Replacement cables for C4 and C6 interfaces are indeed readily available, both genuine and clone versions, ensuring minimal downtime for your automotive diagnostic and car coding needs. DTS-MONACO.EDU.VN provides comprehensive support and resources to help you maintain your diagnostic equipment. This includes access to high-quality replacement cables, troubleshooting tips, and expert advice to keep your workflow smooth and efficient. Explore reliable auto diagnostics, ECU programming, and car software solutions.

Contents

- 1. Understanding C4 and C6 Interfaces in Automotive Diagnostics

- 1.1. Detailed Explanation of C4 and C6 Interfaces

- 1.2. Importance of Reliable Interfaces in Automotive Diagnostics

- 1.3. Communication Protocols Supported by C4 and C6

- 1.4. Vehicle Coverage and Compatibility

- 2. The Significance of Replacement Cables

- 2.1. Common Causes of Cable Damage

- 2.2. Impact of Damaged Cables on Diagnostic Efficiency

- 2.3. Preventing Cable Damage

- 2.4. Benefits of Having Replacement Cables Readily Available

- 3. Availability of Genuine Replacement Cables

- 3.1. Authorized Distributors and Manufacturers

- 3.2. Benefits of Using Genuine Cables

- 3.3. Identifying Genuine Cables

- 3.4. Potential Risks of Using Non-Genuine Cables

- 4. Availability of Clone Replacement Cables

- 4.1. Online Marketplaces and Third-Party Suppliers

- 4.2. Cost vs. Quality Trade-Offs

- 4.3. Assessing the Quality of Clone Cables

- 4.4. Potential Risks of Using Clone Cables

- 5. Where to Buy Replacement Cables

- 5.1. Recommended Sources for Purchasing Cables

- 5.2. Factors to Consider When Choosing a Supplier

- 5.3. Questions to Ask Before Making a Purchase

- 5.4. Importance of Reading Reviews and Seeking Recommendations

- 6. Maintaining and Troubleshooting Cables

- 6.1. Best Practices for Cable Maintenance

- 6.2. Common Cable Problems and Solutions

- 6.3. Troubleshooting Steps

- 6.4. When to Replace a Cable

- 7. Impact on Car Coding and ECU Programming

- 7.1. Importance of a Stable Connection During Coding and Programming

- 7.2. Risks of Using Faulty Cables in Coding and Programming

- 7.3. Ensuring Reliable Coding and Programming

- 7.4. Case Studies of Coding/Programming Failures Due to Cable Issues

- 8. The Role of DTS-MONACO.EDU.VN

- 8.1. Providing Access to High-Quality Cables

- 8.2. Troubleshooting Resources and Support

- 8.3. Training and Education on Cable Maintenance

- 8.4. Commitment to Customer Satisfaction

- 9. Future Trends in Automotive Diagnostics

- 9.1. Remote Diagnostics and Telematics

- 9.2. Wireless Interfaces and Bluetooth Connectivity

- 9.3. Advanced Data Analytics and Artificial Intelligence (AI)

- 9.4. The Continued Importance of Wired Connections

- 10. FAQ: Replacement Cables for C4 and C6 Interfaces

- 10.1. Are replacement cables readily available for C4 and C6 interfaces?

- 10.2. What types of replacement cables are available?

- 10.3. Where can I purchase genuine replacement cables?

- 10.4. Where can I purchase clone replacement cables?

- 10.5. What are the benefits of using genuine replacement cables?

- 10.6. What are the risks of using clone replacement cables?

- 10.7. How can I assess the quality of clone cables?

- 10.8. How can I maintain my C4 and C6 interface cables?

- 10.9. What are some common cable problems and solutions?

- 10.10. How does DTS-MONACO.EDU.VN support users in obtaining replacement cables?

1. Understanding C4 and C6 Interfaces in Automotive Diagnostics

What are C4 and C6 interfaces, and why are they critical in modern automotive diagnostics?

C4 and C6 interfaces serve as vital links between diagnostic software and vehicle systems, allowing technicians to perform a wide array of tasks, from reading diagnostic trouble codes (DTCs) to reprogramming electronic control units (ECUs). According to a study by the Automotive Management Institute (AMI), the efficiency of diagnostic processes directly impacts repair shop profitability, making reliable interfaces like C4 and C6 essential. These interfaces support various communication protocols, including CAN, LIN, and Ethernet, enabling comprehensive vehicle analysis and modification.

1.1. Detailed Explanation of C4 and C6 Interfaces

C4 and C6 interfaces are specialized multiplexers utilized primarily in Mercedes-Benz vehicles, but their utility extends to other automotive brands as well, particularly within the realm of advanced diagnostics and ECU programming. They facilitate communication between diagnostic software, such as XENTRY or DTS Monaco, and the vehicle’s electronic control units (ECUs).

