DPF regeneration is a crucial maintenance procedure for diesel vehicles. Discover the detailed steps and best practices for performing a DPF regeneration to maintain optimal engine performance and reduce emissions, with expert insights from DTS-MONACO.EDU.VN that can help you master this process. Explore advanced car coding techniques and diagnostic software to enhance your skills.

Contents

- 1. Understanding the Diesel Particulate Filter (DPF)

- 2. A Brief History of DPF Technology

- 3. Expected Lifespan of a DPF

- 4. What is DPF Regeneration?

- 5. Types of DPF Regeneration: A Detailed Comparison

- 6. Passive DPF Regeneration Explained

- 7. Active DPF Regeneration Explained

- 8. Manual DPF Regeneration: Step-by-Step Guide

- 9. Potential Issues and Troubleshooting During DPF Regeneration

- 10. The Role of Scan Tools in DPF Regeneration

- 11. Choosing the Right Diagnostic Scan Tool for DPF Regeneration

- 12. Safety Precautions During DPF Regeneration

- 13. The Importance of Regular DPF Maintenance

- 14. How Driving Habits Impact DPF Performance

- 15. DPF Cleaning vs. DPF Replacement: Making the Right Choice

- 16. Understanding DPF Warning Lights and Indicators

- 17. The Environmental Benefits of DPF Regeneration

- 18. Common Myths About DPF Regeneration

- 19. Resources for Learning More About DPF Systems and Regeneration

- 20. Optimizing Your DPF Knowledge with DTS-MONACO.EDU.VN

- FAQ: DPF Regeneration

1. Understanding the Diesel Particulate Filter (DPF)

A Diesel Particulate Filter (DPF) is an essential component in modern diesel engines designed to capture and store particulate matter, also known as soot, produced during combustion. The primary function of the DPF is to filter exhaust gases, trapping soot particles while allowing cleaner gases to exit, thereby reducing harmful emissions into the atmosphere. This system plays a vital role in meeting environmental regulations and improving air quality, which is increasingly important in automotive maintenance and diagnostics.

According to the Environmental Protection Agency (EPA), DPFs can reduce particulate matter emissions by over 85%, significantly improving air quality in urban areas. Proper maintenance and regeneration of the DPF are essential to ensure its long-term effectiveness and to avoid costly repairs. Key aspects of the DPF include:

- Function: Trapping soot particles from diesel engine exhaust.

- Benefit: Reducing emissions and improving air quality.

- Importance: Meeting environmental regulations and maintaining engine performance.

2. A Brief History of DPF Technology

The development of DPF technology is rooted in the need to address increasing air pollution from diesel engines. In the 1960s, cities like Los Angeles faced severe smog issues, prompting the introduction of emissions standards. The U.S. enacted its first automobile emissions standards in 1963, setting a precedent for other countries.

California’s emission laws led to the creation of the Positive Crankcase Ventilation (PCV) valve in 1961, which was an initial step in reducing emissions by removing blow-by gases from the crankcase. By the late 2000s, Diesel Particulate Filters (DPFs) started appearing on vehicles, first on Mercedes-Benz models sold in California and then becoming widespread in both passenger and commercial vehicles globally. The evolution of DPF technology reflects ongoing efforts to minimize the environmental impact of diesel engines. According to a study by the California Air Resources Board (CARB), the implementation of DPFs has significantly reduced particulate matter emissions, contributing to cleaner air and improved public health.

- 1960s: Initial efforts to address air pollution.

- 1961: Introduction of the PCV valve.

- Late 2000s: Widespread adoption of DPFs.

3. Expected Lifespan of a DPF

Typically, a DPF should last around 100,000 miles before needing replacement. However, this can vary significantly based on the level of maintenance. A well-maintained DPF might last up to 150,000 miles, while a poorly maintained one may fail much sooner. Regular DPF regeneration is crucial for extending its lifespan and maintaining performance.

