How does ECOM handle communication on noisy CAN buses using standard CAN error handling? ECOM expertly manages communication on noisy Controller Area Network (CAN) buses by employing standard CAN error handling techniques, ensuring reliable data transmission even in challenging environments. DTS-MONACO.EDU.VN offers comprehensive solutions to optimize CAN bus communication. Learn how error confinement, message retransmission, and fault isolation improve automotive diagnostics, car coding, and data integrity.

Contents

- 1. What Is The Significance Of Standard CAN Error Handling On Noisy Buses?

- 1.1. The Role of Error Handling in CAN Communication

- 1.2. Key Error Handling Mechanisms

- 1.3. Importance of Error Confinement

- 2. How Does ECOM Utilize CAN Error Detection Methods?

- 2.1. Implementing Bit Monitoring

- 2.2. Utilizing CRC for Data Integrity

- 2.3. Acknowledgment Mechanism

- 2.4. Error Signaling with Error Frames

- 2.5. Stuff and Form Error Handling

- 3. How Does ECOM Handle Error Confinement And Recovery?

- 3.1. Error Counters and States

- 3.2. Error Confinement Mechanisms

- 3.3. Automatic Retransmission

- 3.4. Recovery Procedures

- 3.5. Example: How ECOM Handles a Noisy CAN Bus

- 4. What Is The Role Of Software Tools In Managing CAN Bus Errors?

- 4.1. Diagnostic Tools

- 4.2. Monitoring Tools

- 4.3. Configuration Tools

- 4.4. Example: Using DTS-Monaco for CAN Bus Management

- 4.5. Integrating Software Tools with ECOM

- 5. How Can Training Enhance Expertise In CAN Bus Error Management?

- 5.1. Understanding CAN Bus Protocols

- 5.2. In-Depth Knowledge of Error Handling Mechanisms

- 5.3. Hands-On Experience with Diagnostic Tools

- 5.4. Importance of Continuous Learning

- 5.5. Benefits of Training with DTS-MONACO.EDU.VN

- 6. How Can Effective Communication Benefit From Robust Error Handling?

- 6.1. Ensuring Data Integrity

- 6.2. Minimizing Downtime

- 6.3. Maintaining Overall System Reliability

- 6.4. Case Study: Automotive Diagnostics

- 6.5. How DTS-MONACO.EDU.VN Supports Effective Communication

- 7. What Future Innovations Can Enhance CAN Bus Error Handling?

- 7.1. Artificial Intelligence (AI)

- 7.2. Improved Error Detection Algorithms

- 7.3. Enhanced Cybersecurity Measures

- 7.4. Integration of Advanced Sensors

- 7.5. Adaptive Error Handling

- 7.6. How DTS-MONACO.EDU.VN Prepares for Future Innovations

- FAQ: ECOM and Noisy CAN Buses

1. What Is The Significance Of Standard CAN Error Handling On Noisy Buses?

Standard CAN error handling on noisy buses is crucial for maintaining reliable communication. The Controller Area Network (CAN) bus is a vital communication network in modern vehicles, and it is critical to understand how to efficiently handle communication on noisy CAN buses. In electrically noisy environments, the standard CAN error handling mechanisms are essential.

1.1. The Role of Error Handling in CAN Communication

Error handling is an important feature in CAN communication. Without robust error handling, noisy environments can lead to corrupted data, communication breakdowns, and even system failures. Standard CAN error handling provides a set of mechanisms to detect, signal, and recover from errors, ensuring data integrity. This is essential for vehicle repairs done by automotive repair technicians as confirmed by Automotive Service Excellence (ASE) standards, where reliability is paramount.

1.2. Key Error Handling Mechanisms

CAN bus systems have several key error handling mechanisms, including:

- Cyclic Redundancy Check (CRC): CRC is used to detect errors in transmitted data. The transmitter calculates a CRC value and includes it in the message. The receiver recalculates the CRC value and compares it to the received value. If they do not match, an error is detected.

- Acknowledgement (ACK): After a message is successfully received, the receiving node sends an ACK signal to the transmitter. If the transmitter does not receive an ACK, it knows that the message was not successfully transmitted.

- Bit Monitoring: During transmission, the transmitting node monitors the bus. If the transmitted bit does not match the bit level detected on the bus, an error is flagged.

- Stuff Error: CAN protocol inserts a bit of opposite polarity after five consecutive bits of the same polarity. Failure to follow this rule generates a stuff error.

