Are you curious about whether the MB SD Connect C4 can perform variant coding on Diagnostics over Internet Protocol (DoIP) modules when accessed through a gateway CAN? The short answer is no; Direct DoIP connection is required for coding. At DTS-MONACO.EDU.VN, we’re committed to providing in-depth knowledge and solutions for automotive diagnostics and car coding. Let’s dive into the reasons and explore alternative methods, focusing on the importance of DoIP for coding, the limitations of CAN, and how tools like the MB SD Connect C4 and software such as DTS Monaco play a crucial role in modern vehicle diagnostics.

Contents

- 1. Understanding the Basics: CAN vs. DoIP

- 1.1. What is CAN (Controller Area Network)?

- 1.2. What is DoIP (Diagnostics over Internet Protocol)?

- 1.3. Why CAN Falls Short for Modern Coding

- 1.4. The Necessity of DoIP for Variant Coding

- 2. Decoding Variant Coding and Module Access

- 2.1. What is Variant Coding?

- 2.2. Why Direct Access Matters for DoIP Modules

- 2.3. The Role of Gateways in Vehicle Networks

- 2.4. Case Study: Variant Coding on a Modern Mercedes-Benz

- 3. Exploring the Capabilities of MB SD Connect C4

- 3.1. Overview of MB SD Connect C4

- 3.2. Limitations of CAN Communication

- 3.3. DoIP Support in Newer C4 Units

- 3.4. How to Identify a DoIP-Enabled C4 Unit

- 3.5. Using MB SD Connect C4 with DTS Monaco

- 4. The Role of DTS Monaco in Modern Car Coding

- 4.1. Overview of DTS Monaco

- 4.2. Advantages of Using DTS Monaco for Car Coding

- 4.3. How DTS Monaco Enhances DoIP Capabilities

- 4.4. Step-by-Step Guide: Variant Coding with DTS Monaco on a DoIP Module

- 4.5. Best Practices for Using DTS Monaco

- 5. Practical Examples and Use Cases

- 5.1. Example 1: Enabling Adaptive Cruise Control

- 5.2. Example 2: Retrofitting a New Infotainment System

- 5.3. Example 3: Updating ECU Software

- 5.4. Example 4: Diagnosing Complex Electrical Issues

- 5.5. Example 5: Activating Driver-Assistance Systems

- 6. Troubleshooting Common Issues

- 6.1. Connectivity Problems

- 6.2. Slow Data Transfer Rates

- 6.3. ECU Communication Errors

- 6.4. Security Certificate Issues

- 6.5. Software Compatibility Problems

- 6.6. Power Supply Issues

- 7. Training and Certification for DoIP Diagnostics

- 7.1. Importance of Training and Certification

- 7.2. Key Training Programs and Certifications

- 7.3. What to Look for in a Training Program

- 7.4. Benefits of Certified Technicians for Auto Repair Shops

- 7.5. Staying Updated with Industry Advancements

- 8. Future Trends in Automotive Diagnostics

- 8.1. Remote Diagnostics

- 8.2. Artificial Intelligence (AI) in Diagnostics

- 8.3. Augmented Reality (AR) in Diagnostics

- 8.4. Over-the-Air (OTA) Updates

- 8.5. Enhanced Cybersecurity Measures

- 8.6. Integration of Diagnostic Data with Vehicle Health Monitoring Systems

- 9. FAQ: Common Questions About C4, DoIP, and Variant Coding

- 9.1. Can the MB SD Connect C4 perform variant coding on DoIP modules if accessed via gateway CAN?

- 9.2. What is DoIP and why is it important?

- 9.3. What is variant coding?

- 9.4. What are the limitations of CAN communication?

- 9.5. What is DTS Monaco and how does it help with car coding?

- 9.6. How do I identify if my MB SD Connect C4 unit supports DoIP communication?

- 9.7. What are some common issues encountered when working with DoIP?

- 9.8. Where can technicians get certified to work with DoIP-enabled systems?

- 9.9. What are some future trends in automotive diagnostics?

- 9.10. Why is direct access important for DoIP modules?

- 10. Conclusion: Embrace the Future of Car Coding

This article is your ultimate guide to understanding DoIP, CAN, and variant coding, ensuring you stay ahead in the rapidly evolving field of automotive technology with valuable insights and practical advice.

1. Understanding the Basics: CAN vs. DoIP

What are the fundamental differences between CAN and DoIP, and why does it matter for car coding?

To truly understand why a C4 device cannot perform variant coding on DoIP modules through a CAN gateway, we must first understand the fundamentals of Controller Area Network (CAN) and Diagnostics over Internet Protocol (DoIP).

1.1. What is CAN (Controller Area Network)?

CAN, or Controller Area Network, is a robust communication protocol designed to allow microcontrollers and devices to communicate with each other in applications without a host computer. It is primarily used in automotive applications but is also found in industrial automation, medical equipment, and other fields.

- History and Development: Developed by Robert Bosch GmbH in the 1980s, CAN was created to reduce the amount of wiring required in vehicles. Instead of having individual wiring harnesses for each electronic device, CAN allowed multiple devices to communicate over a single pair of wires.

- Key Features:

- Reliability: CAN is known for its robust error detection and correction capabilities.

- Efficiency: It supports real-time communication, making it suitable for critical applications.

- Cost-Effectiveness: Reduces wiring complexity and weight, leading to cost savings.

- Technical Specifications:

- Data Rate: CAN supports data rates up to 1 Mbps, though the actual rate depends on the network length.

- Message Format: CAN messages consist of an identifier, control fields, data fields, and error-checking fields.

- Addressing: CAN uses a message-based protocol where messages are identified by a unique identifier rather than a specific address.

1.2. What is DoIP (Diagnostics over Internet Protocol)?

DoIP, or Diagnostics over Internet Protocol, is a diagnostic communication protocol used in modern vehicles to perform diagnostics and ECU (Electronic Control Unit) reprogramming over Ethernet. It is defined in the ISO 13400 standard and is becoming increasingly important as vehicles adopt more complex electronic architectures.

- History and Development: As automotive systems became more complex, the limitations of CAN became apparent. DoIP was developed to address these limitations by leveraging Ethernet technology.

- Key Features:

- High Bandwidth: DoIP supports much higher data rates compared to CAN, enabling faster diagnostics and reprogramming.

- Standardization: Defined by the ISO 13400 standard, ensuring interoperability between different diagnostic tools and vehicle systems.

- Remote Diagnostics: Enables remote diagnostics and ECU reprogramming, which is essential for modern connected vehicles.

- Technical Specifications:

- Data Rate: DoIP supports data rates up to 100 Mbps or higher, depending on the Ethernet hardware used.

- Protocol Stack: DoIP uses a layered protocol stack based on the TCP/IP model.

