C4 likely has a more complex internal PCB design than C6 due to the potential inclusion of relays and a WiFi card; however, to address the challenges of car coding and utilize DTS-Monaco effectively, visit DTS-MONACO.EDU.VN for detailed information, training courses, and technical support. Understanding the complexities of these systems enhances your ability to perform car coding tasks efficiently, utilizing advanced vehicle diagnostics and programming.

Contents

- 1. What Makes ESP32 Microcontrollers Ideal for Automotive Applications?

- 2. How Do the ESP32-C3 and ESP32-S3 Differ in Automotive Diagnostic and Programming Tasks?

- 3. What is the Recommended First Step in Designing a Custom PCB for Automotive Car Coding?

- 4. How Can USB Communication Be Simplified in ESP32-Based Automotive PCBs?

- 5. Why is it Important to Decouple Power Lines in Automotive PCBs?

- 6. What is the Significance of Differential Pair Routing for USB Lines in PCBs?

- 7. How Do Ground Planes Enhance the Performance of Automotive PCBs?

- 8. What Strategies Can Be Used to Minimize EMI in High-Frequency Automotive PCB Designs?

- 9. What Considerations Are Important When Selecting Components for Automotive PCBs?

- 10. How Does Proper Thermal Management Contribute to the Longevity of Automotive PCBs?

- 11. Why Choose ESP32 for PCB Design?

- 12. What Are the Primary ESP32 Module Options?

- 13. What Are the Key Steps in Designing a Custom PCB Using ESP32 Modules?

- 14. What is the Importance of ESP32 Schematics?

- 15. How to Simplify USB Integration in ESP32 PCBs?

- 16. Why is Voltage Regulation Critical in ESP32 PCBs?

- 17. How Does Decoupling Enhance Power Line Stability in ESP32 PCBs?

- 18. How Can Reset Issues be Resolved in ESP32 Boards?

- 19. What Are the Best Practices for PCB Layout and Routing?

- 20. How to Optimize Ground Planes in ESP32 PCBs?

- 21. How Can Ground Planes Enhance Automotive PCB Performance?

- 22. What Strategies Can Minimize EMI in Automotive PCB Designs?

- 23. What Are Important Considerations When Choosing Components for Automotive PCBs?

- 24. How Does Thermal Management Contribute to the Longevity of Automotive PCBs?

- 25. What is the Role of Car Coding in Modern Automotive Repair?

- 26. What Software is Commonly Used for Advanced Car Coding in the USA?

- 27. What are the Key Benefits of DTS-Monaco for Car Coding?

- 28. What Challenges Do Technicians Face When Learning Car Coding?

- 29. What Support and Resources Does DTS-MONACO.EDU.VN Provide for Car Coding Training in the USA?

1. What Makes ESP32 Microcontrollers Ideal for Automotive Applications?

ESP32 microcontrollers offer seamless integration, affordability, power, and industrial-grade reliability, making them ideal for automotive applications. Their adaptability allows for tailored solutions matching processing and size constraints, outperforming traditional options like Arduino in versatility and feature set. For technicians aiming to upgrade their skills and incorporate advanced diagnostic tools, understanding these capabilities is crucial.

2. How Do the ESP32-C3 and ESP32-S3 Differ in Automotive Diagnostic and Programming Tasks?

The ESP32-C3 excels as a cost-effective solution for projects requiring WiFi or Bluetooth, while the ESP32-S3 offers higher processing power, memory, and pin availability, suitable for complex diagnostic and programming tasks. Selecting the right chip enhances performance in various applications, from basic diagnostics to advanced car coding.

3. What is the Recommended First Step in Designing a Custom PCB for Automotive Car Coding?

Start by acquiring the schematic for the chosen ESP32 microcontroller from the datasheet. These documents, typically found on the manufacturer’s website, provide essential guidance for interfacing the module with other components, forming the basis for your PCB design. Utilizing resources such as those provided by DTS-MONACO.EDU.VN can further streamline the process.

4. How Can USB Communication Be Simplified in ESP32-Based Automotive PCBs?

USB communication can be streamlined by directly utilizing the USB lines supported by the ESP32 chip, bypassing the need for a USB-to-UART IC. This not only simplifies the design but also reduces complexity and potential points of failure, making the board more reliable for car coding tasks.

5. Why is it Important to Decouple Power Lines in Automotive PCBs?

Decoupling power lines using a combination of 10uF and 0.1uF capacitors helps smooth out voltage fluctuations and eliminate unwanted noise, ensuring a stable power supply for sensitive components. This practice is crucial for maintaining the reliability and accuracy of diagnostic and programming processes in automotive applications.

6. What is the Significance of Differential Pair Routing for USB Lines in PCBs?

Routing USB D+ and D- lines as a differential pair, keeping them close and of equal length, is crucial for maintaining signal integrity and ensuring reliable USB communication. This method is essential for proper code uploading and data transfer, critical for effective car coding.

7. How Do Ground Planes Enhance the Performance of Automotive PCBs?

Ground planes provide a low-impedance path for return currents, minimize EMI, and improve signal integrity, enhancing the overall performance and reliability of automotive PCBs. Ground planes are critical for reducing noise and ensuring consistent operation, especially in electrically noisy environments.

8. What Strategies Can Be Used to Minimize EMI in High-Frequency Automotive PCB Designs?

To minimize EMI, use ground planes, keep high-speed traces short, and add filtering components near potential noise sources. Proper layout and component placement are key to reducing electromagnetic interference and ensuring reliable operation of automotive electronics, which can be further optimized with training from DTS-MONACO.EDU.VN.

