A C6 VCI, when paired with an online XENTRY subscription, absolutely can perform SCN coding, offering technicians a powerful tool for Mercedes-Benz diagnostics and programming. DTS-MONACO.EDU.VN is dedicated to empowering automotive professionals with the knowledge and resources needed to excel in modern vehicle servicing, including advanced car coding techniques. Dive into the world of car diagnostics and coding with confidence, unlocking new capabilities for your business and expanding your expertise.

Contents

- 1. Understanding SCN Coding and its Importance

- 1.1 What is SCN Coding?

- 1.2 Why is SCN Coding Necessary?

- 1.3 The Role of Online Access in SCN Coding

- 2. What is a C6 VCI?

- 2.1 Key Features and Capabilities of the C6 VCI

- 2.2 Benefits of Using a C6 VCI

- 3. XENTRY: The Diagnostic Software for Mercedes-Benz

- 3.1 XENTRY’s Role in Diagnostics and Coding

- 3.2 Online vs. Offline XENTRY: Understanding the Differences

- 3.3 Benefits of Online XENTRY for SCN Coding

- 4. Can a C6 VCI Perform SCN Coding? (The Definitive Answer)

- 4.1 The Synergistic Relationship Between C6 VCI and Online XENTRY

- 4.2 Step-by-Step Guide: Performing SCN Coding with C6 VCI and Online XENTRY

- 4.3 Ensuring a Successful SCN Coding Process

- 5. What about Offline SCN Coding?

- 5.1 Limitations of Offline SCN Coding

- 5.2 When is Offline SCN Coding a Viable Option?

- 5.3 Tools and Resources for Offline SCN Coding

- 6. DTS Monaco: An Alternative Solution for Coding

- 6.1 Capabilities of DTS Monaco

- 6.2 How DTS Monaco Complements XENTRY

- 6.3 Learning DTS Monaco with DTS-MONACO.EDU.VN

- 7. Choosing the Right Diagnostic Tool: C6 VCI, ECOM, and Others

- 7.1 Comparing C6 VCI to Other Diagnostic Tools

- 7.2 Factors to Consider When Choosing a Diagnostic Tool

- 7.3 Investing in the Right Equipment for Your Business

- 8. Common Challenges and Troubleshooting Tips for SCN Coding

- 8.1 Addressing Communication Errors

- 8.2 Resolving SCN Coding Errors

- 8.3 Dealing with Software Incompatibilities

- 9. The Future of SCN Coding and Automotive Diagnostics

- 9.1 Emerging Technologies in Automotive Diagnostics

- 9.2 The Impact of Cybersecurity on SCN Coding

- 9.3 Preparing for the Next Generation of Vehicles

- 10. Why Choose DTS-MONACO.EDU.VN for Your Car Coding Needs?

- 10.1 Comprehensive Training Programs

- 10.2 Expert Support and Resources

- 10.3 Gaining a Competitive Edge in the Automotive Industry

- FAQ: SCN Coding and C6 VCI

1. Understanding SCN Coding and its Importance

SCN (Software Calibration Number) coding is a critical process for Mercedes-Benz vehicles. It involves programming control units with specific software configurations to ensure proper function and integration within the vehicle’s systems.

1.1 What is SCN Coding?

SCN coding, also known as Software Calibration Number coding, programs a control unit using a specific software configuration. This calibration ensures seamless integration of the control unit within the vehicle’s complex network. Without correct SCN coding, a newly installed or replaced control unit may not function properly, leading to various performance issues. According to Mercedes-Benz official documentation, correct SCN coding is essential for maintaining the vehicle’s original performance and safety standards.

1.2 Why is SCN Coding Necessary?

SCN coding is necessary for several reasons:

- Component Replacement: When a control unit is replaced, it often comes as a blank unit. SCN coding ensures it’s programmed with the correct software variant for that specific vehicle.

- Software Updates: SCN coding is used during software updates to ensure that all control units are running the latest and most compatible software versions.

- Feature Activation: Certain vehicle features may require SCN coding to be activated or configured correctly.

1.3 The Role of Online Access in SCN Coding

Online access to the Mercedes-Benz servers is vital for SCN coding because it provides access to the most up-to-date software and calibration data. This ensures that the coding process is accurate and that the control unit is programmed with the correct parameters for the vehicle’s specific configuration.

2. What is a C6 VCI?

A C6 VCI (Vehicle Communication Interface) is a diagnostic tool used for Mercedes-Benz vehicles. It acts as a bridge between the vehicle’s electronic systems and diagnostic software like XENTRY. The C6 VCI is the latest generation of Mercedes-Benz diagnostic interfaces, replacing older models like the C4.

