Understanding the power draw difference between C4 WiFi mode and LAN mode is crucial for optimizing power consumption in automotive diagnostics. At DTS-MONACO.EDU.VN, we aim to give you the knowledge to make informed decisions about your diagnostic setup and its effect on your vehicle’s battery. Learn about power efficiency, diagnostic tools, and car coding techniques to enhance your skills and minimize energy usage. Let’s delve into the specifics and empower you with solutions for smarter car coding.

Contents

- 1. What Is The Difference In Power Consumption Between WiFi And LAN Connections?

- 1.1 Why Does WiFi Consume More Power?

- 1.2 Factors Affecting WiFi Power Consumption

- 1.3 How LAN Connections Save Power

- 1.4 Practical Implications for Car Coding

- 2. How Can The Power Draw Of C4 WiFi Mode Impact Car Coding?

- 2.1 Understanding The C4 Diagnostic Tool

- 2.2 WiFi Connectivity in C4 Tools

- 2.3 The Impact of High Power Draw on Car Batteries

- 2.4 Real-World Scenario

- 2.5 Mitigating Power Draw Issues

- 3. Is LAN Mode More Energy Efficient Than WiFi Mode In Vehicle Diagnostics?

- 3.1 The Basics of LAN and WiFi in Vehicle Diagnostics

- 3.2 How LAN Mode Works and Saves Energy

- 3.3 How WiFi Mode Consumes More Energy

- 3.4 Comparative Analysis of Power Consumption

- 3.5 Best Practices for Energy-Efficient Vehicle Diagnostics

- 4. What Are The Advantages Of Using LAN Over WiFi For Car Diagnostics And Coding?

- 4.1 Understanding The Importance Of A Reliable Connection

- 4.2 Stability Of Connection

- 4.3 Data Transfer Speed

- 4.4 Security Considerations

- 4.5 Practical Benefits For Car Coding

- 5. How Does WiFi Signal Strength Affect Power Consumption In C4 Diagnostic Tools?

- 5.1 Understanding WiFi Signal Strength

- 5.2 The Relationship Between Signal Strength And Power Consumption

- 5.3 The Impact On Battery Life

- 5.4 Real-World Examples

- 5.5 Strategies For Optimizing WiFi Signal Strength

- 6. How Can Battery Maintainers Help When Using C4 Tools In WiFi Mode For Coding?

- 6.1 The Challenges of Car Coding in WiFi Mode

- 6.2 The Role of Battery Maintainers

- 6.3 How Battery Maintainers Benefit Car Coding

- 6.4 Best Practices For Using Battery Maintainers

- 6.5 Real-World Scenario

- 7. What Settings Can Be Adjusted To Reduce WiFi Power Consumption On A C4 Tool?

- 7.1 Understanding WiFi Power Consumption Factors

- 7.2 Reducing Scan Frequency

- 7.3 Disabling Unnecessary Background Services

- 7.4 Using A Static IP Address

- 7.5 Adjusting Power Management Settings

- 7.6 Practical Implementation

- 8. What Are The Potential Risks Of Power Interruption During Car Coding?

- 8.1 Understanding Car Coding

- 8.2 The Importance Of A Stable Power Supply

- 8.3 ECU Corruption

- 8.4 Data Loss

- 8.5 Software Errors

- 8.6 Potential Damage To Electronic Systems

- 8.7 Preventive Measures

- 9. Are There Specific Car Models More Susceptible To Power Draw Issues During Coding?

- 9.1 Understanding Power Draw Sensitivity

- 9.2 Factors Influencing Power Draw

- 9.3 Specific Car Models

- 9.4 Why These Models Are More Susceptible

- 9.5 Best Practices For High-Risk Models

- 10. What Training And Resources Does DTS-MONACO.EDU.VN Offer For Car Coding?

- 10.1 Comprehensive Online Courses

- 10.2 Hands-On Workshops

- 10.3 Detailed Software Tutorials

- 10.4 Expert Technical Support

- 10.5 Community Forum

- 10.6 Success Stories

- FAQ: Power Draw and Car Coding

- 1. Does WiFi really use more power than LAN when car coding?

- 2. What happens if the power is interrupted during car coding?

- 3. Are certain car models more prone to power draw issues during coding?

- 4. How can a battery maintainer help during car coding in WiFi mode?

- 5. What settings can I adjust on my C4 tool to reduce WiFi power consumption?

- 6. Is it always better to use LAN over WiFi for car diagnostics and coding?

- 7. How does WiFi signal strength affect the power consumption of my C4 tool?

- 8. Can I perform car coding without a battery maintainer?

