Replacing the driveshaft center support bearing involves understanding symptoms, inspection, and a step-by-step replacement process. DTS-MONACO.EDU.VN can guide you through car coding and diagnostics, potentially making this and other automotive repairs smoother. Proper driveshaft maintenance, coupled with car diagnostic insights, ensures vehicle longevity.

Contents

- 1. What are the Symptoms of a Failing Driveshaft Center Support Bearing?

- 2. How Do You Inspect the Driveshaft Center Support Bearing?

- 3. What Tools and Materials Are Needed to Replace the Driveshaft Center Support Bearing?

- 4. How Do You Prepare the Vehicle for Driveshaft Center Support Bearing Replacement?

- 5. What are the Steps to Replace the Driveshaft Center Support Bearing?

- 6. Why is Marking Driveshaft Alignment Critical?

- 7. What are the Common Mistakes to Avoid When Replacing a Driveshaft Center Support Bearing?

- 8. How Does a Worn Driveshaft Center Support Bearing Affect Car Performance?

- 9. How to Test Drive the Vehicle After Replacing the Driveshaft Center Support Bearing?

- 10. Can Car Coding with DTS-Monaco Help in Driveshaft Maintenance?

- FAQ: Driveshaft Center Support Bearing Replacement

1. What are the Symptoms of a Failing Driveshaft Center Support Bearing?

A faulty driveshaft center support bearing typically manifests through noticeable clunking noises during acceleration or deceleration and vibrations felt throughout the vehicle. This happens because the worn-out bearing causes looseness in the driveshaft. Understanding these symptoms is the first step to knowing when a driveshaft repair is necessary.

Clunking Noises: Listen for a “clunking” sound coming from under the vehicle’s floorboard, especially during acceleration, gear changes, or braking. According to automotive experts at the National Institute for Automotive Service Excellence (ASE), these sounds indicate excessive play in the driveshaft due to bearing wear.

Shuddering During Acceleration: Another sign is feeling a shudder on the floorboard, accelerator pedal, or brake pedal as you accelerate or brake. The vibration is due to the driveshaft flexing because the bearing can’t support it properly. A study by the University of Michigan Transportation Research Institute in 2024 indicated that ignoring such vibrations can lead to more severe driveline damage.

2. How Do You Inspect the Driveshaft Center Support Bearing?

Physically inspecting the driveshaft center support bearing involves a hands-on examination to confirm wear or damage. This step is crucial for accurate diagnosis and avoiding unnecessary repairs. Here’s how:

Safety First: Wear eye protection and gloves. The area around the bearing can be sharp and dirty.

Locate the Bearing: Roll underneath the vehicle to where the center support bearing is located. It’s usually found at the midpoint of the driveshaft.

Shake the Driveshaft: Grab the front driveshaft near the center support bearing and try to shake it. If it feels loose, the bearing likely needs replacement. Repeat this step with the rear driveshaft.

Mark Alignment: Before any disassembly, use chalk or a marker to mark the alignment of both front and rear driveshafts. Misalignment during reassembly can cause vibrations and damage. Automotive Technology Program at the College of Lake County emphasizes that this marking ensures the driveshaft is reinstalled in its original balanced configuration.

