Can the C4/C6 interfaces be used to diagnose issues with CDI diesel engines? Yes, absolutely! Using C4/C6 interfaces for diagnosing issues with CDI diesel engines offers a robust solution, streamlining diagnostics and enhancing accuracy, especially when paired with tools and training from DTS-MONACO.EDU.VN. This approach not only saves time but also ensures comprehensive troubleshooting, leading to efficient repairs and improved vehicle performance. Ready to enhance your diagnostic skills? Explore advanced engine diagnostics, car coding techniques, and ECU programming options.

Contents

- 1. Understanding CDI Diesel Engine Diagnostics

- What is a CDI Diesel Engine and Why is Accurate Diagnosis Important?

- What are the Key Components of a CDI Diesel Engine?

- Why is Proper Diagnostic Tooling Important for CDI Engines?

- 2. Exploring the C4/C6 Interfaces

- What are C4 and C6 Interfaces?

- What are the Key Features and Capabilities of C4/C6 Interfaces?

- How do C4/C6 Interfaces Connect to CDI Diesel Engines?

- 3. Diagnosing CDI Diesel Engine Issues Using C4/C6 Interfaces

- What Types of Issues Can Be Diagnosed Using C4/C6 Interfaces?

- What is the Step-by-Step Process for Diagnosing Issues with CDI Diesel Engines Using C4/C6 Interfaces?

- Can you Provide Real-World Examples of Diagnosing Common CDI Diesel Engine Problems with C4/C6 Interfaces?

- 4. Advantages of Using C4/C6 Interfaces for CDI Diesel Engine Diagnostics

- What are the Key Benefits of Using C4/C6 Interfaces?

- How do C4/C6 Interfaces Improve Diagnostic Accuracy and Efficiency?

- Are There Any Limitations to Using C4/C6 Interfaces?

- 5. Integrating DTS Monaco with C4/C6 Interfaces

- What is DTS Monaco and How Does It Work with C4/C6 Interfaces?

- What are the Key Features of DTS Monaco for CDI Diesel Engine Diagnostics?

- How Does DTS Monaco Enhance the Capabilities of C4/C6 Interfaces?

- 6. Car Coding with C4/C6 Interfaces and DTS Monaco

- What is Car Coding and Why is it Important?

- What Kind of Car Coding Can Be Performed on CDI Diesel Engines?

- How Does Car Coding Enhance Vehicle Performance and Functionality?

- 7. Best Practices for Using C4/C6 Interfaces and DTS Monaco

- What are Some Important Considerations When Using C4/C6 Interfaces and DTS Monaco?

- What Safety Precautions Should Be Taken When Performing Diagnostics and Car Coding?

- How Can Technicians Stay Up-to-Date with the Latest Technologies and Techniques?

- 8. Training and Certification Programs for CDI Diesel Engine Diagnostics

- What Training Programs are Available for Technicians Working on CDI Diesel Engines?

- What Certifications are Relevant for CDI Diesel Engine Diagnostics?

- How Can Technicians Benefit from Participating in Training and Certification Programs?

- 9. Troubleshooting Common Issues with C4/C6 Interfaces and DTS Monaco

- What are Some Common Problems Technicians Might Encounter When Using C4/C6 Interfaces and DTS Monaco?

- How Can These Issues Be Troubleshooted and Resolved?

- Where Can Technicians Find Support and Resources for Troubleshooting?

- 10. The Future of CDI Diesel Engine Diagnostics

- What are the Emerging Technologies and Trends in CDI Diesel Engine Diagnostics?

- How Will These Advancements Impact the Role of Technicians?

- What Skills Will Technicians Need to Succeed in the Future of CDI Diesel Engine Diagnostics?

- FAQ: Diagnosing CDI Diesel Engines with C4/C6 Interfaces

- 1. Can I use a C4 interface on all CDI diesel engine models?

- 2. Is DTS Monaco required to use a C4/C6 interface for CDI diesel engine diagnostics?