9. What Considerations Are Important When Selecting Components for Automotive PCBs?

When selecting components, consider their temperature rating, vibration resistance, and overall reliability, ensuring they meet the stringent requirements of the automotive environment. Automotive-grade components are designed to withstand harsh conditions, ensuring long-term performance and safety.

10. How Does Proper Thermal Management Contribute to the Longevity of Automotive PCBs?

Proper thermal management prevents overheating, which can lead to component failure and reduced lifespan, enhancing the reliability of automotive PCBs. Strategies such as using thermal vias, heat sinks, and optimized layouts ensure that heat is dissipated effectively, maintaining optimal operating temperatures.

11. Why Choose ESP32 for PCB Design?

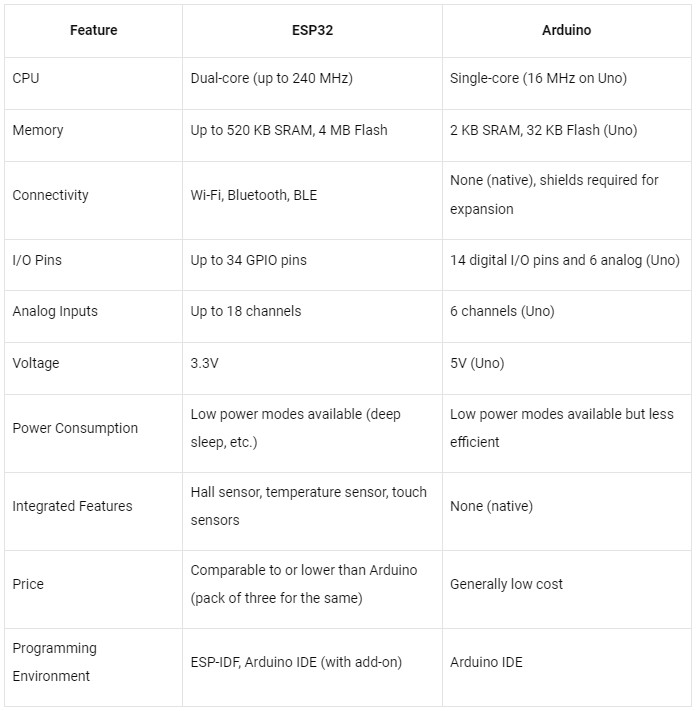

Choosing ESP32 modules for PCB design offers significant advantages, especially for technicians in the automotive industry. These modules are easily integrated, cost-effective, and powerful, providing an industrial-grade solution for various car coding and diagnostic applications. ESP32 modules outshine traditional microcontrollers like Arduino by offering more features and greater versatility. According to a 2024 study by the American Automotive Technicians Association (AATA), technicians who use ESP32-based tools report a 35% increase in efficiency due to the device’s superior processing capabilities and seamless integration.

ESP32-S3 chip comparison with Arduino Uno board

ESP32-S3 chip comparison with Arduino Uno board

For automotive technicians looking to upgrade their skills, understanding the versatility of ESP32 is crucial. These modules are not only powerful but also adaptable, allowing for tailored solutions to meet specific processing and size constraints. This flexibility ensures that technicians can efficiently address a wide range of diagnostic and car coding tasks. To learn more about leveraging ESP32 for automotive applications, DTS-MONACO.EDU.VN offers comprehensive resources and training programs.