- Addressing: DoIP uses IP addresses to identify and communicate with ECUs.

1.3. Why CAN Falls Short for Modern Coding

CAN is still extensively used in automotive networks for various control and communication tasks. However, it has inherent limitations that make it unsuitable for certain modern coding and diagnostic procedures, especially those involving large data transfers and complex algorithms:

- Bandwidth Limitations: CAN’s limited bandwidth is a significant bottleneck when dealing with the large data volumes required for ECU flashing and advanced diagnostics.

- Complex Data Transfers: CAN struggles with the efficient transfer of complex data structures, which are increasingly common in modern vehicle systems.

- Security Concerns: CAN’s lack of inherent security features makes it vulnerable to cyberattacks, which is a growing concern in connected vehicles.

1.4. The Necessity of DoIP for Variant Coding

Variant coding involves configuring the software parameters of an ECU to match the specific features and options of a vehicle. This process often requires transferring large amounts of data and performing complex calculations. DoIP’s high bandwidth and standardized protocol make it ideal for these tasks:

- Faster Data Transfer: DoIP’s high bandwidth allows for much faster data transfer compared to CAN, reducing the time required for variant coding.

- Standardized Protocol: The ISO 13400 standard ensures that DoIP-based diagnostic tools and vehicle systems can communicate seamlessly.

- Enhanced Security: DoIP incorporates security features such as authentication and encryption to protect against unauthorized access and tampering.

CAN vs DoIP in automotive diagnostics

CAN vs DoIP in automotive diagnostics

2. Decoding Variant Coding and Module Access

What exactly is variant coding, and why is direct access to DoIP modules so crucial?

To understand why a C4 device cannot perform variant coding on DoIP modules through a CAN gateway, we need to delve deeper into the concept of variant coding and the necessity for direct access to DoIP modules.

2.1. What is Variant Coding?

Variant coding, also known as parameterization or configuration, involves customizing the software settings within an Electronic Control Unit (ECU) to match the specific features and options of a vehicle. This process is essential for ensuring that all components and systems function correctly together.

- Purpose of Variant Coding:

- Customization: Tailoring ECU settings to match the vehicle’s specific configuration.

- Compatibility: Ensuring that different components and systems work together seamlessly.

- Optimization: Optimizing performance and functionality based on the vehicle’s intended use.

- Examples of Variant Coding:

- Enabling/Disabling Features: Activating or deactivating features such as adaptive cruise control, lane departure warning, or automatic parking assist.

- Adjusting Parameters: Modifying parameters such as engine timing, fuel injection, or transmission shift points.

- Configuring Sensors: Calibrating and configuring sensors for optimal performance.

2.2. Why Direct Access Matters for DoIP Modules

Direct access to DoIP modules is crucial for variant coding due to the high bandwidth and standardized protocol required for efficient and reliable data transfer. When attempting to perform variant coding through a CAN gateway, several limitations arise:

- Bandwidth Constraints: CAN’s limited bandwidth becomes a bottleneck when transferring the large data volumes required for variant coding.

- Protocol Incompatibilities: CAN and DoIP use different communication protocols, making it difficult to translate and transfer data between the two networks.

- Security Concerns: Attempting to perform variant coding through a CAN gateway may introduce security vulnerabilities, as CAN lacks the robust security features of DoIP.

2.3. The Role of Gateways in Vehicle Networks

Gateways play a crucial role in modern vehicle networks by acting as intermediaries between different communication buses. However, they are not designed to handle the high bandwidth and complex data transfers required for variant coding on DoIP modules.

- Function of Gateways:

- Protocol Translation: Converting data between different communication protocols.

- Network Segmentation: Dividing the vehicle network into smaller, more manageable segments.

- Security Enforcement: Implementing security policies to protect the vehicle network from unauthorized access.

- Limitations of Gateways:

- Bandwidth Bottlenecks: Gateways can introduce bandwidth bottlenecks, especially when transferring large data volumes.

- Processing Delays: Gateways can introduce processing delays due to the overhead of protocol translation and security enforcement.

- Compatibility Issues: Gateways may not be fully compatible with all diagnostic tools and vehicle systems.

2.4. Case Study: Variant Coding on a Modern Mercedes-Benz

To illustrate the importance of direct access for variant coding, consider the example of a modern Mercedes-Benz equipped with advanced driver-assistance systems (ADAS). These systems rely on multiple ECUs communicating over a DoIP network.

- Scenario:

- A technician needs to enable the lane-keeping assist feature on a Mercedes-Benz that was not originally equipped with this option.

- Challenges:

- The lane-keeping assist feature requires modifying the software parameters of several ECUs, including the front camera, radar sensors, and steering control module.

- These ECUs communicate over a DoIP network, which requires a high-bandwidth connection for efficient data transfer.

- Solution:

- The technician must use a diagnostic tool that supports DoIP communication and connect directly to the vehicle’s Ethernet port.

- Attempting to perform variant coding through a CAN gateway would be impractical due to the bandwidth limitations and protocol incompatibilities.

Mercedes-Benz diagnostic tool connecting via OBDII port

Mercedes-Benz diagnostic tool connecting via OBDII port

3. Exploring the Capabilities of MB SD Connect C4

What can the MB SD Connect C4 actually do, and what are its limitations when it comes to DoIP?

The MB SD Connect C4 is a diagnostic tool used for Mercedes-Benz vehicles. While it’s a powerful tool, it has limitations regarding DoIP and variant coding.

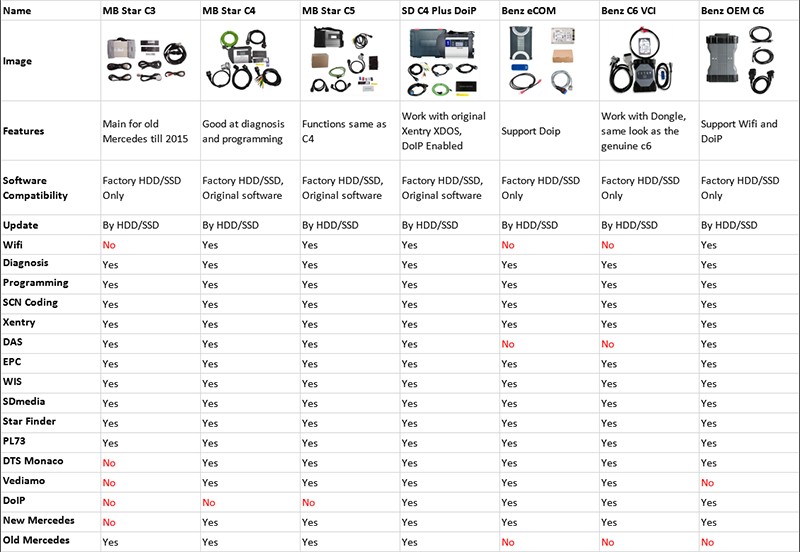

3.1. Overview of MB SD Connect C4

The MB SD Connect C4 is a diagnostic tool designed for Mercedes-Benz vehicles. It is used by technicians to perform a wide range of diagnostic and programming tasks.

