Which Mercedes models demand a DoIP-capable interface like the C6 for diagnostics and programming? This is a crucial question for automotive technicians. DTS-MONACO.EDU.VN is here to clarify which Mercedes-Benz vehicles necessitate this advanced interface, particularly focusing on models like the W223, W206, and newer EVs. Understanding DoIP protocol and its applications is essential for performing effective car coding, flash programming, and advanced diagnostic tasks on modern Mercedes-Benz vehicles.

Contents

- 1. What is DoIP and Why is it Important for Mercedes-Benz Diagnostics?

- 1.1 How Does DoIP Work?

- 1.2 Benefits of Using DoIP

- 1.3 Why is a DoIP Interface Necessary for Some Mercedes-Benz Models?

- 2. Which Mercedes-Benz Models Require a DoIP Interface?

- 2.1 Specific Mercedes-Benz Models Requiring DoIP

- 2.2 Identifying DoIP Requirement by Model Year

- 2.3 How to Confirm if a Mercedes-Benz Model Needs DoIP

- 3. Understanding DoIP-Compatible Diagnostic Tools: VXDIAG C6 and Alternatives

- 3.1 What is VXDIAG C6?

- 3.2 Key Features of VXDIAG C6

- 3.3 Alternatives to VXDIAG C6

- 3.4 Choosing the Right DoIP Interface

- 4. Setting Up and Using a DoIP Interface with Mercedes-Benz Vehicles

- 4.1 Initial Setup

- 4.2 Connecting to the Vehicle

- 4.3 Performing Diagnostic Tests

- 4.4 ECU Programming and Coding

- 4.5 Best Practices for DoIP Interface Use

- 5. Common Issues and Troubleshooting with DoIP Interfaces

- 5.1 Communication Errors

- 5.2 Software Installation Issues

- 5.3 Programming Failures

- 5.4 DoIP-Specific Issues

- 5.5 Seeking Expert Assistance

- 6. Staying Updated with the Latest Mercedes-Benz Diagnostic Technologies

- 6.1 Continuous Learning

- 6.2 Software and Firmware Updates

- 6.3 Industry Events and Trade Shows

- 7. The Role of DTS-MONACO in Advanced Mercedes-Benz Diagnostics and Car Coding

- 7.1 What is DTS-MONACO?

- 7.2 Key Features of DTS-MONACO

- 7.3 Using DTS-MONACO with a DoIP Interface

- 7.4 Learning DTS-MONACO

- 7.5 Benefits of Mastering DTS-MONACO

- 8. Car Coding with DTS-MONACO: Unlocking Hidden Features and Customizations

- 8.1 What is Car Coding?

- 8.2 Common Car Coding Applications

- 8.3 Tools and Equipment for Car Coding

- 8.4 Car Coding Procedures

- 8.5 Safety Precautions for Car Coding

- 9. The Importance of Proper Training and Certification for Automotive Technicians

- 9.1 Benefits of Training and Certification

- 9.2 Automotive Training Programs

- 9.3 Automotive Certifications

- 9.4 Maintaining Certification

- 10. Future Trends in Mercedes-Benz Diagnostics and Programming

- 10.1 Over-the-Air (OTA) Updates

- 10.2 Artificial Intelligence (AI) in Diagnostics

- 10.3 Cybersecurity

- 10.4 Electric Vehicle (EV) Technology

- 10.5 Augmented Reality (AR) in Repair

- Frequently Asked Questions (FAQ) About DoIP and Mercedes-Benz Diagnostics

- 1. What is DoIP, and why is it important for Mercedes-Benz vehicles?

- 2. Which Mercedes-Benz models require a DoIP-capable interface?

- 3. What is the VXDIAG C6, and how does it help with Mercedes-Benz diagnostics?

- 4. Are there alternatives to the VXDIAG C6 for DoIP diagnostics on Mercedes-Benz vehicles?

- 5. How do I set up a DoIP interface for use with Mercedes-Benz vehicles?