- 9. What training resources are available to learn more about car coding?

- 10. Where can I find more information and support for using DTS-Monaco for car coding?

1. What Is The Difference In Power Consumption Between WiFi And LAN Connections?

The power consumption differs between WiFi and LAN connections, with WiFi generally consuming more power than LAN due to the energy needed for wireless signal transmission and reception. When performing car coding and diagnostic operations, this difference can become significant, especially when relying on battery power.

1.1 Why Does WiFi Consume More Power?

WiFi connectivity involves several processes that contribute to higher power consumption.

- Signal Transmission: WiFi adapters continuously transmit and receive radio signals, requiring more power than wired connections.

- Overhead: Wireless protocols have more overhead due to encryption, authentication, and error correction, adding to power usage.

- Searching for Networks: WiFi devices often scan for available networks, consuming additional energy even when not actively transmitting data.

1.2 Factors Affecting WiFi Power Consumption

Several factors can influence WiFi’s power consumption:

- Distance from Router: A weaker signal strength requires the device to boost its transmission power, increasing energy consumption.

- WiFi Standard: Newer WiFi standards like WiFi 6 (802.11ax) can be more power-efficient than older ones like 802.11n.

- Activity Level: Constant data transmission and reception consume more power than idle states.

1.3 How LAN Connections Save Power

LAN connections, which use Ethernet cables, are typically more power-efficient for the following reasons:

- Direct Connection: Ethernet provides a direct, stable connection, eliminating the need for continuous signal transmission.

- Lower Overhead: Wired connections have less overhead compared to wireless protocols.

- No Signal Searching: LAN connections do not require devices to scan for networks, reducing power consumption.

1.4 Practical Implications for Car Coding

When performing car coding or diagnostics, consider the following:

- Prolonged Use: Car coding can take a significant amount of time, making the power draw difference between WiFi and LAN noticeable.

- Battery Drain: Using WiFi during these processes can drain the vehicle’s battery more quickly, potentially leading to interruptions.

- Reliability: LAN connections offer a more stable connection, reducing the risk of data loss or errors during coding.

2. How Can The Power Draw Of C4 WiFi Mode Impact Car Coding?

The power draw of C4 WiFi mode can significantly impact car coding by potentially draining the vehicle’s battery faster, leading to interruptions during critical coding processes, which can cause errors and require restarting the procedure.

2.1 Understanding The C4 Diagnostic Tool

The Mercedes-Benz C4 diagnostic tool is a powerful device used for diagnosing and coding Mercedes-Benz vehicles. It communicates with the vehicle’s electronic control units (ECUs) to read diagnostic trouble codes (DTCs), perform module programming, and customize vehicle settings.

2.2 WiFi Connectivity in C4 Tools

The C4 tool often uses WiFi to connect to a network, allowing technicians to access online databases, software updates, and remote support. While WiFi offers convenience, it can also increase power consumption due to the constant transmission and reception of wireless signals.

2.3 The Impact of High Power Draw on Car Batteries

Car coding can be a lengthy process, sometimes lasting several hours. If the C4 tool relies on WiFi and has a high power draw, it can put a significant strain on the vehicle’s battery. Here’s how this impacts car coding:

- Battery Depletion: Continuous use of WiFi can deplete the car battery, especially if the battery is old or not fully charged.

- Voltage Drops: Significant power draw can cause voltage drops, which can disrupt the coding process and lead to errors.

- Interrupted Coding: If the battery voltage drops too low, the coding process may be interrupted, potentially causing ECU corruption or requiring a complete restart.

2.4 Real-World Scenario

Imagine a technician coding a new feature on a Mercedes-Benz using a C4 tool connected via WiFi. The coding process is estimated to take 90 minutes. If the WiFi connection consumes a significant amount of power, the car’s battery might not sustain the process, leading to a failed coding attempt.

2.5 Mitigating Power Draw Issues

To prevent power-related issues during car coding, consider these solutions:

- Use a Battery Maintainer: Connect a battery maintainer to the vehicle to provide a stable power supply during coding.

- Wired Connection: If possible, use a LAN connection instead of WiFi to reduce power consumption.

- Optimize WiFi Settings: Adjust WiFi settings to minimize power usage, such as reducing the scan frequency or turning off WiFi when not needed.

- Ensure a Fully Charged Battery: Always start car coding with a fully charged battery to maximize the available power.