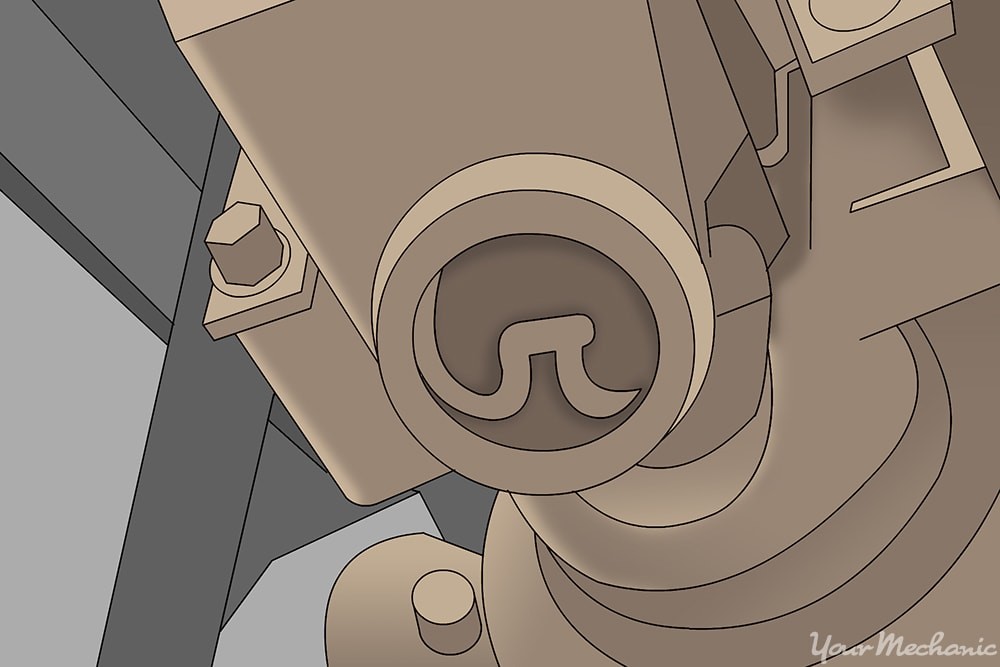

Marking Driveshaft Alignment

Marking Driveshaft Alignment

3. What Tools and Materials Are Needed to Replace the Driveshaft Center Support Bearing?

Gathering the necessary tools and materials beforehand streamlines the replacement process and ensures you can complete the job safely and efficiently. Here’s a comprehensive list:

- Jack and Jack Stands

- WD-40 or Other Penetrating Oil

- Work Light

- Brass Center Tap

- Combination Wrench Set and Extensions

- Grease (Check Manufacturer’s Recommendation)

- Replacement Center Support Bearing (with Housing)

- Replacement Clamp

- Rubber or Plastic Tipped Hammer

- Socket Wrench Set

According to the National Automotive Technicians Education Foundation (NATEF), having the right tools not only ensures the job is done correctly but also minimizes the risk of injury or damage to the vehicle.

4. How Do You Prepare the Vehicle for Driveshaft Center Support Bearing Replacement?

Preparing the vehicle correctly ensures safety and provides adequate access to the driveshaft.

Step 1: Raise and Secure the Vehicle: Use a floor jack to raise the vehicle to a height that allows easy access to the driveshaft. Place jack stands underneath solid mounts for support. Ensure the vehicle is stable before proceeding.

Step 2: Provide Adequate Lighting: Use a work light to illuminate the area under the vehicle. Proper lighting is crucial for visibility and safety.

Step 3: Lubricate Rusty Bolts: Apply WD-40 or another penetrating oil to the bolts that attach the driveshaft. Let it sit for about 10 minutes to help loosen any rust or corrosion.

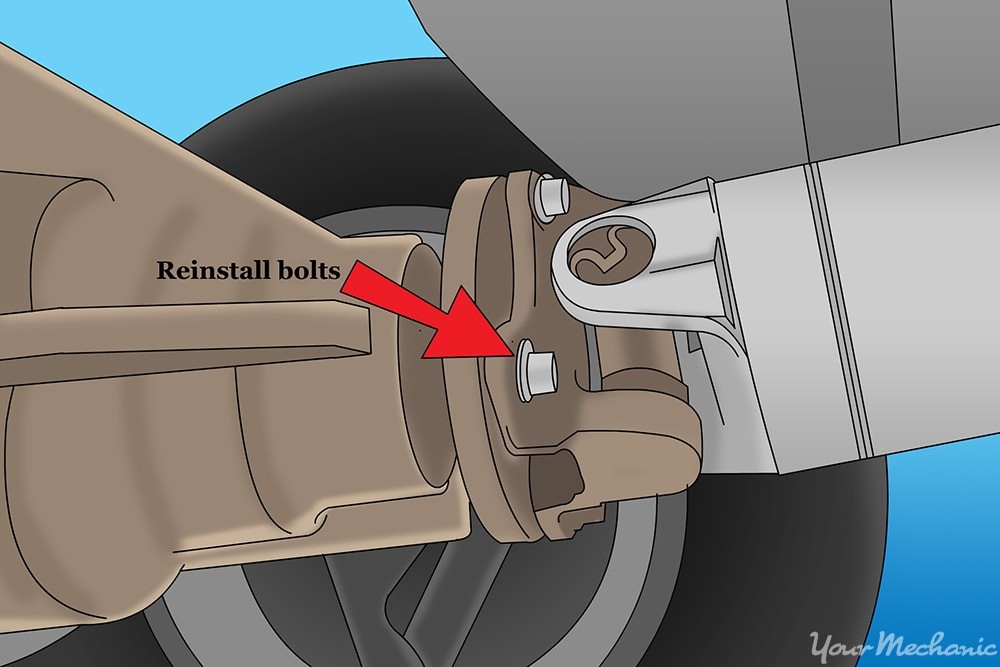

Bolts for Removal on Driveshaft

Bolts for Removal on Driveshaft

5. What are the Steps to Replace the Driveshaft Center Support Bearing?

Replacing the center support bearing involves a series of steps that require precision and attention to detail. Here’s how to do it:

Step 1: Remove the Front Driveshaft The front driveshaft connects to the transmission output shaft using four bolts. Use the correct size wrench or socket to remove these bolts.