- 6. What are some common issues I might encounter when using a DoIP interface, and how can I troubleshoot them?

- 7. What is DTS-MONACO, and how is it used in advanced Mercedes-Benz diagnostics and car coding?

- 8. What is car coding, and how can it be used to customize Mercedes-Benz vehicles?

- 9. Why is proper training and certification important for automotive technicians working on Mercedes-Benz vehicles?

- 10. What are some future trends in Mercedes-Benz diagnostics and programming that I should be aware of?

1. What is DoIP and Why is it Important for Mercedes-Benz Diagnostics?

DoIP, or Diagnostics over Internet Protocol, is a communication standard increasingly used in modern vehicles, including Mercedes-Benz. DoIP is vital because it allows for faster and more efficient data transfer compared to older protocols like CAN (Controller Area Network). This is particularly important for tasks like ECU flashing, diagnostics, and module programming in newer Mercedes-Benz models.

1.1 How Does DoIP Work?

DoIP works by using Ethernet as the physical layer for communication between diagnostic tools and vehicle ECUs (Electronic Control Units). According to research from the Society of Automotive Engineers (SAE), DoIP provides a standardized approach for vehicle diagnostics, enabling faster data transfer rates and improved security. This is especially beneficial for handling the large amounts of data involved in modern vehicle systems, where multiple ECUs communicate complex information.

1.2 Benefits of Using DoIP

- Faster Data Transfer: DoIP significantly reduces the time required for flashing and programming ECUs.

- Enhanced Security: DoIP includes security measures to protect against unauthorized access and tampering.

- Improved Diagnostics: DoIP supports advanced diagnostic functions, allowing technicians to identify and resolve complex issues more effectively.

- Future-Proofing: As vehicles become more complex and software-driven, DoIP ensures compatibility with future technologies.

1.3 Why is a DoIP Interface Necessary for Some Mercedes-Benz Models?

Certain Mercedes-Benz models, especially those manufactured from around 2018 onwards, utilize DoIP for their diagnostic and programming interfaces. Without a DoIP-capable interface like the VXDIAG C6 or similar, technicians cannot fully access and service these vehicles. This limitation is because older diagnostic tools that rely solely on CAN or other legacy protocols cannot communicate with the DoIP-enabled ECUs.

2. Which Mercedes-Benz Models Require a DoIP Interface?

Knowing which Mercedes-Benz models require a DoIP interface is essential for technicians aiming to provide comprehensive service. Generally, newer models, particularly those from 2018 onwards, are more likely to use DoIP.

2.1 Specific Mercedes-Benz Models Requiring DoIP

- W223 (S-Class, 2021+): The latest S-Class generation heavily relies on DoIP for diagnostics, programming, and advanced functions.

- W206 (C-Class, 2022+): The newest C-Class models also require DoIP for full access to their electronic systems.

- Newer Electric Vehicles (EVs): Mercedes-Benz EVs, such as the EQS, EQE, and EQC, use DoIP for battery management, motor control, and other EV-specific functions.

- Other Models: Many other recent models, including certain GLE, GLS, and E-Class variants, also incorporate DoIP.

2.2 Identifying DoIP Requirement by Model Year

A general guideline is that Mercedes-Benz models from 2018 onwards increasingly use DoIP. However, it’s crucial to verify the specific model and production date. Some models introduced in 2018 may have a mix of CAN and DoIP interfaces, depending on the specific ECU and function.

2.3 How to Confirm if a Mercedes-Benz Model Needs DoIP

- Consult the Vehicle’s Service Manual: The service manual will specify the required diagnostic protocols.

- Check the Diagnostic Port: Some vehicles have labels indicating DoIP support.

- Use a Diagnostic Tool with Auto-Detect Function: Modern diagnostic tools can automatically detect the communication protocol used by the vehicle.

- Contact Mercedes-Benz Technical Support: They can provide definitive information based on the VIN (Vehicle Identification Number).