- 3. What level of technical expertise is needed to use C4/C6 interfaces effectively?

- 4. Are there any risks involved in performing car coding on CDI diesel engines?

- 5. How often should I update the software for my C4/C6 interface and DTS Monaco?

- 6. Can I perform remote diagnostics on CDI diesel engines using a C4/C6 interface?

- 7. What should I do if I encounter a fault code that I don’t understand?

- 8. Can I use a C4/C6 interface to diagnose emission control problems on CDI diesel engines?

- 9. What are the essential tools and equipment needed for CDI diesel engine diagnostics besides the C4/C6 interface?

- 10. How can I ensure the safety of my vehicle’s data when performing diagnostics and car coding?

- Conclusion

1. Understanding CDI Diesel Engine Diagnostics

What is a CDI Diesel Engine and Why is Accurate Diagnosis Important?

CDI (Common Rail Direct Injection) diesel engines represent a sophisticated advancement in diesel technology, offering improved fuel efficiency, reduced emissions, and enhanced performance. These engines rely on precise electronic control and intricate systems, making accurate diagnosis crucial for maintaining optimal operation. According to Bosch, a leading automotive supplier, accurate diagnostics of CDI systems can significantly reduce repair times and improve customer satisfaction.

What are the Key Components of a CDI Diesel Engine?

A CDI diesel engine consists of several key components:

- High-Pressure Pump: Delivers fuel at extremely high pressure to the common rail.

- Common Rail: Acts as an accumulator, storing fuel at high pressure for injection.

- Injectors: Precisely control the injection of fuel into the cylinders.

- Electronic Control Unit (ECU): Manages the entire injection process based on sensor inputs.

- Sensors: Monitor various parameters such as fuel pressure, temperature, and engine speed.

Why is Proper Diagnostic Tooling Important for CDI Engines?

Proper diagnostic tooling is essential due to the complexity of CDI systems. Traditional methods may fall short in accurately identifying issues. Diagnostic tools like DTS Monaco, when used with appropriate interfaces, provide in-depth access to the ECU, allowing technicians to read fault codes, monitor live data, and perform diagnostic tests. A study by the National Institute for Automotive Service Excellence (ASE) highlights that technicians using advanced diagnostic tools experience a 40% reduction in diagnostic errors.

2. Exploring the C4/C6 Interfaces

What are C4 and C6 Interfaces?

C4 and C6 interfaces are specialized diagnostic tools used to communicate with a vehicle’s ECU. These interfaces act as a bridge between the diagnostic software (like DTS Monaco) and the vehicle’s electronic systems. The C4 interface typically connects via a wired connection, while the C6 interface offers wireless connectivity, providing greater flexibility in the workshop.

What are the Key Features and Capabilities of C4/C6 Interfaces?

Key features of C4/C6 interfaces include:

- ECU Communication: Facilitates reading and writing data to the ECU.

- Fault Code Reading: Retrieves diagnostic trouble codes (DTCs) to identify issues.

- Live Data Monitoring: Provides real-time data from sensors and components.

- Actuation Tests: Allows technicians to activate and test individual components.

- Car Coding: Enables customization and programming of vehicle functions.

How do C4/C6 Interfaces Connect to CDI Diesel Engines?

C4/C6 interfaces connect to CDI diesel engines via the vehicle’s diagnostic port, typically an OBD-II (On-Board Diagnostics II) port. This port provides access to the ECU and other electronic modules, allowing the interface to communicate with the engine’s control systems. According to SAE International, the OBD-II port is a standardized interface, ensuring compatibility across different vehicle makes and models.

3. Diagnosing CDI Diesel Engine Issues Using C4/C6 Interfaces

What Types of Issues Can Be Diagnosed Using C4/C6 Interfaces?

C4/C6 interfaces can diagnose a wide range of issues in CDI diesel engines, including:

- Fuel Injection Problems: Injector malfunctions, fuel pressure issues, and common rail faults.

- Sensor Failures: Faulty fuel pressure sensors, temperature sensors, and airflow sensors.

