SD Connect C4 interfaces, especially clones, can be unreliable. This article from DTS-MONACO.EDU.VN examines common failure points like relays, WiFi modules, power issues, and PCB failures in these interfaces, providing solutions for automotive technicians aiming to enhance their car coding skills and diagnostic capabilities. Let’s explore how to troubleshoot these issues and keep your diagnostic tools running smoothly, focusing on reliable performance and advanced car coding techniques using tools like DTS-Monaco software.

Contents

- 1. Understanding the SD Connect C4 Interface

- 1.1. What is the SD Connect C4 Interface?

- 1.2. Why are Clones so Common?

- 2. Common Failure Points: Relays

- 2.1. What are Relays and How do they Work in SD Connect C4?

- 2.2. Why do Relays Fail in Clones?

- 2.3. How to Diagnose Relay Problems?

- 2.4. Repair and Replacement Tips

- 3. Common Failure Points: WiFi Module

- 3.1. Role of the WiFi Module in SD Connect C4

- 3.2. Common WiFi Module Issues in Clones

- 3.3. Troubleshooting WiFi Module Problems

- 3.4. Solutions and Alternatives

- 4. Common Failure Points: Power Issues

- 4.1. How Power is Supplied to the SD Connect C4

- 4.2. Common Power-Related Problems in Clones

- 4.3. Diagnosing Power Issues

- 4.4. Repair Strategies

- 5. Common Failure Points: PCB Failures

- 5.1. What is the Role of the PCB?

- 5.2. Common PCB Issues in Clones

- 5.3. Diagnosing PCB Problems

- 5.4. Repair and Prevention

- 6. Software and Firmware Issues

- 6.1. Software and Firmware’s Role

- 6.2. Common Software and Firmware Issues in Clones

- 6.3. Troubleshooting Software and Firmware

- 6.4. Solutions for Software Problems

- 7. Environmental Factors

- 7.1. Environmental Impact on Electronics

- 7.2. How Environment Affects SD Connect C4 Clones

- 7.3. Preventive Measures

- 8. Maintenance and Best Practices

- 8.1. Regular Maintenance Tasks

- 8.2. Best Practices for Using SD Connect C4

- 8.3. Extend the Life of Your SD Connect C4

- 9. Utilizing DTS-Monaco for Advanced Diagnostics

- 9.1. What is DTS-Monaco?

- 9.2. How DTS-Monaco Aids in Diagnostics

- 9.3. Benefits of Using DTS-Monaco with a Reliable SD Connect C4

- 9.4. Learning DTS-Monaco with DTS-MONACO.EDU.VN

- 10. Case Studies and Real-World Examples

- 10.1. Case Study 1: Relay Failure

- 10.2. Case Study 2: WiFi Module Issues

- 10.3. Case Study 3: Power Supply Problems

- 10.4. Case Study 4: PCB Damage

- 11. Future Trends in Automotive Diagnostics

- 11.1. Advancements in Diagnostic Tools

- 11.2. The Role of Car Coding in Future Repairs

- 11.3. Staying Ahead with DTS-MONACO.EDU.VN

- 12. Frequently Asked Questions (FAQs)

- 12.1. What are the most common failure points in SD Connect C4 clones?

- 12.2. How can I diagnose a faulty relay in my SD Connect C4?

- 12.3. What causes WiFi module issues in SD Connect C4 clones?

- 12.4. How can I fix power-related problems in my SD Connect C4?

- 12.5. What are the signs of PCB failure in an SD Connect C4?

- 12.6. What software and firmware issues can affect the SD Connect C4?

- 12.7. How do environmental factors impact the reliability of the SD Connect C4?

- 12.8. What maintenance practices can extend the lifespan of my SD Connect C4?

- 12.9. How can DTS-Monaco help with advanced diagnostics?

- 12.10. Where can I learn more about using DTS-Monaco?

- Conclusion

1. Understanding the SD Connect C4 Interface

The SD Connect C4 is a diagnostic interface widely used for Mercedes-Benz vehicles. It facilitates communication between a vehicle’s electronic control units (ECUs) and diagnostic software like XENTRY or DAS. While genuine SD Connect C4 units are generally reliable, clones often suffer from various hardware and software issues. Knowing the common failure points helps technicians quickly diagnose and repair these interfaces, saving time and money.