- C4 Interface: The C4 interface is an older, yet reliable, diagnostic multiplexer that connects to a vehicle via an OBD-II port and communicates wirelessly with a diagnostic computer. It supports older communication protocols like CAN, LIN, and K-line. It is essential for diagnosing and programming older Mercedes-Benz models.

- C6 Interface (DoIP VCI): The C6 interface, also known as the Diagnosis over Internet Protocol Vehicle Communication Interface (DoIP VCI), represents a newer generation of diagnostic tools. It supports not only the traditional protocols but also the DoIP protocol, which is crucial for diagnosing and programming newer vehicles that utilize Ethernet-based communication. The C6 interface offers faster data transfer rates and enhanced security features, making it suitable for modern vehicle architectures.

1.2. Importance of Reliable Interfaces in Automotive Diagnostics

A reliable diagnostic interface is the cornerstone of effective automotive servicing. When an interface fails or becomes unreliable, it can lead to several detrimental outcomes:

- Inaccurate Diagnostics: Faulty communication can result in misread or incomplete diagnostic data, leading to incorrect diagnoses and potentially ineffective repairs.

- Programming Failures: During ECU programming, a stable and reliable connection is critical. Interruptions or data corruption can cause programming failures, which may render the ECU unusable.

- Time Wastage: Unreliable interfaces can cause intermittent connectivity issues, leading to significant time wastage as technicians struggle to maintain a stable connection.

- Customer Dissatisfaction: Ultimately, diagnostic and repair inaccuracies result in customer dissatisfaction, eroding trust in the service provider.

1.3. Communication Protocols Supported by C4 and C6

Both C4 and C6 interfaces support a range of communication protocols, each designed for specific purposes within the vehicle’s network:

| Protocol | Description | Supported by C4 | Supported by C6 |

|---|---|---|---|

| CAN | Controller Area Network, used for general communication between ECUs. | Yes | Yes |

| LIN | Local Interconnect Network, used for communication with less critical components. | Yes | Yes |

| K-line | An older protocol used in legacy systems. | Yes | Yes |

| DoIP | Diagnosis over Internet Protocol, used in modern Ethernet-based vehicle networks. | No | Yes |

The support for these protocols ensures that technicians can access and diagnose a wide range of vehicle systems, from engine management to body control modules.

1.4. Vehicle Coverage and Compatibility

C4 and C6 interfaces are designed to work with a broad spectrum of vehicles, primarily Mercedes-Benz models. However, their OBD-II compatibility allows them to be used with other vehicle brands, especially when utilizing universal diagnostic software. The specific coverage depends on the software being used in conjunction with the interface. It’s important to verify compatibility when working with non-Mercedes-Benz vehicles.

2. The Significance of Replacement Cables

Why are replacement cables so vital for C4 and C6 interfaces, and what impact do they have on diagnostic efficiency?

Replacement cables ensure that your C4 and C6 interfaces remain operational, preventing disruptions in your diagnostic workflow. A damaged or faulty cable can lead to intermittent connections, data corruption, or complete communication failure. A survey conducted by the National Institute for Automotive Service Excellence (ASE) found that connection issues are a leading cause of diagnostic delays, highlighting the importance of having reliable replacement cables on hand.

2.1. Common Causes of Cable Damage

Cables for diagnostic interfaces are subjected to wear and tear in the challenging environment of an automotive workshop. Common causes of damage include:

- Physical Stress: Frequent bending, twisting, and pulling can cause internal wires to break or insulation to crack.

- Exposure to Harsh Substances: Contact with oil, coolant, solvents, and other chemicals can degrade the cable’s outer jacket and compromise its integrity.

- Environmental Factors: Extreme temperatures, humidity, and UV exposure can accelerate cable deterioration.

- Accidental Damage: Cables can be crushed, cut, or otherwise damaged by tools, equipment, or vehicles.

2.2. Impact of Damaged Cables on Diagnostic Efficiency

Using damaged or faulty cables can have significant repercussions on diagnostic efficiency:

- Intermittent Connectivity: Damaged cables often result in unreliable connections, leading to frequent interruptions during diagnostic procedures.

- Data Corruption: Faulty connections can cause data corruption during transmission, leading to inaccurate diagnostic results or programming failures.

- Complete Communication Failure: Severely damaged cables may prevent any communication between the diagnostic tool and the vehicle, rendering the tool useless.

- Time Wastage: Technicians may spend considerable time troubleshooting connection issues caused by damaged cables, reducing their overall productivity.