Factors affecting DPF lifespan include driving conditions, engine type, and maintenance practices. Vehicles used primarily for short trips or in stop-and-go traffic may require more frequent regeneration to prevent clogging. Consistent monitoring and proper maintenance are essential to maximize the DPF’s lifespan. According to data from the National Institute for Automotive Service Excellence (ASE), regular inspections and timely maintenance can significantly extend the life of a DPF, reducing the overall cost of vehicle ownership.

- Typical Lifespan: Approximately 100,000 miles.

- Factors Affecting Lifespan: Maintenance, driving conditions, and engine type.

- Maintenance Tip: Regular inspections and timely regeneration.

4. What is DPF Regeneration?

DPF regeneration is the process of cleaning the Diesel Particulate Filter (DPF) by burning off accumulated soot particles. This involves heating the DPF to a very high temperature to incinerate the soot, restoring the filter’s functionality. There are two primary methods for DPF regeneration: active and passive.

Active regeneration is initiated by the engine control unit (ECU) when the DPF reaches a specific saturation level, while passive regeneration occurs naturally during normal driving conditions. Understanding these methods and how they work is essential for maintaining the DPF and ensuring optimal engine performance. Research from the Society of Automotive Engineers (SAE) indicates that effective DPF regeneration is crucial for reducing emissions and maintaining fuel efficiency in diesel vehicles.

- Definition: Cleaning the DPF by burning off soot.

- Methods: Active and passive regeneration.

- Importance: Maintaining engine performance and reducing emissions.

5. Types of DPF Regeneration: A Detailed Comparison

There are three main types of DPF regeneration: passive, active, and manual. Each method has its own advantages and is suitable for different driving conditions and maintenance needs.

| Type | Description | Conditions | Advantages | Disadvantages |

|---|---|---|---|---|

| Passive | Occurs naturally during normal driving when exhaust gas temperatures are high enough to burn off particulate matter. | Highway driving, long trips, high-speed conditions. | No intervention required, automatic process. | Not always effective for vehicles used in short trips or cold weather. |

| Active | Initiated by the Engine Control Unit (ECU) when the DPF reaches a certain saturation level. The ECU injects additional fuel to increase exhaust gas temperature. | When DPF reaches a specified saturation level. | Controlled process, ensures thorough cleaning. | Requires ECU intervention, may lead to increased fuel consumption. |

| Manual (Forced) | Performed using a diagnostic scan tool when the vehicle cannot perform automatic regeneration due to driving conditions or other issues. This involves commanding the engine to run at a higher temperature to burn off accumulated soot. | When DPF is heavily clogged or when automatic regeneration fails. Often needed for vehicles driven at low speeds or short distances. | Ensures complete cleaning, resolves severe clogging issues, useful in extreme cases. | Requires specialized equipment, can be time-consuming, potential risk of overheating if not performed correctly. |

Understanding the differences between these types of DPF regeneration is essential for effective vehicle maintenance and diagnostics. Each method plays a crucial role in keeping the DPF functioning correctly and reducing emissions.

6. Passive DPF Regeneration Explained

Passive DPF regeneration occurs spontaneously during normal driving conditions when the exhaust gas temperature reaches a high enough level to burn off the accumulated soot. This process is most effective during long drives at highway speeds, where the engine consistently operates at higher temperatures.

However, passive regeneration may not be sufficient for vehicles primarily used for short trips or in urban areas with stop-and-go traffic. In these conditions, the exhaust gas temperature may not reach the required level for effective soot combustion. Data from the U.S. Department of Energy indicates that vehicles driven at highway speeds benefit most from passive DPF regeneration, contributing to improved fuel efficiency and reduced emissions.

- Process: Soot burns off naturally during high-temperature driving.

- Best Conditions: Long drives at highway speeds.

- Limitations: Ineffective for short trips or stop-and-go traffic.