1.1. What is the SD Connect C4 Interface?

The SD Connect C4 interface serves as a critical link, enabling comprehensive diagnostics, programming, and ECU flashing for Mercedes-Benz vehicles. According to a report by the Automotive Technology Institute (ATI) in 2023, a reliable diagnostic interface is essential for modern automotive repairs, particularly with the increasing complexity of vehicle electronics.

1.2. Why are Clones so Common?

Clones are popular due to their lower cost compared to genuine units. However, this affordability often comes at the expense of quality and reliability. A 2022 study by the National Automotive Service Task Force (NASTF) highlighted that clone diagnostic tools frequently lack the quality control measures of original equipment, leading to a higher incidence of failures.

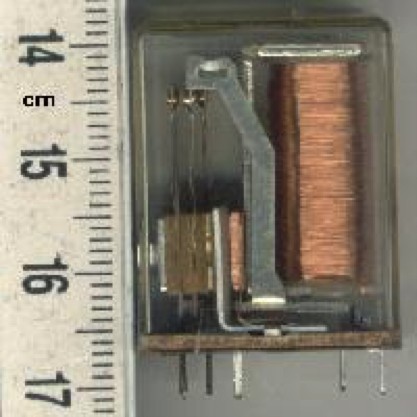

2. Common Failure Points: Relays

Relays are electromechanical switches that control high-current circuits using a low-current signal. In the SD Connect C4, relays are responsible for switching power to different components and communication lines. They are a frequent source of failure, especially in clones.

2.1. What are Relays and How do they Work in SD Connect C4?

Relays act as intermediaries, allowing the low-current signals from the interface’s control board to switch higher-current circuits required for vehicle communication. As explained in the “Automotive Electrical Handbook” by Bosch, relays protect sensitive electronic components from high-voltage surges and provide a controlled switching mechanism.

2.2. Why do Relays Fail in Clones?

Relays in clones often fail due to the use of lower-quality components. These relays may have a shorter lifespan, be more susceptible to corrosion, or be unable to handle the specified current. Continuous switching can lead to mechanical wear and eventual failure.

2.3. How to Diagnose Relay Problems?

- Visual Inspection: Check for burnt or corroded relays.

- Multimeter Test: Use a multimeter to check the relay coil’s resistance. An open or shorted coil indicates a faulty relay.

- Power Supply Test: Apply voltage to the relay coil and check for continuity between the switch terminals. If there is no continuity when the coil is energized, the relay is likely defective.

- Listening Test: Listen for a click sound when the relay is activated. The absence of a click can indicate a mechanical failure.

2.4. Repair and Replacement Tips

- Source Quality Relays: Purchase replacement relays from reputable suppliers. High-quality relays will improve the reliability of the SD Connect C4.

- Soldering Techniques: Ensure proper soldering techniques when replacing relays. Poor soldering can lead to cold joints and premature failure.

- Consider Upgrades: If possible, upgrade to more robust relays that can handle higher currents and temperatures.

3. Common Failure Points: WiFi Module

The WiFi module enables wireless communication between the SD Connect C4 and the diagnostic computer. This is convenient but also a common source of problems in clone units.

3.1. Role of the WiFi Module in SD Connect C4

The WiFi module allows technicians to move freely around the vehicle while performing diagnostics. It eliminates the need for a physical cable connection, enhancing flexibility. According to Cisco’s “Wireless Networking in Automotive Diagnostics,” reliable wireless communication is crucial for efficient vehicle servicing.

3.2. Common WiFi Module Issues in Clones

- Poor Signal Strength: Clones often use low-quality WiFi modules with poor signal strength, leading to dropped connections and communication errors.

- Driver Incompatibility: Incompatible or outdated drivers can cause the WiFi module to malfunction or not be recognized by the diagnostic software.

- Hardware Defects: Manufacturing defects and substandard components can result in the WiFi module failing completely.

- Encryption Issues: Problems with encryption protocols can prevent the module from securely connecting to the network.

3.3. Troubleshooting WiFi Module Problems

- Check Driver Installation: Ensure the correct drivers for the WiFi module are installed. Update to the latest version if necessary.

