Can DTS Monaco Test Air Intake Flap Actuators? Yes, DTS Monaco can test air intake flap actuators, offering detailed diagnostics and control for automotive technicians; this is a crucial capability for modern vehicle maintenance. This article from DTS-MONACO.EDU.VN dives deep into the capabilities of DTS Monaco, specifically how it handles air intake flap actuator testing, enhancing your understanding of car coding and diagnostic procedures, also discover how this powerful tool can streamline your workflow and improve diagnostic accuracy. Dive in to uncover the essentials of diagnostic software, automotive diagnostics, and electronic control units.

Contents

- 1. Understanding Air Intake Flap Actuators

- 1.1. Function and Importance

- 1.2. Common Issues with Air Intake Flap Actuators

- 1.3. Diagnostic Challenges

- 2. What is DTS Monaco?

- 2.1. Key Features of DTS Monaco

- 2.2. Benefits of Using DTS Monaco for Diagnostics

- 2.3. DTS Monaco vs. Other Diagnostic Tools

- 3. Testing Air Intake Flap Actuators with DTS Monaco

- 3.1. Step-by-Step Guide

- 3.1.1. Connecting to the Vehicle

- 3.1.2. Accessing the Relevant ECU

- 3.1.3. Performing Actuator Tests

- 3.1.4. Analyzing the Data

- 3.2. Example Scenario

- 3.3. Common Problems and Solutions

- 4. Advanced Diagnostics and Coding

- 4.1. ECU Programming

- 4.1.1. When to Use ECU Programming

- 4.1.2. How to Perform ECU Programming with DTS Monaco

- 4.2. Variant Coding

- 4.2.1. Use Cases for Variant Coding

- 4.2.2. Steps for Variant Coding with DTS Monaco

- 4.3. Live Data Monitoring

- 4.3.1. Key Data Parameters to Monitor

- 4.3.2. How to Use Live Data for Diagnostics

- 5. Best Practices for Using DTS Monaco

- 5.1. Software Updates

- 5.2. Proper Interface and Connections

- 5.3. Vehicle Information

- 5.4. Battery Voltage

- 5.5. Data Backup

- 5.6. Training and Expertise

- 5.7. Use Reputable Data Sources

- 5.8. Follow Procedures Carefully

- 5.9. Document All Work

- 5.10. Stay Informed

- 6. Case Studies

- 6.1. Case Study 1: Diagnosing a Faulty Air Intake Flap Actuator on a BMW 3 Series

- 6.1.1. Diagnostic Process

- 6.1.2. Solution

- 6.2. Case Study 2: ECU Programming on a Mercedes-Benz C-Class After Actuator Replacement

- 6.2.1. Diagnostic Process

- 6.2.2. Solution

- 7. The Future of Automotive Diagnostics

- 7.1. Trends in Automotive Diagnostics

- 7.2. The Role of DTS Monaco in the Future

- 8. Why Choose DTS-MONACO.EDU.VN?

- 9. Frequently Asked Questions (FAQs)

- 9.1. What is DTS Monaco used for?

- 9.2. Can DTS Monaco test air intake flap actuators?

- 9.3. How do I connect DTS Monaco to my vehicle?

- 9.4. What are the key features of DTS Monaco?

- 9.5. Do I need training to use DTS Monaco?

- 9.6. What is ECU programming?

- 9.7. What is variant coding?

- 9.8. How often should I update my DTS Monaco software?

- 9.9. What should I do if I encounter communication errors with the ECU?

- 9.10. Where can I get support for DTS Monaco?

- 10. Take Action Now

1. Understanding Air Intake Flap Actuators

Air intake flap actuators play a vital role in modern combustion engines. They regulate the amount of air entering the engine, optimizing performance, fuel efficiency, and emissions. These actuators control flaps within the intake manifold, adjusting airflow based on engine load and speed.

1.1. Function and Importance

The primary functions of air intake flap actuators include:

- Optimizing Airflow: Adjusting the intake manifold runner length to match engine speed.

- Improving Fuel Efficiency: Ensuring efficient combustion across different engine loads.

- Reducing Emissions: Helping to meet stringent emissions standards by optimizing the air-fuel mixture.

- Enhancing Performance: Boosting torque at low engine speeds and maximizing power at high speeds.

1.2. Common Issues with Air Intake Flap Actuators

Several issues can arise with air intake flap actuators, leading to performance problems and diagnostic trouble codes (DTCs). Common problems include:

- Mechanical Failures: Flaps can become stuck due to carbon buildup or physical damage.

- Electrical Faults: Wiring issues, faulty sensors, or actuator motor failures.

- Vacuum Leaks: In systems that rely on vacuum to actuate the flaps, leaks can prevent proper operation.