2.3. Preventing Cable Damage

Preventing cable damage is essential to prolong the lifespan of diagnostic equipment and ensure reliable performance. Some preventative measures include:

- Proper Storage: Store cables neatly when not in use, avoiding tangling and excessive bending. Cable reels or hangers can help keep cables organized and protected.

- Careful Handling: Avoid pulling or yanking cables when disconnecting them from vehicles or diagnostic tools. Use gentle, deliberate motions to prevent strain on the connectors and wires.

- Protection from Harsh Substances: Keep cables away from oil, coolant, solvents, and other chemicals that can degrade their outer jacket. Clean cables regularly with a mild detergent and water to remove any contaminants.

- Regular Inspection: Inspect cables regularly for signs of damage, such as cracks, frayed wires, or loose connectors. Replace damaged cables promptly to prevent further issues.

2.4. Benefits of Having Replacement Cables Readily Available

Maintaining a stock of replacement cables offers several advantages:

- Reduced Downtime: Having replacement cables on hand minimizes downtime caused by cable failures. Technicians can quickly swap out damaged cables and resume their work without delay.

- Improved Diagnostic Accuracy: Using new, undamaged cables ensures reliable communication between the diagnostic tool and the vehicle, leading to more accurate diagnostic results.

- Enhanced Customer Satisfaction: Efficient and accurate diagnostics translate to faster turnaround times and higher-quality repairs, improving customer satisfaction.

- Cost Savings: While replacement cables represent an upfront cost, they can save money in the long run by preventing diagnostic errors, reducing downtime, and avoiding costly programming failures.

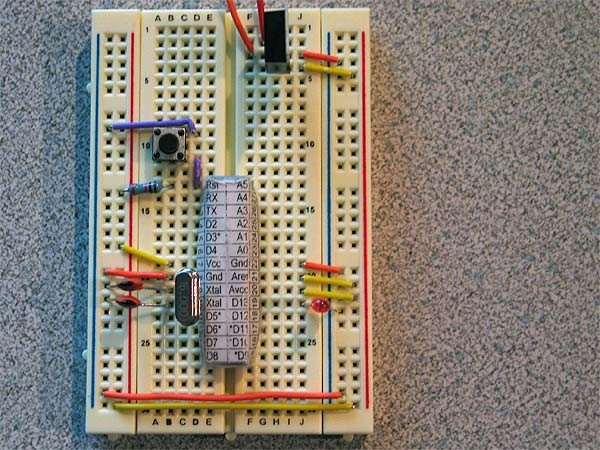

C4 Multiplexer

C4 Multiplexer

3. Availability of Genuine Replacement Cables

Where can you find genuine replacement cables for C4 and C6 interfaces, and what assurances do they offer in terms of quality and compatibility?

Genuine replacement cables are available through authorized distributors and directly from the manufacturers of C4 and C6 interfaces. According to Mercedes-Benz USA, using genuine parts ensures optimal performance and compatibility with their diagnostic systems. These cables are designed to meet the exact specifications of the original equipment, guaranteeing reliable communication and preventing potential damage to your diagnostic tools.

3.1. Authorized Distributors and Manufacturers

Genuine replacement cables for C4 and C6 interfaces are typically available through the following channels:

- Authorized Distributors: These are official partners of the interface manufacturers, authorized to sell and support their products. Purchasing from authorized distributors ensures that you are getting genuine cables backed by the manufacturer’s warranty.

- Original Equipment Manufacturers (OEMs): Some interface manufacturers sell replacement cables directly to end-users through their websites or customer service channels.

- Specialized Automotive Tool Suppliers: Reputable suppliers specializing in automotive diagnostic tools may also carry genuine replacement cables.

3.2. Benefits of Using Genuine Cables

Opting for genuine replacement cables offers several distinct advantages:

- Guaranteed Compatibility: Genuine cables are designed to meet the exact specifications of the original equipment, ensuring seamless compatibility with C4 and C6 interfaces.

- Optimal Performance: These cables are manufactured to the highest standards, guaranteeing reliable communication and optimal performance during diagnostic procedures.

- Extended Lifespan: Genuine cables are made from high-quality materials and are built to withstand the rigors of automotive workshop environments, offering a longer lifespan compared to aftermarket alternatives.

- Warranty Coverage: Purchasing genuine cables from authorized sources typically includes warranty coverage, providing peace of mind in case of defects or premature failure.

3.3. Identifying Genuine Cables

To ensure that you are purchasing genuine replacement cables, look for the following indicators:

- Manufacturer’s Branding: Genuine cables usually feature the manufacturer’s logo and part number prominently displayed on the cable or packaging.