- ECU Issues: Software glitches, communication errors, and programming problems.

- Emission Control Problems: EGR (Exhaust Gas Recirculation) valve issues, DPF (Diesel Particulate Filter) blockages, and NOx sensor failures.

What is the Step-by-Step Process for Diagnosing Issues with CDI Diesel Engines Using C4/C6 Interfaces?

The diagnostic process typically involves these steps:

- Connect the Interface: Connect the C4/C6 interface to the vehicle’s OBD-II port.

- Launch Diagnostic Software: Open DTS Monaco on your computer and establish a connection with the interface.

- Read Fault Codes: Retrieve any stored diagnostic trouble codes (DTCs) from the ECU.

- Interpret Fault Codes: Use the fault code descriptions to identify potential issues.

- Monitor Live Data: Observe real-time data from sensors and components to pinpoint anomalies.

- Perform Actuation Tests: Activate individual components to assess their functionality.

- Analyze Data: Evaluate the collected data to determine the root cause of the problem.

- Implement Repairs: Perform necessary repairs based on the diagnostic findings.

- Clear Fault Codes: After completing repairs, clear the fault codes from the ECU.

- Verify Repair: Confirm that the issue has been resolved and no new fault codes appear.

Can you Provide Real-World Examples of Diagnosing Common CDI Diesel Engine Problems with C4/C6 Interfaces?

Here are a couple of real-world examples:

Example 1: Diagnosing a Faulty Fuel Injector

- Problem: Engine misfire and rough idling.

- Diagnosis:

- Connect the C4/C6 interface and launch DTS Monaco.

- Read fault codes and find a code indicating a fuel injector malfunction.

- Monitor live data of the fuel injectors and notice that one injector is not functioning correctly.

- Perform an actuation test on the injector to confirm its failure.

- Solution: Replace the faulty fuel injector and clear the fault codes.

Example 2: Diagnosing a Blocked DPF

- Problem: Reduced engine power and increased fuel consumption.

- Diagnosis:

- Connect the C4/C6 interface and launch DTS Monaco.

- Read fault codes and find a code indicating a blocked DPF.

- Monitor live data of the DPF pressure and temperature sensors and observe high pressure readings.

- Perform a DPF regeneration cycle using DTS Monaco.

- Solution: If regeneration is unsuccessful, remove and clean the DPF or replace it if necessary, then clear the fault codes.

4. Advantages of Using C4/C6 Interfaces for CDI Diesel Engine Diagnostics

What are the Key Benefits of Using C4/C6 Interfaces?

Using C4/C6 interfaces offers several advantages:

- Accuracy: Provides precise diagnostic information, reducing the likelihood of errors.

- Efficiency: Streamlines the diagnostic process, saving time and labor costs.

- Comprehensive Coverage: Supports a wide range of CDI diesel engine models and systems.

- Advanced Functionality: Enables car coding and ECU programming for enhanced customization.

- User-Friendliness: Offers intuitive software interfaces for ease of use.

How do C4/C6 Interfaces Improve Diagnostic Accuracy and Efficiency?

C4/C6 interfaces improve diagnostic accuracy by providing access to detailed data and diagnostic tests that are not available with traditional methods. They enhance efficiency by automating many diagnostic tasks, reducing the time required to identify and resolve issues. According to a study by the Automotive Management Institute (AMI), shops using advanced diagnostic tools experience a 25% increase in overall efficiency.

Are There Any Limitations to Using C4/C6 Interfaces?

While C4/C6 interfaces are powerful tools, they do have some limitations:

- Cost: The initial investment can be significant.

- Training: Requires proper training to use the software and interpret the data effectively.

- Compatibility: May not be compatible with all vehicle models or diagnostic protocols.

- Software Updates: Requires regular software updates to maintain compatibility and access the latest features.

5. Integrating DTS Monaco with C4/C6 Interfaces

What is DTS Monaco and How Does It Work with C4/C6 Interfaces?

