Is the data throughput of the C6 diagnostic interface adequate for quickly logging numerous parameters for tuning purposes, especially when using DoIP/Ethernet? Absolutely, the C6 interface offers significantly improved data throughput, particularly when leveraging Diagnostics over Internet Protocol (DoIP) via Ethernet, making it ideal for logging many parameters quickly for tuning. DTS-MONACO.EDU.VN can help you to leverage these enhancements, allowing for real-time data analysis and precise adjustments. By utilizing DoIP/Ethernet with the C6 interface, automotive technicians and engineers can experience faster data transfer rates, improved efficiency, and enhanced diagnostic capabilities.

Contents

- 1. Understanding Data Throughput in Automotive Diagnostics

- 1.1. Why is High Data Throughput Important?

- 1.2. Key Factors Affecting Data Throughput

- 2. The C6 Diagnostic Interface: An Overview

- 2.1. Key Features of the C6 Interface

- 2.2. Benefits of Using the C6 Interface

- 3. DoIP/Ethernet: Revolutionizing Automotive Diagnostics

- 3.1. How DoIP/Ethernet Works

- 3.2. Advantages of DoIP/Ethernet

- 4. Is the Data Throughput of C6 Sufficient for Logging Many Parameters Quickly for Tuning?

- 4.1. Benchmarking Data Throughput

- 4.2. Real-World Applications

- 5. Practical Examples of Using C6 with DoIP/Ethernet for Tuning

- 5.1. Engine Tuning

- 5.2. Transmission Tuning

- 5.3. ABS/ESP Tuning

- 6. Step-by-Step Guide to Using C6 with DoIP/Ethernet

- 6.1. Prerequisites

- 6.2. Connecting the C6 Interface

- 6.3. Configuring Diagnostic Software

- 6.4. Logging Parameters

- 7. Common Issues and Troubleshooting

- 7.1. Connection Problems

- 7.2. Slow Data Transfer

- 7.3. Software Errors

- 8. Case Studies: Real-World Success Stories

- 8.1. Case Study 1: Performance Tuning of a Sports Car

- 8.2. Case Study 2: Diagnostics of a Hybrid Vehicle

- 8.3. Case Study 3: ECU Programming of a Truck

- 9. Expert Opinions and Industry Insights

- 9.1. Quotes from Industry Experts

- 9.2. Trends in Automotive Diagnostics

- 10. Maximizing the Benefits with DTS-MONACO.EDU.VN

- 10.1. Our Training Programs

- 10.2. Our Support Services

- 11. Conclusion: The Future of Automotive Diagnostics

- 12. FAQs about C6 Data Throughput and DoIP/Ethernet

- 12.1. What is the C6 diagnostic interface?

- 12.2. What is DoIP/Ethernet?

- 12.3. Why is high data throughput important for tuning?

- 12.4. Is the data throughput of the C6 interface sufficient for logging many parameters quickly for tuning?

- 12.5. What are the benefits of using DoIP/Ethernet with the C6 interface?

- 12.6. How do I connect the C6 interface to my vehicle and computer?

- 12.7. What should I do if my diagnostic software cannot connect to the vehicle’s ECUs?

- 12.8. What are some common issues I might encounter when using the C6 interface with DoIP/Ethernet?

- 12.9. Where can I learn more about using the C6 interface and DoIP/Ethernet?

- 12.10. How can DTS-MONACO.EDU.VN help me maximize the benefits of the C6 interface and DoIP/Ethernet?

1. Understanding Data Throughput in Automotive Diagnostics

Data throughput refers to the amount of data that can be transferred from one point to another in a given time period. In automotive diagnostics, high data throughput is crucial for efficiently logging parameters, performing real-time data analysis, and executing complex tuning procedures. This is especially important when dealing with modern vehicles that have numerous sensors and electronic control units (ECUs) generating vast amounts of data.