2.1 Key Features and Capabilities of the C6 VCI

The C6 VCI boasts several key features that make it a valuable tool for automotive technicians:

- Broad Vehicle Compatibility: The C6 VCI supports a wide range of Mercedes-Benz vehicles, including the latest models.

- Advanced Diagnostic Functions: It enables comprehensive diagnostics, including reading and clearing fault codes, live data streaming, and component testing.

- SCN Coding and Programming: When used with an online XENTRY subscription, the C6 VCI can perform SCN coding and other programming functions.

- DoIP Support: The C6 VCI supports the Diagnostic over Internet Protocol (DoIP), which is necessary for diagnosing and programming newer Mercedes-Benz models like the W223 and W206.

2.2 Benefits of Using a C6 VCI

Using a C6 VCI offers numerous benefits for automotive technicians:

- Faster Diagnostics: The C6 VCI’s advanced processing power and DoIP support enable faster and more efficient diagnostics.

- Accurate Coding: When used with online XENTRY, the C6 VCI ensures accurate SCN coding, minimizing the risk of errors and ensuring proper vehicle function.

- Future-Proofing: The C6 VCI’s support for DoIP and newer vehicle models ensures that technicians are equipped to handle the latest Mercedes-Benz vehicles.

- Enhanced Capabilities: The C6 VCI unlocks advanced diagnostic and programming capabilities, allowing technicians to perform a wider range of services.

Mercedes-Benz C6 VCI Diagnostic Tool

Mercedes-Benz C6 VCI Diagnostic Tool

3. XENTRY: The Diagnostic Software for Mercedes-Benz

XENTRY is the official diagnostic software used by Mercedes-Benz dealerships and authorized service centers. It provides comprehensive diagnostic, programming, and information retrieval capabilities for Mercedes-Benz vehicles.

3.1 XENTRY’s Role in Diagnostics and Coding

XENTRY plays a crucial role in both diagnostics and coding:

- Diagnostics: XENTRY provides access to a wealth of diagnostic information, including fault codes, live data, and guided tests. This information helps technicians quickly and accurately diagnose vehicle problems.

- Coding: XENTRY is used to perform SCN coding, programming, and other configuration tasks. It ensures that control units are properly programmed and configured for the vehicle’s specific requirements.

3.2 Online vs. Offline XENTRY: Understanding the Differences

There are two main versions of XENTRY: online and offline. The key difference lies in their connectivity to the Mercedes-Benz servers.

- Online XENTRY: This version requires an active internet connection to access the Mercedes-Benz servers. Online XENTRY provides access to the latest software updates, SCN coding data, and other online resources.

- Offline XENTRY: This version does not require an internet connection. However, it has limited functionality compared to online XENTRY. Offline XENTRY can be used for basic diagnostics, but it cannot perform SCN coding or access the latest software updates without additional solutions.

3.3 Benefits of Online XENTRY for SCN Coding

Using online XENTRY for SCN coding offers several advantages:

- Access to the Latest Data: Online XENTRY provides access to the most up-to-date SCN coding data, ensuring accurate and reliable coding results.

- Simplified Process: The online SCN coding process is typically more streamlined and user-friendly than offline methods.

- Reduced Risk of Errors: Online XENTRY reduces the risk of errors during SCN coding by automatically verifying the coding data and configuration parameters.

4. Can a C6 VCI Perform SCN Coding? (The Definitive Answer)

Yes, a C6 VCI absolutely can perform SCN coding when used with an active online XENTRY subscription. The C6 VCI acts as the essential hardware interface, while the online XENTRY software provides the necessary data and protocols to execute the SCN coding process. Let’s delve deeper into the specifics and requirements.

4.1 The Synergistic Relationship Between C6 VCI and Online XENTRY

The C6 VCI and online XENTRY work together seamlessly to enable SCN coding. The C6 VCI provides the physical connection to the vehicle’s diagnostic port and handles the communication between the vehicle’s control units and the XENTRY software. Online XENTRY, in turn, provides the following:

- Vehicle Identification: XENTRY automatically identifies the vehicle and its specific configuration.

- SCN Coding Data: XENTRY retrieves the correct SCN coding data from the Mercedes-Benz servers.

- Coding Protocols: XENTRY provides the necessary protocols and procedures for performing SCN coding.

- Verification: XENTRY verifies the SCN coding process to ensure that it has been completed successfully.