- Key Features:

- Diagnostic Testing: Reading and clearing diagnostic trouble codes (DTCs).

- ECU Programming: Flashing and programming ECUs.

- Variant Coding: Configuring ECU settings to match the vehicle’s specific features.

- Live Data Monitoring: Monitoring real-time data from various sensors and systems.

- Communication Protocols:

- CAN: Controller Area Network.

- K-Line: A single-wire communication protocol used in older vehicles.

- DoIP: Diagnostics over Internet Protocol (supported by newer C4 units).

3.2. Limitations of CAN Communication

While the MB SD Connect C4 supports CAN communication, it has limitations when dealing with modern vehicles that rely on DoIP for certain functions:

- Bandwidth Constraints: CAN’s limited bandwidth becomes a bottleneck when transferring large data volumes required for ECU flashing and advanced diagnostics.

- Protocol Incompatibilities: CAN and DoIP use different communication protocols, making it difficult to translate and transfer data between the two networks.

- Security Concerns: CAN’s lack of inherent security features makes it vulnerable to cyberattacks, which is a growing concern in connected vehicles.

3.3. DoIP Support in Newer C4 Units

Newer versions of the MB SD Connect C4 support DoIP communication, allowing technicians to perform variant coding and other advanced diagnostic tasks on modern vehicles:

- Ethernet Interface: The newer C4 units are equipped with an Ethernet interface for connecting to the vehicle’s DoIP network.

- High-Speed Data Transfer: DoIP’s high bandwidth enables faster data transfer compared to CAN, reducing the time required for ECU flashing and variant coding.

- Enhanced Security: DoIP incorporates security features such as authentication and encryption to protect against unauthorized access and tampering.

3.4. How to Identify a DoIP-Enabled C4 Unit

To determine whether an MB SD Connect C4 unit supports DoIP communication, look for the following features:

- Ethernet Port: A physical Ethernet port on the device.

- Software Support: Compatibility with diagnostic software that supports DoIP communication.

- Documentation: Documentation indicating that the device supports DoIP.

