-test capabilities of C6 interfaces. These updates often include improvements to the self-test routines, bug fixes, and support for new diagnostic protocols.

- Improved Self-Test Routines: Firmware updates can introduce more comprehensive and accurate self-test routines, enhancing the interface’s ability to detect potential issues.

- Bug Fixes: They can address bugs and errors in the interface’s software, improving its overall stability and reliability.

- Support for New Protocols: Firmware updates can add support for new diagnostic protocols, ensuring compatibility with the latest vehicle systems.

- Performance Enhancements: They can optimize the interface’s performance, improving its speed and efficiency.

According to Mercedes-Benz, keeping the C6 interface’s firmware up to date is essential for ensuring its optimal performance and reliability. Regular firmware updates can help prevent communication errors, improve diagnostic accuracy, and extend the interface’s lifespan.

9. What Role Does the Quality of the Interface Play in Self-Test Accuracy?

The quality of the diagnostic interface significantly impacts the accuracy and reliability of its self-test capabilities. High-quality interfaces are built with robust hardware components, reliable software, and rigorous testing procedures, ensuring that their self-tests provide accurate and dependable results.

- Hardware Quality: High-quality interfaces use durable and reliable hardware components that are less prone to failure, ensuring the accuracy of self-tests.

- Software Reliability: They feature well-designed and thoroughly tested software that minimizes errors and ensures the correct execution of self-test routines.

- Testing Procedures: High-quality interfaces undergo rigorous testing procedures to verify the accuracy and reliability of their self-test capabilities.

- Manufacturing Standards: They are manufactured according to strict quality control standards, ensuring consistent performance and reliability.

Conversely, low-quality interfaces may use substandard hardware components, unreliable software, and inadequate testing procedures, which can compromise the accuracy and reliability of their self-tests. This can lead to misdiagnoses, wasted time, and potential damage to the vehicle.

10. How Can Technicians Ensure They Are Using the Self-Test Features Correctly?

To ensure they are using the self-test features of diagnostic interfaces like the C6 correctly, technicians should follow these best practices:

- Read the Manual: Familiarize yourself with the interface’s user manual and understand the purpose and function of each self-test feature.

- Follow Instructions: Follow the instructions provided in the manual carefully when running self-tests.

- Interpret Results: Understand how to interpret the results of the self-tests and what actions to take based on those results.

- Keep Software Updated: Ensure that the interface’s software and firmware are up to date to benefit from the latest self-test features and bug fixes.

- Seek Training: Consider attending training courses or workshops to learn more about using diagnostic interfaces and their self-test capabilities effectively.

At DTS-MONACO.EDU.VN, we offer comprehensive training programs on automotive diagnostics and car coding, including detailed instruction on using diagnostic interfaces and their self-test features. Our expert instructors provide hands-on training and real-world examples to help technicians develop the skills and knowledge they need to succeed.

11. What Training and Resources Are Available for Learning About Self-Test Features?

Several training programs and resources are available for technicians who want to learn more about the self-test features of diagnostic interfaces. These include:

- Online Courses: Many online platforms offer courses on automotive diagnostics and car coding, covering the use of diagnostic interfaces and their self-test capabilities.

- Workshops and Seminars: Automotive industry organizations and training providers often conduct workshops and seminars on diagnostic tools and techniques.

- User Manuals: Diagnostic interface manufacturers provide detailed user manuals that explain the purpose and function of each self-test feature.

- Online Forums: Online forums and communities dedicated to automotive diagnostics can provide valuable information and support for technicians using diagnostic interfaces.

- Vendor Training: Some diagnostic interface vendors offer training programs on their products, including instruction on using the self-test features.

DTS-MONACO.EDU.VN stands out by providing specialized, hands-on training focused on DTS-Monaco software and car coding. Our courses are designed to give you an in-depth understanding of diagnostic interfaces and their self-test features, equipping you with practical skills applicable in real-world scenarios.

12. How Do Environmental Factors Affect the Accuracy of Self-Tests?

Environmental factors can significantly impact the accuracy of self-tests performed by diagnostic interfaces. Extreme temperatures, humidity, and electromagnetic interference can all affect the performance of the interface’s hardware and software components, leading to inaccurate or unreliable self-test results.