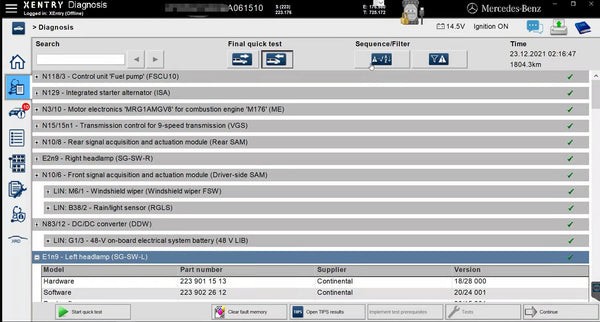

4.2 Step-by-Step Guide: Performing SCN Coding with C6 VCI and Online XENTRY

Here’s a general outline of the steps involved in performing SCN coding with a C6 VCI and online XENTRY:

- Connect the C6 VCI: Connect the C6 VCI to the vehicle’s diagnostic port (OBD-II port) and to your computer via USB or Wi-Fi.

- Launch XENTRY: Start the XENTRY diagnostic software on your computer.

- Vehicle Identification: Allow XENTRY to automatically identify the vehicle.

- Select Control Unit: Choose the control unit that requires SCN coding.

- Initiate SCN Coding: Follow the on-screen prompts to initiate the SCN coding process.

- Online Verification: XENTRY will connect to the Mercedes-Benz servers to retrieve the necessary SCN coding data.

- Coding Execution: XENTRY will execute the SCN coding process, programming the control unit with the correct software configuration.

- Verification: XENTRY will verify the SCN coding process to ensure that it has been completed successfully.

- Finalization: Follow the on-screen prompts to finalize the SCN coding process.

Note: The specific steps may vary slightly depending on the vehicle model and the control unit being coded.

4.3 Ensuring a Successful SCN Coding Process

To ensure a successful SCN coding process, keep the following in mind:

- Stable Internet Connection: Maintain a stable and reliable internet connection throughout the SCN coding process.

- Correct C6 VCI Configuration: Ensure that the C6 VCI is properly configured and connected to your computer.

- Valid XENTRY Subscription: Have a valid and active online XENTRY subscription.

- Vehicle Battery Voltage: Maintain a stable vehicle battery voltage during the SCN coding process. Consider using a battery support unit to prevent voltage fluctuations.

- Follow Instructions Carefully: Follow the on-screen prompts and instructions provided by XENTRY carefully.

5. What about Offline SCN Coding?

While online XENTRY is the preferred method for SCN coding, offline SCN coding may be possible in certain situations. However, it typically requires specialized software and data, and it may not be supported for all vehicle models or control units.

5.1 Limitations of Offline SCN Coding

Offline SCN coding has several limitations compared to online SCN coding:

- Limited Data Availability: Access to SCN coding data may be limited or outdated.

- Increased Complexity: The offline SCN coding process can be more complex and require specialized knowledge.

- Higher Risk of Errors: The risk of errors during offline SCN coding is higher due to the lack of online verification.

- Vehicle Compatibility: Offline SCN coding may not be supported for all vehicle models or control units.

5.2 When is Offline SCN Coding a Viable Option?

Offline SCN coding may be a viable option in situations where online access is not available or practical. For example, in remote locations or when working on older vehicles that are no longer supported by online XENTRY.

5.3 Tools and Resources for Offline SCN Coding

Offline SCN coding typically requires specialized software and data, such as:

- DTS Monaco: A powerful diagnostic and coding tool that can be used for offline SCN coding.

- SCN Coding Databases: Databases containing SCN coding data for various Mercedes-Benz vehicles.

- Experienced Technicians: Offline SCN coding should only be performed by experienced technicians who have a thorough understanding of the process and the risks involved.

6. DTS Monaco: An Alternative Solution for Coding

DTS Monaco is a powerful diagnostic and engineering software used extensively for advanced coding, programming, and diagnostics of Mercedes-Benz vehicles. It offers functionalities beyond the standard XENTRY, making it a favorite among experienced technicians and those specializing in complex vehicle modifications.

6.1 Capabilities of DTS Monaco

DTS Monaco’s capabilities include, but aren’t limited to:

- ECU Flashing: Updating or replacing the software on electronic control units (ECUs).

- Variant Coding: Customizing vehicle features and functions by modifying ECU parameters.

- Diagnostic Trouble Code (DTC) Analysis: In-depth analysis of diagnostic codes to pinpoint issues.

- Advanced Diagnostics: Performing specialized diagnostic routines not available in standard diagnostic tools.