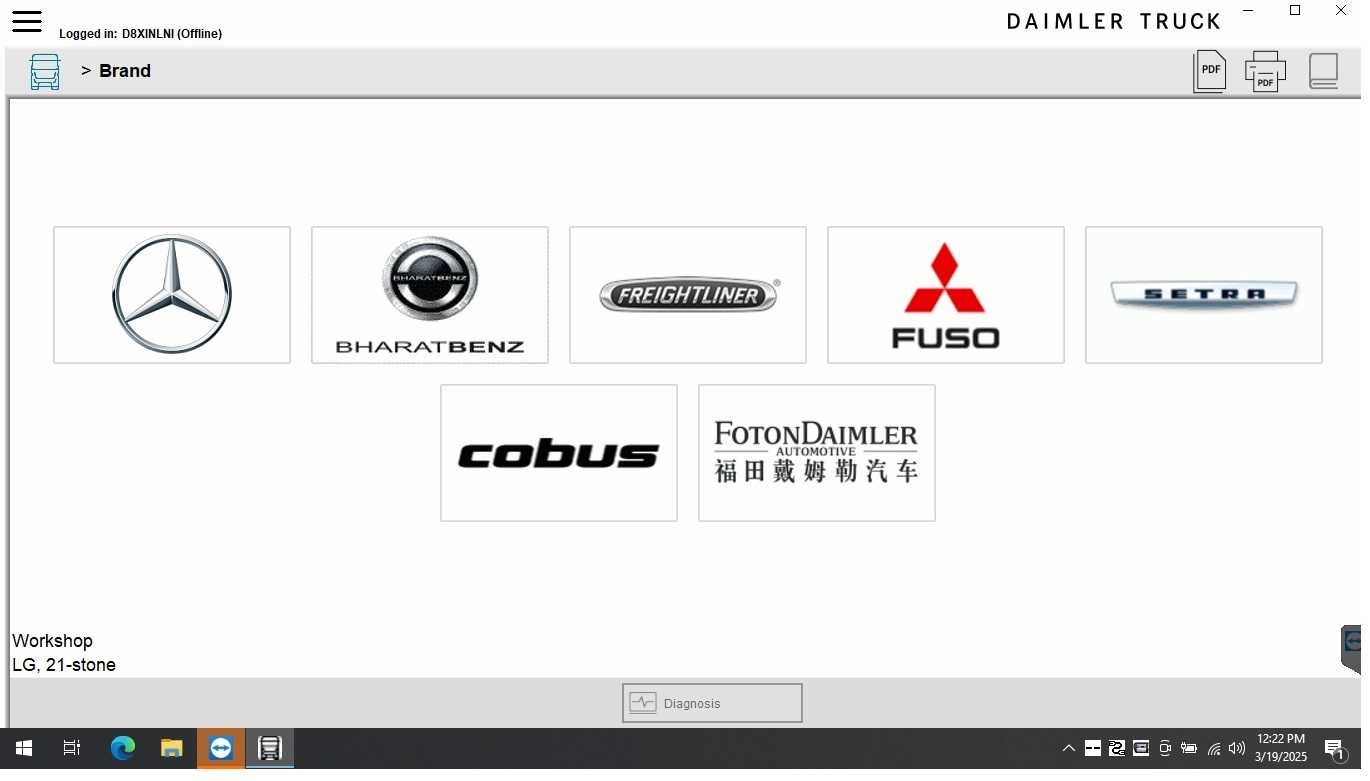

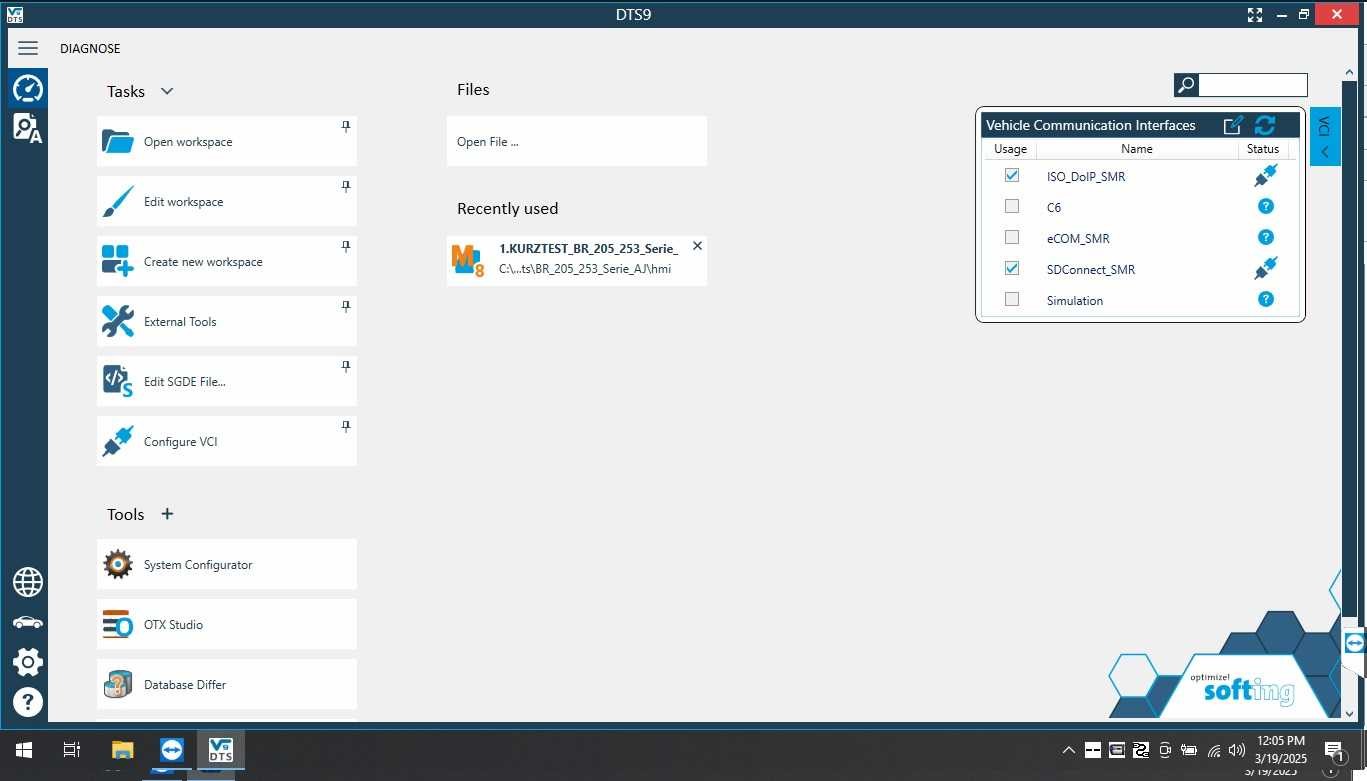

3.5. Using MB SD Connect C4 with DTS Monaco

DTS Monaco is a diagnostic and programming software used by Mercedes-Benz engineers. It supports DoIP communication and is often used in conjunction with the MB SD Connect C4 for advanced diagnostic tasks:

- Compatibility: DTS Monaco is compatible with both CAN and DoIP communication protocols.

- Advanced Features: DTS Monaco offers advanced features such as ECU flashing, variant coding, and live data monitoring.

- User Interface: DTS Monaco has a user-friendly interface that makes it easy to perform complex diagnostic tasks.

DTS Monaco interface displaying ECU data

DTS Monaco interface displaying ECU data

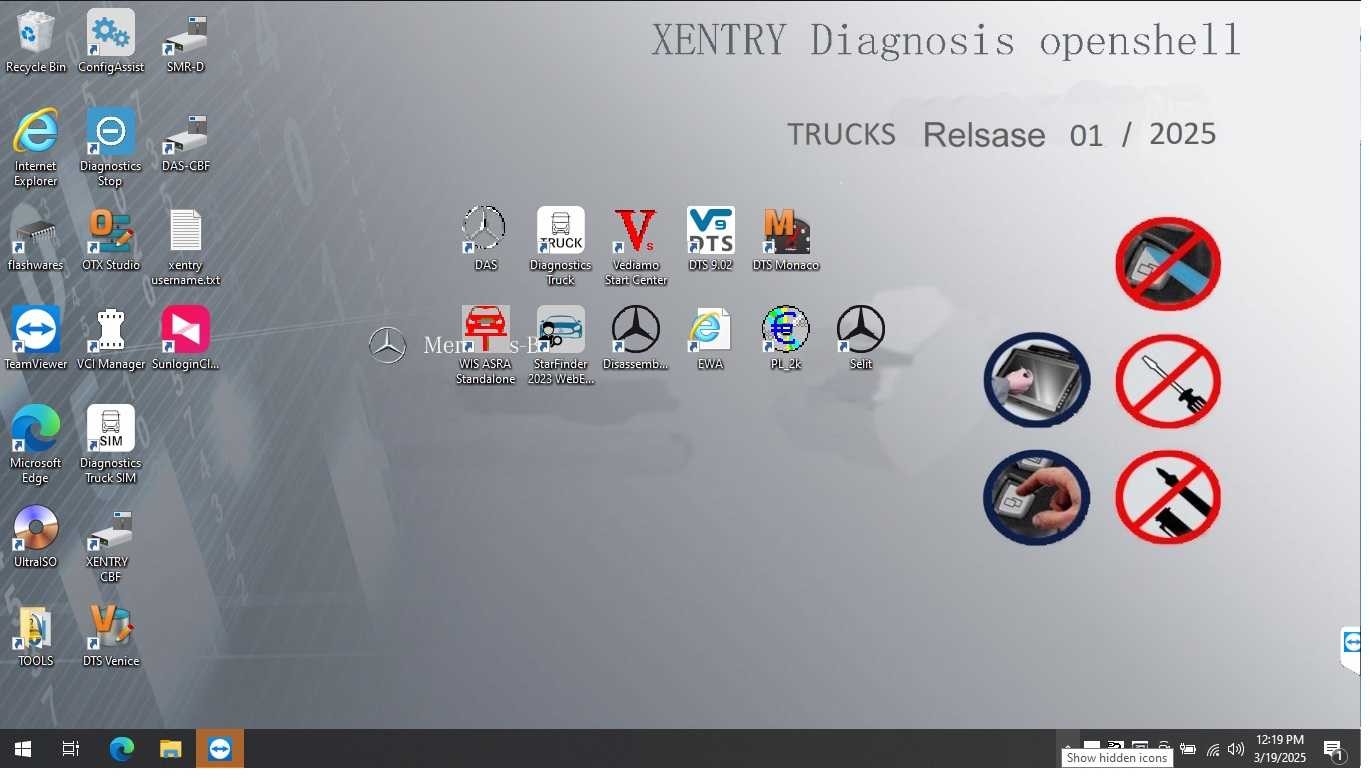

4. The Role of DTS Monaco in Modern Car Coding

How does DTS Monaco enhance car coding capabilities, especially for DoIP-enabled vehicles?

DTS Monaco is a powerful diagnostic and programming software used by Mercedes-Benz engineers. It plays a crucial role in modern car coding, especially for DoIP-enabled vehicles.