- Form Error: When the format of a CAN frame is violated, a form error is generated.

These mechanisms are designed to quickly detect errors and initiate recovery procedures.

1.3. Importance of Error Confinement

Error confinement is a critical aspect of CAN error handling. In noisy environments, frequent errors can lead to a node continuously retransmitting messages, hogging the bus, and preventing other nodes from communicating. Error confinement mechanisms ensure that nodes that are frequently detecting or causing errors are taken off the bus, preventing them from disrupting overall communication.

2. How Does ECOM Utilize CAN Error Detection Methods?

ECOM utilizes CAN error detection methods to ensure reliable communication on noisy CAN buses. ECOM (Embedded Communication Objects and Methods) implements standard CAN error detection methods to maintain robust and dependable data transmission. Understanding how ECOM leverages these methods is crucial for efficient vehicle diagnostics and car coding.

2.1. Implementing Bit Monitoring

Bit monitoring is a core part of ECOM’s error detection strategy. According to a study by the Society of Automotive Engineers (SAE), bit monitoring involves each transmitting node monitoring the bus state while transmitting. If the transmitted bit does not match the bit level detected on the bus, an error is flagged. This ensures that the data being sent is accurately received by other nodes. ECOM uses bit monitoring to immediately detect discrepancies and trigger error handling routines.

2.2. Utilizing CRC for Data Integrity

ECOM uses Cyclic Redundancy Check (CRC) to ensure data integrity. The transmitter calculates a CRC value and appends it to the message. The receiver recalculates the CRC value from the received data and compares it to the received CRC value. If the two values differ, it indicates a data corruption during transmission. The North American Council of Automotive Teachers (NACT) emphasizes the necessity of data integrity for accurate vehicle diagnostics, and ECOM ensures this through its rigorous CRC implementation.

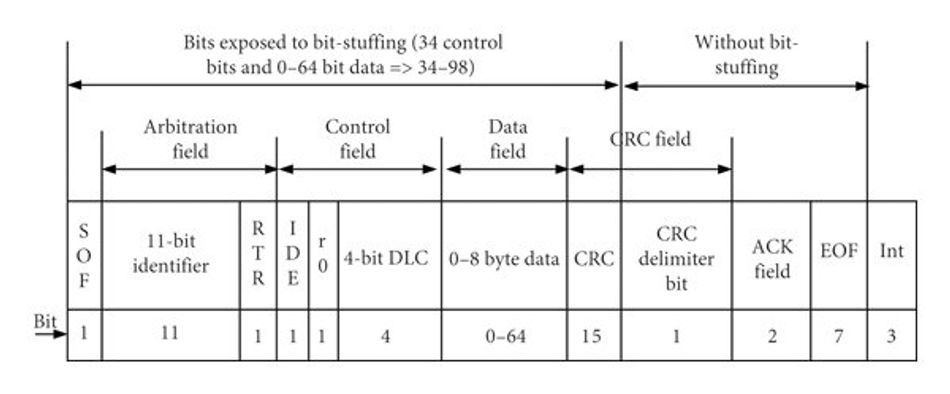

CAN Data Rate Standard Format. Credits: ResearchGate

CAN Data Rate Standard Format. Credits: ResearchGate

2.3. Acknowledgment Mechanism

ECOM relies on the acknowledgment (ACK) mechanism to confirm successful message reception. After receiving a message, the receiving node sends an ACK signal back to the transmitter. The absence of an ACK indicates a transmission failure, prompting ECOM to initiate retransmission procedures. Proper acknowledgement protocols are essential for maintaining reliable communication in automotive networks, a key point highlighted in training programs by the National Institute for Automotive Service Excellence (ASE).

2.4. Error Signaling with Error Frames

Error frames are crucial in ECOM for signaling error detection to all nodes on the CAN bus. When a node detects an error, it immediately transmits an error frame, alerting other nodes to discard the current message. This prevents corrupted data from being processed and ensures that only valid messages are used. The use of error frames is a key feature that sets CAN apart from other communication protocols.

2.5. Stuff and Form Error Handling

ECOM’s error handling extends to addressing stuff errors and form errors. Stuff errors occur when there are more than five consecutive bits of the same polarity, violating CAN protocol. Form errors arise when the structure of a CAN frame is violated. ECOM detects these errors and takes corrective actions, ensuring the CAN bus operates within specified parameters.