3. Understanding DoIP-Compatible Diagnostic Tools: VXDIAG C6 and Alternatives

To work on Mercedes-Benz models that use DoIP, technicians need a compatible diagnostic tool. The VXDIAG C6 is a popular option, but several alternatives are available.

3.1 What is VXDIAG C6?

The VXDIAG C6 is a diagnostic interface designed for Mercedes-Benz vehicles. It supports both CAN and DoIP protocols, making it suitable for a wide range of models. According to VXDAS, a reputable supplier of automotive diagnostic tools, the VXDIAG C6 offers comprehensive diagnostic, programming, and coding capabilities for Mercedes-Benz vehicles.

VXDIAG VCX SE for Benz Diagnostic & Programming Tool Support Benz till 2020

VXDIAG VCX SE for Benz Diagnostic & Programming Tool Support Benz till 2020

3.2 Key Features of VXDIAG C6

- DoIP Support: Enables communication with newer Mercedes-Benz models.

- CAN Support: Compatible with older models that use CAN protocol.

- Comprehensive Diagnostics: Supports reading and clearing fault codes, live data streaming, and actuation tests.

- ECU Programming: Allows for flashing and programming ECUs.

- Coding and Adaptations: Supports personalization and adaptation of vehicle functions.

- Wi-Fi Connectivity: Offers wireless connectivity for convenient use.

- Software Compatibility: Works with Mercedes-Benz diagnostic software like XENTRY and DAS.

3.3 Alternatives to VXDIAG C6

- Mercedes-Benz eCOM: The official Mercedes-Benz diagnostic interface, offering full compatibility and access to all functions.

- Autel MaxiSys Elite II Pro: A high-end diagnostic tool that supports DoIP and a wide range of vehicle brands.

- Launch X431 V+: Another versatile diagnostic tool with DoIP support and extensive vehicle coverage.

- Other DoIP-Enabled Interfaces: Several other diagnostic tools from reputable brands also offer DoIP support.

3.4 Choosing the Right DoIP Interface

When selecting a DoIP interface, consider the following factors:

- Compatibility: Ensure the tool supports the specific Mercedes-Benz models you need to service.

- Functionality: Verify the tool offers the diagnostic, programming, and coding functions you require.

- Software Support: Check compatibility with Mercedes-Benz diagnostic software like XENTRY and DAS.

- User Reviews: Read reviews from other technicians to assess the tool’s reliability and ease of use.

- Cost: Compare the prices of different tools and consider the overall value they offer.

4. Setting Up and Using a DoIP Interface with Mercedes-Benz Vehicles

Proper setup and usage of a DoIP interface are crucial for successful diagnostics and programming.

4.1 Initial Setup

- Install Diagnostic Software: Install the necessary Mercedes-Benz diagnostic software, such as XENTRY or DAS, on your computer.

- Connect the Interface: Connect the DoIP interface to your computer via USB or Wi-Fi.

- Install Drivers: Install the drivers for the DoIP interface on your computer.

- Configure Software: Configure the diagnostic software to recognize the DoIP interface.

4.2 Connecting to the Vehicle

- Locate the Diagnostic Port: Find the OBD-II (On-Board Diagnostics II) port in the vehicle, typically located under the dashboard.

- Connect the Interface: Connect the DoIP interface to the OBD-II port.

- Turn on the Ignition: Turn the vehicle’s ignition to the “ON” position.

- Establish Communication: In the diagnostic software, select the vehicle model and initiate communication with the vehicle’s ECUs.

4.3 Performing Diagnostic Tests

- Read Fault Codes: Use the diagnostic software to read and record any stored fault codes.

- Interpret Fault Codes: Research the meaning of the fault codes and identify potential causes.

- Live Data: Monitor live data streams from various sensors and modules to assess vehicle performance.

- Actuation Tests: Perform actuation tests to verify the functionality of actuators and components.

4.4 ECU Programming and Coding

- Identify ECU: Determine the ECU that needs to be programmed or coded.