6.2 How DTS Monaco Complements XENTRY

While XENTRY is excellent for standard diagnostics and SCN coding with online access, DTS Monaco shines in scenarios requiring more in-depth customization or offline work. Technicians often use XENTRY for initial diagnostics and then switch to DTS Monaco for advanced coding tasks.

6.3 Learning DTS Monaco with DTS-MONACO.EDU.VN

DTS-MONACO.EDU.VN provides comprehensive training and resources for mastering DTS Monaco. Whether you’re a beginner or an experienced technician, their courses can help you unlock the full potential of this powerful software. Learn how to perform complex coding tasks, troubleshoot advanced issues, and customize vehicles to meet specific customer requirements.

7. Choosing the Right Diagnostic Tool: C6 VCI, ECOM, and Others

Selecting the appropriate diagnostic tool is critical for efficient and accurate Mercedes-Benz servicing. Besides the C6 VCI, other options like the ECOM exist, each with its strengths and weaknesses.

7.1 Comparing C6 VCI to Other Diagnostic Tools

- C6 VCI: The latest Mercedes-Benz diagnostic interface, offering broad vehicle compatibility, DoIP support, and advanced diagnostic capabilities.

- ECOM: A compact and robust diagnostic interface that supports DoIP and is well-suited for mobile use.

- C4: An older diagnostic interface that is still used by some technicians but lacks support for DoIP and newer vehicle models.

7.2 Factors to Consider When Choosing a Diagnostic Tool

When choosing a diagnostic tool, consider the following factors:

- Vehicle Compatibility: Ensure that the tool supports the vehicles you will be working on.

- Functionality: Determine the diagnostic and coding functions you require.

- DoIP Support: If you will be working on newer Mercedes-Benz models, DoIP support is essential.

- Ease of Use: Choose a tool that is user-friendly and easy to learn.

- Cost: Compare the cost of different tools and choose one that fits your budget.

7.3 Investing in the Right Equipment for Your Business

Investing in the right diagnostic equipment can significantly improve your business’s efficiency, accuracy, and capabilities. By choosing the right tools, you can:

- Reduce Diagnostic Time: Faster and more accurate diagnostics can save time and money.

- Increase Customer Satisfaction: Providing high-quality service can lead to increased customer satisfaction and loyalty.

- Expand Your Service Offerings: Advanced diagnostic and coding capabilities can allow you to offer a wider range of services.

- Stay Competitive: Keeping up with the latest technology can help you stay competitive in the automotive industry.

8. Common Challenges and Troubleshooting Tips for SCN Coding

SCN coding can sometimes be challenging, and technicians may encounter various issues during the process. Here are some common challenges and troubleshooting tips:

8.1 Addressing Communication Errors

Communication errors between the C6 VCI, XENTRY, and the vehicle can occur due to various reasons.

- Check Cable Connections: Ensure all cables are securely connected.

- Verify VCI Configuration: Confirm the C6 VCI is correctly configured in XENTRY.

- Software Updates: Ensure both XENTRY and the C6 VCI firmware are up-to-date.

- Firewall and Antivirus: Temporarily disable firewall or antivirus software that might interfere with communication.

8.2 Resolving SCN Coding Errors

SCN coding errors can arise from incorrect data or interruptions during the process.

- Verify Vehicle Information: Double-check the vehicle’s VIN and configuration in XENTRY.

- Stable Power Supply: Ensure a stable power supply to the vehicle during coding.

- Retry the Process: If an error occurs, retry the SCN coding process.

- Consult Mercedes-Benz Documentation: Refer to Mercedes-Benz’s official documentation for specific error codes and solutions.

8.3 Dealing with Software Incompatibilities

Software incompatibilities can lead to malfunctions or prevent SCN coding altogether.

- Check Compatibility Charts: Verify that your version of XENTRY is compatible with the vehicle model.

- Update Software: Keep your diagnostic software updated to the latest version.

- Use Correct Software Versions: Ensure you are using the correct software versions for the specific control unit.

9. The Future of SCN Coding and Automotive Diagnostics

The automotive industry is constantly evolving, and SCN coding and diagnostics are no exception. Here’s a glimpse into the future:

9.1 Emerging Technologies in Automotive Diagnostics

- Artificial Intelligence (AI): AI is being used to develop more intelligent diagnostic systems that can automatically identify and diagnose vehicle problems.

- Cloud-Based Diagnostics: Cloud-based diagnostic platforms offer remote diagnostics, data logging, and software updates.

- Augmented Reality (AR): AR is being used to create interactive diagnostic tools that guide technicians through complex procedures.