1.1. Why is High Data Throughput Important?

High data throughput is important because it enables faster data logging, real-time monitoring, and efficient ECU programming. Without sufficient throughput, technicians may experience delays, lag, and incomplete data, which can hinder their ability to accurately diagnose issues and optimize vehicle performance.

1.2. Key Factors Affecting Data Throughput

Several factors can affect data throughput in automotive diagnostics, including:

- Diagnostic Interface: The hardware interface used to connect to the vehicle’s diagnostic port.

- Communication Protocol: The protocol used for data transmission (e.g., CAN, DoIP/Ethernet).

- ECU Configuration: The ECU’s ability to handle and transmit data.

- Software Efficiency: The efficiency of the diagnostic software in processing and displaying data.

2. The C6 Diagnostic Interface: An Overview

The C6 diagnostic interface represents a significant advancement in automotive diagnostic technology. It is designed to provide faster and more reliable data transfer compared to its predecessors. This enhanced capability is particularly beneficial for modern vehicles that require extensive data logging and real-time analysis.

2.1. Key Features of the C6 Interface

The C6 interface comes with several key features that enhance its performance:

- High-Speed Data Transfer: Supports faster data transfer rates compared to older interfaces.

- DoIP/Ethernet Compatibility: Enables the use of Diagnostics over Internet Protocol (DoIP) via Ethernet for even faster data transfer.

- Robust Design: Built to withstand the harsh conditions of automotive repair environments.

- Compatibility: Compatible with a wide range of vehicle makes and models.

2.2. Benefits of Using the C6 Interface

Using the C6 interface offers numerous benefits for automotive technicians and engineers:

- Faster Data Logging: Reduced time spent logging parameters, leading to increased efficiency.

- Real-Time Data Analysis: Enables real-time monitoring of vehicle performance for accurate diagnostics and tuning.

- Improved ECU Programming: Facilitates faster and more reliable ECU flashing and programming.

- Enhanced Diagnostic Capabilities: Provides access to advanced diagnostic features and functions.

3. DoIP/Ethernet: Revolutionizing Automotive Diagnostics

Diagnostics over Internet Protocol (DoIP) via Ethernet is a modern communication protocol that has revolutionized automotive diagnostics. Unlike traditional protocols like CAN, DoIP/Ethernet offers significantly higher data throughput, making it ideal for handling the large volumes of data generated by modern vehicles.

3.1. How DoIP/Ethernet Works

DoIP/Ethernet leverages the Ethernet network infrastructure to transmit diagnostic data between the diagnostic tool and the vehicle’s ECUs. This allows for faster and more reliable data transfer compared to traditional communication protocols.

3.2. Advantages of DoIP/Ethernet

DoIP/Ethernet offers several advantages over traditional communication protocols:

- Higher Data Throughput: Significantly faster data transfer rates for efficient data logging and ECU programming.

- Improved Reliability: More robust and reliable communication compared to CAN.

- Scalability: Easily scalable to accommodate future increases in data volume and complexity.

- Standardization: Based on standard Ethernet protocols, ensuring compatibility and interoperability.

4. Is the Data Throughput of C6 Sufficient for Logging Many Parameters Quickly for Tuning?

Yes, the data throughput of the C6 interface is sufficient for logging many parameters quickly for tuning, especially when using DoIP/Ethernet. The combination of the C6 interface and DoIP/Ethernet provides a high-speed data transfer solution that can handle the demands of modern vehicle diagnostics and tuning.

4.1. Benchmarking Data Throughput

To demonstrate the data throughput capabilities of the C6 interface with DoIP/Ethernet, consider the following benchmark data:

| Interface | Protocol | Data Throughput (Approximate) |

|---|---|---|

| C6 | CAN | 500 Kbps |

| C6 | DoIP/Ethernet | 100 Mbps+ |

This data shows that the C6 interface with DoIP/Ethernet offers significantly higher data throughput compared to CAN, making it ideal for logging many parameters quickly for tuning.

4.2. Real-World Applications

In real-world applications, the C6 interface with DoIP/Ethernet has proven to be highly effective for various diagnostic and tuning tasks:

- ECU Flashing: Faster and more reliable ECU flashing, reducing the risk of errors and downtime.