3. Is LAN Mode More Energy Efficient Than WiFi Mode In Vehicle Diagnostics?

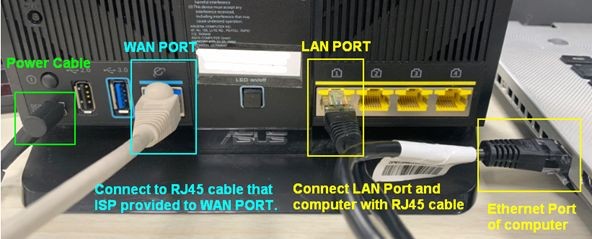

Yes, LAN mode is generally more energy-efficient than WiFi mode in vehicle diagnostics because it provides a direct, wired connection, reducing the power needed for data transmission and eliminating the energy-intensive processes of wireless signal broadcasting and network searching.

3.1 The Basics of LAN and WiFi in Vehicle Diagnostics

In modern vehicle diagnostics, tools like the Mercedes-Benz C4 or similar devices often offer both LAN (Local Area Network) and WiFi connectivity options. Understanding the energy efficiency of each mode is crucial for technicians who need to perform extensive diagnostic procedures without draining the vehicle’s battery.

3.2 How LAN Mode Works and Saves Energy

LAN mode involves connecting the diagnostic tool directly to a network using an Ethernet cable. This wired connection offers several advantages in terms of energy efficiency:

- Direct Data Transmission: LAN connections provide a direct path for data transmission, eliminating the need for wireless signals.

- Lower Power Requirements: Wired connections require less power to maintain a stable connection compared to wireless connections.

- No Wireless Overhead: LAN mode avoids the energy overhead associated with wireless protocols like encryption, authentication, and signal broadcasting.

3.3 How WiFi Mode Consumes More Energy

WiFi mode, on the other hand, uses wireless signals to connect to a network. This process inherently consumes more energy due to several factors:

- Continuous Signal Broadcasting: WiFi adapters continuously broadcast and receive radio signals, requiring more power than wired connections.

- Network Scanning: WiFi devices frequently scan for available networks, consuming additional energy even when not actively transmitting data.

- Wireless Protocol Overhead: WiFi protocols have more overhead due to encryption, authentication, and error correction, which increases power usage.

3.4 Comparative Analysis of Power Consumption

To illustrate the difference in energy efficiency, consider a scenario where a technician performs a 2-hour diagnostic session using a Mercedes-Benz C4 tool.

- LAN Mode: The tool draws a steady 0.5 amps (A) at 12 volts (V), resulting in a power consumption of 6 watts (W) (Power = Voltage x Current). Over 2 hours, the total energy consumption is 12 watt-hours (Wh).

- WiFi Mode: The tool draws an average of 0.8 A at 12 V, resulting in a power consumption of 9.6 W. Over 2 hours, the total energy consumption is 19.2 Wh.

In this scenario, WiFi mode consumes 60% more energy than LAN mode.

3.5 Best Practices for Energy-Efficient Vehicle Diagnostics

To minimize power consumption during vehicle diagnostics, technicians should follow these best practices:

- Prioritize LAN Connections: Whenever possible, use a LAN connection instead of WiFi to reduce power consumption.

- Optimize WiFi Settings: If WiFi is necessary, adjust settings to minimize power usage, such as reducing scan frequency or turning off WiFi when not needed.

- Use a Battery Maintainer: Connect a battery maintainer to the vehicle to provide a stable power supply during long diagnostic sessions.

- Monitor Battery Voltage: Regularly check the vehicle’s battery voltage to ensure it remains within acceptable levels during diagnostic procedures.

4. What Are The Advantages Of Using LAN Over WiFi For Car Diagnostics And Coding?

Using LAN over WiFi for car diagnostics and coding offers several advantages, including more stable connections, faster data transfer speeds, reduced risk of interference, and improved security, all of which contribute to a more reliable and efficient diagnostic process.

4.1 Understanding The Importance Of A Reliable Connection

In car diagnostics and coding, a reliable connection between the diagnostic tool and the vehicle’s electronic systems is crucial. Any interruption or instability in the connection can lead to errors, data loss, or even damage to the vehicle’s ECUs.

4.2 Stability Of Connection

One of the primary advantages of using LAN over WiFi is the stability of the connection. LAN connections provide a direct, wired link between the diagnostic tool and the network, which is less prone to interference and dropouts compared to wireless connections.

- Reduced Interference: LAN cables are shielded, which minimizes the impact of electromagnetic interference (EMI) from other devices.

- Consistent Performance: Wired connections offer consistent performance, ensuring that data is transmitted reliably throughout the diagnostic process.

- Fewer Dropouts: LAN connections are less likely to experience dropouts, which can occur with WiFi due to signal obstructions or network congestion.