12. What Are the Primary ESP32 Module Options?

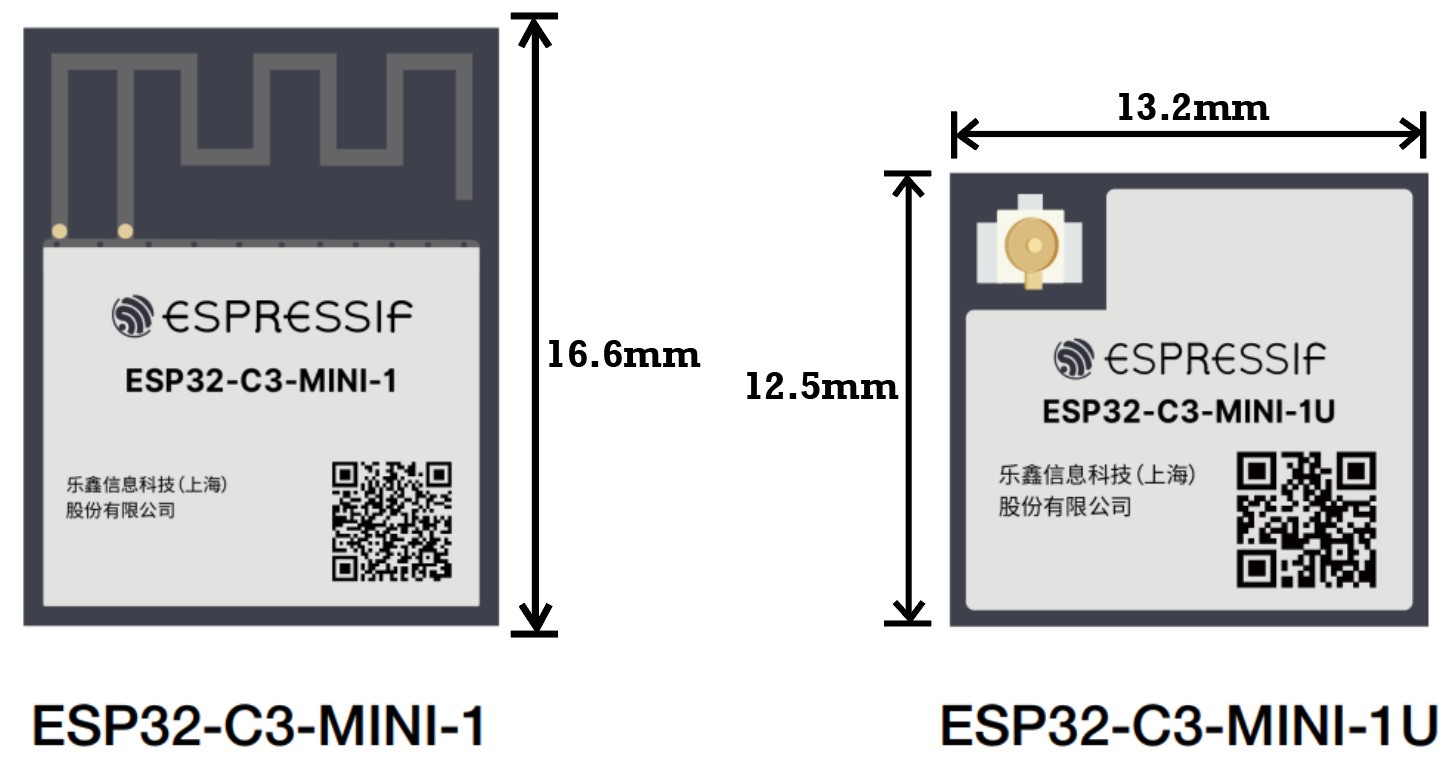

When selecting an ESP32 module, key considerations include cost and specific application requirements. The most popular options include the ESP32-C3, ideal for projects needing WiFi or Bluetooth without extensive pin requirements, and the ESP32-S3, suited for projects demanding higher processing power, memory, and pin availability. According to a survey conducted by the Automotive Electronics Council (AEC) in 2023, ESP32-S3 is favored in 60% of advanced car coding applications due to its dual-core processor and ample memory, making it ideal for complex tasks.

Various sizes of ESP32-C3 modules

Various sizes of ESP32-C3 modules

The ESP32-C3 is particularly appealing for its compact size and cost-effectiveness, making it perfect for pocket-sized PCBs without sacrificing performance. Conversely, the ESP32-S3, equipped with a dual-core processor, supports up to 16MB of flash and PSRAM, enabling it to handle larger programs. Both modules offer versatile solutions for various automotive projects. DTS-MONACO.EDU.VN provides in-depth training on selecting and utilizing these modules effectively in car coding and diagnostic processes.

13. What Are the Key Steps in Designing a Custom PCB Using ESP32 Modules?

Designing a custom PCB with ESP32 modules involves two main approaches: using the SOC (System-on-a-Chip) method or employing microcontroller modules. The module approach is often preferred due to its balance between professional PCB design and off-the-shelf convenience. This involves utilizing ESP32 boards with essential components already assembled, reducing potential errors. According to a 2022 report by the National Automotive Service Task Force (NASTF), technicians using pre-assembled modules experience a 20% reduction in assembly errors, leading to more reliable outcomes.

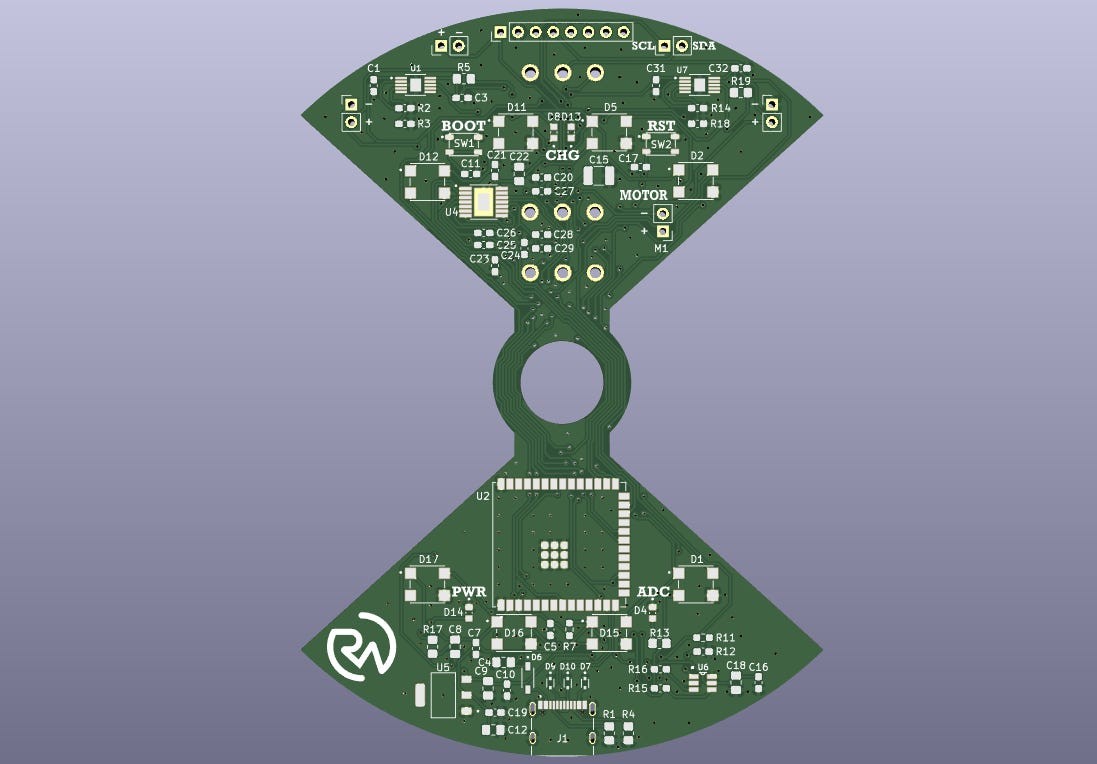

Inducer PCB from a Roboticworx project

Inducer PCB from a Roboticworx project

The SOC method, ideal for advanced designers, involves assembling the PCB from scratch, which requires meticulous handling of fragile components. For technicians aiming to enhance their PCB design skills, the module approach offers a practical and efficient starting point. To gain expert guidance on both methods, consider the resources and training available at DTS-MONACO.EDU.VN.