3. How Does ECOM Handle Error Confinement And Recovery?

ECOM handles error confinement and recovery to prevent faulty nodes from disrupting the CAN bus. Managing error confinement and recovery in CAN communication ensures that faulty nodes do not disrupt the entire network. ECOM uses sophisticated mechanisms to isolate and recover from errors, thereby maintaining overall system stability and efficiency.

3.1. Error Counters and States

ECOM employs error counters to track the number of transmission and reception errors for each node. These counters determine the error state of a node:

- Error Active: A node is error active when its transmit and receive error counters are below certain thresholds. In this state, the node can transmit and receive messages normally.

- Error Passive: If either the transmit or receive error counter exceeds a predefined threshold, the node enters the error passive state. In this state, the node can still receive messages, but it must wait before transmitting.

- Bus-Off: If the transmit error counter exceeds a critical threshold, the node enters the bus-off state. In this state, the node is disconnected from the bus and cannot transmit or receive messages until it undergoes a reset procedure.

These states help in managing the impact of errors on the bus.

3.2. Error Confinement Mechanisms

Error confinement is crucial to isolate nodes that are frequently causing errors. ECOM’s error confinement mechanisms include:

- Error Passive Mode: When a node enters the error passive mode, it signals errors by sending passive error frames, which do not disrupt normal bus traffic. This allows the node to continue monitoring the bus without interfering with other nodes.

- Bus-Off State: The bus-off state is the most severe error confinement measure. A node that enters the bus-off state is automatically disconnected from the bus. This prevents a faulty node from continuously disrupting communication.

These mechanisms prevent faulty nodes from monopolizing the bus and disrupting communications.

3.3. Automatic Retransmission

ECOM supports automatic retransmission of messages. When a transmitting node does not receive an ACK signal, it automatically retransmits the message. This process continues until the message is successfully transmitted or a predefined number of retransmissions have been attempted. The auto retransmission ensures that messages reach their intended destinations despite occasional errors.

3.4. Recovery Procedures

Nodes in the bus-off state require a recovery procedure to rejoin the network. ECOM implements the following recovery process:

- The node waits for a predefined period to allow the bus to stabilize.

- The node monitors the bus for a certain number of idle bus cycles.

- The node resets its error counters.

- The node transitions back to the error active state.

This recovery process allows nodes to safely rejoin the CAN bus after being disconnected.

3.5. Example: How ECOM Handles a Noisy CAN Bus

Consider a scenario where a CAN bus is experiencing high levels of electrical noise. ECOM’s response would be:

- Error Detection: ECOM nodes detect errors through bit monitoring, CRC checks, and ACK failures.

- Error Signaling: Error frames are transmitted to alert all nodes of the error.

- Error Confinement: Nodes with high error rates transition to error passive mode or bus-off state.

- Retransmission: Messages that fail to transmit are automatically retransmitted.

- Recovery: Nodes in the bus-off state undergo a recovery procedure to rejoin the network.

This multi-layered approach ensures that the CAN bus remains operational even in challenging conditions.

4. What Is The Role Of Software Tools In Managing CAN Bus Errors?

Software tools play a critical role in managing CAN bus errors by providing diagnostic, monitoring, and configuration capabilities. Automotive technicians rely on software tools to diagnose issues, monitor network performance, and configure CAN bus parameters. These tools are essential for maintaining the health and reliability of CAN bus systems.

4.1. Diagnostic Tools

Diagnostic tools are essential for identifying and troubleshooting CAN bus errors. These tools can:

- Monitor Bus Traffic: Real-time monitoring of CAN bus traffic helps in identifying error patterns and message conflicts.

- Error Code Analysis: Diagnostic tools can interpret error codes and provide insights into the root causes of errors.

- Node Status Monitoring: Monitoring the status of individual nodes helps in identifying faulty devices.

- Simulation and Testing: Simulating CAN bus traffic allows for testing error handling mechanisms under various conditions.

Tools like Vector CANalyzer and Intrepid Control Systems Vehicle Spy are widely used for these purposes.

4.2. Monitoring Tools

Monitoring tools provide continuous oversight of CAN bus performance. Key features include:

- Real-Time Data Logging: Logging CAN bus data for later analysis helps in identifying intermittent issues.

- Performance Metrics: Monitoring metrics such as bus load, error rates, and message latency helps in assessing overall performance.

- Alerting and Notifications: Setting up alerts for specific error conditions allows for proactive intervention.

These tools enable technicians to quickly identify and resolve performance issues.