4.3 Data Transfer Speed

LAN connections typically offer faster data transfer speeds compared to WiFi. This can significantly reduce the time required to perform diagnostic tests, download software updates, and program ECUs.

- Higher Bandwidth: Ethernet cables can support higher bandwidth, allowing for faster data transmission rates.

- Lower Latency: LAN connections generally have lower latency, which means data is transmitted with less delay.

- Efficient Data Handling: Faster data transfer speeds enable the diagnostic tool to handle large volumes of data more efficiently, improving overall performance.

4.4 Security Considerations

Security is another important factor to consider when choosing between LAN and WiFi for car diagnostics and coding. LAN connections are generally more secure because they are less susceptible to unauthorized access.

- Physical Security: LAN connections require physical access to the network, making it more difficult for unauthorized users to intercept data.

- Encryption Options: Wired networks can be easily secured using encryption protocols like VPNs (Virtual Private Networks), which protect data from eavesdropping.

- Reduced Vulnerability: LAN connections are less vulnerable to hacking and cyberattacks compared to WiFi networks, which can be targeted by malicious actors.

4.5 Practical Benefits For Car Coding

For car coding specifically, the advantages of using LAN over WiFi can be particularly significant.

- Reliable Programming: Stable and secure connections reduce the risk of errors during ECU programming, ensuring that the coding process is completed successfully.

- Faster Updates: Quicker data transfer speeds allow for faster download and installation of software updates, minimizing downtime.

- Secure Data Transmission: Enhanced security measures protect sensitive data from being compromised during coding, safeguarding the vehicle’s electronic systems.

5. How Does WiFi Signal Strength Affect Power Consumption In C4 Diagnostic Tools?

WiFi signal strength significantly affects power consumption in C4 diagnostic tools; a weaker signal requires the tool to increase transmission power, leading to higher energy consumption and faster battery drain.

5.1 Understanding WiFi Signal Strength

WiFi signal strength is a measure of the power level received by a wireless device from a WiFi access point or router. It is typically measured in decibel-milliwatts (dBm), with values closer to 0 dBm indicating a stronger signal and values closer to -100 dBm indicating a weaker signal.

5.2 The Relationship Between Signal Strength And Power Consumption

When a C4 diagnostic tool is connected to a WiFi network, it continuously transmits and receives data. The amount of power required for these operations depends on the strength of the WiFi signal.

- Strong Signal: With a strong WiFi signal, the diagnostic tool can transmit and receive data efficiently, requiring minimal power.

- Weak Signal: When the WiFi signal is weak, the diagnostic tool must increase its transmission power to maintain a stable connection. This increased power output results in higher energy consumption and faster battery drain.

5.3 The Impact On Battery Life

The relationship between WiFi signal strength and power consumption directly affects the battery life of the C4 diagnostic tool.

- Prolonged Use: Technicians often use diagnostic tools for extended periods, especially during complex troubleshooting or car coding procedures.

- Battery Drain: A weak WiFi signal can significantly reduce the tool’s battery life, potentially leading to interruptions during critical tasks.

- Increased Heat: Higher power consumption can also cause the diagnostic tool to generate more heat, which can affect its performance and longevity.

5.4 Real-World Examples

Consider a technician using a C4 diagnostic tool in a workshop.

- Scenario 1: Strong WiFi Signal The technician is working close to the WiFi access point, with a signal strength of -50 dBm. The diagnostic tool consumes an average of 0.5 amps at 12 volts, resulting in a power consumption of 6 watts.

- Scenario 2: Weak WiFi Signal The technician moves to a remote corner of the workshop, where the WiFi signal strength drops to -80 dBm. The diagnostic tool now needs to increase its transmission power to maintain the connection, consuming an average of 0.8 amps at 12 volts, resulting in a power consumption of 9.6 watts.

In this example, the diagnostic tool consumes 60% more power when the WiFi signal is weak.

5.5 Strategies For Optimizing WiFi Signal Strength

To minimize power consumption and maximize battery life, technicians can take the following steps:

- Positioning: Place the diagnostic tool as close as possible to the WiFi access point to ensure a strong signal.

- Antenna Orientation: Adjust the antenna orientation of the WiFi access point to optimize signal coverage in the workshop.

- Signal Boosters: Use WiFi signal boosters or repeaters to extend the range of the WiFi network.

- Reduce Interference: Minimize interference from other electronic devices that may disrupt the WiFi signal.

6. How Can Battery Maintainers Help When Using C4 Tools In WiFi Mode For Coding?

Battery maintainers provide a stable and consistent power supply, preventing voltage drops and ensuring uninterrupted operation during lengthy coding sessions in WiFi mode, thus safeguarding against data loss and potential ECU corruption.