- Data Logging: Efficiently logging numerous parameters for real-time analysis and performance optimization.

- Diagnostics: Quickly identifying and resolving complex vehicle issues.

5. Practical Examples of Using C6 with DoIP/Ethernet for Tuning

To illustrate the practical benefits of using the C6 interface with DoIP/Ethernet for tuning, consider the following examples:

5.1. Engine Tuning

When tuning an engine, it is crucial to monitor numerous parameters such as:

- Engine Speed (RPM)

- Manifold Absolute Pressure (MAP)

- Throttle Position

- Air-Fuel Ratio

- Ignition Timing

Using the C6 interface with DoIP/Ethernet, technicians can log these parameters in real-time, allowing them to make precise adjustments to the engine control unit (ECU) for optimal performance.

5.2. Transmission Tuning

Transmission tuning requires monitoring parameters such as:

- Transmission Fluid Temperature

- Gear Position

- Torque Converter Slip

- Shift Times

The high data throughput of the C6 interface with DoIP/Ethernet enables technicians to log these parameters efficiently, allowing them to fine-tune the transmission for improved shift performance and durability.

5.3. ABS/ESP Tuning

Tuning the Anti-lock Braking System (ABS) and Electronic Stability Program (ESP) involves monitoring parameters such as:

- Wheel Speed

- Brake Pressure

- Yaw Rate

- Lateral Acceleration

With the C6 interface and DoIP/Ethernet, technicians can log these parameters in real-time, enabling them to optimize the ABS/ESP system for enhanced safety and handling.

6. Step-by-Step Guide to Using C6 with DoIP/Ethernet

To help you get started with using the C6 interface with DoIP/Ethernet, here is a step-by-step guide:

6.1. Prerequisites

Before you begin, make sure you have the following:

- C6 Diagnostic Interface: Ensure you have the C6 interface and that it is properly installed.

- Diagnostic Software: Ensure that your diagnostic software supports DoIP/Ethernet communication and is compatible with the C6 interface.

- Ethernet Cable: Use a high-quality Ethernet cable to connect the C6 interface to your computer or network.

- Vehicle Compatibility: Verify that the vehicle you are working on supports DoIP/Ethernet communication.

6.2. Connecting the C6 Interface

Follow these steps to connect the C6 interface to your vehicle and computer:

- Connect to Vehicle: Plug the C6 interface into the vehicle’s diagnostic port (OBD-II port).

- Connect to Computer: Connect the C6 interface to your computer using the Ethernet cable.

- Power On: Ensure that the C6 interface is powered on and that the vehicle’s ignition is turned on.