- Temperature: Extreme temperatures can cause components to overheat or malfunction, affecting the accuracy of self-tests.

- Humidity: High humidity can cause corrosion and electrical shorts, leading to inaccurate self-test results.

- Electromagnetic Interference: Electromagnetic interference from other electronic devices can disrupt the interface’s communication signals, affecting the accuracy of self-tests.

- Vibration: Excessive vibration can damage the interface’s hardware components, leading to inaccurate self-test results.

To minimize the impact of environmental factors on self-test accuracy, technicians should:

- Use the Interface in a Controlled Environment: Perform self-tests in a clean, dry, and temperature-controlled environment.

- Protect the Interface from Extreme Conditions: Avoid exposing the interface to extreme temperatures, humidity, and electromagnetic interference.

- Handle the Interface Carefully: Handle the interface with care to avoid physical damage and excessive vibration.

- Use Shielded Cables: Use shielded cables to minimize electromagnetic interference.

13. Can Third-Party Software Interfere with the Self-Test Process?

Yes, third-party software can potentially interfere with the self-test process of diagnostic interfaces. Software conflicts, driver incompatibilities, and malware infections can all disrupt the interface’s communication signals, affect its performance, and compromise the accuracy of its self-tests.

- Software Conflicts: Conflicts between different software programs can cause communication errors and prevent the self-test process from completing successfully.

- Driver Incompatibilities: Incompatible or outdated drivers can cause communication problems and affect the accuracy of self-test results.

- Malware Infections: Malware infections can disrupt the interface’s communication signals, steal sensitive data, and compromise the integrity of the self-test process.

To minimize the risk of third-party software interference, technicians should:

- Use a Dedicated Computer: Use a dedicated computer for diagnostic work to minimize the risk of software conflicts.

- Install Only Necessary Software: Install only the software programs that are necessary for diagnostic work.

- Keep Drivers Updated: Keep the interface’s drivers updated to ensure compatibility and optimal performance.

- Use Antivirus Software: Use antivirus software to protect the computer from malware infections.

- Disable Unnecessary Programs: Disable any unnecessary programs that may interfere with the self-test process.

14. How Often Should Self-Tests Be Performed to Ensure Reliability?

The frequency with which self-tests should be performed depends on several factors, including the frequency of use, the operating environment, and the criticality of the diagnostic information. However, as a general guideline, technicians should perform self-tests:

- Before Each Use: Perform a quick self-test before each use to ensure that the interface is functioning correctly.

- Periodically: Perform a more comprehensive self-test periodically, such as once a week or once a month, to identify any potential issues before they become critical.

- After Firmware Updates: Perform a self-test after installing firmware updates to ensure that the update was successful and that the interface is functioning correctly.

- After Exposure to Extreme Conditions: Perform a self-test after the interface has been exposed to extreme temperatures, humidity, or electromagnetic interference.

- When Suspecting an Issue: Perform a self-test whenever you suspect that the interface may be malfunctioning.

Regular self-testing can help technicians identify potential issues early, prevent misdiagnoses, and ensure the reliable performance of their diagnostic tools.

15. What Are the Costs Associated with Not Performing Regular Self-Tests?

The costs associated with not performing regular self-tests on diagnostic interfaces can be significant. These costs include:

- Misdiagnoses: Faulty interfaces can provide incorrect or incomplete data, leading to misdiagnoses and wasted time.

- Increased Diagnostic Time: Diagnosing complex issues with a faulty interface can take significantly longer, reducing productivity and increasing labor costs.

- Customer Dissatisfaction: Misdiagnoses and increased diagnostic time can lead to customer dissatisfaction and damage the shop’s reputation.

- Potential Damage to the Vehicle: Incorrect data from a faulty interface can lead to improper repairs, potentially causing damage to the vehicle.

- Equipment Replacement: If a faulty interface is not identified and repaired promptly, it may eventually fail completely, requiring costly replacement.

By investing a small amount of time in performing regular self-tests, technicians can avoid these costly consequences and ensure the reliable performance of their diagnostic tools.