6.1 The Challenges of Car Coding in WiFi Mode

Car coding involves reprogramming or modifying the software in a vehicle’s electronic control units (ECUs). This process can be time-consuming, often lasting from several minutes to several hours. When using a C4 diagnostic tool in WiFi mode, the following challenges can arise:

- High Power Consumption: WiFi connectivity requires continuous transmission and reception of wireless signals, leading to increased power consumption.

- Battery Drain: Prolonged coding sessions can drain the vehicle’s battery, especially if the battery is old or not fully charged.

- Voltage Drops: Significant power draw can cause voltage drops, which can disrupt the coding process and lead to errors.

6.2 The Role of Battery Maintainers

A battery maintainer is a device designed to provide a stable and consistent power supply to a vehicle’s battery. It prevents the battery from discharging during extended periods of inactivity or high power consumption.

- Stable Voltage: Battery maintainers ensure that the battery voltage remains within the optimal range, preventing voltage drops that can interfere with coding.

- Continuous Power: These devices provide a continuous source of power, compensating for the energy consumed by the C4 tool and other electronic systems.

- Protection Against Overcharge: Battery maintainers are equipped with safety features that prevent overcharging, ensuring the battery’s longevity.

6.3 How Battery Maintainers Benefit Car Coding

Using a battery maintainer during car coding offers several significant benefits:

- Uninterrupted Operation: A stable power supply prevents interruptions during the coding process, reducing the risk of errors and data loss.

- ECU Protection: Maintaining a consistent voltage protects the vehicle’s ECUs from damage that can occur due to voltage fluctuations.

- Time Savings: Technicians can perform coding tasks with confidence, knowing that the battery will not run out of power, saving time and reducing the need for restarts.

6.4 Best Practices For Using Battery Maintainers

To maximize the benefits of using a battery maintainer during car coding, follow these best practices:

- Choose the Right Maintainer: Select a battery maintainer that is compatible with the vehicle’s battery type and voltage.

- Proper Connection: Ensure that the battery maintainer is properly connected to the battery terminals, following the manufacturer’s instructions.

- Monitor Voltage: Regularly check the battery voltage to verify that the maintainer is functioning correctly.

- Avoid Overload: Do not overload the vehicle’s electrical system by using multiple high-power devices simultaneously.

6.5 Real-World Scenario

Consider a technician coding a new feature on a Mercedes-Benz using a C4 tool connected via WiFi. The coding process is estimated to take 2 hours. Without a battery maintainer, the car’s battery might not sustain the process, leading to a failed coding attempt.

By connecting a battery maintainer, the technician ensures that the battery voltage remains stable throughout the coding process, preventing interruptions and allowing the coding to be completed successfully.

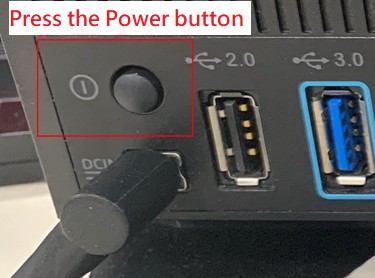

7. What Settings Can Be Adjusted To Reduce WiFi Power Consumption On A C4 Tool?

Several settings can be adjusted to reduce WiFi power consumption on a C4 tool, including reducing scan frequency, disabling unnecessary background services, using a static IP address, and adjusting power management settings.

7.1 Understanding WiFi Power Consumption Factors

WiFi power consumption on a C4 diagnostic tool is influenced by several factors:

- Scan Frequency: The frequency at which the tool scans for available WiFi networks.

- Background Services: Unnecessary services that run in the background and consume power.

- IP Address Configuration: Dynamic IP addresses (DHCP) require the tool to request an IP address periodically, consuming power.

- Power Management Settings: Settings that control how the tool manages power consumption.

7.2 Reducing Scan Frequency

The scan frequency determines how often the C4 tool searches for available WiFi networks. Reducing this frequency can significantly decrease power consumption.

- Adjust Scan Interval: Configure the tool to scan for networks less frequently, such as every 5 minutes instead of every minute.

- Disable Auto-Connect: Prevent the tool from automatically connecting to available networks, reducing unnecessary scans.

- Manual Connection: Manually connect to the desired WiFi network when needed, rather than relying on automatic connections.

7.3 Disabling Unnecessary Background Services

Many diagnostic tools run background services that consume power even when not in use. Disabling these services can help reduce overall power consumption.