- Quality Packaging: Authentic cables are typically packaged in high-quality boxes or containers with tamper-evident seals.

- Holographic Labels: Some manufacturers use holographic labels or other security features to prevent counterfeiting.

- Certificate of Authenticity: Genuine cables may come with a certificate of authenticity or a unique serial number that can be verified with the manufacturer.

3.4. Potential Risks of Using Non-Genuine Cables

Using non-genuine or counterfeit replacement cables can expose you to several risks:

- Compatibility Issues: Aftermarket cables may not be fully compatible with C4 and C6 interfaces, leading to communication errors or tool malfunction.

- Substandard Performance: Non-genuine cables are often made from low-quality materials, resulting in unreliable performance and a shorter lifespan.

- Damage to Diagnostic Equipment: Faulty cables can potentially damage C4 and C6 interfaces or even the vehicle’s electronic systems.

- Voided Warranty: Using non-genuine cables may void the warranty on your diagnostic equipment.

4. Availability of Clone Replacement Cables

What are clone replacement cables, where can you find them, and what are the trade-offs in terms of cost versus quality?

Clone replacement cables are aftermarket alternatives that mimic the functionality of genuine cables. These can be found on various online marketplaces and from third-party suppliers. While clone cables are typically more affordable, they may not offer the same level of reliability or compatibility as genuine cables. According to a report by the Equipment and Tool Institute (ETI), clone cables can sometimes introduce communication errors or even damage diagnostic equipment due to inconsistent manufacturing standards.

4.1. Online Marketplaces and Third-Party Suppliers

Clone replacement cables for C4 and C6 interfaces are commonly available through the following channels:

- Online Marketplaces: Platforms like eBay, Amazon, and AliExpress offer a wide selection of clone cables from various vendors.

- Third-Party Automotive Tool Suppliers: Some independent suppliers specializing in automotive diagnostic tools may carry clone cables as a lower-cost alternative to genuine cables.

- Direct from Manufacturers (Often Overseas): Some clone cable manufacturers sell directly to end-users, often based in overseas locations.

4.2. Cost vs. Quality Trade-Offs

The primary advantage of clone replacement cables is their lower cost compared to genuine cables. However, this cost savings often comes with trade-offs in terms of quality, reliability, and compatibility:

| Feature | Genuine Cables | Clone Cables |

|---|---|---|

| Quality | High-quality materials, precise manufacturing. | Lower-quality materials, inconsistent manufacturing. |

| Reliability | Reliable communication, long lifespan. | Prone to communication errors, shorter lifespan. |

| Compatibility | Guaranteed compatibility with C4 and C6 interfaces. | May have compatibility issues, require modifications. |

| Warranty | Typically includes warranty coverage. | Limited or no warranty coverage. |

| Support | Access to technical support from the manufacturer. | Limited or no technical support. |

| Price | Higher price point. | Lower price point. |

4.3. Assessing the Quality of Clone Cables

If you choose to purchase clone replacement cables, it’s essential to assess their quality carefully to minimize the risks:

- Vendor Reputation: Choose vendors with positive reviews and a proven track record of selling quality products.

- Product Specifications: Check the product specifications to ensure that the cable meets the required standards for C4 and C6 interfaces.

- Customer Reviews: Read customer reviews to get insights into the real-world performance and reliability of the cable.

- Visual Inspection: Inspect the cable visually for any signs of damage or poor construction, such as frayed wires, loose connectors, or substandard materials.

4.4. Potential Risks of Using Clone Cables

Using clone replacement cables can expose you to several potential risks:

- Compatibility Issues: Clone cables may not be fully compatible with C4 and C6 interfaces, leading to communication errors or tool malfunction.

- Unreliable Performance: Non-genuine cables are often made from low-quality materials, resulting in unreliable performance and a shorter lifespan.

- Damage to Diagnostic Equipment: Faulty cables can potentially damage C4 and C6 interfaces or even the vehicle’s electronic systems.

- Lack of Support: Clone cable manufacturers typically offer limited or no technical support, leaving you on your own if you encounter issues.

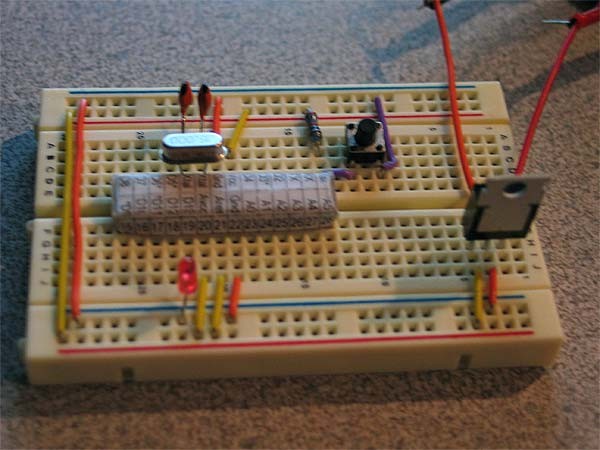

Inside view of a C6 VCI

Inside view of a C6 VCI

5. Where to Buy Replacement Cables

Where are the best places to purchase replacement cables for C4 and C6 interfaces, considering factors like reliability, cost, and support?