7. Active DPF Regeneration Explained

Active DPF regeneration is a controlled process initiated by the engine control unit (ECU) when the DPF reaches a predetermined level of soot saturation. The ECU monitors exhaust gas temperature, pressure, and flow rate to determine when active regeneration is necessary. When triggered, the ECU injects additional fuel into the engine to raise the exhaust gas temperature to around 600-700 degrees Celsius (1100-1300 Fahrenheit), which is necessary to burn off the accumulated soot.

During active regeneration, the engine may run in a high-idle mode, or the vehicle may need to be driven at higher speeds to maintain the required temperature. This process ensures a more thorough cleaning of the DPF compared to passive regeneration. Automotive research firm J.D. Power notes that active DPF regeneration is a critical function for maintaining the performance and longevity of diesel engines, particularly in vehicles used in diverse driving conditions.

- Process: ECU injects extra fuel to raise exhaust gas temperature.

- Temperature Required: 600-700 degrees Celsius (1100-1300 Fahrenheit).

- Benefits: Thorough cleaning of the DPF.

8. Manual DPF Regeneration: Step-by-Step Guide

Manual DPF regeneration is typically required when a vehicle is driven under conditions that prevent automatic regeneration, such as frequent short trips or low-speed driving. This method involves using a diagnostic scan tool to manually initiate the regeneration process. It is crucial to ensure the DPF is not severely blocked (over 90% capacity) before attempting manual regeneration. If the DPF is too full, it may require professional cleaning or replacement.

Here is a step-by-step guide for performing manual DPF regeneration:

-

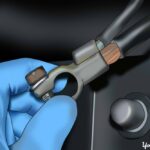

Connect Scan Tool: Connect the diagnostic scan tool to the vehicle’s diagnostic port. Follow the manufacturer’s instructions to access the DPF regeneration function. For instance, the Snap-on TRITON-D10 is a tool that supports this function.

Alt text: Connecting a diagnostic scan tool, such as the Snap-on TRITON-D10, to a vehicle’s diagnostic port to initiate DPF regeneration.

-

Warm-Up Engine: Ensure the engine is fully warmed up and the DPF is not excessively clogged. The scan tool can provide diagnostic information on the DPF’s condition.

Alt text: Warming up the engine to operating temperature before initiating DPF regeneration process using a diagnostic tool.

-

Initiate Regeneration: Follow the prompts on the scan tool to initiate the manual regeneration process. This typically involves commanding the engine to run at a higher temperature to burn off the accumulated soot.

Alt text: Initiating manual DPF regeneration using a diagnostic scan tool, showing on-screen prompts and engine commands.

-

Monitor Process: Monitor the regeneration process through the scan tool, ensuring that the temperature and other parameters remain within the specified ranges.

Alt text: Monitoring the progress of DPF regeneration via a diagnostic scan tool, displaying real-time temperature and parameter data.

-

Test Drive: After the regeneration is complete, perform a test drive to confirm that the DPF warning light is no longer illuminated and that the engine is running smoothly.

*Note: Some Original Equipment Manufacturers (OEMs) require a special function, such as “Replace or Reset DPF,” after replacing the filter. This function can typically be found in the ‘Service Resets and Relearns’ menu of the scan tool.

9. Potential Issues and Troubleshooting During DPF Regeneration

During DPF regeneration, several issues can arise, requiring careful monitoring and troubleshooting.

| Issue | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Regeneration Fails to Initiate | Faulty sensors, low fuel level, engine problems, DPF too clogged. | Check sensor readings, ensure adequate fuel, diagnose engine issues, verify DPF blockage level. |

| Excessive Smoke During Regeneration | Overfueling, issues with fuel injectors, problems with the DPF itself. | Inspect fuel injectors, check fuel pressure, examine DPF for damage or excessive soot buildup. |

| Engine Stalling | Insufficient air intake, issues with the EGR (Exhaust Gas Recirculation) system, problems with fuel delivery. | Check air intake system, inspect EGR valve, verify proper fuel delivery. |

| DPF Warning Light Remains On | Regeneration incomplete, recurring issues with soot buildup, sensor malfunction. | Repeat regeneration process, address underlying issues causing soot buildup, check and replace faulty sensors. |

| Overheating | Incorrect regeneration parameters, issues with cooling system, excessive soot load. | Verify regeneration parameters, inspect cooling system, reduce soot load before attempting regeneration. |

Addressing these issues promptly can prevent further damage and ensure the DPF operates efficiently. Always consult the vehicle’s service manual and use appropriate diagnostic tools for accurate troubleshooting.