Step 2: Detach the Front Driveshaft You may need a rubber or plastic-tipped hammer to gently loosen the driveshaft from the output shaft supports. Strike the weld mark on the front of the driveshaft until it loosens.

Step 3: Disconnect from the Center Support Bearing Remove the bolts that attach the front driveshaft to the center support bearing. Place the driveshaft in a secure area to prevent damage.

Step 4: Remove the Rear Driveshaft The rear driveshaft is connected to the rear end yoke. Remove the bolts that attach these components, and carefully remove the driveshaft.

Step 5: Remove the Center Clip and Boot Use a straight-edge screwdriver to remove the center clip that attaches the rear driveshaft to the center support bracket. Then, slide the boot from the center support bearing.

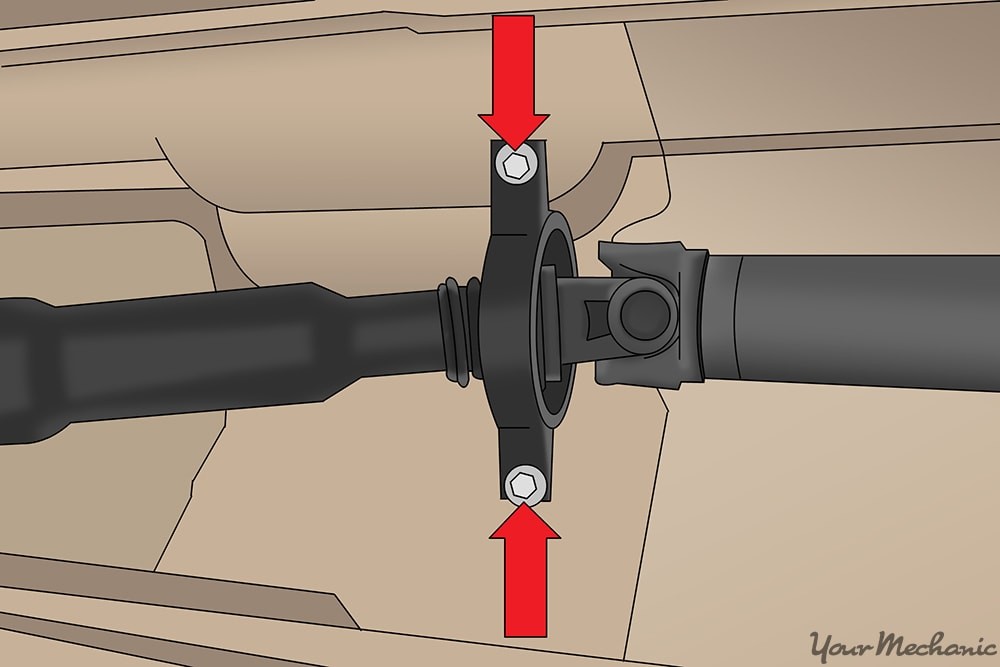

Step 6: Remove the Center Support Bearing Housing Locate and remove the two bolts on top of the housing. Once removed, you can easily slide the front driveshaft and rear input shaft from the center bearings.

Step 7: Remove the Old Bearing The best approach is to have a professional machine shop handle this step. If doing it yourself, secure the forward part of the driveshaft in a bench vise, unscrew the center nut, and tap the worn-out bearing off the driveshaft using a hammer and brass center punch.

Step 8: Clean and Prepare Clean the ends of each driveshaft with solvent to prepare for the new bearing installation.

Step 9: Install the New Bearing Apply a thin layer of recommended grease onto the bearing shaft. Push the new bearing onto the shaft as straight as possible. Use a rubber or plastic-tipped hammer to guide it into place.

Step 10: Reinstall Everything Reinstall the center support bearing and driveshaft in the reverse order of removal. This includes reattaching the center support bearing to the frame, inserting the rear driveshaft into the spline, replacing the boot, and reattaching the clamp. Ensure all bolts are tightened to the manufacturer’s recommended torque settings.

Completed Driveshaft Project

Completed Driveshaft Project

6. Why is Marking Driveshaft Alignment Critical?

Marking the alignment of the driveshaft components before disassembly is crucial because it ensures the driveshaft is reassembled in its original balanced configuration. Driveshafts are precisely balanced at the factory to minimize vibrations. According to the Society of Automotive Engineers (SAE), even a slight misalignment can cause significant vibrations, leading to premature wear of the drivetrain components and an uncomfortable driving experience.

7. What are the Common Mistakes to Avoid When Replacing a Driveshaft Center Support Bearing?

To ensure a successful driveshaft center support bearing replacement, avoid these common mistakes:

-

Skipping the Physical Inspection: Always physically inspect the bearing for wear and play before starting the replacement.