4.1. Overview of DTS Monaco

DTS Monaco is the official software used by Daimler Benz development engineers. It is a universal engineering test terminal for the diagnosis and control function of the vehicle controller.

- Key Features:

- Quick Test: Entire vehicle ECU quick test, and the test can choose to edit more.

- Variant Coding: Coding with variation add VO- delete VO function.

- ID Identification: One click to read the whole car and save all modules programmed numbers.

- Complete Variant Coding: One time to read all the ECU coding vehicle data, can be written to the vehicle again, completely off-line operation.

- Diagnostic Services: Advanced features can see your choice of internal and external data module, turn on the computer authorization (not driving license), Activate ECU, reset ECU, modifying the original chassis number.

- Flash Programming: Fully offline programming.

- Diagnostic Trouble Code: Diagnostic module DTC fault code.

- ECU Exchange: Two of the same ECU, by reading data import data exchange.

- Symbolic Trace: Record and track the file, after repeated viewing, analysis of fault logic point.

4.2. Advantages of Using DTS Monaco for Car Coding

DTS Monaco offers several advantages over other diagnostic tools when it comes to car coding:

- Comprehensive Functionality: DTS Monaco covers all the tasks in the field of engineering, testing, and production test preparation.

- High Authority: When Mercedes-Benz maintenance tests, it is the greatest authority, the perfect support for C4 (SDconnect) and (Ecom) Hardware (at present, Das-xentry.Vediamo lower authority).

- Offline Operation: DTS Monaco allows for complete offline operation, which means you can perform coding and programming tasks without an internet connection.

- User-Friendly Interface: DTS Monaco has a user-friendly interface that makes it easy to perform complex diagnostic tasks.

4.3. How DTS Monaco Enhances DoIP Capabilities

DTS Monaco enhances DoIP capabilities by providing a standardized and efficient way to communicate with ECUs over Ethernet:

- High-Speed Data Transfer: DTS Monaco leverages DoIP’s high bandwidth to enable faster data transfer, reducing the time required for ECU flashing and variant coding.

- Standardized Protocol: DTS Monaco supports the ISO 13400 standard, ensuring that it can communicate seamlessly with DoIP-enabled ECUs.

- Enhanced Security: DTS Monaco incorporates security features such as authentication and encryption to protect against unauthorized access and tampering.

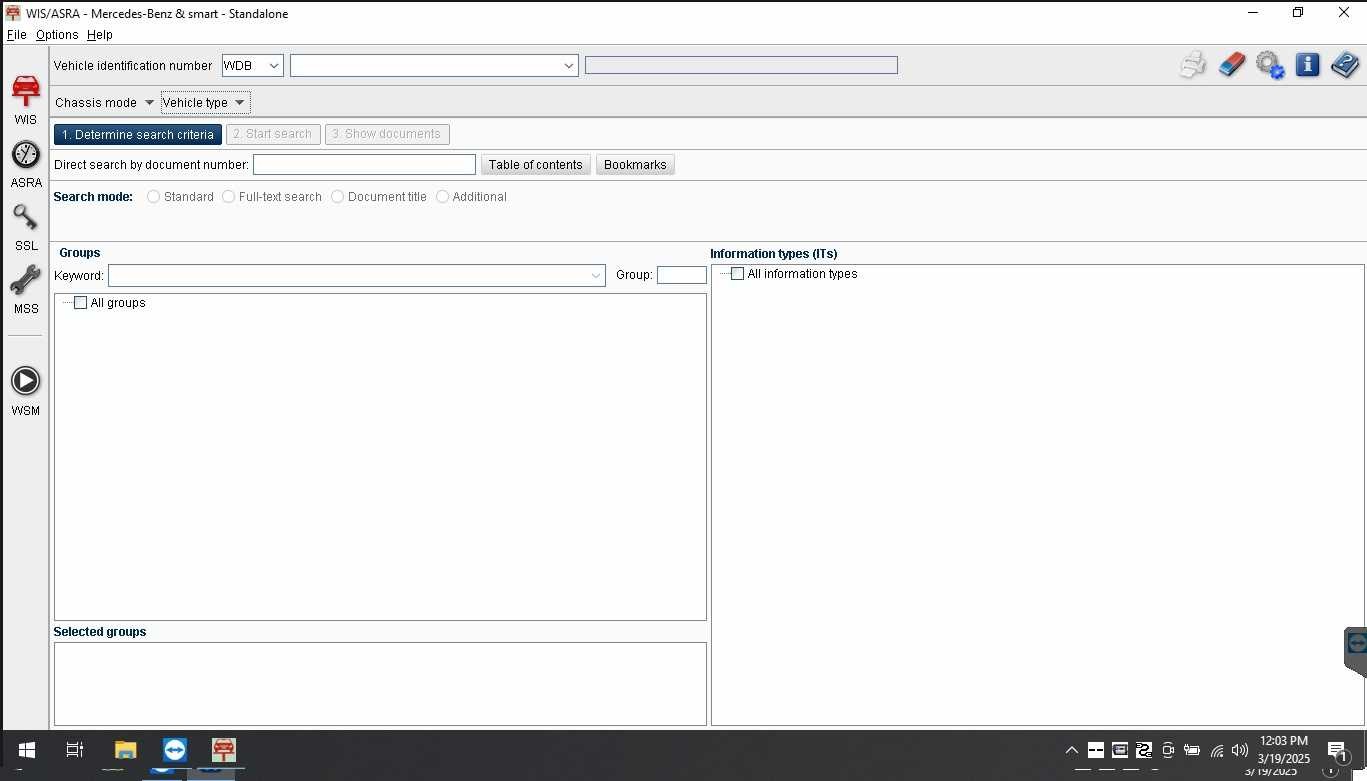

4.4. Step-by-Step Guide: Variant Coding with DTS Monaco on a DoIP Module

To perform variant coding with DTS Monaco on a DoIP module, follow these steps:

- Connect the MB SD Connect C4 to the Vehicle: Connect the MB SD Connect C4 to the vehicle’s OBDII port and the Ethernet port.

- Launch DTS Monaco: Launch the DTS Monaco software on your computer.

- Select the Vehicle: Select the vehicle model and year from the DTS Monaco database.

- Connect to the ECU: Select the ECU you want to code and establish a connection.

- Read the Current Coding: Read the current coding data from the ECU.

- Modify the Coding: Modify the coding data to match the desired configuration.

- Write the New Coding: Write the new coding data to the ECU.

- Verify the Coding: Verify that the new coding data has been successfully written to the ECU.

- Test the Functionality: Test the functionality of the coded feature to ensure that it is working correctly.

4.5. Best Practices for Using DTS Monaco

To ensure successful car coding with DTS Monaco, follow these best practices:

- Use a Stable Power Supply: Ensure that the vehicle has a stable power supply to prevent interruptions during the coding process.