- Obtain Software Files: Obtain the correct software files for the ECU from Mercedes-Benz or a trusted source.

- Follow Programming Procedures: Follow the specific programming procedures outlined in the service manual or diagnostic software.

- Verify Programming: After programming, verify that the ECU is functioning correctly and that no new fault codes are present.

- Car Coding: Modify vehicle settings and parameters to customize vehicle functions according to customer preferences or specifications.

4.5 Best Practices for DoIP Interface Use

- Use a Stable Power Supply: Ensure a stable power supply to prevent interruptions during programming.

- Maintain a Reliable Network Connection: A stable network connection is crucial for online programming and coding.

- Follow Instructions Carefully: Always follow the instructions in the service manual or diagnostic software.

- Back Up Data: Before making any changes, back up the vehicle’s configuration data to prevent data loss.

- Stay Updated: Keep your diagnostic software and interface firmware updated to ensure compatibility and access to the latest features.

5. Common Issues and Troubleshooting with DoIP Interfaces

Even with the best equipment and practices, issues can arise when using DoIP interfaces. Knowing how to troubleshoot common problems is essential for efficient diagnostics and repairs.

5.1 Communication Errors

- Problem: The diagnostic tool cannot establish communication with the vehicle.

- Possible Causes:

- Incorrect interface configuration

- Faulty cable or connection

- Incorrect vehicle selection in the software

- ECU not responding

- Troubleshooting Steps:

- Verify interface configuration and drivers

- Check cable connections and replace if necessary

- Confirm the correct vehicle model is selected in the software

- Check the vehicle’s battery voltage

- Try connecting to a different ECU

5.2 Software Installation Issues

- Problem: The diagnostic software fails to install or run correctly.

- Possible Causes:

- Incompatible operating system

- Corrupted installation files

- Missing dependencies

- Firewall or antivirus interference

- Troubleshooting Steps:

- Ensure the operating system meets the software requirements

- Download the installation files again from a trusted source

- Install any missing dependencies

- Temporarily disable firewall and antivirus software during installation

- Run the software as an administrator

5.3 Programming Failures

- Problem: ECU programming fails to complete successfully.

- Possible Causes:

- Unstable power supply

- Interrupted network connection

- Incorrect software files

- ECU failure

- Troubleshooting Steps:

- Use a stable power supply

- Ensure a reliable network connection

- Verify the correct software files are being used

- Check the ECU for damage or malfunction

- Try programming the ECU again

5.4 DoIP-Specific Issues

- Problem: The DoIP interface cannot communicate with DoIP-enabled ECUs.

- Possible Causes:

- DoIP protocol not enabled in the software

- Incorrect DoIP settings

- Firmware incompatibility

- Troubleshooting Steps:

- Ensure DoIP protocol is enabled in the diagnostic software

- Verify the DoIP settings are correct

- Update the DoIP interface firmware

5.5 Seeking Expert Assistance

If you encounter persistent issues that you cannot resolve, seek assistance from experienced technicians or the diagnostic tool manufacturer. They can provide specialized support and guidance.

6. Staying Updated with the Latest Mercedes-Benz Diagnostic Technologies

The automotive industry is constantly evolving, with new technologies and diagnostic methods emerging regularly. Staying updated is essential for technicians to provide the best possible service.

6.1 Continuous Learning

- Attend Training Courses: Participate in training courses offered by Mercedes-Benz, diagnostic tool manufacturers, and industry organizations.

- Read Technical Publications: Stay informed by reading technical publications, service manuals, and diagnostic guides.

- Online Forums and Communities: Engage with online forums and communities of automotive technicians to share knowledge and experiences.

6.2 Software and Firmware Updates

- Regularly Update Software: Keep your diagnostic software updated to access the latest features, bug fixes, and vehicle coverage.

- Update Firmware: Update the firmware of your DoIP interface to ensure compatibility with new vehicle models and protocols.