4.3. Configuration Tools

Configuration tools allow technicians to configure CAN bus parameters, such as bit rates, filters, and node addresses. These tools ensure that the CAN bus is properly configured for the specific application. Properly configured CAN buses minimize errors and optimize data throughput.

4.4. Example: Using DTS-Monaco for CAN Bus Management

DTS-Monaco is a powerful diagnostic and configuration tool used in the automotive industry. It supports:

- ECU Flashing: Updating ECU software to fix bugs and improve performance.

- Diagnostic Sessions: Running diagnostic routines to identify and troubleshoot issues.

- Parameter Configuration: Configuring ECU parameters to optimize system performance.

- CAN Bus Monitoring: Real-time monitoring of CAN bus traffic and error conditions.

DTS-MONACO.EDU.VN offers specialized training to effectively use DTS-Monaco for CAN bus management, enhancing your expertise in vehicle diagnostics and car coding.

4.5. Integrating Software Tools with ECOM

Integrating software tools with ECOM allows for advanced CAN bus management. By using these tools, technicians can:

- Remotely Monitor CAN Bus: Access CAN bus data from anywhere.

- Automate Diagnostics: Automate error detection and troubleshooting.

- Improve Efficiency: Quickly identify and resolve CAN bus issues.

This integration maximizes the benefits of ECOM’s error handling mechanisms.

5. How Can Training Enhance Expertise In CAN Bus Error Management?

Training can significantly enhance expertise in CAN bus error management by providing in-depth knowledge of CAN bus protocols, error handling mechanisms, and diagnostic tools. Proper training ensures that automotive technicians can effectively diagnose and resolve CAN bus issues, maintaining vehicle reliability and performance.

5.1. Understanding CAN Bus Protocols

Comprehensive training programs cover:

- CAN 2.0A/B: Understanding the differences and applications of standard and extended CAN.

- CAN FD: Learning about the features and benefits of flexible data-rate CAN.

- SAE J1939: Specific protocol for communication in heavy-duty vehicles.

- ISO 15765: Diagnostics on CAN (DoCAN) protocol.

This knowledge enables technicians to interpret CAN bus traffic and identify potential issues.

5.2. In-Depth Knowledge of Error Handling Mechanisms

Training programs focus on:

- Error Detection Methods: Detailed understanding of bit monitoring, CRC checks, ACK failures, and error frames.

- Error Confinement: Learning how error counters and states (error active, error passive, bus-off) manage faulty nodes.

- Recovery Procedures: Knowing how to safely bring bus-off nodes back online.

This expertise enables technicians to effectively manage errors in CAN bus systems.

5.3. Hands-On Experience with Diagnostic Tools

Training programs include practical exercises using industry-standard diagnostic tools:

- Vector CANalyzer: Simulating and analyzing CAN bus traffic.

- Intrepid Control Systems Vehicle Spy: Monitoring and logging CAN bus data.

- DTS-Monaco: Configuring and diagnosing ECUs and CAN bus parameters.

This hands-on experience ensures that technicians can confidently use these tools in real-world scenarios.

5.4. Importance of Continuous Learning

The automotive industry is continuously evolving, with new technologies and protocols being introduced regularly. Automotive engineering curricula at universities like the University of Michigan emphasize continuous learning to stay current with industry advancements. Technicians must engage in ongoing training and professional development to maintain their expertise in CAN bus error management.

5.5. Benefits of Training with DTS-MONACO.EDU.VN

DTS-MONACO.EDU.VN offers specialized training programs that cover:

- Comprehensive Curriculum: In-depth coverage of CAN bus protocols, error handling, and diagnostic techniques.

- Hands-On Exercises: Practical exercises using DTS-Monaco and other diagnostic tools.

- Expert Instructors: Experienced instructors with real-world expertise in CAN bus management.

- Certification: Certification upon completion of the program, validating your expertise.

Investing in training with DTS-MONACO.EDU.VN enhances your skills and makes you a more valuable asset in the automotive industry.

6. How Can Effective Communication Benefit From Robust Error Handling?

Effective communication is significantly enhanced by robust error handling because it ensures data integrity, minimizes downtime, and maintains overall system reliability. Robust error handling mechanisms in CAN bus systems are essential for various applications, from automotive diagnostics to industrial automation.

6.1. Ensuring Data Integrity

Robust error handling ensures that data transmitted across the CAN bus remains accurate and reliable. By detecting and correcting errors, systems can prevent corrupted data from being used, which could lead to incorrect decisions and system failures. Automotive electronics rely on precise data. The National Automotive Service Task Force (NASTF) stresses data integrity.