DTS Monaco is a diagnostic and car coding software widely used in the automotive industry. It works seamlessly with C4/C6 interfaces to provide advanced diagnostic capabilities, ECU programming, and car coding functions. DTS Monaco allows technicians to access and modify ECU parameters, customize vehicle features, and perform in-depth diagnostics.

What are the Key Features of DTS Monaco for CDI Diesel Engine Diagnostics?

Key features of DTS Monaco include:

- Guided Diagnostics: Step-by-step diagnostic procedures for common issues.

- ECU Flashing: Programming and updating ECU software.

- Car Coding: Customizing vehicle features and functions.

- Variant Coding: Modifying vehicle parameters to match specific requirements.

- Data Logging: Recording and analyzing data from sensors and components.

How Does DTS Monaco Enhance the Capabilities of C4/C6 Interfaces?

DTS Monaco enhances the capabilities of C4/C6 interfaces by providing a user-friendly interface, advanced diagnostic functions, and comprehensive vehicle coverage. It simplifies complex diagnostic tasks, allowing technicians to quickly identify and resolve issues. According to Mercedes-Benz, DTS Monaco is the preferred diagnostic tool for their vehicles due to its advanced capabilities and ease of use.

6. Car Coding with C4/C6 Interfaces and DTS Monaco

What is Car Coding and Why is it Important?

Car coding involves modifying the software parameters of a vehicle’s ECU to customize features and functions. This can include enabling or disabling certain options, adjusting performance settings, and personalizing the driving experience. Car coding is important because it allows technicians to tailor the vehicle to the customer’s specific needs and preferences.

What Kind of Car Coding Can Be Performed on CDI Diesel Engines?

Common car coding modifications for CDI diesel engines include:

- Activating or deactivating features: Such as daytime running lights, automatic door locking, and seat belt reminders.

- Adjusting performance parameters: Such as throttle response, fuel injection timing, and turbocharger settings.

- Enabling or disabling diagnostic functions: Such as DPF regeneration and EGR valve control.

- Customizing comfort settings: Such as climate control preferences and seat settings.

How Does Car Coding Enhance Vehicle Performance and Functionality?

Car coding can enhance vehicle performance and functionality by optimizing engine parameters, improving fuel efficiency, and personalizing the driving experience. For example, adjusting the throttle response can make the vehicle feel more responsive, while optimizing fuel injection timing can improve fuel economy.

Mercedes-Benz MBUX System

Mercedes-Benz MBUX System

7. Best Practices for Using C4/C6 Interfaces and DTS Monaco

What are Some Important Considerations When Using C4/C6 Interfaces and DTS Monaco?

When using C4/C6 interfaces and DTS Monaco, keep these considerations in mind:

- Proper Training: Ensure you have adequate training on how to use the software and interface.

- Software Updates: Keep your software and interface firmware up to date.

- Backup Data: Always back up the vehicle’s ECU data before making any changes.

- Battery Voltage: Ensure the vehicle’s battery voltage is stable during diagnostic and coding procedures.

- Follow Instructions: Carefully follow the instructions in the software and documentation.

What Safety Precautions Should Be Taken When Performing Diagnostics and Car Coding?

Safety precautions include:

- Wear Safety Gear: Always wear appropriate safety gear, such as gloves and eye protection.

- Work in a Well-Ventilated Area: Ensure the work area is well-ventilated to avoid exposure to harmful fumes.

- Disconnect Power: Disconnect the vehicle’s battery before performing any major repairs.

- Use Proper Tools: Use the correct tools for the job and follow proper procedures.

- Follow Safety Guidelines: Adhere to all safety guidelines and regulations.

How Can Technicians Stay Up-to-Date with the Latest Technologies and Techniques?

Technicians can stay up-to-date by:

- Attending Training Courses: Participate in training courses offered by manufacturers and industry organizations.

- Reading Technical Publications: Stay informed by reading technical publications and journals.

- Joining Online Forums: Participate in online forums and communities to exchange information and ideas.

- Networking with Peers: Network with other technicians and industry professionals.