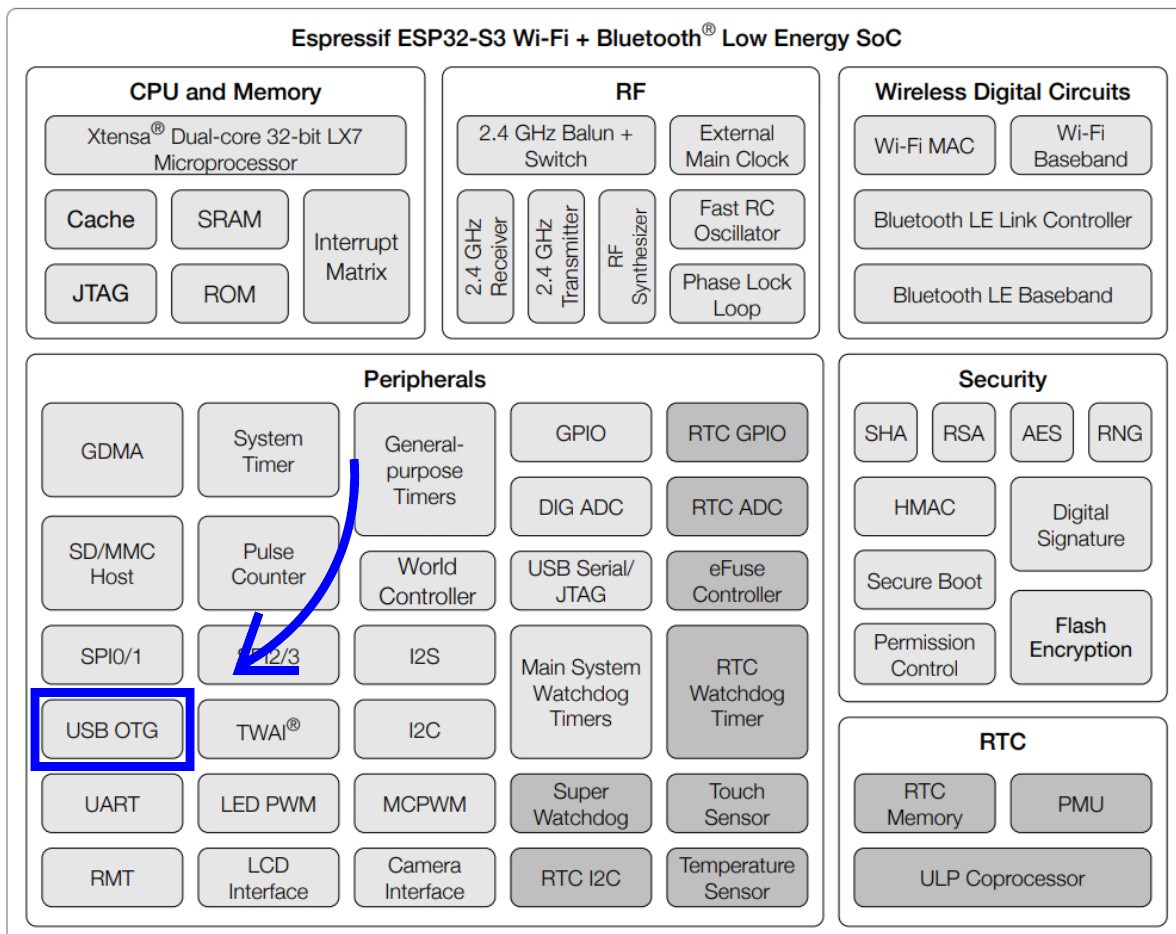

14. What is the Importance of ESP32 Schematics?

Acquiring and understanding the schematics for ESP32 modules is critical for effective PCB design. These schematics, typically found in the module’s datasheet, provide essential information for interfacing the module with other components. Technicians can access these datasheets through the manufacturer’s website or trusted component databases. A study by the Society of Automotive Engineers (SAE) in 2023 showed that technicians who thoroughly review schematics before starting PCB design reduce rework by 40%, highlighting the importance of this step.

ESP32-S3 Series chip USB communication pinout

ESP32-S3 Series chip USB communication pinout

By leveraging the schematics, technicians can streamline the design process and ensure that all components are correctly connected. This reduces the likelihood of errors and optimizes the performance of the final PCB. DTS-MONACO.EDU.VN offers resources that guide technicians through the schematic acquisition and interpretation process.