6.3 Industry Events and Trade Shows

- Attend Trade Shows: Participate in industry events and trade shows to see the latest diagnostic tools and technologies.

- Network with Professionals: Network with other technicians and industry professionals to exchange ideas and learn about new developments.

7. The Role of DTS-MONACO in Advanced Mercedes-Benz Diagnostics and Car Coding

DTS-MONACO is a powerful engineering software used for advanced diagnostics, programming, and car coding in Mercedes-Benz vehicles.

7.1 What is DTS-MONACO?

DTS-MONACO (Diagnostic Tool Set – Mercedes-Benz Common Operation Application) is a software platform used by engineers and technicians for in-depth diagnostics, ECU flashing, and car coding. According to Mercedes-Benz, DTS-MONACO provides a comprehensive set of tools for accessing and modifying vehicle parameters.

7.2 Key Features of DTS-MONACO

- ECU Flashing: Allows for updating ECU software with the latest versions.

- Car Coding: Enables customization of vehicle functions and parameters.

- Advanced Diagnostics: Supports in-depth diagnostics and troubleshooting.

- Variant Coding: Allows for changing vehicle configurations to match specific requirements.

- Engineering Functions: Provides access to advanced engineering functions for vehicle development and testing.

7.3 Using DTS-MONACO with a DoIP Interface

DTS-MONACO can be used with a DoIP interface to perform advanced functions on newer Mercedes-Benz models. The DoIP interface provides the necessary communication speed and bandwidth for these tasks.

7.4 Learning DTS-MONACO

Mastering DTS-MONACO requires specialized training and expertise. Consider the following resources:

- Online Courses: Enroll in online courses that teach the fundamentals and advanced techniques of DTS-MONACO.

- Training Workshops: Attend hands-on training workshops to gain practical experience with the software.

- Expert Guidance: Seek guidance from experienced DTS-MONACO users and trainers.

7.5 Benefits of Mastering DTS-MONACO

- Enhanced Diagnostic Capabilities: Perform in-depth diagnostics and troubleshooting.

- Advanced Programming Skills: Update ECU software and customize vehicle functions.

- Increased Earning Potential: Offer specialized services that require DTS-MONACO expertise.

- Competitive Advantage: Stand out from other technicians with advanced skills and knowledge.

8. Car Coding with DTS-MONACO: Unlocking Hidden Features and Customizations

Car coding is a powerful technique that allows technicians to modify vehicle settings and parameters to customize functions and unlock hidden features.

8.1 What is Car Coding?

Car coding involves changing the software configuration of a vehicle’s ECUs to enable or disable certain features, adjust parameters, and personalize the driving experience. According to automotive coding experts, car coding can enhance vehicle performance, improve comfort, and add new functionalities.

8.2 Common Car Coding Applications

- Enabling Hidden Features: Activating features that are present in the vehicle’s software but not enabled by default, such as cornering lights, enhanced instrument cluster displays, and customized ambient lighting.

- Adjusting Vehicle Parameters: Modifying parameters such as throttle response, steering sensitivity, and suspension settings.

- Retrofitting Equipment: Coding the vehicle to recognize and properly function with newly installed equipment, such as aftermarket headlights, audio systems, and performance upgrades.

- Disabling Unwanted Features: Disabling features that are not desired by the vehicle owner, such as automatic start-stop systems and seatbelt reminders.

8.3 Tools and Equipment for Car Coding

- DTS-MONACO: The primary software for car coding on Mercedes-Benz vehicles.

- DoIP Interface: A compatible DoIP interface for communicating with the vehicle’s ECUs.

- Laptop Computer: A laptop computer with the necessary software and drivers installed.

- Stable Power Supply: A stable power supply to prevent interruptions during coding.

8.4 Car Coding Procedures

- Connect to the Vehicle: Connect the DoIP interface to the vehicle’s OBD-II port and establish communication with DTS-MONACO.

- Identify the ECU: Determine the ECU that needs to be coded.