- Seeking Certifications: Obtain certifications to demonstrate competency and stay current with industry standards.

8. Training and Certification Programs for CDI Diesel Engine Diagnostics

What Training Programs are Available for Technicians Working on CDI Diesel Engines?

Several training programs are available for technicians, including those offered by:

- Automotive Manufacturers: Mercedes-Benz, BMW, and other manufacturers offer training programs specific to their vehicles.

- Technical Schools: Vocational and technical schools provide comprehensive training in automotive diagnostics and repair.

- Industry Organizations: Organizations like ASE and AMI offer training and certification programs.

- Online Platforms: Online platforms offer a variety of courses and resources for automotive technicians. DTS-MONACO.EDU.VN also provides specialized training on DTS Monaco and car coding.

What Certifications are Relevant for CDI Diesel Engine Diagnostics?

Relevant certifications include:

- ASE Certifications: ASE offers certifications in various areas of automotive repair, including diesel engines.

- Manufacturer-Specific Certifications: Manufacturers offer certifications specific to their vehicles and diagnostic tools.

- Industry-Recognized Certifications: Certifications from organizations like AMI are recognized throughout the industry.

How Can Technicians Benefit from Participating in Training and Certification Programs?

Technicians can benefit by:

- Improving Skills: Enhancing their diagnostic and repair skills.

- Increasing Knowledge: Gaining a deeper understanding of CDI diesel engine technology.

- Boosting Credibility: Demonstrating their competency and expertise to employers and customers.

- Earning Higher Wages: Qualifying for higher-paying positions.

- Advancing Career: Opening up opportunities for career advancement.

9. Troubleshooting Common Issues with C4/C6 Interfaces and DTS Monaco

What are Some Common Problems Technicians Might Encounter When Using C4/C6 Interfaces and DTS Monaco?

Common problems include:

- Connection Issues: Problems establishing a connection between the interface and the vehicle or computer.

- Software Errors: Error messages or crashes in the DTS Monaco software.

- Compatibility Problems: Issues with the interface or software not being compatible with the vehicle.

- Data Errors: Incorrect or corrupted data being displayed in the software.

- Coding Failures: Problems with car coding or ECU programming procedures.

How Can These Issues Be Troubleshooted and Resolved?

Troubleshooting tips include:

- Check Connections: Verify that all cables and connections are secure.

- Restart Devices: Restart the interface, computer, and vehicle.

- Update Software: Ensure that the software and interface firmware are up to date.

- Check Compatibility: Verify that the interface and software are compatible with the vehicle.

- Consult Documentation: Refer to the software and interface documentation for troubleshooting tips.

- Seek Support: Contact the software or interface vendor for technical support.

- Use Online Resources: Consult online forums and communities for troubleshooting advice.

Where Can Technicians Find Support and Resources for Troubleshooting?

Technicians can find support and resources from:

- Software Vendors: Contact the vendors of DTS Monaco and other diagnostic software.

- Interface Manufacturers: Contact the manufacturers of C4/C6 interfaces.

- Online Forums: Participate in online forums and communities for automotive technicians.

- Technical Publications: Consult technical publications and journals for troubleshooting tips.

- Training Courses: Attend training courses to learn troubleshooting techniques.

- DTS-MONACO.EDU.VN: We provide extensive resources and support for DTS Monaco users.

10. The Future of CDI Diesel Engine Diagnostics

What are the Emerging Technologies and Trends in CDI Diesel Engine Diagnostics?

Emerging technologies and trends include:

- Wireless Diagnostics: Using wireless interfaces and cloud-based software for remote diagnostics.

- Artificial Intelligence (AI): AI-powered diagnostic tools that can analyze data and identify issues automatically.

- Predictive Diagnostics: Using data analytics to predict potential issues before they occur.

- Augmented Reality (AR): AR-based diagnostic tools that overlay diagnostic information onto the vehicle.

- Remote Diagnostics: Performing diagnostics remotely using telematics and remote access technology.