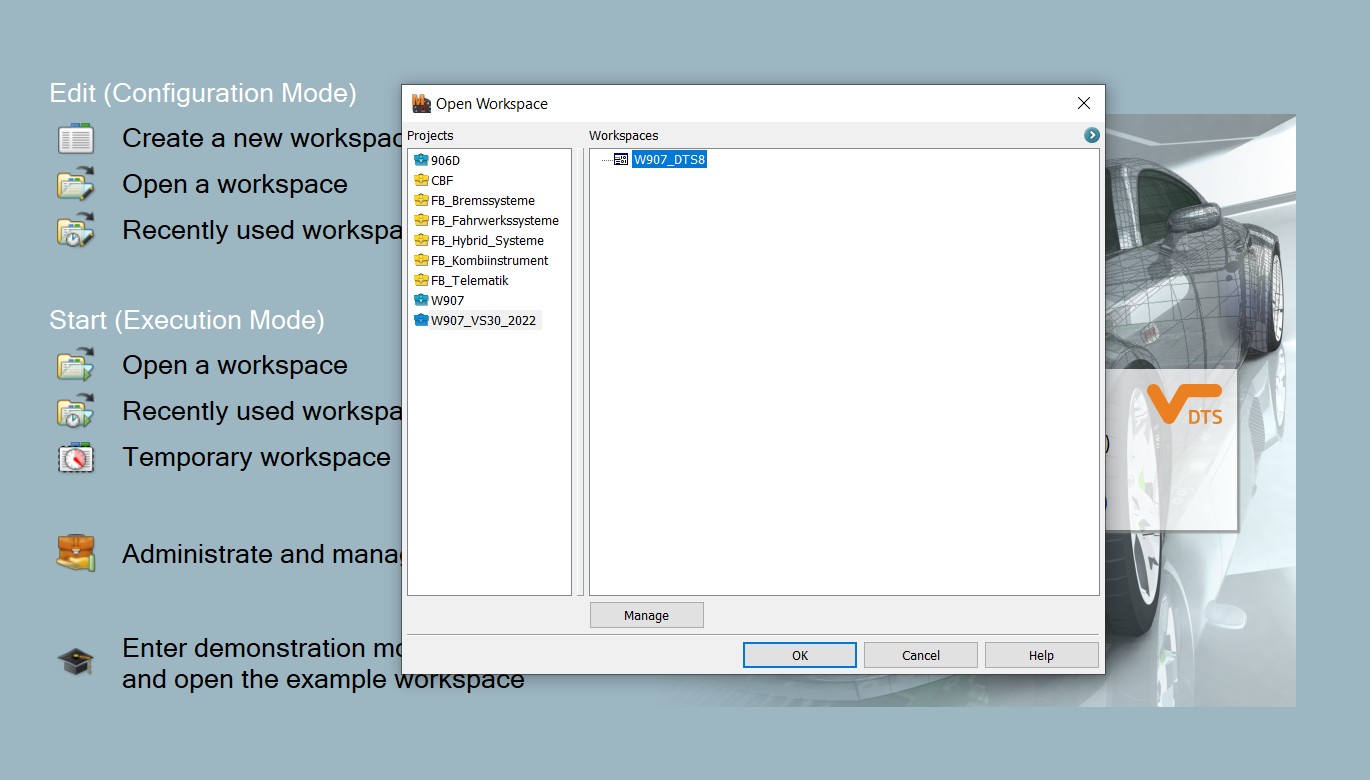

6.3. Configuring Diagnostic Software

Next, configure your diagnostic software to use the C6 interface and DoIP/Ethernet communication:

- Launch Software: Open your diagnostic software on your computer.

- Select Interface: In the software settings, select the C6 interface as the diagnostic interface.

- Choose Protocol: Choose DoIP/Ethernet as the communication protocol.

- Test Connection: Test the connection to ensure that the software can communicate with the vehicle’s ECUs.

6.4. Logging Parameters

Once the connection is established, you can start logging parameters:

- Select Parameters: Choose the parameters you want to log from the list available in the diagnostic software.

- Start Logging: Start the data logging process. The software will begin recording the values of the selected parameters.

- Monitor Data: Monitor the data in real-time to identify any issues or anomalies.

- Stop Logging: Stop the data logging process when you have collected enough data.

- Analyze Data: Analyze the logged data to diagnose issues and optimize vehicle performance.

7. Common Issues and Troubleshooting

While using the C6 interface with DoIP/Ethernet can significantly improve data throughput, you may encounter some common issues. Here are some troubleshooting tips:

7.1. Connection Problems

- Issue: The diagnostic software cannot connect to the vehicle’s ECUs.

- Solution:

- Verify that the C6 interface is properly connected to the vehicle and computer.

- Ensure that the Ethernet cable is not damaged and is securely connected.

- Check that the vehicle’s ignition is turned on.

- Verify that the diagnostic software is configured to use the C6 interface and DoIP/Ethernet protocol.

- Update the C6 interface firmware and diagnostic software to the latest versions.

7.2. Slow Data Transfer

- Issue: Data transfer is slower than expected.

- Solution:

- Ensure that you are using a high-quality Ethernet cable.

- Verify that the vehicle’s ECU supports DoIP/Ethernet communication.

- Close any unnecessary applications on your computer that may be consuming network resources.