- Read the Coding Data: Read the current coding data from the ECU.

- Modify the Coding Data: Modify the coding data to enable or disable features, adjust parameters, or configure new equipment.

- Write the Coding Data: Write the modified coding data back to the ECU.

- Verify the Changes: Verify that the changes have been applied correctly and that the vehicle is functioning as expected.

8.5 Safety Precautions for Car Coding

- Back Up Data: Always back up the vehicle’s original coding data before making any changes.

- Follow Instructions Carefully: Follow the coding instructions in DTS-MONACO or the service manual.

- Avoid Unnecessary Changes: Only make changes that are necessary and well-understood.

- Test the Changes: Thoroughly test the changes after coding to ensure they are functioning correctly.

- Seek Expert Assistance: If you are unsure about any aspect of car coding, seek assistance from experienced technicians.

9. The Importance of Proper Training and Certification for Automotive Technicians

Proper training and certification are essential for automotive technicians to provide high-quality service and stay updated with the latest technologies.

9.1 Benefits of Training and Certification

- Enhanced Skills and Knowledge: Training and certification programs provide technicians with the skills and knowledge they need to diagnose and repair modern vehicles.

- Increased Earning Potential: Certified technicians often earn higher salaries than non-certified technicians.

- Career Advancement Opportunities: Certification can open doors to career advancement opportunities, such as lead technician or service manager positions.

- Improved Job Security: Certified technicians are in high demand in the automotive industry.

- Professional Recognition: Certification demonstrates a commitment to professionalism and excellence.

9.2 Automotive Training Programs

- Vocational Schools: Vocational schools offer comprehensive training programs in automotive technology.

- Community Colleges: Community colleges provide associate degrees and certificate programs in automotive technology.

- Manufacturer-Specific Training: Automakers like Mercedes-Benz offer training programs specifically designed for their vehicles.

- Online Courses: Online courses offer flexible and convenient training options for technicians.

9.3 Automotive Certifications

- ASE Certification: ASE (Automotive Service Excellence) certification is the industry standard for automotive technicians in the United States.

- Manufacturer-Specific Certifications: Automakers offer certifications specifically for their vehicles, such as Mercedes-Benz Master Technician certification.

- Specialty Certifications: Certifications are available for specific areas of automotive technology, such as diagnostics, engine repair, and electrical systems.

9.4 Maintaining Certification

- Continuing Education: Technicians must complete continuing education requirements to maintain their certifications.

- Recertification Exams: Technicians must pass recertification exams to demonstrate their continued competence.

10. Future Trends in Mercedes-Benz Diagnostics and Programming

The field of Mercedes-Benz diagnostics and programming is constantly evolving, with new technologies and methods emerging regularly.

10.1 Over-the-Air (OTA) Updates

- Trend: Over-the-air (OTA) updates are becoming increasingly common in modern vehicles.

- Impact: OTA updates allow automakers to remotely update vehicle software, fix bugs, and add new features.

- Technician Role: Technicians will need to understand how OTA updates work and how to troubleshoot issues that may arise.

10.2 Artificial Intelligence (AI) in Diagnostics

- Trend: Artificial intelligence (AI) is being used to improve diagnostic accuracy and efficiency.

- Impact: AI-powered diagnostic tools can analyze vehicle data, identify patterns, and suggest potential causes of problems.

- Technician Role: Technicians will need to learn how to use AI-powered diagnostic tools and interpret their results.

10.3 Cybersecurity

- Trend: Cybersecurity is becoming increasingly important in the automotive industry.

- Impact: Modern vehicles are vulnerable to cyberattacks, which can compromise vehicle safety and security.

- Technician Role: Technicians will need to understand cybersecurity threats and how to protect vehicles from attacks.

10.4 Electric Vehicle (EV) Technology

- Trend: Electric vehicles (EVs) are becoming increasingly popular.

- Impact: EVs require specialized diagnostic and repair techniques.

- Technician Role: Technicians will need to learn about EV technology, including battery management systems, electric motors, and charging systems.