- Use a Reliable Internet Connection: If performing online coding, use a reliable internet connection to prevent data loss or corruption.

- Back Up the Original Coding: Before making any changes, back up the original coding data so that you can restore it if necessary.

- Follow the Manufacturer’s Instructions: Always follow the manufacturer’s instructions for coding and programming.

- Test Thoroughly: After coding, test the functionality of the coded feature to ensure that it is working correctly.

DTS Monaco showing vehicle communication interfaces

DTS Monaco showing vehicle communication interfaces

5. Practical Examples and Use Cases

Where might you encounter DoIP in real-world car coding scenarios?

Understanding when and how DoIP comes into play can clarify its importance in modern automotive diagnostics and coding.

5.1. Example 1: Enabling Adaptive Cruise Control

- Scenario: A customer wants to enable adaptive cruise control (ACC) on their new Mercedes-Benz C-Class, which was not originally equipped with this feature.

- Challenge: Enabling ACC requires modifying the software parameters of several ECUs, including the engine control unit (ECU), transmission control unit (TCU), and radar sensors. These ECUs communicate over a DoIP network, which requires a high-bandwidth connection for efficient data transfer.

- Solution: A technician uses an MB SD Connect C4 with DoIP support and DTS Monaco software to connect to the vehicle’s DoIP network. The technician then modifies the software parameters of the relevant ECUs to enable ACC.

- Outcome: The customer now has ACC enabled on their vehicle.

5.2. Example 2: Retrofitting a New Infotainment System

- Scenario: A customer wants to retrofit a new infotainment system in their BMW 5 Series.

- Challenge: Retrofitting a new infotainment system requires coding the vehicle to recognize and integrate the new system. This involves modifying the software parameters of several ECUs, including the head unit, amplifier, and speakers. These ECUs communicate over a DoIP network, which requires a high-bandwidth connection for efficient data transfer.

- Solution: A technician uses an ENET cable and E-SYS software to connect to the vehicle’s DoIP network. The technician then modifies the software parameters of the relevant ECUs to code the new infotainment system.

- Outcome: The customer now has a new infotainment system that is fully integrated with their vehicle.

5.3. Example 3: Updating ECU Software

- Scenario: A vehicle manufacturer releases a software update for the engine control unit (ECU) in a certain model of car.

- Challenge: Updating the ECU software requires flashing the ECU with the new software image. This involves transferring a large amount of data to the ECU, which requires a high-bandwidth connection.

- Solution: A technician uses a diagnostic tool with DoIP support to connect to the vehicle’s DoIP network. The technician then uses the diagnostic tool to flash the ECU with the new software image.

- Outcome: The ECU software is updated to the latest version, which may improve performance, fuel economy, or emissions.

5.4. Example 4: Diagnosing Complex Electrical Issues

- Scenario: A vehicle is experiencing intermittent electrical issues, such as flickering lights or a malfunctioning sensor.

- Challenge: Diagnosing complex electrical issues requires monitoring real-time data from various sensors and systems. This involves transferring a large amount of data from the vehicle’s ECUs to the diagnostic tool, which requires a high-bandwidth connection.

- Solution: A technician uses a diagnostic tool with DoIP support to connect to the vehicle’s DoIP network. The technician then uses the diagnostic tool to monitor real-time data from the relevant sensors and systems.

- Outcome: The technician is able to identify the source of the electrical issues and repair the vehicle.

5.5. Example 5: Activating Driver-Assistance Systems

- Scenario: A vehicle is equipped with advanced driver-assistance systems (ADAS), such as lane departure warning, blind-spot monitoring, and adaptive cruise control. However, these systems are not activated from the factory.

- Challenge: Activating ADAS requires coding the vehicle to enable these features. This involves modifying the software parameters of several ECUs, which requires a high-bandwidth connection for efficient data transfer.

- Solution: A technician uses a diagnostic tool with DoIP support to connect to the vehicle’s DoIP network. The technician then modifies the software parameters of the relevant ECUs to activate ADAS.

- Outcome: The customer now has ADAS enabled on their vehicle, which improves safety and convenience.

Vehicle diagnostic interface showing connection details

Vehicle diagnostic interface showing connection details

6. Troubleshooting Common Issues

What are some typical problems encountered when working with DoIP and how can they be resolved?

When working with DoIP, technicians may encounter several common issues that can hinder the diagnostic and coding process. Understanding these issues and their solutions is crucial for efficient and effective vehicle maintenance.

6.1. Connectivity Problems

- Issue: The diagnostic tool is unable to establish a connection with the vehicle’s DoIP network.

- Possible Causes:

- Incorrect Ethernet cable or adapter.

- Firewall or antivirus software blocking the connection.

- Incorrect IP address or network settings.

- Faulty DoIP interface on the vehicle.

- Troubleshooting Steps:

- Verify that you are using a compatible Ethernet cable and adapter.

- Temporarily disable firewall and antivirus software to see if they are blocking the connection.

- Check the IP address and network settings on both the diagnostic tool and the vehicle.

- Test the DoIP interface on the vehicle with another diagnostic tool to rule out a hardware issue.

6.2. Slow Data Transfer Rates

- Issue: Data transfer rates are slow, making ECU flashing and variant coding take longer than expected.

- Possible Causes:

- Poor network connection.

- Outdated diagnostic tool software.

- High network traffic.

- Faulty Ethernet cable or adapter.

- Troubleshooting Steps:

- Ensure that you have a stable and reliable network connection.

- Update the diagnostic tool software to the latest version.

- Minimize network traffic by closing unnecessary applications.

- Try using a different Ethernet cable and adapter.