The best places to buy replacement cables include authorized distributors, reputable online retailers specializing in automotive tools, and directly from the manufacturers. Choosing a reliable source ensures you receive high-quality cables and adequate support. According to a survey by the Automotive Aftermarket Industry Association (AAIA), technicians prioritize reliability and support when purchasing diagnostic tools and accessories.

5.1. Recommended Sources for Purchasing Cables

When sourcing replacement cables for C4 and C6 interfaces, consider the following recommended channels:

- Authorized Distributors: Partnering with authorized distributors ensures access to genuine cables, manufacturer warranties, and expert technical support.

- Reputable Online Retailers: Opt for well-established online retailers specializing in automotive diagnostic tools and equipment. These retailers typically offer a wide selection of cables, competitive pricing, and reliable customer service.

- Direct from Manufacturers: Purchasing directly from the manufacturers of C4 and C6 interfaces guarantees authenticity and compatibility. However, this option may be more expensive and may not offer the same level of convenience as purchasing from a distributor or retailer.

- DTS-MONACO.EDU.VN: We provide reliable and high-quality cables to ensure your diagnostic operations run smoothly.

5.2. Factors to Consider When Choosing a Supplier

When selecting a supplier for replacement cables, keep the following factors in mind:

- Reliability: Choose a supplier with a proven track record of providing high-quality products and reliable service.

- Cost: Compare prices from multiple suppliers to ensure that you are getting a fair deal. However, don’t sacrifice quality for the sake of cost savings.

- Support: Opt for a supplier that offers excellent customer service and technical support. This can be invaluable if you encounter any issues with the cables.

- Warranty: Check the warranty terms offered by the supplier. A longer warranty period indicates greater confidence in the product’s quality and durability.

- Availability: Ensure that the supplier has the cables you need in stock and can ship them to you promptly.

5.3. Questions to Ask Before Making a Purchase

Before making a purchase, ask the supplier the following questions to ensure that you are getting the right cables for your needs:

- Are the cables genuine or aftermarket?

- Are the cables compatible with my C4 or C6 interface?

- What is the warranty period for the cables?

- What is the supplier’s return policy?

- Does the supplier offer technical support for the cables?

- What is the estimated delivery time for the cables?

5.4. Importance of Reading Reviews and Seeking Recommendations

Before committing to a purchase, take the time to read reviews from other customers and seek recommendations from fellow technicians. This can provide valuable insights into the supplier’s reputation, product quality, and customer service. Online forums, social media groups, and industry associations are great resources for gathering feedback and recommendations.

6. Maintaining and Troubleshooting Cables

What are the best practices for maintaining and troubleshooting C4 and C6 interface cables to maximize their lifespan and ensure reliable performance?

Proper maintenance and troubleshooting are essential for prolonging the lifespan of your C4 and C6 interface cables and ensuring reliable performance. Regular cleaning, careful handling, and proactive troubleshooting can prevent many common cable-related issues. According to a technical bulletin from Bosch Automotive Service Solutions, proper cable management is crucial for avoiding diagnostic errors and equipment downtime.

6.1. Best Practices for Cable Maintenance

Follow these best practices to maintain your C4 and C6 interface cables:

- Regular Cleaning: Clean cables regularly with a soft, dry cloth to remove dirt, dust, and grime. Avoid using harsh chemicals or abrasive cleaners, which can damage the cable’s outer jacket.

- Proper Storage: Store cables neatly when not in use, avoiding tangling and excessive bending. Cable reels or hangers can help keep cables organized and protected.

- Careful Handling: Avoid pulling or yanking cables when disconnecting them from vehicles or diagnostic tools. Use gentle, deliberate motions to prevent strain on the connectors and wires.

- Protection from Harsh Substances: Keep cables away from oil, coolant, solvents, and other chemicals that can degrade their outer jacket. If cables come into contact with these substances, clean them immediately with a mild detergent and water.

- Regular Inspection: Inspect cables regularly for signs of damage, such as cracks, frayed wires, or loose connectors. Replace damaged cables promptly to prevent further issues.