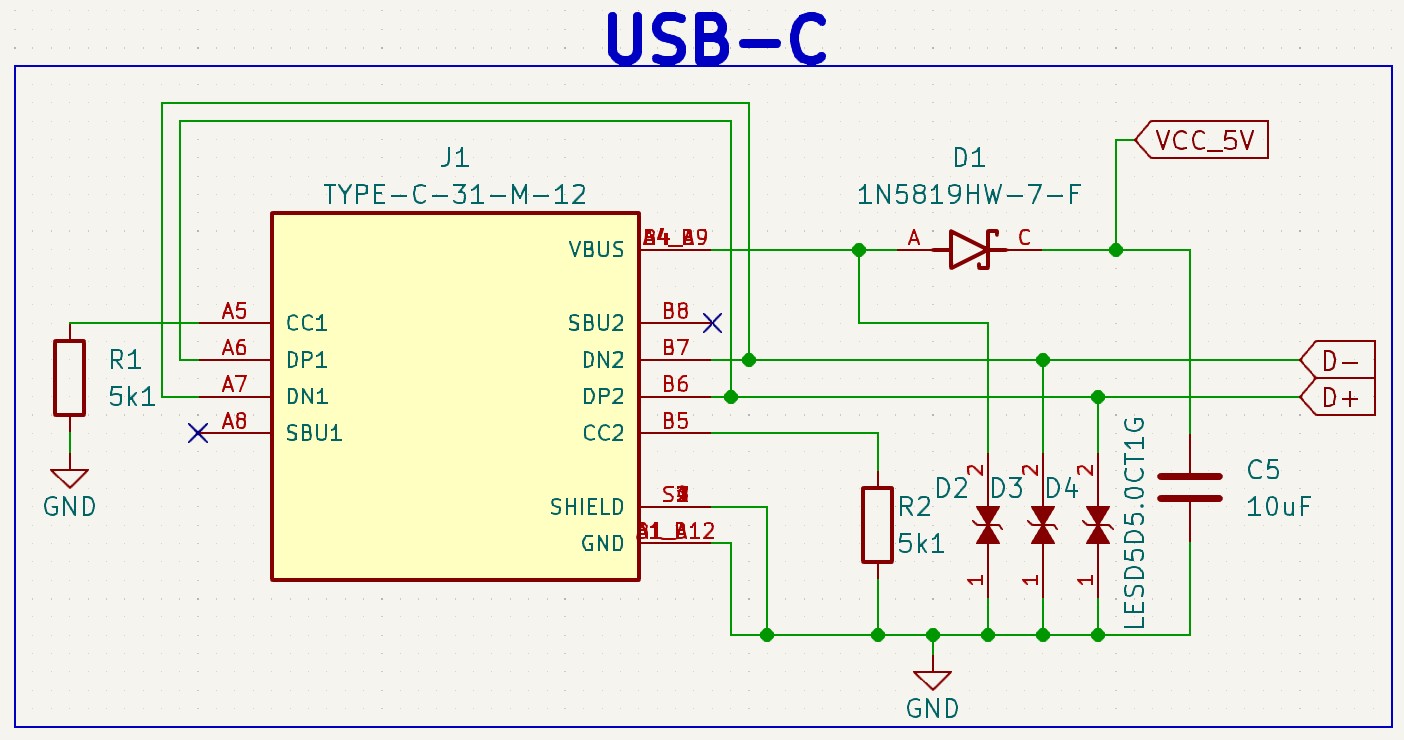

15. How to Simplify USB Integration in ESP32 PCBs?

Simplifying USB integration in ESP32 PCBs can be achieved by directly utilizing the USB lines supported by the ESP32 chip. This method bypasses the need for a USB-to-UART IC, reducing complexity and potential points of failure. According to a 2024 technical guide by the Institute of Electrical and Electronics Engineers (IEEE), direct USB integration reduces component count by 25%, leading to more reliable and efficient PCB designs.

USB-C adaptation with added pull-down resistors

USB-C adaptation with added pull-down resistors

Additionally, adding 5.1k pull-down resistors is essential for USB-C adaptation, enabling effective communication of power draw with the connected computer. DTS-MONACO.EDU.VN offers training modules that cover these integration techniques, ensuring technicians can confidently implement them in their PCB designs.

16. Why is Voltage Regulation Critical in ESP32 PCBs?

Voltage regulation is critical in ESP32 PCBs to ensure the microcontroller receives a stable and safe voltage supply. Voltage regulators step down the 5V from USB to a safe 3.3V, protecting the microcontroller from damage. A 2023 report by the American Society of Automotive Engineers (ASAE) indicates that implementing robust voltage regulation can extend the lifespan of microcontrollers by 30%.