10. The Role of Scan Tools in DPF Regeneration

Scan tools play a critical role in DPF regeneration, allowing technicians to monitor the process, diagnose issues, and manually initiate regeneration when necessary. Modern scan tools provide real-time data on DPF saturation levels, exhaust gas temperatures, and other critical parameters, enabling precise control and troubleshooting.

According to a report by the Automotive Aftermarket Industry Association (AAIA), the use of advanced scan tools can significantly improve the efficiency and effectiveness of DPF maintenance, reducing downtime and repair costs. For example, tools like the Snap-on TRITON-D10 offer comprehensive diagnostic capabilities and guided procedures for DPF regeneration, making the process more straightforward and reliable.

- Function: Monitoring DPF parameters and initiating manual regeneration.

- Benefits: Precise control, efficient troubleshooting, and reduced downtime.

- Example: Snap-on TRITON-D10.

11. Choosing the Right Diagnostic Scan Tool for DPF Regeneration

Selecting the appropriate diagnostic scan tool is essential for effective DPF regeneration. The ideal scan tool should offer comprehensive coverage for various vehicle makes and models, provide real-time data monitoring, and support manual regeneration functions.

Key features to look for in a diagnostic scan tool include:

- Vehicle Coverage: Ensure the tool supports the specific makes and models you service.

- Real-Time Data: The ability to monitor DPF saturation, temperature, and pressure.

- Manual Regeneration: Capability to initiate and control manual DPF regeneration.

- User-Friendly Interface: An intuitive interface for easy navigation and operation.

- Software Updates: Regular updates to support new vehicles and diagnostic functions.

Examples of popular diagnostic scan tools for DPF regeneration include the Snap-on TRITON-D10, Autel MaxiSys MS906BT, and Launch X431 V+. These tools offer a range of features suitable for both professional technicians and advanced DIY enthusiasts.

12. Safety Precautions During DPF Regeneration

Performing DPF regeneration involves high temperatures and potentially hazardous conditions, making safety precautions essential.

- Wear Protective Gear: Always wear safety glasses, gloves, and heat-resistant clothing to protect against burns and injuries.

- Ensure Proper Ventilation: Perform regeneration in a well-ventilated area to avoid inhaling harmful exhaust fumes.

- Monitor Temperature: Use a scan tool to monitor exhaust gas temperatures and prevent overheating.

- Keep Flammable Materials Away: Ensure no flammable materials are near the vehicle during regeneration.

- Follow Manufacturer Instructions: Always follow the vehicle manufacturer’s instructions and guidelines for DPF regeneration.

By following these safety precautions, technicians can minimize the risk of accidents and ensure a safe working environment during DPF regeneration.

13. The Importance of Regular DPF Maintenance

Regular DPF maintenance is essential for ensuring optimal engine performance, reducing emissions, and extending the lifespan of the DPF. Neglecting DPF maintenance can lead to clogs, reduced fuel efficiency, and costly repairs.

Key aspects of regular DPF maintenance include:

- Regular Regeneration: Perform active or manual regeneration as needed to prevent soot buildup.

- Use High-Quality Oil: Use low-ash engine oil that is specifically designed for vehicles with DPFs.

- Inspect Sensors: Regularly inspect and replace faulty sensors that monitor DPF performance.

- Address Engine Issues: Promptly address any engine issues that can cause excessive soot production.

- Monitor Driving Habits: Adjust driving habits to promote passive regeneration, such as taking longer trips at highway speeds.

According to the Diesel Technology Forum, proper DPF maintenance can significantly reduce emissions and improve the overall performance of diesel vehicles.