How Will These Advancements Impact the Role of Technicians?

These advancements will require technicians to:

- Adapt to New Technologies: Learn how to use new diagnostic tools and software.

- Develop Data Analysis Skills: Interpret data and identify trends.

- Enhance Problem-Solving Abilities: Diagnose complex issues using advanced technologies.

- Embrace Continuous Learning: Stay up-to-date with the latest technologies and techniques.

What Skills Will Technicians Need to Succeed in the Future of CDI Diesel Engine Diagnostics?

Technicians will need:

- Technical Skills: A strong understanding of CDI diesel engine technology and diagnostic procedures.

- Computer Skills: Proficiency in using diagnostic software and computer systems.

- Data Analysis Skills: The ability to interpret data and identify trends.

- Problem-Solving Skills: Strong problem-solving abilities to diagnose complex issues.

- Communication Skills: Effective communication skills to explain diagnostic findings to customers.

By embracing these advancements and developing the necessary skills, technicians can continue to provide high-quality diagnostic and repair services for CDI diesel engines.

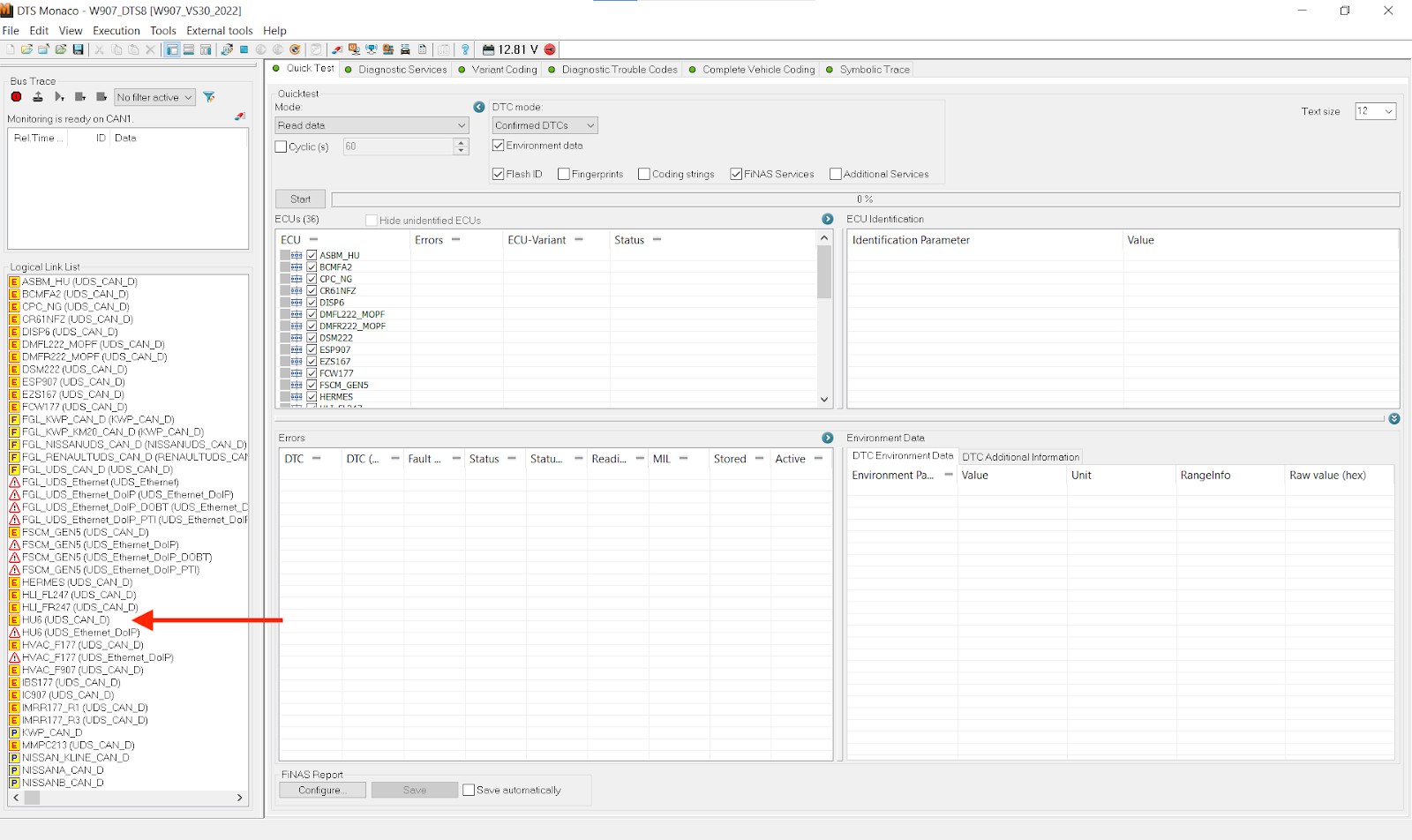

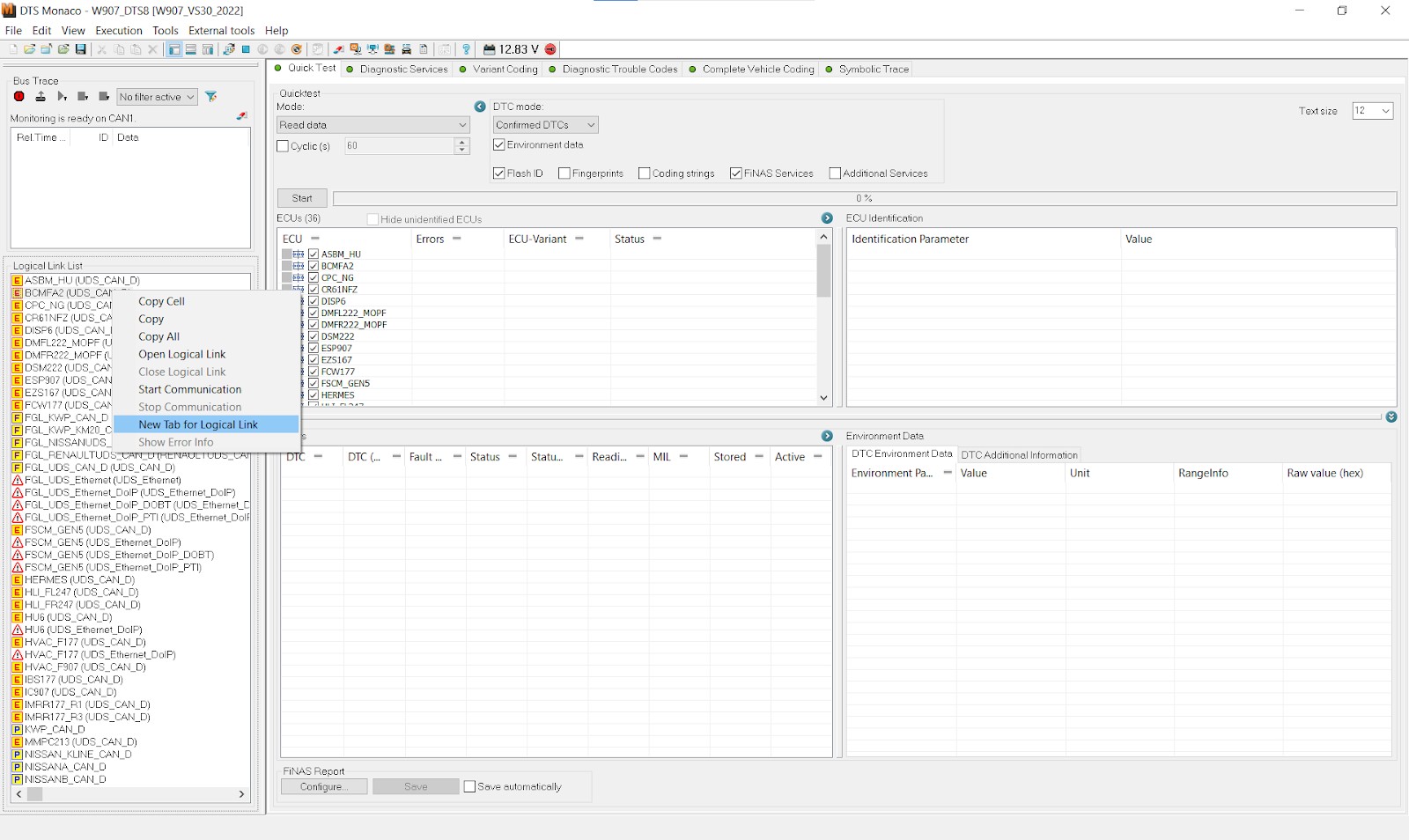

Mercedes-Benz Diagnostic Interface

Mercedes-Benz Diagnostic Interface

FAQ: Diagnosing CDI Diesel Engines with C4/C6 Interfaces

1. Can I use a C4 interface on all CDI diesel engine models?

While the C4 interface is versatile, compatibility can vary. Always check the interface’s specifications and vehicle compatibility list to ensure it supports the specific model you’re working on.