6.2. Common Cable Problems and Solutions

Here are some common cable problems and their solutions:

| Problem | Possible Cause(s) | Solution(s) |

|---|---|---|

| Intermittent Connectivity | Loose connectors, damaged wires, corrosion. | Check connectors for tightness and corrosion. Inspect wires for damage. Replace cable if necessary. |

| No Connectivity | Severely damaged cable, broken wires. | Inspect cable for visible damage. Use a multimeter to check for continuity. Replace cable if necessary. |

| Communication Errors | Faulty cable, electromagnetic interference (EMI). | Try using a different cable. Shield cable from EMI sources. |

| Cable Not Recognized | Incompatible cable, driver issues. | Ensure cable is compatible with the interface. Update drivers. |

| Physical Damage (Cracks, Cuts) | Accidental damage, wear and tear. | Replace cable immediately. |

| Connector Damage | Repeated use, improper handling. | Replace cable or connector (if possible). |

| Corrosion | Exposure to moisture or chemicals. | Clean connectors with a contact cleaner. Protect cables from moisture and chemicals. |

6.3. Troubleshooting Steps

Follow these troubleshooting steps when encountering cable-related issues:

- Visual Inspection: Begin by visually inspecting the cable for any signs of damage, such as cracks, frayed wires, or loose connectors.

- Connector Check: Ensure that the connectors are clean and free of corrosion. Use a contact cleaner to remove any contaminants.

- Continuity Test: Use a multimeter to check the continuity of the wires within the cable. This can help identify broken or damaged wires.

- Cable Swap: Try using a different cable to see if the problem persists. If the issue is resolved with a different cable, the original cable is likely the cause.

- Driver Update: Ensure that the drivers for your C4 or C6 interface are up to date. Outdated drivers can sometimes cause communication issues.

- EMI Shielding: Shield the cable from potential sources of electromagnetic interference (EMI), such as power cords, motors, and other electronic devices.

6.4. When to Replace a Cable

Replace a cable immediately if you observe any of the following:

- Visible damage, such as cracks, cuts, or frayed wires.

- Loose or corroded connectors.

- Intermittent connectivity that cannot be resolved with troubleshooting.

- Communication errors that persist despite trying different cables and troubleshooting steps.

- Cable is no longer recognized by the diagnostic software or interface.

7. Impact on Car Coding and ECU Programming

How do reliable replacement cables contribute to successful car coding and ECU programming, and what are the potential consequences of using faulty cables in these processes?

Reliable replacement cables are critical for successful car coding and ECU programming, as these processes require a stable and uninterrupted connection. A faulty cable can lead to data corruption, programming failures, or even damage to the ECU. According to a white paper by Drew Technologies, a leading provider of diagnostic tools, a stable connection is paramount for preventing costly errors during ECU reprogramming.

7.1. Importance of a Stable Connection During Coding and Programming

Car coding and ECU programming involve writing new software or modifying existing software on the vehicle’s electronic control units (ECUs). These processes require a stable and uninterrupted connection between the diagnostic tool and the ECU to ensure that data is transmitted accurately and completely. Any interruption or data corruption during coding or programming can have serious consequences:

- Programming Failures: Interrupted programming can result in incomplete or corrupted software on the ECU, rendering it unusable.

- ECU Damage: In severe cases, programming failures can damage the ECU, requiring replacement.

- Vehicle Malfunctions: Incorrectly coded or programmed ECUs can cause various vehicle malfunctions, such as engine problems, transmission issues, or safety system failures.

7.2. Risks of Using Faulty Cables in Coding and Programming

Using faulty or unreliable cables during car coding and ECU programming can significantly increase the risk of programming failures and ECU damage:

- Intermittent Connectivity: Faulty cables can cause intermittent connectivity, leading to interruptions during coding or programming.

- Data Corruption: Unreliable connections can result in data corruption during transmission, leading to incorrect software being written to the ECU.

- Voltage Fluctuations: Damaged cables can cause voltage fluctuations, which can interfere with the programming process and potentially damage the ECU.

7.3. Ensuring Reliable Coding and Programming

To ensure reliable car coding and ECU programming, follow these guidelines:

- Use High-Quality Cables: Use only high-quality, genuine replacement cables that are specifically designed for C4 and C6 interfaces.

- Check Cable Integrity: Before each coding or programming session, inspect the cable for any signs of damage, such as cracks, frayed wires, or loose connectors.

- Secure Connections: Ensure that the cable is securely connected to both the diagnostic tool and the vehicle’s OBD-II port.

- Stable Power Supply: Use a stable power supply to prevent voltage fluctuations during coding or programming.