14. How Driving Habits Impact DPF Performance

Driving habits play a significant role in DPF performance and longevity. Frequent short trips, stop-and-go traffic, and low-speed driving can prevent passive regeneration, leading to soot buildup and increased active regeneration cycles.

To optimize DPF performance, consider the following driving tips:

- Take Longer Trips: Regularly take longer trips at highway speeds to promote passive regeneration.

- Avoid Stop-and-Go Traffic: Minimize driving in heavy traffic whenever possible.

- Maintain Consistent Speed: Maintain a consistent speed on highways to keep exhaust gas temperatures high.

- Use Recommended Fuel: Use high-quality diesel fuel that meets the vehicle manufacturer’s specifications.

- Avoid Idling: Minimize idling to reduce soot production.

By adopting these driving habits, vehicle owners can help maintain the DPF and reduce the need for frequent regeneration.

15. DPF Cleaning vs. DPF Replacement: Making the Right Choice

When a DPF becomes excessively clogged, vehicle owners face the decision of whether to clean or replace the filter. The best option depends on the severity of the clog, the age of the DPF, and the overall condition of the vehicle.

| Factor | DPF Cleaning | DPF Replacement |

|---|---|---|

| Severity of Clog | Suitable for moderately clogged DPFs. | Recommended for severely clogged or damaged DPFs. |

| Age of DPF | Cost-effective for newer DPFs with relatively low mileage. | May be more economical for older DPFs nearing the end of their lifespan. |

| Vehicle Condition | A good option if the vehicle is in good overall condition and likely to be kept for several more years. | Suitable for vehicles with other maintenance issues or those nearing the end of their usable life. |

| Cost | Typically less expensive than replacement. | More expensive upfront but may provide long-term benefits. |

| Long-Term Benefits | Can restore DPF performance and extend its lifespan if done correctly. | Ensures optimal performance and compliance with emissions standards. |

DPF cleaning involves removing the filter and using specialized equipment to remove accumulated soot and debris. DPF replacement involves installing a new filter, which ensures optimal performance but is a more costly option. Consulting with a qualified technician can help determine the best course of action for your specific situation.

16. Understanding DPF Warning Lights and Indicators

DPF warning lights and indicators alert drivers to potential issues with the DPF system. Understanding these warnings can help prevent further damage and ensure timely maintenance.

Common DPF warning lights and their meanings include:

- DPF Light On: Indicates that the DPF is becoming clogged and needs regeneration.

- Flashing DPF Light: Indicates a more severe issue, such as a failed regeneration attempt or a heavily clogged DPF.

- Check Engine Light: May indicate a DPF-related issue along with other potential engine problems.

- Reduced Engine Power: Some vehicles may reduce engine power when the DPF is severely clogged to prevent damage.

When a DPF warning light illuminates, it is essential to take action promptly. Attempting a manual regeneration or seeking professional diagnosis can help resolve the issue and prevent costly repairs.

17. The Environmental Benefits of DPF Regeneration

DPF regeneration plays a crucial role in reducing harmful emissions from diesel vehicles, contributing to improved air quality and environmental protection. By trapping and burning off particulate matter, DPFs significantly reduce the amount of soot released into the atmosphere.

According to the European Automobile Manufacturers Association (ACEA), DPFs can reduce particulate matter emissions by over 85%, helping to meet stringent emissions standards and protect public health. The environmental benefits of DPF regeneration include:

- Reduced Air Pollution: Lower levels of particulate matter and other harmful pollutants.

- Improved Air Quality: Cleaner air in urban areas and reduced respiratory health issues.

- Compliance with Regulations: Meeting emissions standards set by regulatory agencies.

- Sustainable Transportation: Promoting more environmentally friendly transportation options.

18. Common Myths About DPF Regeneration

Several myths surround DPF regeneration, leading to misunderstandings and potentially incorrect maintenance practices.

Common myths about DPF regeneration include:

- Myth: DPF regeneration is bad for the engine.