2. Is DTS Monaco required to use a C4/C6 interface for CDI diesel engine diagnostics?

DTS Monaco is highly recommended for advanced diagnostics, car coding, and ECU programming. While other software may work, DTS Monaco provides comprehensive features and seamless integration.

3. What level of technical expertise is needed to use C4/C6 interfaces effectively?

A solid understanding of automotive diagnostics and CDI diesel engine systems is essential. Proper training on the software and interface is highly recommended for accurate and safe operation.

4. Are there any risks involved in performing car coding on CDI diesel engines?

Yes, incorrect coding can lead to vehicle malfunction or damage. Always back up the ECU data before making changes and follow instructions carefully.

5. How often should I update the software for my C4/C6 interface and DTS Monaco?

Regular updates are crucial for maintaining compatibility with new vehicle models and accessing the latest features and bug fixes. Check for updates regularly.

6. Can I perform remote diagnostics on CDI diesel engines using a C4/C6 interface?

Yes, some C4/C6 interfaces support remote diagnostics through wireless connectivity and cloud-based software. This allows technicians to diagnose issues from a remote location.

7. What should I do if I encounter a fault code that I don’t understand?

Consult the vehicle’s service manual or online resources for fault code descriptions and troubleshooting tips. You can also seek assistance from online forums and communities.