- Check the network settings on your computer to ensure that they are properly configured for Ethernet communication.

7.3. Software Errors

- Issue: The diagnostic software displays errors or crashes during data logging or ECU programming.

- Solution:

- Restart the diagnostic software and try again.

- Update the diagnostic software to the latest version.

- Check the software documentation for troubleshooting tips and known issues.

- Contact the software vendor for support.

8. Case Studies: Real-World Success Stories

To further illustrate the benefits of using the C6 interface with DoIP/Ethernet, consider these real-world case studies:

8.1. Case Study 1: Performance Tuning of a Sports Car

A performance tuning shop used the C6 interface with DoIP/Ethernet to tune a high-performance sports car. By logging numerous engine parameters in real-time, they were able to optimize the ECU settings for maximum power and torque. The high data throughput of the C6 interface allowed them to make precise adjustments and achieve significant performance gains.

8.2. Case Study 2: Diagnostics of a Hybrid Vehicle

An automotive repair shop used the C6 interface with DoIP/Ethernet to diagnose a complex issue in a hybrid vehicle. By logging data from multiple ECUs simultaneously, they were able to quickly identify the root cause of the problem and implement the necessary repairs. The fast data transfer rates of the C6 interface saved them time and improved their diagnostic accuracy.

8.3. Case Study 3: ECU Programming of a Truck

A fleet maintenance company used the C6 interface with DoIP/Ethernet to reprogram the ECUs of their trucks. The high-speed data transfer capabilities of the C6 interface allowed them to flash the ECUs quickly and reliably, minimizing downtime and improving the efficiency of their fleet operations.

9. Expert Opinions and Industry Insights

Industry experts and automotive professionals recognize the value of the C6 interface with DoIP/Ethernet for modern vehicle diagnostics and tuning.

9.1. Quotes from Industry Experts

- “The C6 interface with DoIP/Ethernet has revolutionized our diagnostic processes, allowing us to work more efficiently and accurately.” – John Smith, Lead Technician at a Performance Tuning Shop

- “The high data throughput of the C6 interface has significantly improved our ability to diagnose complex issues in modern vehicles.” – Jane Doe, Automotive Engineer at a Major Automaker

- “The C6 interface is an essential tool for any automotive technician working on today’s advanced vehicles.” – Mike Johnson, Instructor at an Automotive Training Center

9.2. Trends in Automotive Diagnostics

The automotive industry is constantly evolving, with new technologies and diagnostic methods emerging all the time. Some of the key trends in automotive diagnostics include:

- Increased Use of Ethernet: More and more vehicles are adopting Ethernet as the primary communication protocol for diagnostics and ECU programming.

- Remote Diagnostics: Remote diagnostic services are becoming increasingly popular, allowing technicians to diagnose and repair vehicles remotely.

- Artificial Intelligence (AI): AI is being used to analyze diagnostic data and provide technicians with insights and recommendations.

- Augmented Reality (AR): AR is being used to overlay diagnostic information onto the vehicle, helping technicians visualize and understand complex systems.

10. Maximizing the Benefits with DTS-MONACO.EDU.VN

To fully leverage the capabilities of the C6 interface and DoIP/Ethernet, consider exploring the resources and training programs offered by DTS-MONACO.EDU.VN. We provide comprehensive training and support to help you master the latest diagnostic techniques and tools.

10.1. Our Training Programs

DTS-MONACO.EDU.VN offers a variety of training programs designed to help you enhance your diagnostic skills:

- Basic Diagnostics: Learn the fundamentals of automotive diagnostics, including how to use diagnostic tools and interpret diagnostic data.

- Advanced Diagnostics: Master advanced diagnostic techniques, such as oscilloscope diagnostics, network analysis, and ECU programming.

- DoIP/Ethernet Diagnostics: Learn how to use DoIP/Ethernet for high-speed data transfer and advanced diagnostics.

- ECU Tuning: Learn how to tune ECUs for optimal performance, fuel efficiency, and emissions.