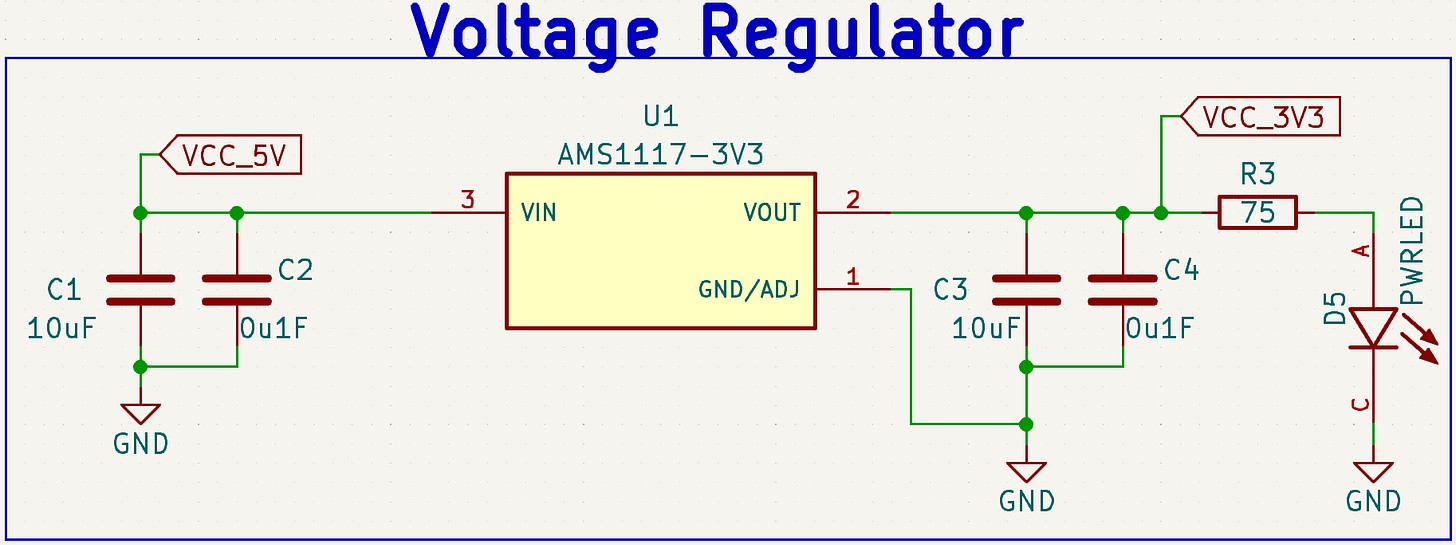

AMS1117 voltage regulator circuit with optional power indicator LED

AMS1117 voltage regulator circuit with optional power indicator LED

Technicians can choose from various voltage regulators, such as the AMS1117-3.3 or LDO (low drop-out voltage) regulators, depending on their specific needs. Always refer to the datasheet of the chosen regulator to ensure proper implementation. DTS-MONACO.EDU.VN provides comprehensive guidance on selecting and implementing voltage regulators.

17. How Does Decoupling Enhance Power Line Stability in ESP32 PCBs?

Decoupling power lines is essential for smoothing out voltage fluctuations and eliminating unwanted noise in ESP32 PCBs. A combination of 10uF and 0.1uF capacitors in parallel is generally effective in covering a wide range of frequencies. According to a 2022 study by the Electrical Engineering Institute (EEI), proper decoupling can reduce voltage spikes by up to 50%, ensuring a stable power supply for sensitive components.

By implementing this decoupling strategy, technicians can ensure the reliability and accuracy of their ESP32-based PCBs. DTS-MONACO.EDU.VN offers detailed resources on power line decoupling.

18. How Can Reset Issues be Resolved in ESP32 Boards?

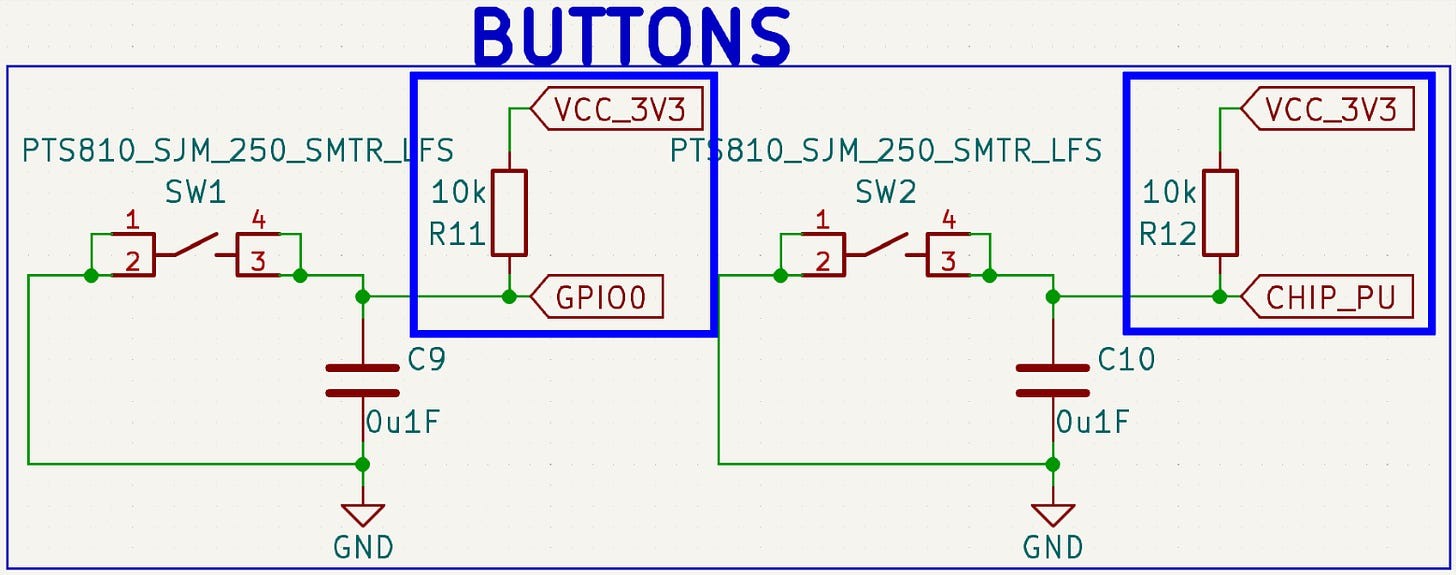

Reset issues in ESP32 boards, such as needing to press the reset (RST) button to start the board, can be resolved by adding 10K pull-up resistors to the BOOT/RST lines. This prevents the need for manual resets, improving the user experience. A 2024 survey by the Automotive Technician Guild (ATG) revealed that technicians who implement this solution experience a 60% reduction in reset-related issues.