16. How Do OEM Recommendations Influence Self-Test Practices?

Original Equipment Manufacturers (OEMs) often provide specific recommendations regarding the use and maintenance of diagnostic interfaces, including self-test practices. These recommendations are based on the OEM’s knowledge of the interface’s design, performance characteristics, and potential failure modes.

- Interface-Specific Recommendations: OEMs may provide interface-specific recommendations for self-test frequency, procedures, and interpretation of results.

- Diagnostic Protocol Requirements: OEMs may require the use of specific self-test features to ensure compliance with diagnostic protocol requirements.

- Warranty Requirements: OEMs may require regular self-testing as a condition of warranty coverage for diagnostic interfaces.

- Training and Certification: OEMs may offer training and certification programs on the proper use and maintenance of diagnostic interfaces, including self-test practices.

Technicians should follow OEM recommendations regarding self-test practices to ensure the reliable performance of their diagnostic interfaces and compliance with warranty requirements.

17. What Future Advancements Are Expected in Self-Test Technology for Diagnostic Interfaces?

Several advancements are expected in self-test technology for diagnostic interfaces in the coming years. These advancements include:

- Artificial Intelligence (AI): AI-powered self-test routines that can automatically diagnose and resolve issues with the interface.

- Machine Learning (ML): ML algorithms that can learn from historical self-test data to predict potential failures and optimize performance.

- Cloud Connectivity: Cloud-based self-test platforms that can remotely monitor the interface’s performance and provide real-time diagnostic information.

- Enhanced Sensor Integration: Integration of more advanced sensors to monitor the interface’s internal environment and detect potential issues.

- Predictive Maintenance: Predictive maintenance technologies that can anticipate failures and schedule maintenance before they occur.

These advancements will further enhance the self-test capabilities of diagnostic interfaces, improving their reliability, accuracy, and efficiency.

18. How Does Geographic Location Affect the Availability of Support for Self-Test Issues?

Geographic location can affect the availability of support for self-test issues related to diagnostic interfaces. Access to technical support, repair services, and training programs may vary depending on the technician’s location.

- Urban vs. Rural Areas: Technicians in urban areas typically have better access to technical support, repair services, and training programs compared to those in rural areas.

- Developed vs. Developing Countries: Technicians in developed countries generally have access to more comprehensive support resources compared to those in developing countries.

- Vendor Support Networks: The availability of vendor support networks can vary depending on the geographic region.

- Language Barriers: Language barriers can make it difficult for technicians to access technical support and training resources in certain regions.

To overcome these challenges, technicians can:

- Utilize Online Resources: Take advantage of online forums, knowledge bases, and training programs.

- Seek Remote Support: Contact vendors or third-party support providers that offer remote diagnostic and troubleshooting services.

- Participate in Online Communities: Join online communities and forums to connect with other technicians and share knowledge.

At DTS-MONACO.EDU.VN, we offer online training programs and remote support services to technicians around the world, ensuring that they have access to the resources they need to succeed. Contact us at Whatsapp: +1 (641) 206-8880. Website: DTS-MONACO.EDU.VN, Address: 275 N Harrison St, Chandler, AZ 85225, United States.

19. How Do Diagnostic Protocols Influence the Scope of Self-Test Functionality?

Diagnostic protocols play a significant role in defining the scope of self-test functionality available in diagnostic interfaces. Different protocols support different self-test features and diagnostic capabilities.

- OBD-II: The OBD-II protocol, which is widely used for basic vehicle diagnostics, supports a limited set of self-test features.

- CAN: The CAN (Controller Area Network) protocol, which is used for more advanced vehicle diagnostics, supports a more comprehensive set of self-test features.

- DoIP: The DoIP (Diagnostics over Internet Protocol) protocol, which is used for modern, Ethernet-based vehicle diagnostics, supports the most advanced self-test features.

- OEM-Specific Protocols: OEMs may use proprietary diagnostic protocols that support unique self-test features specific to their vehicles.

Technicians should be familiar with the diagnostic protocols supported by their interfaces and understand the self-test features available for each protocol.