- Fact: DPF regeneration is a necessary process for maintaining engine performance and reducing emissions.

- Myth: All diesel vehicles require frequent DPF regeneration.

- Fact: The frequency of regeneration depends on driving conditions and maintenance practices.

- Myth: DPF removal is a cost-effective solution.

- Fact: DPF removal is illegal in many regions and can lead to severe penalties and environmental damage.

- Myth: Any scan tool can perform DPF regeneration.

- Fact: Only scan tools with specific DPF regeneration functions can perform the process correctly.

Understanding the facts about DPF regeneration can help vehicle owners make informed decisions and ensure proper maintenance.

19. Resources for Learning More About DPF Systems and Regeneration

Numerous resources are available for technicians and vehicle owners looking to learn more about DPF systems and regeneration.

- DTS-MONACO.EDU.VN: Offers comprehensive information, training courses, and diagnostic tools for DPF systems and car coding.

- Automotive Service Excellence (ASE): Provides certification programs and training resources for automotive technicians.

- Society of Automotive Engineers (SAE): Offers technical papers, standards, and educational resources related to DPF technology.

- Diesel Technology Forum: Provides information and resources on diesel engine technology and emissions control.

- Vehicle Manufacturer Service Manuals: Offer detailed information on DPF systems and regeneration procedures for specific vehicle models.

These resources can help technicians and vehicle owners stay informed and up-to-date on the latest DPF technologies and maintenance practices.

20. Optimizing Your DPF Knowledge with DTS-MONACO.EDU.VN

To truly master DPF regeneration and car coding, consider leveraging the resources available at DTS-MONACO.EDU.VN. We offer in-depth training courses, advanced diagnostic software, and expert support to help you enhance your skills and stay ahead in the automotive industry.

Address: 275 N Harrison St, Chandler, AZ 85225, United States.

Whatsapp: +1 (641) 206-8880.

Website: DTS-MONACO.EDU.VN.

Why choose DTS-MONACO.EDU.VN?

- Comprehensive Training: Our courses cover everything from basic diagnostics to advanced car coding techniques.

- Expert Instructors: Learn from industry professionals with years of experience.

- Cutting-Edge Software: Gain hands-on experience with the latest diagnostic tools and software.

- Flexible Learning Options: Choose from online courses, in-person workshops, and customized training programs.

Don’t let a lack of knowledge hold you back. Visit DTS-MONACO.EDU.VN today to explore our offerings and take your automotive skills to the next level.

FAQ: DPF Regeneration

1. What does DPF regeneration mean?

DPF regeneration is the process of burning off accumulated soot particles in the Diesel Particulate Filter (DPF) to restore its functionality.

2. How often should DPF regeneration occur?

The frequency of DPF regeneration depends on driving conditions, typically every 300 to 500 miles for active regeneration.

3. What happens if DPF regeneration is not performed?

If DPF regeneration is not performed, the DPF can become clogged, leading to reduced engine performance, increased emissions, and potential damage.

4. Can I drive during DPF regeneration?

Yes, you can drive during active DPF regeneration. In fact, driving at higher speeds can help the process.

5. What is the ideal temperature for DPF regeneration?

The ideal temperature for DPF regeneration is between 600 and 700 degrees Celsius (1100-1300 Fahrenheit).

6. What are the signs of a clogged DPF?

Signs of a clogged DPF include a DPF warning light, reduced engine power, and increased fuel consumption.

7. Is DPF regeneration bad for the engine?

No, DPF regeneration is a necessary process for maintaining engine performance and reducing emissions.

8. Can I clean the DPF myself?

While DIY DPF cleaning kits are available, professional cleaning is recommended for optimal results.

9. What is the cost of DPF replacement?

The cost of DPF replacement can range from $1,000 to $3,000, depending on the vehicle make and model.

10. How can I extend the life of my DPF?

You can extend the life of your DPF by using high-quality oil, performing regular regeneration, and maintaining good driving habits.