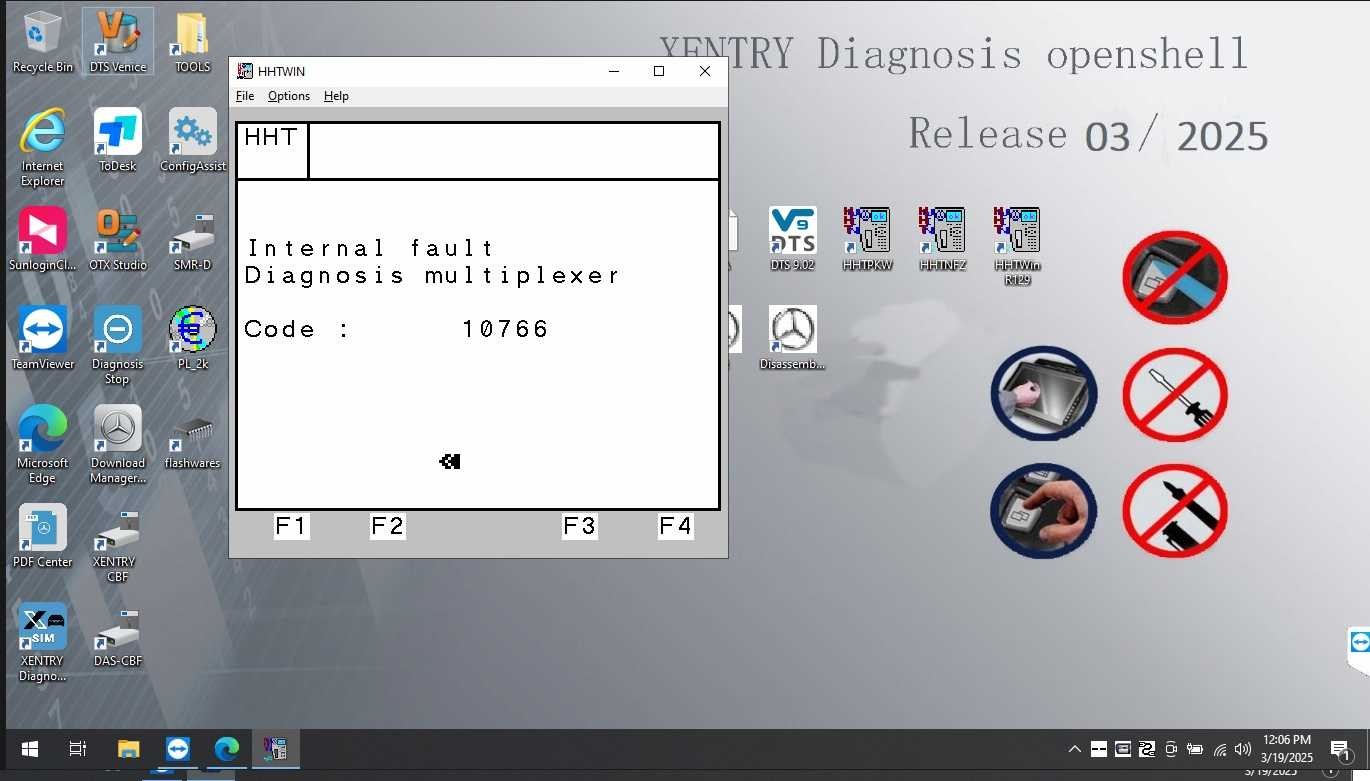

6.3. ECU Communication Errors

- Issue: The diagnostic tool is unable to communicate with certain ECUs over DoIP.

- Possible Causes:

- Incorrect diagnostic protocol.

- ECU not supporting DoIP communication.

- Faulty ECU hardware.

- Software incompatibility.

- Troubleshooting Steps:

- Verify that you are using the correct diagnostic protocol for the vehicle and ECU.

- Check whether the ECU supports DoIP communication.

- Test the ECU with another diagnostic tool to rule out a hardware issue.

- Ensure that the diagnostic tool software is compatible with the vehicle and ECU.

6.4. Security Certificate Issues

- Issue: The diagnostic tool is unable to authenticate with the vehicle due to security certificate issues.

- Possible Causes:

- Expired security certificate.

- Incorrect security certificate.

- Faulty security module.

- Unauthorized access attempt.

- Troubleshooting Steps:

- Verify that the security certificate is valid and not expired.

- Ensure that you are using the correct security certificate for the vehicle.

- Check the security module for any errors or faults.

- Contact the vehicle manufacturer or diagnostic tool vendor for assistance.

6.5. Software Compatibility Problems

- Issue: The diagnostic tool software is not compatible with the vehicle or ECU, causing errors or malfunctions.

- Possible Causes:

- Outdated software version.

- Incorrect software configuration.

- Software bugs or glitches.

- Incompatible operating system.

- Troubleshooting Steps:

- Update the diagnostic tool software to the latest version.

- Verify that the software is configured correctly for the vehicle and ECU.

- Check for any known software bugs or glitches and apply any available patches or fixes.

- Ensure that the operating system is compatible with the diagnostic tool software.

6.6. Power Supply Issues

- Issue: The vehicle’s power supply is unstable, causing interruptions during the diagnostic or coding process.

- Possible Causes:

- Weak or discharged battery.

- Faulty alternator.

- Loose or corroded battery terminals.

- Electrical shorts or faults.

- Troubleshooting Steps:

- Check the battery voltage and charge level.

- Test the alternator output to ensure that it is charging the battery properly.

- Clean and tighten the battery terminals.

- Inspect the electrical system for any shorts or faults.

Diagnostic tool displaying error messages

Diagnostic tool displaying error messages

7. Training and Certification for DoIP Diagnostics

Where can technicians get certified to work with DoIP-enabled systems?

7.1. Importance of Training and Certification

As vehicles become more complex with advanced technologies like DoIP, it’s crucial for technicians to receive proper training and certification to ensure they can accurately diagnose and repair these systems. Training and certification provide technicians with the knowledge, skills, and confidence to work on modern vehicles effectively.

- Enhanced Skills: Training programs equip technicians with the latest diagnostic and repair techniques.

- Industry Recognition: Certifications validate technicians’ expertise and competence in specific areas.

- Career Advancement: Certified technicians often have better job opportunities and higher earning potential.

7.2. Key Training Programs and Certifications

Several organizations and institutions offer training programs and certifications for DoIP diagnostics. Here are some of the most reputable options:

- ASE (Automotive Service Excellence): ASE offers certifications in various automotive specialties, including electrical and electronic systems. While not specifically focused on DoIP, these certifications cover the fundamental knowledge required to work on DoIP-enabled vehicles.

- OEM (Original Equipment Manufacturer) Training: Many vehicle manufacturers offer training programs for their own vehicles. These programs often include specific training on DoIP diagnostics and coding.

- Vocational Schools and Technical Colleges: Many vocational schools and technical colleges offer automotive technology programs that include training on DoIP diagnostics.

- Online Training Providers: Several online training providers offer courses on DoIP diagnostics and coding. These courses can be a convenient and affordable way to learn the basics of DoIP.

7.3. What to Look for in a Training Program

When choosing a training program for DoIP diagnostics, consider the following factors:

- Curriculum: The curriculum should cover the fundamentals of DoIP, as well as advanced diagnostic and coding techniques.

- Instructors: The instructors should be experienced technicians with expertise in DoIP diagnostics.

- Hands-On Training: The program should include hands-on training with real vehicles and diagnostic tools.

- Certification: The program should offer a recognized certification upon completion.

7.4. Benefits of Certified Technicians for Auto Repair Shops

Hiring certified technicians can bring several benefits to auto repair shops:

- Improved Customer Satisfaction: Certified technicians are more likely to accurately diagnose and repair vehicles, leading to higher customer satisfaction.