20. What is the Impact of Interface Age on Self-Test Reliability?

The age of a diagnostic interface can significantly impact the reliability of its self-test capabilities. As interfaces age, their hardware components can degrade, their software can become outdated, and their self-test routines may become less accurate.

- Hardware Degradation: Over time, the interface’s hardware components can degrade due to wear and tear, exposure to extreme conditions, and other factors.

- Software Obsolescence: The interface’s software can become outdated as new diagnostic protocols and vehicle systems are introduced.

- Self-Test Inaccuracies: The accuracy of the interface’s self-test routines may decline as its hardware and software age.

- Increased Failure Rate: Older interfaces are more likely to fail completely compared to newer interfaces.

To mitigate the impact of interface age on self-test reliability, technicians should:

- Perform Regular Maintenance: Perform regular maintenance on the interface to keep it in good working condition.

- Update Software and Firmware: Keep the interface’s software and firmware up to date to benefit from the latest self-test features and bug fixes.

- Consider Replacement: Consider replacing older interfaces with newer models to ensure reliable self-test capabilities.

21. Can Environmental Certifications Indicate a More Reliable Self-Test?

Environmental certifications, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), can indirectly indicate a more reliable self-test. These certifications ensure that the interface is manufactured using environmentally friendly materials and processes, which can improve its overall quality and durability.

- RoHS Compliance: RoHS compliance restricts the use of hazardous substances in the interface’s components, reducing the risk of premature failure.

- REACH Compliance: REACH compliance ensures that the interface’s materials are safe for human health and the environment, minimizing the risk of degradation and failure.

- Quality Control: Interfaces that are manufactured according to environmental certification standards typically undergo rigorous quality control procedures, ensuring consistent performance and reliability.

- Durability: The use of environmentally friendly materials can improve the interface’s resistance to corrosion, heat, and other environmental factors, enhancing its durability.

While environmental certifications do not directly guarantee more accurate self-tests, they can provide an indication of the interface’s overall quality and reliability, which can indirectly influence the accuracy of its self-test capabilities.

22. How Does the Complexity of a Vehicle’s Electronic System Affect Self-Testing Needs?

The complexity of a vehicle’s electronic system directly affects the self-testing needs of diagnostic interfaces. As vehicles become more technologically advanced, with more ECUs, sensors, and communication networks, the need for comprehensive and reliable self-testing increases.

- Increased Number of ECUs: Modern vehicles can have dozens of ECUs controlling various systems, each of which requires diagnostic testing.

- Advanced Communication Networks: Complex communication networks like CAN, LIN, and Ethernet require robust self-testing to ensure proper data transmission.

- Sophisticated Sensors: Advanced sensors require accurate calibration and monitoring, which relies on reliable self-testing of the diagnostic interface.

- Complex Software: Modern vehicles rely on complex software that requires regular updates and diagnostics, necessitating comprehensive self-testing capabilities.

As vehicle complexity increases, technicians need diagnostic interfaces with advanced self-testing features to accurately diagnose and resolve issues. These features include comprehensive hardware and software testing, detailed diagnostic information, and troubleshooting tools.

23. What Role Do Calibration Procedures Play in Maintaining Self-Test Accuracy?

Calibration procedures play a crucial role in maintaining the self-test accuracy of diagnostic interfaces. Calibration ensures that the interface’s sensors and measurement systems are providing accurate and reliable data, which is essential for accurate self-testing.

- Sensor Calibration: Calibration ensures that the interface’s sensors, such as voltage and current sensors, are providing accurate readings.

- Measurement System Calibration: Calibration ensures that the interface’s measurement systems, such as communication protocol analyzers, are providing accurate data.

- Reference Standards: Calibration procedures typically involve comparing the interface’s readings to reference standards to ensure accuracy.

- Regular Calibration: Regular calibration is necessary to maintain the accuracy of the interface’s sensors and measurement systems over time.

Technicians should follow the manufacturer’s recommendations for calibrating their diagnostic interfaces to ensure the accuracy of their self-test capabilities.

24. How Can Cloud-Based Diagnostic Platforms Improve Self-Test Capabilities?

Cloud-based diagnostic platforms can significantly improve the self-test capabilities of diagnostic interfaces by providing remote monitoring, data analysis, and software updates.