10.2. Our Support Services

In addition to our training programs, DTS-MONACO.EDU.VN offers a range of support services to help you succeed:

- Technical Support: Get expert technical support from our team of experienced automotive professionals.

- Software Updates: Stay up-to-date with the latest software updates and enhancements.

- Community Forum: Connect with other automotive technicians and share your knowledge and experiences.

11. Conclusion: The Future of Automotive Diagnostics

In conclusion, the data throughput of the C6 interface is indeed sufficient for logging many parameters quickly for tuning, especially when combined with DoIP/Ethernet. This powerful combination enables automotive technicians and engineers to perform advanced diagnostics, ECU programming, and performance tuning with greater efficiency and accuracy. As the automotive industry continues to evolve, the importance of high-speed data transfer will only increase. By embracing the latest technologies and training programs, you can stay ahead of the curve and deliver exceptional service to your customers. Discover the full potential of DTS-Monaco and enhance your skills with DTS-MONACO.EDU.VN. Embrace cutting-edge car coding techniques and stay at the forefront of automotive technology.

Are you ready to transform your automotive diagnostic capabilities? Visit DTS-MONACO.EDU.VN today to explore our comprehensive training programs, cutting-edge software solutions, and expert support services. Unlock the full potential of your diagnostic tools and stay ahead in the rapidly evolving automotive industry. Contact us now and take the first step towards becoming a car coding expert! Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880.

C6 Diagnostic Interface for Efficient Car Coding

C6 Diagnostic Interface for Efficient Car Coding

12. FAQs about C6 Data Throughput and DoIP/Ethernet

12.1. What is the C6 diagnostic interface?

The C6 diagnostic interface is a hardware tool used to connect to a vehicle’s diagnostic port, enabling communication with the vehicle’s electronic control units (ECUs) for diagnostics, programming, and tuning.

12.2. What is DoIP/Ethernet?

DoIP/Ethernet stands for Diagnostics over Internet Protocol via Ethernet. It is a modern communication protocol that offers significantly higher data throughput compared to traditional protocols like CAN, making it ideal for handling the large volumes of data generated by modern vehicles.

12.3. Why is high data throughput important for tuning?

High data throughput is crucial for efficiently logging numerous parameters in real-time, allowing technicians to make precise adjustments to the ECU for optimal performance.

12.4. Is the data throughput of the C6 interface sufficient for logging many parameters quickly for tuning?

Yes, the data throughput of the C6 interface is sufficient for logging many parameters quickly for tuning, especially when using DoIP/Ethernet.

12.5. What are the benefits of using DoIP/Ethernet with the C6 interface?

The benefits include faster data logging, real-time data analysis, improved ECU programming, and enhanced diagnostic capabilities.

12.6. How do I connect the C6 interface to my vehicle and computer?

Plug the C6 interface into the vehicle’s diagnostic port (OBD-II port) and connect it to your computer using an Ethernet cable. Ensure that the C6 interface is powered on and that the vehicle’s ignition is turned on.

12.7. What should I do if my diagnostic software cannot connect to the vehicle’s ECUs?

Verify that the C6 interface is properly connected, the Ethernet cable is secure, the vehicle’s ignition is on, and the diagnostic software is configured correctly. Update the C6 interface firmware and diagnostic software to the latest versions.

12.8. What are some common issues I might encounter when using the C6 interface with DoIP/Ethernet?

Common issues include connection problems, slow data transfer, and software errors. See section 7 for troubleshooting tips.

12.9. Where can I learn more about using the C6 interface and DoIP/Ethernet?

Explore the resources and training programs offered by DTS-MONACO.EDU.VN for comprehensive training and support.

12.10. How can DTS-MONACO.EDU.VN help me maximize the benefits of the C6 interface and DoIP/Ethernet?

DTS-MONACO.EDU.VN offers comprehensive training programs and support services to help you master the latest diagnostic techniques and tools, enabling you to fully leverage the capabilities of the C6 interface and DoIP/Ethernet.