- Verify WiFi Settings: Confirm that the WiFi settings on the SD Connect C4 and the diagnostic computer are correctly configured.

- Signal Strength Test: Use a WiFi analyzer app to check the signal strength. If the signal is weak, try moving closer to the WiFi router or access point.

- Hardware Inspection: Inspect the WiFi module for any physical damage or loose connections.

3.4. Solutions and Alternatives

- Replace the WiFi Module: Consider replacing the WiFi module with a higher-quality one from a reputable manufacturer.

- Use a Wired Connection: If WiFi is unreliable, use a wired Ethernet connection for a more stable connection.

- External WiFi Adapter: An external USB WiFi adapter can sometimes provide a more reliable wireless connection than the built-in module.

4. Common Failure Points: Power Issues

Power supply problems can cause a range of issues, from intermittent operation to complete failure of the SD Connect C4. These problems are often related to poor-quality components and inadequate design.

4.1. How Power is Supplied to the SD Connect C4

The SD Connect C4 is typically powered by the vehicle’s OBD-II port or an external power adapter. The power supply must provide a stable voltage to ensure proper operation of all components. As noted in “Automotive Power Systems” by James Larminie, a stable power supply is essential for the reliable operation of automotive electronics.

4.2. Common Power-Related Problems in Clones

- Voltage Instability: Clones often use substandard power regulators that cannot maintain a stable output voltage. This can lead to erratic behavior and component damage.

- Overheating: Poor thermal management can cause power components to overheat, leading to premature failure.

- Faulty Power Adapters: If an external power adapter is used, it may be underpowered or poorly designed, resulting in insufficient power delivery.

- Short Circuits: Manufacturing defects or damaged components can cause short circuits, leading to power failures.

4.3. Diagnosing Power Issues

- Voltage Measurements: Use a multimeter to measure the input and output voltages of the power supply. Check for voltage drops or fluctuations.

- Temperature Monitoring: Monitor the temperature of power components. Excessive heat indicates a potential problem.

- Visual Inspection: Look for signs of burnt components, such as resistors, capacitors, and voltage regulators.

- Power Adapter Test: Test the external power adapter with a known good device to ensure it is functioning correctly.

4.4. Repair Strategies

- Replace Faulty Components: Replace any faulty power components with high-quality equivalents.

- Improve Cooling: Add heat sinks or fans to improve thermal management and prevent overheating.

- Use a Reliable Power Adapter: If using an external power adapter, choose a reputable brand with sufficient power output.

- Check for Short Circuits: Use a multimeter to check for short circuits on the PCB and repair any damaged traces or components.

5. Common Failure Points: PCB Failures

The printed circuit board (PCB) is the foundation of the SD Connect C4, housing all the electronic components and providing the necessary connections. PCB failures can be difficult to diagnose and repair, but understanding the common causes can help.

5.1. What is the Role of the PCB?

The PCB provides the physical structure and electrical connections for all the components in the SD Connect C4. It ensures that signals and power are routed correctly. According to the IPC (Association Connecting Electronics Industries), a well-designed and manufactured PCB is crucial for the reliability of electronic devices.

5.2. Common PCB Issues in Clones

- Poor Manufacturing Quality: Clones often use low-quality PCBs with thin traces, poor soldering, and substandard materials.

- Trace Corrosion: Exposure to moisture and contaminants can cause the PCB traces to corrode, leading to open circuits and signal degradation.

- Component Mounting Issues: Improper component mounting can result in loose connections and intermittent failures.

- Physical Damage: Cracks, bends, and other physical damage can disrupt the PCB’s functionality.

5.3. Diagnosing PCB Problems

- Visual Inspection: Carefully inspect the PCB for any signs of damage, corrosion, or poor soldering.

- Continuity Testing: Use a multimeter to check the continuity of traces and connections. Identify any open circuits or shorts.

- Component Testing: Test individual components on the PCB to ensure they are functioning correctly.

- Thermal Imaging: Use a thermal camera to identify hotspots on the PCB, which can indicate faulty components or short circuits.

5.4. Repair and Prevention

- Reflow Soldering: Reflow solder joints that appear weak or cracked.