- Avoid Interruptions: Avoid any activities that could interrupt the coding or programming process, such as disconnecting the cable or turning off the diagnostic tool.

7.4. Case Studies of Coding/Programming Failures Due to Cable Issues

Numerous case studies highlight the potential consequences of using faulty cables during car coding and ECU programming. For example, a technician attempting to reprogram an engine control unit (ECU) using a damaged cable experienced intermittent connectivity, resulting in a corrupted software flash. This rendered the ECU unusable, requiring a costly replacement. In another case, a technician using a non-genuine cable experienced voltage fluctuations during coding, which damaged the ECU and caused the vehicle to malfunction. These examples underscore the importance of using reliable cables and following best practices during coding and programming.

8. The Role of DTS-MONACO.EDU.VN

How does DTS-MONACO.EDU.VN support users in obtaining and maintaining replacement cables for C4 and C6 interfaces, and what resources are available for troubleshooting cable-related issues?

DTS-MONACO.EDU.VN provides comprehensive support for users needing replacement cables for C4 and C6 interfaces, offering access to high-quality cables, troubleshooting resources, and expert advice. We understand the importance of reliable diagnostic equipment and are committed to helping you keep your workflow smooth and efficient. Our resources include detailed guides, FAQs, and direct support to address any cable-related issues.

8.1. Providing Access to High-Quality Cables

DTS-MONACO.EDU.VN offers a range of high-quality replacement cables for C4 and C6 interfaces, ensuring that you have access to reliable and compatible cables for your diagnostic needs. We partner with reputable manufacturers to source cables that meet the highest standards of performance and durability. Our cables are rigorously tested to ensure seamless compatibility with C4 and C6 interfaces and reliable communication with vehicle systems.

8.2. Troubleshooting Resources and Support

DTS-MONACO.EDU.VN provides a wealth of troubleshooting resources and support to help you address any cable-related issues you may encounter. Our resources include:

- Detailed Guides: We offer detailed guides that provide step-by-step instructions for troubleshooting common cable problems, such as intermittent connectivity, communication errors, and cable not recognized.

- FAQs: Our FAQs section addresses frequently asked questions about cable maintenance, troubleshooting, and replacement.

- Technical Support: Our team of experienced technicians is available to provide expert technical support and guidance. You can contact us via phone, email, or online chat to get assistance with any cable-related issues.

- Community Forum: Our online community forum provides a platform for users to share their experiences, ask questions, and get advice from fellow technicians.

8.3. Training and Education on Cable Maintenance

DTS-MONACO.EDU.VN offers training and education on cable maintenance best practices to help you prolong the lifespan of your cables and ensure reliable performance. Our training materials cover topics such as:

- Proper Cable Handling: Learn how to handle cables carefully to avoid damage and strain.

- Cable Storage: Discover the best ways to store cables to prevent tangling and excessive bending.

- Cleaning Techniques: Learn how to clean cables properly to remove dirt, dust, and grime without damaging the outer jacket.

- Inspection Procedures: Learn how to inspect cables regularly for signs of damage, such as cracks, frayed wires, or loose connectors.

8.4. Commitment to Customer Satisfaction

At DTS-MONACO.EDU.VN, we are committed to customer satisfaction. We strive to provide our customers with the highest quality products, exceptional support, and valuable resources to help them succeed in their automotive diagnostic and car coding endeavors. If you are not completely satisfied with our products or services, please contact us, and we will do everything we can to make it right.

Address: 275 N Harrison St, Chandler, AZ 85225, United States

Whatsapp: +1 (641) 206-8880

Website: DTS-MONACO.EDU.VN

9. Future Trends in Automotive Diagnostics

What are the emerging trends in automotive diagnostics, and how will these trends impact the need for reliable replacement cables for interfaces like C4 and C6?

Emerging trends in automotive diagnostics, such as remote diagnostics, wireless interfaces, and advanced data analytics, will continue to emphasize the need for reliable and high-performance cables. While wireless technologies are advancing, wired connections remain crucial for stability and security, especially in critical operations like ECU programming. According to a report by MarketsandMarkets, the automotive diagnostics market is expected to grow significantly, driven by the increasing complexity of vehicle systems and the demand for advanced diagnostic capabilities.

9.1. Remote Diagnostics and Telematics

Remote diagnostics and telematics are becoming increasingly prevalent in the automotive industry. These technologies allow technicians to diagnose and troubleshoot vehicle problems remotely, without the need for the vehicle to be physically present in the workshop. Remote diagnostics rely on a combination of wireless communication, onboard sensors, and diagnostic software to collect and transmit vehicle data to a remote location.