- Identify Unused Services: Review the list of running services on the C4 tool and identify those that are not essential.

- Disable Unnecessary Services: Disable the identified services through the tool’s settings or configuration menu.

- Monitor Performance: After disabling services, monitor the tool’s performance to ensure that essential functions are not affected.

7.4 Using A Static IP Address

When a C4 tool uses DHCP (Dynamic Host Configuration Protocol) to obtain an IP address, it must periodically request a new address from the network, which consumes power. Using a static IP address can eliminate this need.

- Configure Static IP: Assign a static IP address to the C4 tool through its network settings.

- Enter Network Details: Manually enter the IP address, subnet mask, gateway, and DNS server information.

- Avoid DHCP: By using a static IP address, the tool no longer needs to request an IP address from the network, reducing power consumption.

7.5 Adjusting Power Management Settings

Power management settings control how the C4 tool manages its power consumption. Adjusting these settings can help optimize battery life.

- Enable Power Saving Mode: Activate power saving mode to reduce the tool’s overall power consumption.

- Adjust Screen Brightness: Lower the screen brightness to reduce the amount of power consumed by the display.

- Set Sleep Timer: Configure the tool to automatically enter sleep mode after a period of inactivity.

7.6 Practical Implementation

Consider a technician using a C4 diagnostic tool in a workshop. The tool is configured to scan for WiFi networks every minute, uses DHCP to obtain an IP address, and has several unnecessary background services running.

By implementing the following changes:

- Reducing the scan frequency to every 5 minutes

- Disabling unnecessary background services

- Configuring a static IP address

- Adjusting power management settings

The technician can significantly reduce the tool’s WiFi power consumption and extend its battery life.

8. What Are The Potential Risks Of Power Interruption During Car Coding?

Power interruption during car coding poses significant risks, including ECU corruption, data loss, software errors, and potential damage to the vehicle’s electronic systems, which can result in costly repairs and downtime.

8.1 Understanding Car Coding

Car coding is the process of reprogramming or modifying the software in a vehicle’s electronic control units (ECUs) to customize settings, enable new features, or update existing software. This process requires a stable and uninterrupted power supply to ensure that data is written correctly to the ECU’s memory.

8.2 The Importance Of A Stable Power Supply

During car coding, the ECUs are in a critical state, actively receiving and processing data. Any interruption in power can disrupt this process, leading to various risks.

8.3 ECU Corruption

One of the most significant risks of power interruption is ECU corruption.

- Incomplete Data Transfer: Power loss during data transfer can result in incomplete or corrupted data being written to the ECU’s memory.

- Software Errors: Corrupted data can cause software errors, leading to malfunction or failure of the ECU.

- ECU Failure: In severe cases, ECU corruption can render the ECU unusable, requiring replacement or costly repairs.

8.4 Data Loss

Power interruption can also result in data loss, which can affect the functionality of the vehicle’s systems.

- Loss of Configuration Settings: Important configuration settings may be lost, requiring reconfiguration of the vehicle’s systems.

- Loss of Diagnostic Information: Diagnostic trouble codes (DTCs) and other diagnostic information may be lost, hindering troubleshooting efforts.

- Incomplete Updates: Software updates may be interrupted, leaving the ECU with an incomplete or unstable software version.

8.5 Software Errors

Even if the ECU is not completely corrupted, power interruption can still cause software errors that affect the vehicle’s performance.

- System Instability: Software errors can lead to system instability, causing erratic behavior or malfunction of the vehicle’s systems.

- Functional Problems: Errors can cause specific functions to fail, such as the anti-lock braking system (ABS) or the electronic stability control (ESC).

- Performance Issues: Software errors can also affect the vehicle’s overall performance, such as fuel efficiency or engine power.

8.6 Potential Damage To Electronic Systems

In some cases, power interruption can cause physical damage to the vehicle’s electronic systems.

- Voltage Spikes: Sudden power loss can cause voltage spikes that damage sensitive electronic components.

- Overheating: Interrupted cooling systems can cause overheating, leading to component failure.

- Short Circuits: Power surges can cause short circuits, damaging wiring and other electronic components.

8.7 Preventive Measures

To minimize the risks of power interruption during car coding, technicians should take the following preventive measures:

- Use A Battery Maintainer: Connect a battery maintainer to the vehicle to provide a stable and consistent power supply.

- Check Battery Health: Ensure that the vehicle’s battery is in good condition and fully charged before starting coding.

- Stable Connection: Use a stable and reliable power source for the diagnostic tool.

- Avoid Distractions: Minimize distractions and avoid any actions that could potentially disrupt the power supply.