8. Can I use a C4/C6 interface to diagnose emission control problems on CDI diesel engines?

Yes, C4/C6 interfaces can diagnose a wide range of emission control problems, including EGR valve issues, DPF blockages, and NOx sensor failures.

9. What are the essential tools and equipment needed for CDI diesel engine diagnostics besides the C4/C6 interface?

Other essential tools include a multimeter, oscilloscope, fuel pressure gauge, and a smoke machine for detecting leaks.

10. How can I ensure the safety of my vehicle’s data when performing diagnostics and car coding?

Always use a secure connection and back up your vehicle’s ECU data before making any changes. Be cautious of unauthorized access and follow security best practices.

Conclusion

Using C4/C6 interfaces with DTS Monaco for diagnosing CDI diesel engines is a game-changer for automotive technicians. These tools provide unparalleled accuracy, efficiency, and comprehensive coverage, enabling you to tackle even the most complex issues with confidence. Whether you’re troubleshooting fuel injection problems, sensor failures, or emission control issues, C4/C6 interfaces and DTS Monaco offer the advanced functionality you need.

Ready to take your diagnostic skills to the next level? Explore the training programs and resources available at DTS-MONACO.EDU.VN. Contact us today at Whatsapp: +1 (641) 206-8880 or visit our location at 275 N Harrison St, Chandler, AZ 85225, United States to learn more about how we can help you master CDI diesel engine diagnostics and car coding. Unleash your full potential and drive your career forward with DTS-MONACO.EDU.VN!