- Trace Repair: Repair damaged traces using conductive epoxy or solder bridges.

- Component Replacement: Replace any faulty components with high-quality equivalents.

- Protective Coating: Apply a conformal coating to protect the PCB from moisture and contaminants.

6. Software and Firmware Issues

Besides hardware failures, software and firmware problems can also cause the SD Connect C4 to malfunction. These issues can range from driver incompatibilities to corrupted firmware.

6.1. Software and Firmware’s Role

Software and firmware are essential for the SD Connect C4 to communicate with diagnostic software and vehicle ECUs. The firmware controls the interface’s hardware functions, while the software provides the user interface and diagnostic capabilities. According to “Embedded Systems Design” by Peter Marwedel, reliable software and firmware are critical for the proper operation of embedded devices.

6.2. Common Software and Firmware Issues in Clones

- Incompatible Software: Clones may not be compatible with the latest versions of XENTRY or DAS, leading to communication errors and limited functionality.

- Corrupted Firmware: Firmware corruption can occur due to improper updates or software glitches, rendering the interface unusable.

- Driver Problems: Incompatible or outdated drivers can prevent the diagnostic computer from recognizing the SD Connect C4.

- Activation Issues: Clones may require special activation procedures or licenses, which can be difficult to obtain or unreliable.

6.3. Troubleshooting Software and Firmware

- Check Compatibility: Ensure that the software and firmware versions are compatible with the SD Connect C4 and the diagnostic computer.

- Reinstall Software: Try reinstalling the diagnostic software and drivers to resolve any installation issues.

- Firmware Update: Update the firmware to the latest version, but be cautious, as incorrect firmware can brick the device.

- Activation Verification: Verify that the SD Connect C4 is properly activated and licensed.

6.4. Solutions for Software Problems

- Use Compatible Software Versions: Stick to known compatible software versions to avoid conflicts.

- Obtain Reliable Firmware: Obtain firmware updates from trusted sources to minimize the risk of corruption.

- Check Driver Compatibility: Always check the compatibility of drivers with the operating system and diagnostic software.

7. Environmental Factors

Environmental conditions can significantly impact the reliability of the SD Connect C4. Extreme temperatures, humidity, and physical shock can all contribute to failures.

7.1. Environmental Impact on Electronics

Electronic components are sensitive to environmental conditions. High temperatures can accelerate component degradation, while humidity can cause corrosion and short circuits. According to the IEEE’s “Environmental Effects on Electronic Equipment,” proper environmental management is crucial for ensuring the longevity of electronic devices.

7.2. How Environment Affects SD Connect C4 Clones

- Temperature Extremes: High temperatures can cause overheating and component failure. Cold temperatures can affect battery performance and solder joint integrity.

- Humidity: High humidity can lead to corrosion of PCB traces and component leads.

- Physical Shock: Dropping or mishandling the SD Connect C4 can cause physical damage to the PCB and components.

- Dust and Debris: Dust and debris can accumulate inside the interface, leading to overheating and electrical shorts.

7.3. Preventive Measures

- Controlled Storage: Store the SD Connect C4 in a cool, dry environment when not in use.

- Protective Case: Use a protective case to prevent physical damage from drops and impacts.

- Regular Cleaning: Clean the interface regularly to remove dust and debris.

- Avoid Extreme Conditions: Avoid using the SD Connect C4 in extreme temperatures or high humidity.

8. Maintenance and Best Practices

Proper maintenance and adherence to best practices can significantly extend the lifespan of the SD Connect C4 and minimize the risk of failures.

8.1. Regular Maintenance Tasks

- Software Updates: Keep the diagnostic software and drivers updated to the latest versions.

- Firmware Updates: Update the firmware as needed, but exercise caution to avoid corruption.

- Visual Inspections: Regularly inspect the interface for any signs of damage or corrosion.

- Cleaning: Clean the interface regularly to remove dust and debris.

8.2. Best Practices for Using SD Connect C4

- Stable Power Supply: Use a stable power supply to avoid voltage fluctuations.

- Proper Ventilation: Ensure adequate ventilation to prevent overheating.

- Safe Handling: Handle the interface carefully to avoid physical damage.

- Correct Shutdown Procedure: Follow the correct shutdown procedure to prevent data corruption.