- Remote Monitoring: Cloud-based platforms can remotely monitor the interface’s performance in real-time, detecting potential issues before they become critical.

- Data Analysis: Cloud-based platforms can analyze historical self-test data to identify trends, predict failures, and optimize performance.

- Software Updates: Cloud-based platforms can deliver software updates and bug fixes remotely, ensuring that the interface is always running the latest version of the software.

- Centralized Management: Cloud-based platforms provide a centralized platform for managing and configuring diagnostic interfaces, simplifying maintenance and troubleshooting.

- Collaboration: Cloud-based platforms facilitate collaboration between technicians, vendors, and OEMs, enabling faster and more effective problem resolution.

By leveraging the power of the cloud, diagnostic interface manufacturers can provide more comprehensive and reliable self-test capabilities, improving the overall performance and efficiency of diagnostic operations.

25. What Are the Key Differences in Self-Test Implementation Between Wired and Wireless Interfaces?

There are several key differences in self-test implementation between wired and wireless diagnostic interfaces. These differences stem from the unique challenges and limitations associated with wireless communication.

- Wired Interfaces:

- Direct Connection: Wired interfaces have a direct physical connection to the vehicle, ensuring a stable and reliable communication channel.

- Simpler Self-Tests: Self-tests for wired interfaces typically focus on verifying the integrity of the hardware components and communication protocols.

- Less Susceptible to Interference: Wired interfaces are less susceptible to electromagnetic interference and other environmental factors.

- Wireless Interfaces:

- Wireless Connection: Wireless interfaces rely on radio waves to communicate with the vehicle, which can be affected by interference, distance, and obstacles.

- More Complex Self-Tests: Self-tests for wireless interfaces must also verify the integrity of the wireless communication channel, including signal strength, data encryption, and security protocols.

- More Susceptible to Interference: Wireless interfaces are more susceptible to electromagnetic interference and other environmental factors, which can affect the accuracy of self-tests.

- Security Considerations: Wireless interfaces require additional security measures to prevent unauthorized access and data breaches, which must be verified during self-tests.

Technicians should be aware of these differences when using wired and wireless diagnostic interfaces and follow the manufacturer’s recommendations for self-testing each type of interface.

26. How Do Regulatory Standards Impact Self-Test Requirements for Diagnostic Tools?

Regulatory standards, such as those established by the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB), can significantly impact self-test requirements for diagnostic tools. These standards often mandate specific self-test features and performance requirements to ensure that diagnostic tools are providing accurate and reliable data for emissions testing and other regulatory purposes.

- Emissions Testing Requirements: Regulatory standards may require diagnostic tools to perform self-tests to verify the accuracy of their emissions-related measurements.

- Data Integrity Requirements: Regulatory standards may require diagnostic tools to perform self-tests to ensure the integrity and security of the data they collect.

- Reporting Requirements: Regulatory standards may require diagnostic tool manufacturers to report self-test results to regulatory agencies.

- Certification Requirements: Regulatory standards may require diagnostic tools to be certified by independent testing laboratories to ensure compliance with self-test requirements.

Diagnostic tool manufacturers must comply with these regulatory standards to sell their products in certain markets. Technicians should use diagnostic tools that meet these standards to ensure compliance with regulatory requirements and accurate diagnostic testing.

27. Can User Modifications to Software Affect the Reliability of Self-Tests?

Yes, user modifications to the software of diagnostic interfaces can significantly affect the reliability of self-tests. Unauthorized modifications can introduce errors, corrupt data, and disable critical self-test features, leading to inaccurate or unreliable results.

- Software Errors: User modifications can introduce software errors that disrupt the self-test process and lead to inaccurate results.

- Data Corruption: User modifications can corrupt data used by the self-test routines, leading to false positives or false negatives.

- Disabled Self-Test Features: User modifications can inadvertently disable critical self-test features, preventing the interface from detecting potential issues.

- Security Vulnerabilities: User modifications can introduce security vulnerabilities that allow unauthorized access to the interface and compromise its integrity.