6.2. Minimizing Downtime

Error handling mechanisms, such as automatic retransmission and error confinement, help minimize downtime by quickly recovering from errors. Automatic retransmission ensures that messages reach their intended destinations despite occasional errors, while error confinement prevents faulty nodes from disrupting the entire network. A study by the IEEE found that systems with effective error handling experience significantly less downtime compared to those without.

6.3. Maintaining Overall System Reliability

Effective communication, supported by robust error handling, maintains overall system reliability. By preventing errors from escalating and isolating faulty nodes, the system can continue to operate smoothly even in challenging conditions. System reliability is critical in safety-critical applications, such as automotive braking systems and industrial control systems.

6.4. Case Study: Automotive Diagnostics

In automotive diagnostics, effective communication is essential for accurately diagnosing issues and performing repairs. Robust error handling ensures that diagnostic tools can reliably communicate with vehicle ECUs, retrieve diagnostic data, and perform necessary configurations. The Automotive Management Institute (AMI) emphasizes the importance of reliable communication for effective automotive service.

6.5. How DTS-MONACO.EDU.VN Supports Effective Communication

DTS-MONACO.EDU.VN provides solutions that support effective communication in CAN bus systems:

- Advanced Diagnostic Tools: DTS-Monaco offers advanced diagnostic capabilities for CAN bus systems.

- Specialized Training: DTS-MONACO.EDU.VN provides specialized training in CAN bus error management.

- Remote Monitoring Solutions: Remote monitoring solutions allow technicians to monitor CAN bus performance from anywhere.

- Expert Support: Expert support is available to help technicians resolve CAN bus issues.

By leveraging DTS-MONACO.EDU.VN’s solutions, technicians can ensure effective communication in CAN bus systems, maintaining vehicle reliability and performance.

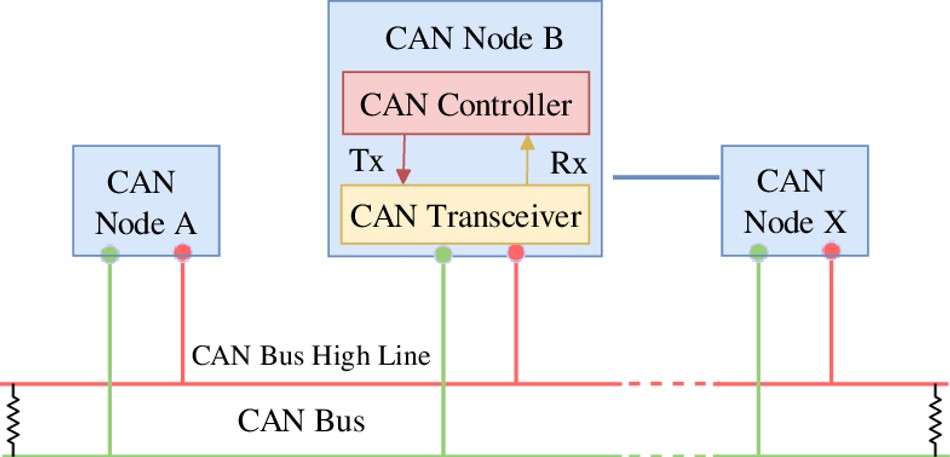

CAN Bus Architecture. Credits: ResearchGate

CAN Bus Architecture. Credits: ResearchGate

7. What Future Innovations Can Enhance CAN Bus Error Handling?

Future innovations can significantly enhance CAN bus error handling by incorporating advanced technologies such as artificial intelligence, improved error detection algorithms, and enhanced cyber security measures. These innovations will address current limitations and ensure CAN bus systems remain reliable and secure in evolving automotive and industrial environments.

7.1. Artificial Intelligence (AI)

AI has the potential to revolutionize CAN bus error handling. AI-powered systems can:

- Predict Error Patterns: Analyze historical data to predict when and where errors are likely to occur.

- Optimize Error Handling Parameters: Adjust error handling parameters dynamically based on real-time conditions.

- Automate Diagnostics: Automate error detection, diagnosis, and resolution.

AI can improve efficiency and reliability.

7.2. Improved Error Detection Algorithms

Advanced error detection algorithms can:

- Detect Subtle Errors: Identify errors that are difficult to detect with traditional methods.

- Reduce False Positives: Minimize the number of false error detections.