8.3. Extend the Life of Your SD Connect C4

- Invest in Quality Components: Replace faulty components with high-quality equivalents.

- Provide Adequate Cooling: Improve cooling with heat sinks or fans.

- Protect from Environment: Protect the interface from extreme temperatures and humidity.

- Follow Maintenance Schedule: Adhere to a regular maintenance schedule to identify and address potential problems early.

9. Utilizing DTS-Monaco for Advanced Diagnostics

While addressing hardware failure points is crucial, leveraging advanced diagnostic software like DTS-Monaco can significantly enhance your ability to troubleshoot and repair Mercedes-Benz vehicles. DTS-Monaco allows for in-depth ECU programming, coding, and diagnostics, providing capabilities beyond standard diagnostic tools.

9.1. What is DTS-Monaco?

DTS-Monaco is a powerful diagnostic and engineering software used for Mercedes-Benz vehicles. It enables advanced functions such as ECU flashing, coding, and parameter adjustments. According to Mercedes-Benz AG’s official documentation, DTS-Monaco is designed for engineers and specialists who require deep access to vehicle systems.

9.2. How DTS-Monaco Aids in Diagnostics

- Detailed ECU Analysis: DTS-Monaco provides detailed information about ECU configurations, software versions, and parameters, aiding in identifying discrepancies and potential issues.

- Coding and Programming: Allows for coding and programming of ECUs to resolve software glitches or enable new features.

- Diagnostic Routines: Offers advanced diagnostic routines to pinpoint specific problems within the vehicle’s electronic systems.

- Data Logging: Enables data logging for real-time monitoring of ECU parameters, helping to diagnose intermittent issues.

9.3. Benefits of Using DTS-Monaco with a Reliable SD Connect C4

When paired with a reliable SD Connect C4 interface, DTS-Monaco becomes an indispensable tool for advanced diagnostics and repairs. The stability of the interface ensures that the software can communicate effectively with the vehicle’s ECUs, providing accurate and reliable results.

- Enhanced Troubleshooting: Faster and more accurate identification of problems.

- Expanded Repair Capabilities: Ability to perform complex coding and programming tasks.

- Improved Efficiency: Streamlined diagnostic process, saving time and resources.

9.4. Learning DTS-Monaco with DTS-MONACO.EDU.VN

To fully leverage the capabilities of DTS-Monaco, consider enrolling in training programs offered by DTS-MONACO.EDU.VN. These programs provide comprehensive instruction on using the software, covering everything from basic diagnostics to advanced coding techniques.

- Comprehensive Training: Structured courses covering all aspects of DTS-Monaco.

- Expert Instructors: Experienced professionals providing hands-on training and guidance.

- Practical Exercises: Real-world scenarios and practical exercises to reinforce learning.

- Certification: Certification upon completion of the program, demonstrating proficiency in using DTS-Monaco.

10. Case Studies and Real-World Examples

Examining real-world examples of SD Connect C4 failures can provide valuable insights into common issues and effective repair strategies.

10.1. Case Study 1: Relay Failure

- Problem: An SD Connect C4 clone exhibited intermittent communication issues.

- Diagnosis: Visual inspection revealed a burnt relay. Multimeter testing confirmed the relay was faulty.

- Solution: The relay was replaced with a high-quality equivalent, restoring normal operation.

10.2. Case Study 2: WiFi Module Issues

- Problem: An SD Connect C4 clone had poor WiFi signal strength and frequent disconnections.

- Diagnosis: Driver updates did not resolve the issue. Hardware inspection revealed a poorly connected antenna.

- Solution: The WiFi module was replaced with an external USB WiFi adapter, providing a stable wireless connection.

10.3. Case Study 3: Power Supply Problems

- Problem: An SD Connect C4 clone would randomly shut down during diagnostic procedures.

- Diagnosis: Voltage measurements revealed unstable output from the power supply.

- Solution: The power supply components were replaced with higher-quality regulators, resolving the stability issues.

10.4. Case Study 4: PCB Damage

- Problem: An SD Connect C4 clone stopped working after being dropped.

- Diagnosis: Visual inspection revealed a cracked PCB. Continuity testing confirmed broken traces.