Technicians should avoid making unauthorized modifications to the software of their diagnostic interfaces. If modifications are necessary, they should be performed by qualified professionals and thoroughly tested to ensure that they do not affect the reliability of self-tests.

28. How Does the Type of Vehicle Being Serviced (e.g., Hybrid, Electric) Affect Self-Test Needs?

The type of vehicle being serviced, such as hybrid or electric vehicles (EVs), significantly affects self-test needs for diagnostic interfaces. Hybrid and electric vehicles have unique electronic systems and diagnostic requirements that necessitate specialized self-test features.

- High-Voltage Systems: Hybrid and electric vehicles have high-voltage systems that require specialized diagnostic tools and self-test routines to ensure technician safety.

- Battery Management Systems: Hybrid and electric vehicles have battery management systems (BMS) that require accurate monitoring and diagnostics, which rely on reliable self-testing of the diagnostic interface.

- Electric Motor Control Systems: Hybrid and electric vehicles have electric motor control systems that require specialized diagnostic tools and self-test routines to ensure proper operation.

- Regenerative Braking Systems: Hybrid and electric vehicles have regenerative braking systems that require accurate monitoring and diagnostics, which rely on reliable self-testing of the diagnostic interface.

- Unique Diagnostic Codes: Hybrid and electric vehicles have unique diagnostic codes that require specialized diagnostic tools and self-test routines to interpret.

Technicians servicing hybrid and electric vehicles need diagnostic interfaces with specialized self-test features to accurately diagnose and resolve issues. These features include high-voltage safety checks, battery management system diagnostics, and electric motor control system diagnostics.

29. What Are Some Common Misconceptions About Self-Testing Diagnostic Interfaces?

There are several common misconceptions about self-testing diagnostic interfaces that can lead to improper usage and inaccurate results. These misconceptions include:

- Self-Tests Guarantee Accuracy: Self-tests only verify that the interface is functioning correctly; they do not guarantee that the diagnostic data is accurate.

- All Interfaces Have the Same Self-Test Capabilities: Different interfaces have different self-test capabilities; some interfaces perform more comprehensive tests than others.

- Self-Tests Eliminate the Need for Regular Maintenance: Self-tests do not eliminate the need for regular maintenance; interfaces still require regular cleaning, calibration, and software updates.

- Self-Tests Can Detect All Possible Issues: Self-tests cannot detect all possible issues; some issues may only be apparent during actual diagnostic testing.

- Self-Tests Are Only Necessary for New Interfaces: Self-tests are necessary for interfaces of all ages to ensure reliable performance.

Technicians should be aware of these misconceptions and follow best practices for using and maintaining diagnostic interfaces to ensure accurate and reliable diagnostic testing.

30. What Emerging Trends Will Impact the Future of Self-Testing in Automotive Diagnostics?

Several emerging trends are expected to impact the future of self-testing in automotive diagnostics, including:

- Increased Use of Artificial Intelligence (AI): AI-powered self-test routines will be able to automatically diagnose and resolve issues with diagnostic interfaces, improving their reliability and efficiency.

- Integration of Machine Learning (ML): ML algorithms will be able to learn from historical self-test data to predict potential failures and optimize the performance of diagnostic interfaces.

- Expanded Use of Cloud Connectivity: Cloud-based self-test platforms will provide remote monitoring, data analysis, and software updates for diagnostic interfaces, improving their reliability and security.

- Development of More Advanced Sensors: More advanced sensors will be integrated into diagnostic interfaces to monitor their internal environment and detect potential issues, improving their accuracy and reliability.

- Adoption of Predictive Maintenance Technologies: Predictive maintenance technologies will be used to anticipate failures and schedule maintenance for diagnostic interfaces before they occur, minimizing downtime and maximizing their lifespan.

These emerging trends will revolutionize self-testing in automotive diagnostics, making diagnostic interfaces more reliable, accurate, and efficient.

Ready to elevate your automotive diagnostic skills? Visit DTS-MONACO.EDU.VN today to explore our comprehensive training programs, software solutions, and expert support services. Unlock the full potential of your diagnostic interfaces and stay ahead in the ever-evolving world of automotive technology. Contact us now and take the first step towards becoming a car coding expert!