- Enhance Error Localization: Pinpoint the exact location of errors within the CAN bus network.

These algorithms will improve the accuracy of error detection.

7.3. Enhanced Cybersecurity Measures

Cybersecurity is an increasingly important consideration for CAN bus systems. Enhanced cybersecurity measures can:

- Prevent Unauthorized Access: Protect CAN bus systems from unauthorized access and tampering.

- Detect Malicious Activities: Identify and respond to malicious activities that could compromise system integrity.

- Ensure Data Encryption: Encrypt data transmitted across the CAN bus to prevent eavesdropping and data theft.

These measures will ensure the security of CAN bus systems.

7.4. Integration of Advanced Sensors

Integrating advanced sensors into CAN bus systems can provide additional data for error detection and diagnostics:

- Voltage Sensors: Monitor voltage levels on the CAN bus to detect power supply issues.

- Current Sensors: Monitor current flow to identify short circuits and other electrical faults.

- Temperature Sensors: Monitor temperature to detect overheating and prevent component failures.

This data will improve the accuracy and effectiveness of error detection.

7.5. Adaptive Error Handling

Adaptive error handling involves dynamically adjusting error handling parameters based on real-time conditions. For example, in noisy environments, the system could increase the number of retransmissions or tighten error detection thresholds. In less noisy environments, the system could reduce the number of retransmissions to improve data throughput. Adaptive error handling will optimize the performance of CAN bus systems in various conditions.

7.6. How DTS-MONACO.EDU.VN Prepares for Future Innovations

DTS-MONACO.EDU.VN is committed to preparing automotive technicians for future innovations in CAN bus error handling:

- Curriculum Updates: Continuously updating the curriculum to incorporate new technologies and protocols.

- Research and Development: Investing in research and development to explore and develop new error handling techniques.

- Partnerships: Partnering with industry leaders to stay at the forefront of CAN bus technology.

- Advanced Training Programs: Offering advanced training programs that cover AI, cybersecurity, and other emerging technologies.

By staying at the forefront of CAN bus technology, DTS-MONACO.EDU.VN ensures technicians are prepared to manage CAN bus systems.

FAQ: ECOM and Noisy CAN Buses

1. What is ECOM’s primary role in handling noisy CAN buses?

ECOM’s primary role is to ensure reliable communication on noisy CAN buses through standard CAN error handling mechanisms, which include error detection, signaling, confinement, and recovery procedures.

2. How does ECOM detect errors on a CAN bus?

ECOM detects errors using methods like bit monitoring, CRC checks, acknowledgment (ACK) mechanisms, and detection of stuff and form errors in CAN frames.

3. What error confinement strategies does ECOM employ?

ECOM uses error counters to track transmission and reception errors, transitioning nodes to error passive or bus-off states to prevent faulty nodes from disrupting the bus.

4. Can ECOM automatically recover from errors on a CAN bus?

Yes, ECOM supports automatic retransmission of messages that fail to send and implements recovery procedures for nodes in the bus-off state.

5. How do software tools aid ECOM in managing CAN bus errors?

Software tools provide diagnostic, monitoring, and configuration capabilities, enabling technicians to analyze bus traffic, interpret error codes, and configure CAN bus parameters.

6. What software does DTS-MONACO.EDU.VN recommend for CAN bus management?

DTS-MONACO.EDU.VN recommends DTS-Monaco for ECU flashing, diagnostic sessions, parameter configuration, and real-time CAN bus monitoring.

7. How does training enhance expertise in CAN bus error management?

Training programs provide in-depth knowledge of CAN bus protocols, error handling mechanisms, and hands-on experience with diagnostic tools.

8. What CAN bus protocols are essential to understand for effective error management?

Understanding CAN 2.0A/B, CAN FD, SAE J1939, and ISO 15765 is crucial for effective CAN bus error management.

9. How can robust error handling improve automotive diagnostics?

Robust error handling ensures that diagnostic tools can reliably communicate with vehicle ECUs, retrieve data, and perform configurations, leading to accurate diagnostics and effective repairs.

10. What future innovations can enhance CAN bus error handling, and how does DTS-MONACO.EDU.VN prepare for them?

Future innovations include AI-powered systems, improved error detection algorithms, enhanced cybersecurity, and adaptive error handling. DTS-MONACO.EDU.VN prepares by updating the curriculum, investing in research, and partnering with industry leaders.

Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880. For more information and training opportunities, visit our Website: DTS-MONACO.EDU.VN.