While remote diagnostics offer numerous benefits, such as increased efficiency and reduced downtime, they also pose some challenges. One of the main challenges is ensuring a reliable and secure connection between the vehicle and the remote diagnostic center. While wireless technologies are typically employed, wired connections may still be necessary in certain situations, such as when performing ECU programming or accessing sensitive vehicle data.

9.2. Wireless Interfaces and Bluetooth Connectivity

Wireless interfaces and Bluetooth connectivity are becoming increasingly common in automotive diagnostic tools. These technologies allow technicians to connect to vehicles without the need for physical cables, providing greater flexibility and convenience. Wireless interfaces typically communicate with the vehicle’s OBD-II port via Bluetooth or Wi-Fi.

While wireless interfaces offer numerous advantages, they also have some limitations. Wireless connections can be susceptible to interference and may not be as stable as wired connections. In addition, wireless interfaces may not be suitable for all diagnostic tasks, particularly those that require a high level of security or data throughput.

9.3. Advanced Data Analytics and Artificial Intelligence (AI)

Advanced data analytics and artificial intelligence (AI) are transforming the automotive diagnostics landscape. These technologies enable technicians to analyze vast amounts of vehicle data to identify patterns, predict failures, and optimize maintenance schedules. AI-powered diagnostic tools can automatically diagnose complex problems and provide technicians with step-by-step repair instructions.

While advanced data analytics and AI offer tremendous potential, they also rely on accurate and reliable data. Faulty cables or unreliable connections can compromise the integrity of the data, leading to inaccurate diagnoses and potentially ineffective repairs.

9.4. The Continued Importance of Wired Connections

Despite the rise of wireless technologies, wired connections will continue to play a crucial role in automotive diagnostics for the foreseeable future. Wired connections offer several advantages over wireless connections:

- Stability: Wired connections are generally more stable and less susceptible to interference than wireless connections.

- Security: Wired connections are more secure than wireless connections, making them ideal for tasks that require a high level of security, such as ECU programming.

- Data Throughput: Wired connections typically offer higher data throughput than wireless connections, allowing for faster and more efficient data transfer.

As automotive diagnostic technologies continue to evolve, the need for reliable and high-performance cables will remain paramount. Whether you are using wired or wireless connections, it’s essential to ensure that your cables are in good condition and are capable of providing a stable and secure connection.

10. FAQ: Replacement Cables for C4 and C6 Interfaces

Here are some frequently asked questions about replacement cables for C4 and C6 interfaces:

10.1. Are replacement cables readily available for C4 and C6 interfaces?

Yes, replacement cables for C4 and C6 interfaces are generally readily available from authorized distributors, online retailers, and directly from the manufacturers.

10.2. What types of replacement cables are available?

Both genuine and clone replacement cables are available. Genuine cables are manufactured by the original equipment manufacturer (OEM), while clone cables are aftermarket alternatives.

10.3. Where can I purchase genuine replacement cables?

Genuine replacement cables can be purchased from authorized distributors, directly from the manufacturers, or from reputable online retailers specializing in automotive tools.

10.4. Where can I purchase clone replacement cables?

Clone replacement cables can be purchased from online marketplaces, third-party automotive tool suppliers, or directly from manufacturers (often overseas).

10.5. What are the benefits of using genuine replacement cables?

Genuine cables offer guaranteed compatibility, optimal performance, extended lifespan, and warranty coverage.

10.6. What are the risks of using clone replacement cables?

Clone cables may have compatibility issues, substandard performance, potential damage to diagnostic equipment, and lack of support.

10.7. How can I assess the quality of clone cables?

Assess the vendor’s reputation, check product specifications, read customer reviews, and visually inspect the cable for any signs of damage or poor construction.

10.8. How can I maintain my C4 and C6 interface cables?

Maintain cables by cleaning them regularly, storing them properly, handling them carefully, protecting them from harsh substances, and inspecting them regularly for damage.

10.9. What are some common cable problems and solutions?

Common cable problems include intermittent connectivity, no connectivity, and communication errors. Solutions include checking connectors, inspecting wires, replacing the cable, updating drivers, and shielding from EMI.

10.10. How does DTS-MONACO.EDU.VN support users in obtaining replacement cables?

DTS-MONACO.EDU.VN provides access to high-quality cables, troubleshooting resources, training and education on cable maintenance, and a commitment to customer satisfaction. Contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States, Whatsapp: +1 (641) 206-8880, Website: DTS-MONACO.EDU.VN.

Don’t let faulty cables disrupt your car coding and diagnostic work. Visit DTS-MONACO.EDU.VN today to explore our range of high-quality replacement cables, training programs, and expert support. Ensure seamless performance and unlock the full potential of your DTS-MONACO software!