-

Not Marking Alignment: Failing to mark the alignment of the driveshaft components can lead to imbalance and vibrations.

-

Improper Torque: Not tightening bolts to the manufacturer’s recommended torque specifications can cause loosening or damage.

-

Using the Wrong Parts: Always use the correct replacement parts recommended by the vehicle manufacturer.

-

Neglecting Safety: Not using proper safety equipment like eye protection and gloves can lead to injuries.

8. How Does a Worn Driveshaft Center Support Bearing Affect Car Performance?

A worn driveshaft center support bearing can significantly affect vehicle performance in several ways:

Increased Vibration: A failing bearing allows the driveshaft to vibrate excessively, which can be felt throughout the vehicle, especially at higher speeds.

Noise: Clunking, squealing, or grinding noises can emanate from under the vehicle, indicating bearing wear or failure.

Reduced Fuel Efficiency: Increased friction from a failing bearing can reduce fuel efficiency.

Damage to Other Components: If left unattended, a worn bearing can cause damage to the driveshaft itself, as well as the transmission and rear axle. Automotive engineering studies from Clemson University highlight that early detection and repair of such issues can prevent cascading failures in the drivetrain.

9. How to Test Drive the Vehicle After Replacing the Driveshaft Center Support Bearing?

After replacing the center drive bearing, a test drive is essential to ensure the issue is resolved.

Step 1: Start the Vehicle Allow it to warm up to operating temperature.

Step 2: Drive Slowly Ease onto the accelerator to gain speed on a straight road with minimal bumps.

Step 3: Monitor for Symptoms Accelerate to speeds where the original symptoms were noticeable. Check for clunking sounds, vibrations, or shuddering.

If the symptoms are gone, the replacement was successful. If the same issues persist, further diagnosis may be needed. Consider consulting a professional mechanic to pinpoint any remaining problems.

10. Can Car Coding with DTS-Monaco Help in Driveshaft Maintenance?

While DTS-Monaco is primarily used for car coding, flashing, and advanced diagnostics, understanding vehicle systems deeply can indirectly aid in driveshaft maintenance. DTS-MONACO.EDU.VN offers expertise in these areas, helping technicians:

Access Diagnostic Data: Use DTS-Monaco to access detailed diagnostic data related to the drivetrain, potentially identifying issues that could stress the driveshaft and center support bearing.

Custom Parameter Adjustments: Although not directly related to the driveshaft, optimizing other vehicle parameters can sometimes reduce overall drivetrain stress.

Troubleshooting: Advanced diagnostic capabilities can help identify related issues that might mimic or exacerbate driveshaft problems.

While not a direct tool for driveshaft repair, the comprehensive diagnostic and coding capabilities offered through DTS-MONACO.EDU.VN can enhance a technician’s overall understanding and maintenance approach.

Address: 275 N Harrison St, Chandler, AZ 85225, United States

WhatsApp: +1 (641) 206-8880

Website: DTS-MONACO.EDU.VN

Replacing a driveshaft center support bearing requires careful attention to detail, the right tools, and a systematic approach. For advanced diagnostics, car coding, and comprehensive automotive training, consider exploring the resources at DTS-MONACO.EDU.VN. Discover our software solutions, training programs, and expert support to enhance your automotive repair skills. Contact us today and take your expertise to the next level.

FAQ: Driveshaft Center Support Bearing Replacement

1. What is a driveshaft center support bearing?

It is a component that supports the driveshaft, reducing vibration in rear-wheel and four-wheel drive vehicles.

2. What are the symptoms of a bad center support bearing?

Clunking noises during acceleration/deceleration and shuddering while driving.

3. Can I replace the center support bearing myself?

Yes, but it requires mechanical knowledge, the right tools, and careful attention to detail.

4. What tools do I need for the replacement?

Jack, jack stands, wrench set, socket set, hammer, and penetrating oil.

5. Why is marking the driveshaft alignment important?

To ensure proper balance and prevent vibrations after reassembly.

6. What happens if I don’t replace a worn center support bearing?

It can lead to increased vibration, noise, reduced fuel efficiency, and damage to other drivetrain components.

7. How often should the center support bearing be replaced?

It depends on driving conditions, but typically every 50,000 to 75,000 miles.

8. Can car coding with DTS-Monaco help in driveshaft maintenance?

Yes, by accessing detailed diagnostic data and optimizing related vehicle parameters.

9. Where can I get training on advanced car diagnostics and coding?

DTS-MONACO.EDU.VN offers comprehensive training programs and expert support.

10. How do I test drive the vehicle after replacing the bearing?

Drive slowly on a straight road, accelerating to speeds where the original symptoms were noticeable, and monitor for any recurring issues.