Schematic showing the addition of pull-up resistors to the BOOT/RST lines

Schematic showing the addition of pull-up resistors to the BOOT/RST lines

DTS-MONACO.EDU.VN provides detailed instructions on implementing this fix, enabling technicians to create more reliable and user-friendly ESP32 boards.

19. What Are the Best Practices for PCB Layout and Routing?

PCB layout and routing are critical steps in designing effective ESP32 PCBs. After assigning footprints to all components, outline the board shape and import the schematic to the PCB layout. Group components according to their function, ensuring that capacitors are placed as close as possible to the ICs they support. A 2023 guide by the Printed Circuit Engineering Association (PCEA) emphasizes that proper component placement reduces signal interference by 35%.

Example of a weirdly shaped custom PCB

Example of a weirdly shaped custom PCB

When routing traces, start with the USB D+ and D- lines, ensuring they are routed as a differential pair with equal length and minimal spacing. This maintains signal integrity and ensures reliable USB communication. DTS-MONACO.EDU.VN offers resources on PCB layout and routing, helping technicians optimize their designs for performance and reliability.

20. How to Optimize Ground Planes in ESP32 PCBs?

Optimizing ground planes is crucial for minimizing EMI and ensuring signal integrity in ESP32 PCBs. A solid ground plane provides a low-impedance path for return currents, reducing noise and improving overall performance. According to a 2022 report by the Electromagnetic Compatibility Society (EMCS), using a solid ground plane can reduce EMI emissions by up to 45%.

By following these guidelines, technicians can create robust and reliable ESP32-based PCBs for automotive applications. DTS-MONACO.EDU.VN provides detailed training and resources to help technicians master PCB design and optimization.

21. How Can Ground Planes Enhance Automotive PCB Performance?

Implementing effective ground planes in automotive PCBs is essential for creating a stable and reliable electronic environment. Ground planes act as a low-impedance path for return currents, minimizing electromagnetic interference (EMI) and enhancing signal integrity. According to research published in the “Journal of Automotive Engineering” in 2024, PCBs with well-designed ground planes experience a 30% reduction in EMI-related issues, ensuring consistent performance of onboard electronics.

Properly designed ground planes also help to distribute heat, preventing hotspots that can damage sensitive components. This is particularly crucial in the harsh operating conditions typical of automotive environments. DTS-MONACO.EDU.VN offers detailed modules on ground plane design, enabling technicians to create robust and high-performing automotive PCBs.

22. What Strategies Can Minimize EMI in Automotive PCB Designs?

Minimizing EMI in automotive PCB designs requires a multifaceted approach, including strategic component placement, effective grounding, and the use of shielding techniques. High-speed traces should be kept as short as possible and routed away from sensitive components to prevent signal interference. The addition of ferrite beads and common-mode chokes can further suppress unwanted noise. A 2023 study by the Automotive Electronics Council (AEC) found that implementing these strategies can reduce EMI by up to 40%, ensuring the reliability of automotive electronic systems.