10.5 Augmented Reality (AR) in Repair

- Trend: Augmented reality (AR) is being used to enhance the repair process.

- Impact: AR can overlay digital information onto the technician’s view of the vehicle, providing step-by-step instructions and diagnostic data.

- Technician Role: Technicians will need to learn how to use AR tools and integrate them into their workflow.

By staying informed about these future trends, automotive technicians can prepare themselves for the challenges and opportunities ahead and continue to provide high-quality service to their customers.

Are you ready to elevate your automotive repair skills and master Mercedes-Benz diagnostics and car coding? Visit DTS-MONACO.EDU.VN today to explore our comprehensive software solutions, training courses, and expert technical support. Unlock the full potential of your diagnostic capabilities and stay ahead in the ever-evolving world of automotive technology!

Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880. Website: DTS-MONACO.EDU.VN.

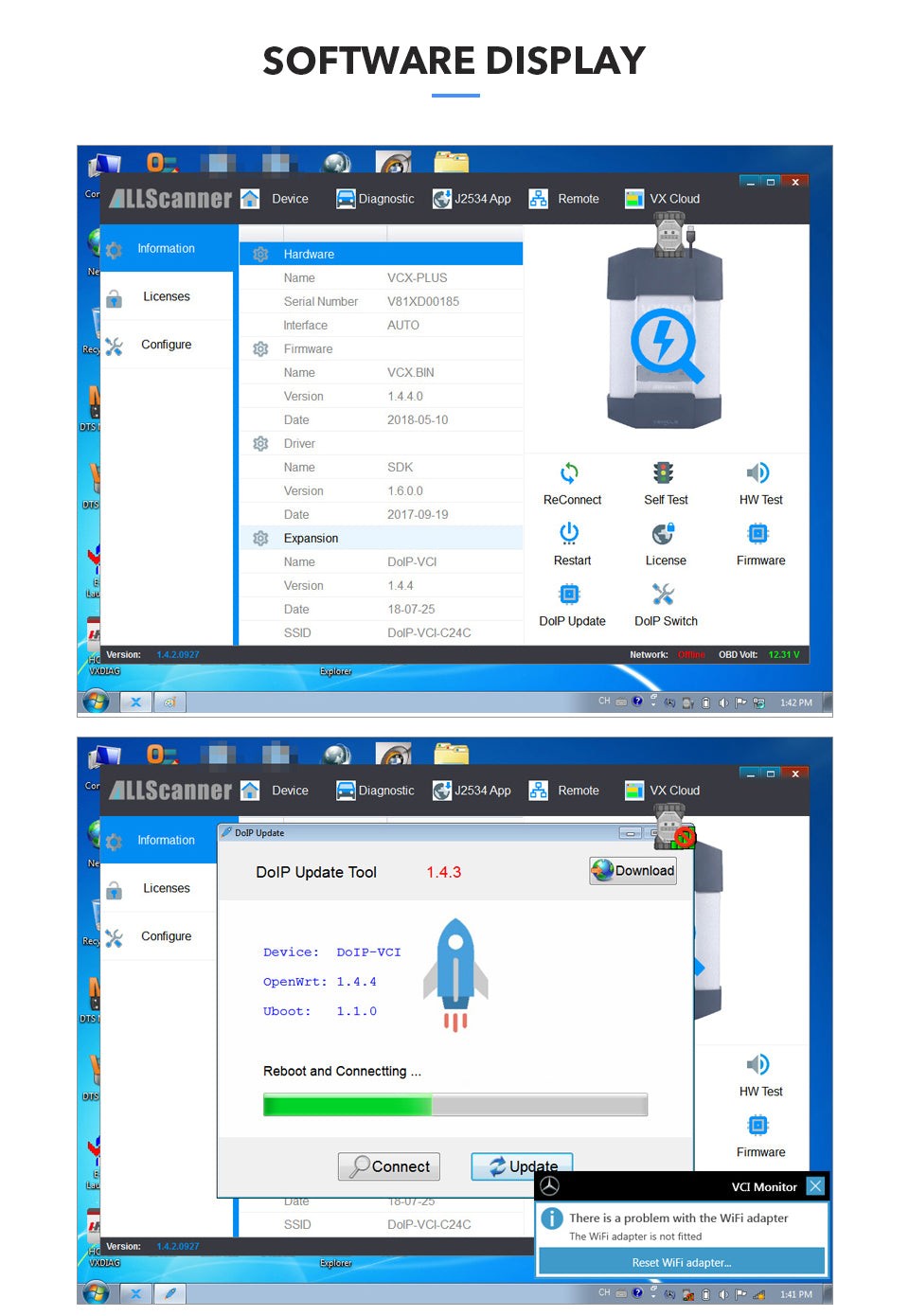

VXDIAG VCX SE for BENZ Software Display

VXDIAG VCX SE for BENZ Software Display

Frequently Asked Questions (FAQ) About DoIP and Mercedes-Benz Diagnostics

1. What is DoIP, and why is it important for Mercedes-Benz vehicles?

DoIP stands for Diagnostics over Internet Protocol, and it is essential because it enables faster and more efficient data transfer for diagnostics, ECU flashing, and module programming in newer Mercedes-Benz models.

2. Which Mercedes-Benz models require a DoIP-capable interface?

Mercedes-Benz models like the W223 (S-Class, 2021+), W206 (C-Class, 2022+), and newer electric vehicles (EVs) such as the EQS and EQE require a DoIP interface for comprehensive diagnostics and programming.

3. What is the VXDIAG C6, and how does it help with Mercedes-Benz diagnostics?

The VXDIAG C6 is a diagnostic interface designed for Mercedes-Benz vehicles that supports both CAN and DoIP protocols, offering comprehensive diagnostic, programming, and coding capabilities.

4. Are there alternatives to the VXDIAG C6 for DoIP diagnostics on Mercedes-Benz vehicles?