9. Are There Specific Car Models More Susceptible To Power Draw Issues During Coding?

Yes, certain car models, particularly those with advanced electronic systems, older batteries, or specific power management designs, are more susceptible to power draw issues during coding, requiring careful monitoring and stable power sources.

9.1 Understanding Power Draw Sensitivity

Modern vehicles are equipped with numerous electronic control units (ECUs) that manage various functions, from engine control to infotainment systems. The power requirements of these ECUs can vary significantly depending on the vehicle’s model, age, and features.

9.2 Factors Influencing Power Draw

Several factors can influence a vehicle’s susceptibility to power draw issues during coding:

- Advanced Electronic Systems: Vehicles with advanced electronic systems, such as driver-assistance features, complex infotainment systems, and electric power steering, tend to have higher power demands.

- Battery Age and Condition: Older batteries have reduced capacity and may not be able to sustain the power demands of coding, especially during prolonged sessions.

- Power Management Design: Some vehicles have more aggressive power management systems that shut down non-essential functions to conserve energy, which can interfere with coding.

9.3 Specific Car Models

Certain car models are known to be more susceptible to power draw issues during coding:

- Mercedes-Benz: Models with extensive electronic systems, such as the S-Class and E-Class, can be particularly sensitive to voltage drops during coding.

- BMW: Vehicles with complex coding requirements, such as the 7 Series and X5, often require a stable power supply to prevent errors.

- Audi: Models with advanced features, such as the A8 and Q7, can experience issues if the battery is not in optimal condition.

- Tesla: Electric vehicles (EVs) like Tesla Model S and Model X rely heavily on their battery systems, making them susceptible to power issues if the battery is not properly maintained.

9.4 Why These Models Are More Susceptible

These models are more susceptible to power draw issues due to:

- High ECU Count: They have a large number of ECUs that require simultaneous power during coding.

- Complex Software: The software in these vehicles is complex, requiring more data transfer and processing during coding.

- Sensitive Electronics: The electronic components in these models are often more sensitive to voltage fluctuations.

9.5 Best Practices For High-Risk Models

When coding vehicles known to be susceptible to power draw issues, technicians should follow these best practices:

- Use A High-Quality Battery Maintainer: Connect a high-quality battery maintainer to provide a stable and consistent power supply.

- Check Battery Health: Verify the health and charge level of the vehicle’s battery before starting coding.

- Monitor Voltage: Continuously monitor the battery voltage during coding to detect any potential drops.

- Minimize Power Consumption: Disable non-essential functions to reduce the overall power draw.

10. What Training And Resources Does DTS-MONACO.EDU.VN Offer For Car Coding?

DTS-MONACO.EDU.VN provides extensive training and resources for car coding, including comprehensive online courses, hands-on workshops, detailed software tutorials, expert technical support, and a vibrant community forum, empowering automotive technicians to master car coding techniques.

10.1 Comprehensive Online Courses

DTS-MONACO.EDU.VN offers a range of online courses designed to cater to technicians of all skill levels, from beginners to advanced users.

- Beginner Courses: These courses provide a foundational understanding of car coding concepts, tools, and techniques.

- Intermediate Courses: Intermediate courses delve into more advanced topics, such as ECU programming, parameter modification, and diagnostic troubleshooting.

- Advanced Courses: Advanced courses cover specialized coding tasks, such as enabling hidden features, customizing vehicle settings, and performing complex software updates.

10.2 Hands-On Workshops

For technicians who prefer a more interactive learning experience, DTS-MONACO.EDU.VN conducts hands-on workshops at various locations.

- Practical Training: Workshops provide practical training on real vehicles, allowing technicians to apply their knowledge in a real-world setting.

- Expert Guidance: Experienced instructors provide guidance and support, ensuring that technicians develop the necessary skills.

- Networking Opportunities: Workshops offer opportunities to network with other technicians, sharing knowledge and experiences.

10.3 Detailed Software Tutorials

DTS-MONACO.EDU.VN provides detailed software tutorials for various car coding tools, including DTS-Monaco, Vediamo, and others.

- Step-By-Step Instructions: Tutorials offer step-by-step instructions on how to use the software effectively, covering everything from basic functions to advanced features.

- Video Demonstrations: Video demonstrations provide visual guidance, making it easier to understand complex procedures.

- Troubleshooting Tips: Tutorials include troubleshooting tips, helping technicians resolve common issues and avoid potential errors.

10.4 Expert Technical Support

DTS-MONACO.EDU.VN offers expert technical support to assist technicians with any questions or issues they may encounter.