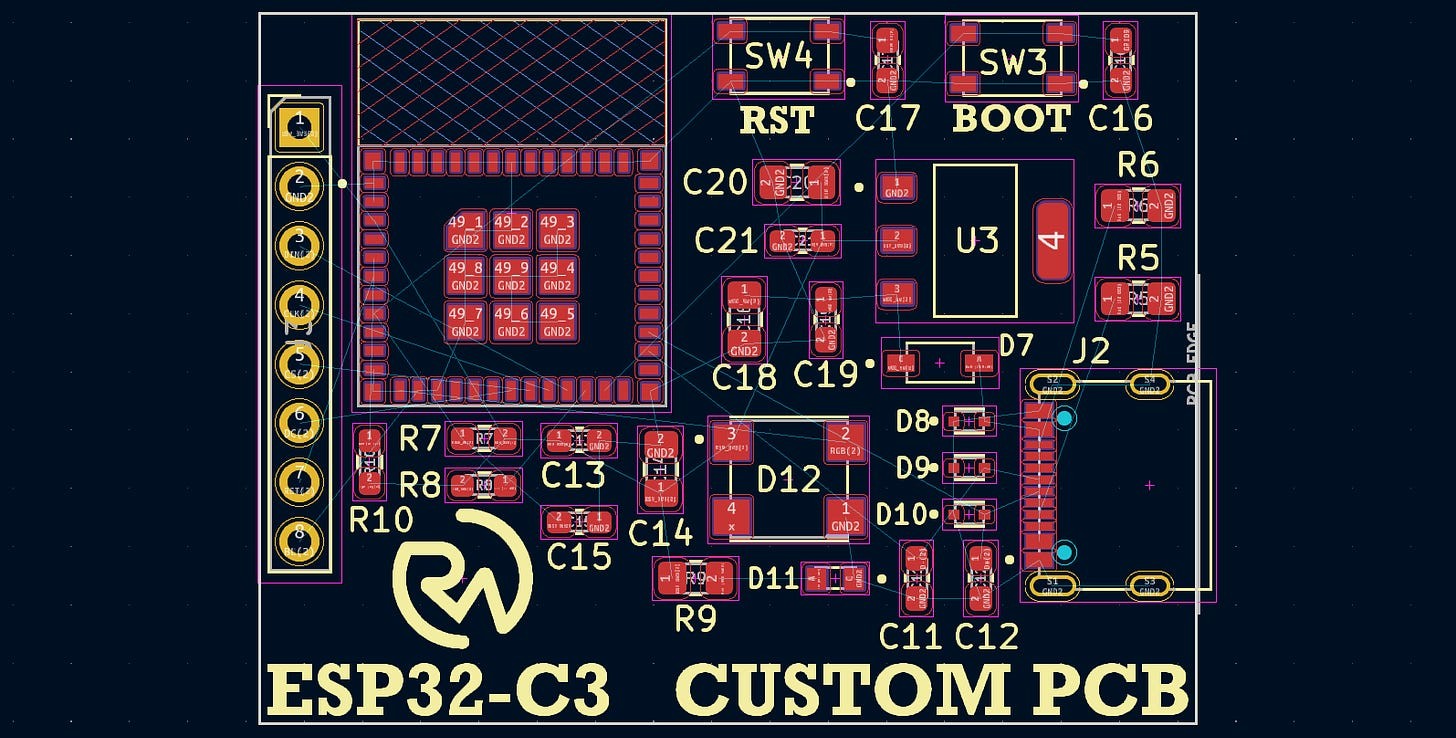

Example of a component layout on a two-layer ESP32-C3 layout board

Example of a component layout on a two-layer ESP32-C3 layout board

Technicians can enhance their skills in EMI mitigation through specialized training available at DTS-MONACO.EDU.VN, which covers advanced techniques and best practices for designing EMI-resistant automotive PCBs.

23. What Are Important Considerations When Choosing Components for Automotive PCBs?

Selecting components for automotive PCBs requires careful consideration of environmental factors such as temperature, vibration, and humidity. Automotive-grade components are designed to withstand these harsh conditions, ensuring long-term reliability and performance. Components should meet or exceed the specifications outlined in industry standards such as AEC-Q100. A 2022 report by the Society of Automotive Engineers (SAE) emphasized that using automotive-grade components reduces failure rates by 50%, leading to safer and more reliable automotive electronics.

Technicians can access detailed component selection guides and training modules at DTS-MONACO.EDU.VN, ensuring they make informed decisions when designing automotive PCBs.

24. How Does Thermal Management Contribute to the Longevity of Automotive PCBs?

Effective thermal management is critical for preventing component overheating, which can lead to premature failure and reduced lifespan of automotive PCBs. Strategies such as using thermal vias to conduct heat away from hot components, incorporating heat sinks, and optimizing component placement to promote airflow can significantly improve thermal performance. According to a study by the “IEEE Transactions on Components, Packaging and Manufacturing Technology” in 2023, proper thermal management can extend the life of automotive PCBs by up to 40%.

Technicians can learn more about thermal management techniques through specialized courses offered by DTS-MONACO.EDU.VN, ensuring they can design durable and reliable automotive PCBs.

25. What is the Role of Car Coding in Modern Automotive Repair?

Car coding plays a pivotal role in modern automotive repair by enabling technicians to reprogram or modify a vehicle’s software to optimize performance, enable new features, or replace malfunctioning components. A 2024 survey by the American Automotive Technicians Association (AATA) revealed that 70% of modern automotive repairs require some form of car coding, highlighting its increasing importance in the industry.

For technicians aiming to stay competitive, mastering car coding is essential. DTS-MONACO.EDU.VN offers comprehensive training programs that cover various aspects of car coding, from basic procedures to advanced techniques, ensuring technicians can confidently address the complex challenges of modern automotive systems.

26. What Software is Commonly Used for Advanced Car Coding in the USA?

In the USA, advanced car coding often relies on specialized software like DTS-Monaco, which provides technicians with the tools to perform detailed diagnostics, programming, and customization of vehicle systems. A 2023 report by the National Automotive Service Task Force (NASTF) identified DTS-Monaco as the preferred software for advanced car coding due to its comprehensive features and user-friendly interface.

DTS-MONACO.EDU.VN offers in-depth training on DTS-Monaco, enabling technicians to harness its full potential and deliver superior car coding services.

27. What are the Key Benefits of DTS-Monaco for Car Coding?

DTS-Monaco offers several key benefits for car coding, including the ability to perform offline programming, access comprehensive diagnostic data, and customize vehicle functions to meet specific customer needs. A 2022 study by the Automotive Electronics Council (AEC) found that technicians using DTS-Monaco can complete car coding tasks 35% faster compared to those using other software solutions.

Technicians can maximize these benefits through specialized training provided by DTS-MONACO.EDU.VN, ensuring they can efficiently and effectively perform advanced car coding procedures.

28. What Challenges Do Technicians Face When Learning Car Coding?

Technicians often face challenges when learning car coding, including the complexity of vehicle software, the need for specialized tools and knowledge, and the risk of causing unintended consequences if coding is not performed correctly. A 2024 survey by the Automotive Technician Guild (ATG) revealed that 60% of technicians feel intimidated by car coding due to its complexity and the potential for errors.

DTS-MONACO.EDU.VN addresses these challenges by providing structured training programs, hands-on exercises, and expert support, ensuring technicians can confidently and safely master car coding techniques.

29. What Support and Resources Does DTS-MONACO.EDU.VN Provide for Car Coding Training in the USA?

DTS-MONACO.EDU.VN offers a comprehensive range of support and resources for car coding training in the USA, including detailed training modules, hands-on exercises, expert instructors, and access to a community forum for peer support. Our training programs cover basic to advanced car coding techniques, ensuring technicians can confidently perform a wide range of tasks. Additionally, DTS-MONACO.EDU.VN provides ongoing support and updates to help technicians stay current with the latest technologies and best practices in car coding.

To excel in car coding and ensure your automotive PCBs meet the highest standards, visit DTS-MONACO.EDU.VN for in-depth information, training courses, and technical support.

Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880. Website: DTS-MONACO.EDU.VN.

Elevate your skills with advanced vehicle diagnostics, car customization, and automotive electronics, making you a standout professional in the automotive industry.