Yes, alternatives include the Mercedes-Benz eCOM, Autel MaxiSys Elite II Pro, and Launch X431 V+, among other DoIP-enabled interfaces from reputable brands.

5. How do I set up a DoIP interface for use with Mercedes-Benz vehicles?

To set up a DoIP interface, install the diagnostic software (e.g., XENTRY or DAS), connect the interface to your computer, install the necessary drivers, and configure the software to recognize the DoIP interface.

6. What are some common issues I might encounter when using a DoIP interface, and how can I troubleshoot them?

Common issues include communication errors, software installation problems, and programming failures. Troubleshooting steps involve verifying interface configurations, checking cable connections, ensuring stable power supplies, and seeking expert assistance when needed.

7. What is DTS-MONACO, and how is it used in advanced Mercedes-Benz diagnostics and car coding?

DTS-MONACO (Diagnostic Tool Set – Mercedes-Benz Common Operation Application) is a software platform used for in-depth diagnostics, ECU flashing, and car coding, providing a comprehensive set of tools for accessing and modifying vehicle parameters.

8. What is car coding, and how can it be used to customize Mercedes-Benz vehicles?

Car coding involves changing the software configuration of a vehicle’s ECUs to enable or disable certain features, adjust parameters, and personalize the driving experience.

9. Why is proper training and certification important for automotive technicians working on Mercedes-Benz vehicles?

Proper training and certification enhance skills and knowledge, increase earning potential, improve job security, and demonstrate a commitment to professionalism, ensuring high-quality service and staying updated with the latest technologies.

10. What are some future trends in Mercedes-Benz diagnostics and programming that I should be aware of?

Future trends include over-the-air (OTA) updates, the use of artificial intelligence (AI) in diagnostics, increased cybersecurity measures, the rise of electric vehicle (EV) technology, and the implementation of augmented reality (AR) in repair processes. Staying informed about these trends is essential for technicians to provide the best possible service.