- Solution: The damaged traces were repaired using conductive epoxy, restoring the PCB’s functionality.

11. Future Trends in Automotive Diagnostics

The field of automotive diagnostics is constantly evolving, with new technologies and techniques emerging to address the increasing complexity of modern vehicles. Staying informed about these trends is essential for automotive technicians.

11.1. Advancements in Diagnostic Tools

- Artificial Intelligence (AI): AI-powered diagnostic tools can analyze vast amounts of data to identify patterns and predict potential failures.

- Cloud-Based Diagnostics: Cloud-based platforms provide access to real-time data, remote diagnostics, and software updates.

- Augmented Reality (AR): AR technology can overlay diagnostic information onto the vehicle, providing technicians with visual guidance.

- Remote Diagnostics: Remote diagnostic tools enable technicians to diagnose and repair vehicles from a distance.

11.2. The Role of Car Coding in Future Repairs

Car coding is becoming increasingly important in automotive repairs, as it allows technicians to customize vehicle settings, enable new features, and resolve software glitches. According to a report by McKinsey & Company, car coding will be a critical skill for automotive technicians in the future.

11.3. Staying Ahead with DTS-MONACO.EDU.VN

DTS-MONACO.EDU.VN is committed to providing automotive technicians with the latest training and resources to stay ahead in the field of automotive diagnostics and car coding. Our comprehensive programs cover the latest technologies and techniques, ensuring that technicians are equipped to handle the challenges of modern vehicle repairs.

12. Frequently Asked Questions (FAQs)

12.1. What are the most common failure points in SD Connect C4 clones?

The most common failure points include relays, WiFi modules, power supplies, and PCB failures due to lower-quality components.

12.2. How can I diagnose a faulty relay in my SD Connect C4?

Perform a visual inspection for burn marks, use a multimeter to check coil resistance, and listen for a click sound when activating the relay.

12.3. What causes WiFi module issues in SD Connect C4 clones?

Common issues include poor signal strength, driver incompatibility, hardware defects, and encryption problems.

12.4. How can I fix power-related problems in my SD Connect C4?

Measure voltage outputs for stability, monitor component temperatures, visually inspect for burnt components, and use a reliable power adapter.

12.5. What are the signs of PCB failure in an SD Connect C4?

Look for physical damage, corrosion, and poor soldering. Use a multimeter to test trace continuity.

12.6. What software and firmware issues can affect the SD Connect C4?

Incompatible software, corrupted firmware, driver problems, and activation issues are common.

12.7. How do environmental factors impact the reliability of the SD Connect C4?

Extreme temperatures, humidity, and physical shock can damage components and cause failures.

12.8. What maintenance practices can extend the lifespan of my SD Connect C4?

Keep software updated, inspect for damage, clean regularly, and store in a controlled environment.

12.9. How can DTS-Monaco help with advanced diagnostics?

DTS-Monaco allows for detailed ECU analysis, coding, programming, and diagnostic routines beyond standard tools.

12.10. Where can I learn more about using DTS-Monaco?

DTS-MONACO.EDU.VN offers comprehensive training programs covering all aspects of DTS-Monaco, ensuring proficiency in advanced diagnostics and car coding.

Conclusion

Troubleshooting SD Connect C4 interface failures, particularly in clones, requires a thorough understanding of common failure points such as relays, WiFi modules, power issues, and PCB failures. By following the diagnostic and repair tips outlined in this article, automotive technicians can effectively maintain their diagnostic tools and minimize downtime. Moreover, leveraging advanced diagnostic software like DTS-Monaco, especially with training from DTS-MONACO.EDU.VN, can significantly enhance diagnostic capabilities and repair efficiency.

relay-diagram

relay-diagram

By staying informed and proactive, technicians can ensure they are well-equipped to handle the challenges of modern automotive diagnostics and car coding, optimizing their performance and service quality.

Are you ready to elevate your automotive diagnostic skills? Visit DTS-MONACO.EDU.VN today to explore our comprehensive training programs, software solutions, and expert support. Unlock the full potential of DTS-Monaco and transform your approach to car coding and advanced diagnostics! Contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880 or visit our Website: DTS-MONACO.EDU.VN.