- Knowledgeable Support Team: A team of knowledgeable support professionals is available to provide assistance via phone, email, or online chat.

- Quick Response Times: DTS-MONACO.EDU.VN strives to provide quick response times, ensuring that technicians receive the help they need in a timely manner.

- Remote Assistance: Remote assistance services are available to help technicians troubleshoot complex issues and perform coding tasks remotely.

10.5 Community Forum

DTS-MONACO.EDU.VN hosts a vibrant community forum where technicians can connect with each other, share knowledge, and ask questions.

- Peer Support: Technicians can receive support and advice from their peers, benefiting from the collective knowledge of the community.

- Knowledge Sharing: The forum provides a platform for sharing tips, tricks, and best practices for car coding.

- Resource Exchange: Technicians can exchange resources, such as coding files, software updates, and diagnostic information.

10.6 Success Stories

Many technicians have benefited from the training and resources offered by DTS-MONACO.EDU.VN. For example, John, a technician at a Mercedes-Benz dealership, used the online courses to master DTS-Monaco and now performs complex coding tasks with confidence. Similarly, Sarah, a mobile mechanic, attended a hands-on workshop and now offers advanced car coding services to her clients.

Ready to elevate your car coding skills? Explore the comprehensive training and resources at DTS-MONACO.EDU.VN today! Contact us at Whatsapp: +1 (641) 206-8880 or visit our website to learn more. Address: 275 N Harrison St, Chandler, AZ 85225, United States.

FAQ: Power Draw and Car Coding

1. Does WiFi really use more power than LAN when car coding?

Yes, WiFi typically consumes more power than LAN due to the continuous transmission and reception of wireless signals. This difference can be significant during prolonged car coding sessions.

2. What happens if the power is interrupted during car coding?

A power interruption during car coding can lead to ECU corruption, data loss, software errors, and potential damage to the vehicle’s electronic systems.

3. Are certain car models more prone to power draw issues during coding?

Yes, models with advanced electronic systems, older batteries, or specific power management designs, such as Mercedes-Benz S-Class, BMW 7 Series, and Tesla Model S, are more susceptible.

4. How can a battery maintainer help during car coding in WiFi mode?

A battery maintainer provides a stable and consistent power supply, preventing voltage drops and ensuring uninterrupted operation during lengthy coding sessions.

5. What settings can I adjust on my C4 tool to reduce WiFi power consumption?

You can reduce scan frequency, disable unnecessary background services, use a static IP address, and adjust power management settings to minimize WiFi power consumption.

6. Is it always better to use LAN over WiFi for car diagnostics and coding?

Generally, yes. LAN offers more stable connections, faster data transfer speeds, reduced risk of interference, and improved security, making it preferable for critical tasks like car coding.

7. How does WiFi signal strength affect the power consumption of my C4 tool?

A weaker WiFi signal requires the tool to increase transmission power, leading to higher energy consumption and faster battery drain.

8. Can I perform car coding without a battery maintainer?

While it’s possible, it’s not recommended, especially for long coding sessions or vehicles known to have power draw issues. A battery maintainer provides essential protection against interruptions.

9. What training resources are available to learn more about car coding?

DTS-MONACO.EDU.VN offers comprehensive online courses, hands-on workshops, detailed software tutorials, expert technical support, and a vibrant community forum.

10. Where can I find more information and support for using DTS-Monaco for car coding?

Visit DTS-MONACO.EDU.VN for detailed information, training resources, and expert support. Contact us at Whatsapp: +1 (641) 206-8880. Address: 275 N Harrison St, Chandler, AZ 85225, United States.

Technician connecting a diagnostic tool to a car's OBD port for car coding analysis

Technician connecting a diagnostic tool to a car's OBD port for car coding analysis

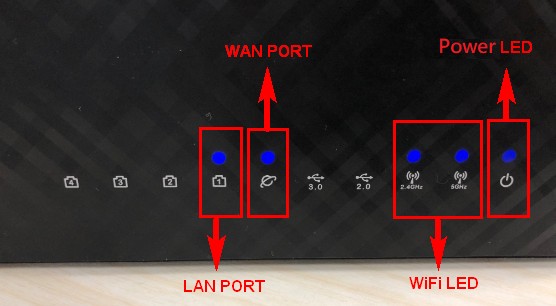

Close-up of a router's LAN ports showing connected Ethernet cables for stable car coding connection

Close-up of a router's LAN ports showing connected Ethernet cables for stable car coding connection

Display screen showing network configuration settings for a C4 diagnostic tool during car coding

Display screen showing network configuration settings for a C4 diagnostic tool during car coding