- Increased Efficiency: Certified technicians can work more efficiently, reducing the time required for repairs.

- Reduced Errors: Certified technicians are less likely to make mistakes, reducing the risk of costly rework.

- Enhanced Reputation: Hiring certified technicians can enhance the reputation of the auto repair shop.

7.5. Staying Updated with Industry Advancements

The automotive industry is constantly evolving, so it’s essential for technicians to stay updated with the latest advancements in DoIP diagnostics and coding. Here are some ways to stay updated:

- Attend Industry Conferences and Trade Shows: These events provide opportunities to learn about the latest technologies and network with other technicians.

- Read Industry Publications: Stay informed about the latest trends and developments in the automotive industry by reading trade magazines and online publications.

- Participate in Online Forums and Communities: Connect with other technicians and share knowledge and experiences in online forums and communities.

- Continue Education: Take continuing education courses to stay updated with the latest diagnostic and repair techniques.

8. Future Trends in Automotive Diagnostics

What innovations can we expect in the realm of vehicle diagnostics?

The field of automotive diagnostics is rapidly evolving, driven by the increasing complexity of vehicle systems and the growing demand for more efficient and effective repair techniques. Several future trends are poised to transform the way technicians diagnose and repair vehicles.

8.1. Remote Diagnostics

- Description: Remote diagnostics involves diagnosing and repairing vehicles remotely using telematics and cloud-based diagnostic tools.

- Benefits:

- Reduced downtime: Remote diagnostics can help identify and resolve issues before they lead to breakdowns.

- Increased efficiency: Technicians can diagnose and repair vehicles without having to be physically present.

- Improved customer satisfaction: Remote diagnostics can provide customers with faster and more convenient service.

8.2. Artificial Intelligence (AI) in Diagnostics

- Description: AI is being used to analyze diagnostic data and identify potential issues.

- Benefits:

- Faster diagnosis: AI can quickly analyze large amounts of data to identify patterns and anomalies.

- More accurate diagnosis: AI can help technicians identify issues that they might otherwise miss.

- Predictive maintenance: AI can predict when components are likely to fail, allowing technicians to perform preventive maintenance.

8.3. Augmented Reality (AR) in Diagnostics

- Description: AR is being used to overlay diagnostic information onto the technician’s view of the vehicle.

- Benefits:

- Improved accuracy: AR can guide technicians through the diagnostic and repair process, reducing the risk of errors.

- Increased efficiency: AR can provide technicians with real-time access to diagnostic information, reducing the time required for repairs.

- Enhanced training: AR can be used to train technicians on new diagnostic and repair techniques.

8.4. Over-the-Air (OTA) Updates

- Description: OTA updates allow vehicle manufacturers to update software and firmware in vehicles remotely.

- Benefits:

- Improved performance: OTA updates can improve vehicle performance, fuel economy, and emissions.

- New features: OTA updates can add new features to vehicles.

- Security enhancements: OTA updates can address security vulnerabilities.

8.5. Enhanced Cybersecurity Measures

- Description: With the increasing connectivity of vehicles, cybersecurity is becoming a major concern.

- Benefits:

- Protection against cyberattacks: Enhanced cybersecurity measures can protect vehicles from unauthorized access and tampering.

- Data privacy: Cybersecurity measures can protect sensitive vehicle data.

- Customer trust: Strong cybersecurity measures can build customer trust in vehicle technology.

8.6. Integration of Diagnostic Data with Vehicle Health Monitoring Systems

- Description: Integrating diagnostic data with vehicle health monitoring systems can provide vehicle owners with real-time information about the health of their vehicles.

- Benefits:

- Proactive maintenance: Vehicle owners can take proactive steps to address potential issues before they lead to breakdowns.

- Reduced repair costs: Early detection of issues can help prevent costly repairs.

- Improved vehicle safety: Vehicle health monitoring systems can alert vehicle owners to potential safety issues.

9. FAQ: Common Questions About C4, DoIP, and Variant Coding

Do you have more questions? Let’s address some frequently asked queries.

9.1. Can the MB SD Connect C4 perform variant coding on DoIP modules if accessed via gateway CAN?

No, the MB SD Connect C4 cannot perform variant coding on DoIP modules if accessed via gateway CAN. DoIP requires a direct Ethernet connection due to the higher bandwidth and different communication protocols.

9.2. What is DoIP and why is it important?

DoIP stands for Diagnostics over Internet Protocol. It’s a modern communication standard used in vehicles for faster and more secure diagnostics and ECU reprogramming. It is important because it enables efficient data transfer and is essential for modern vehicle systems.

9.3. What is variant coding?

Variant coding involves customizing the software settings within an Electronic Control Unit (ECU) to match the specific features and options of a vehicle. This process ensures all components and systems function correctly together.

9.4. What are the limitations of CAN communication?

CAN (Controller Area Network) has limitations in bandwidth, data transfer complexity, and security, making it unsuitable for certain modern coding and diagnostic procedures.

9.5. What is DTS Monaco and how does it help with car coding?

DTS Monaco is a diagnostic and programming software used by Mercedes-Benz engineers. It enhances DoIP capabilities by providing a standardized and efficient way to communicate with ECUs over Ethernet, allowing for faster data transfer and enhanced security.

9.6. How do I identify if my MB SD Connect C4 unit supports DoIP communication?

Look for an Ethernet port on the device, ensure compatibility with diagnostic software that supports DoIP, and check the documentation for DoIP support.

9.7. What are some common issues encountered when working with DoIP?

Common issues include connectivity problems, slow data transfer rates, ECU communication errors, security certificate issues, and software compatibility problems.

9.8. Where can technicians get certified to work with DoIP-enabled systems?

Technicians can get certified through ASE, OEM training programs, vocational schools, technical colleges, and online training providers.

9.9. What are some future trends in automotive diagnostics?

Future trends include remote diagnostics, artificial intelligence (AI) in diagnostics, augmented reality (AR) in diagnostics, over-the-air (OTA) updates, enhanced cybersecurity measures, and integration of diagnostic data with vehicle health monitoring systems.

9.10. Why is direct access important for DoIP modules?

Direct access is crucial for variant coding due to the high bandwidth and standardized protocol required for efficient and reliable data transfer. Attempting to perform variant coding through a CAN gateway can lead to bandwidth constraints, protocol incompatibilities, and security concerns.

10. Conclusion: Embrace the Future of Car Coding

Staying current with the latest technologies is crucial for success in the automotive industry.

In conclusion, while the MB SD Connect C4 is a valuable tool for Mercedes-Benz diagnostics, it cannot perform variant coding on DoIP modules via a gateway CAN. Direct DoIP connectivity is essential for these tasks due to its superior bandwidth and standardized communication protocols. By understanding the limitations of CAN and embracing tools like DTS Monaco, technicians can effectively