9.2 The Impact of Cybersecurity on SCN Coding

Cybersecurity is becoming increasingly important in the automotive industry. SCN coding processes must be secure to prevent unauthorized access and modifications to vehicle software.

9.3 Preparing for the Next Generation of Vehicles

As vehicles become more complex and connected, technicians need to stay up-to-date with the latest technologies and diagnostic techniques. This includes:

- Continuous Learning: Participating in ongoing training and education programs.

- Investing in New Tools: Acquiring the latest diagnostic tools and equipment.

- Adapting to New Technologies: Embracing new technologies and adapting to the changing landscape of the automotive industry.

10. Why Choose DTS-MONACO.EDU.VN for Your Car Coding Needs?

DTS-MONACO.EDU.VN stands out as a premier resource for automotive technicians looking to enhance their skills in car coding and diagnostics. They offer comprehensive training programs, expert support, and a wealth of resources to help you master the complexities of modern vehicle systems.

10.1 Comprehensive Training Programs

DTS-MONACO.EDU.VN offers a range of training programs designed to meet the needs of technicians at all skill levels. From beginner courses to advanced workshops, they provide hands-on training and practical knowledge that you can immediately apply in your work.

10.2 Expert Support and Resources

Their team of experienced instructors and industry experts is dedicated to providing you with the support you need to succeed. They offer personalized guidance, troubleshooting assistance, and access to a vast library of resources, including:

- Detailed Tutorials: Step-by-step guides on performing various coding and diagnostic procedures.

- Software Guides: In-depth documentation on using DTS Monaco and other diagnostic tools.

- Vehicle-Specific Information: Technical data and coding information for a wide range of Mercedes-Benz vehicles.

10.3 Gaining a Competitive Edge in the Automotive Industry

By investing in training from DTS-MONACO.EDU.VN, you can gain a competitive edge in the automotive industry. You’ll be equipped with the skills and knowledge to:

- Perform Advanced Coding Tasks: Customize vehicle features, activate hidden functions, and optimize vehicle performance.

- Troubleshoot Complex Issues: Diagnose and resolve challenging diagnostic problems that others can’t.

- Increase Your Earning Potential: Offer specialized services that command higher rates and attract more customers.

Ready to take your car coding skills to the next level? Visit DTS-MONACO.EDU.VN today to explore their training programs and discover how they can help you achieve your professional goals.

Address: 275 N Harrison St, Chandler, AZ 85225, United States

WhatsApp: +1 (641) 206-8880

Website: DTS-MONACO.EDU.VN

FAQ: SCN Coding and C6 VCI

1. What is the primary function of SCN coding in Mercedes-Benz vehicles?

SCN coding programs control units with specific software configurations to ensure proper function and integration within the vehicle’s systems, maintaining its original performance and safety standards.

2. Can a C6 VCI be used for SCN coding?

Yes, a C6 VCI can perform SCN coding when used with an active online XENTRY subscription, providing the necessary data and protocols to execute the coding process.

3. What is the difference between online and offline XENTRY?

Online XENTRY requires an active internet connection to access the Mercedes-Benz servers for the latest software updates and SCN coding data, while offline XENTRY does not require an internet connection but has limited functionality.

4. What are the limitations of offline SCN coding?

Offline SCN coding has limitations such as limited data availability, increased complexity, a higher risk of errors, and may not be supported for all vehicle models or control units.

5. What is DTS Monaco, and how does it relate to SCN coding?

DTS Monaco is a powerful diagnostic and engineering software used for advanced coding, programming, and diagnostics of Mercedes-Benz vehicles, often used for complex customization or offline work.

6. What factors should be considered when choosing a diagnostic tool like C6 VCI or ECOM?

Factors to consider include vehicle compatibility, functionality, DoIP support, ease of use, and cost.

7. What are some common challenges encountered during SCN coding?

Common challenges include communication errors, SCN coding errors, and software incompatibilities.

8. How can communication errors during SCN coding be addressed?

To address communication errors, check cable connections, verify VCI configuration, ensure software updates, and temporarily disable firewall or antivirus software.

9. What emerging technologies are shaping the future of automotive diagnostics?

Emerging technologies include artificial intelligence (AI), cloud-based diagnostics, and augmented reality (AR).

10. What benefits does DTS-MONACO.EDU.VN offer for technicians seeking to improve their car coding skills?

DTS-MONACO.EDU.VN offers comprehensive training programs, expert support and resources, and personalized guidance to help technicians master car coding and diagnostics.