- Sensor Malfunctions: Issues with the position sensors that provide feedback to the engine control unit (ECU).

1.3. Diagnostic Challenges

Diagnosing air intake flap actuator issues can be challenging without the right tools. Traditional methods might involve visually inspecting the actuator and checking for obvious mechanical problems. However, a comprehensive diagnostic approach requires the ability to:

- Read and Interpret DTCs: Understand the specific fault codes related to the air intake system.

- Monitor Live Data: Observe the actuator’s performance in real-time under different engine conditions.

- Perform Actuator Tests: Command the actuator to move and verify its response.

2. What is DTS Monaco?

DTS Monaco (Diagnostic Tool Set for Monaco) is a comprehensive diagnostic and car coding software used by automotive technicians and engineers. It is designed to communicate with various electronic control units (ECUs) in a vehicle, allowing for advanced diagnostics, programming, and module configuration. DTS Monaco is widely used for its in-depth capabilities and its ability to perform tasks beyond the scope of standard diagnostic tools.

2.1. Key Features of DTS Monaco

DTS Monaco offers a range of powerful features, including:

- ECU Identification: Quickly identify all ECUs present in the vehicle.

- Fault Code Reading and Clearing: Read and clear diagnostic trouble codes (DTCs) from any ECU.

- Live Data Monitoring: Monitor real-time data parameters from sensors and actuators.

- Actuator Testing: Perform functional tests on actuators to verify their operation.

- ECU Programming: Flash and program ECUs with updated software.

- Variant Coding: Customize vehicle settings and parameters.

- Diagnostic Routines: Run guided diagnostic procedures for specific issues.

2.2. Benefits of Using DTS Monaco for Diagnostics

Using DTS Monaco for diagnostics offers several advantages over traditional diagnostic methods:

- Enhanced Accuracy: Provides detailed information about ECU operation and sensor data.

- Efficient Troubleshooting: Streamlines the diagnostic process by quickly identifying faults.

- Advanced Capabilities: Allows for tasks such as ECU programming and variant coding.

- Comprehensive Coverage: Supports a wide range of vehicle makes and models.

2.3. DTS Monaco vs. Other Diagnostic Tools

Compared to other diagnostic tools, DTS Monaco stands out due to its advanced features and capabilities. While standard OBD-II scanners can read and clear basic fault codes, DTS Monaco provides a much deeper level of access and control over vehicle ECUs. This makes it an indispensable tool for technicians working on complex automotive systems.

| Feature | DTS Monaco | Standard OBD-II Scanner | Advanced Diagnostic Tool |

|---|---|---|---|

| ECU Access | Full | Limited | Extensive |

| Fault Code Info | Detailed | Basic | Comprehensive |

| Live Data | Extensive | Limited | Detailed |

| Actuator Tests | Yes | No | Yes |

| ECU Programming | Yes | No | Limited |

| Variant Coding | Yes | No | No |

| Vehicle Coverage | Wide | Limited | Extensive |

| Cost | Higher | Lower | Moderate |

| Complexity | Requires Training/Expertise | User-Friendly | Intermediate |

3. Testing Air Intake Flap Actuators with DTS Monaco

DTS Monaco provides specific functionalities to test air intake flap actuators, ensuring they function correctly. Here’s how you can use DTS Monaco to perform these tests effectively.

3.1. Step-by-Step Guide

3.1.1. Connecting to the Vehicle

- Connect the Interface: Connect the DTS Monaco interface (e.g., a multiplexer) to the vehicle’s OBD-II port.

- Launch DTS Monaco: Open the DTS Monaco software on your computer.

- Select the Vehicle: Choose the correct vehicle make, model, and year from the DTS Monaco database.

3.1.2. Accessing the Relevant ECU

- Identify the ECU: Determine which ECU controls the air intake flap actuator (usually the engine control unit).

- Select the ECU: In DTS Monaco, select the appropriate ECU from the list of available modules.

- Establish Communication: Establish a communication session with the ECU.

3.1.3. Performing Actuator Tests

-

Navigate to Actuator Tests: In DTS Monaco, navigate to the actuator testing section for the selected ECU. This section might be labeled “Actuations,” “Component Activation,” or similar.

-

Select the Air Intake Flap Actuator Test: Choose the specific test for the air intake flap actuator.

-

Run the Test: Follow the on-screen instructions to run the test. DTS Monaco will send commands to the actuator and monitor its response.

-

Observe the Results: Observe the test results, which may include:

- Actuator position feedback

- Current draw

- Error messages (if any)

3.1.4. Analyzing the Data

-

Compare to Specifications: Compare the test results to the manufacturer’s specifications to determine if the actuator is functioning correctly.

-

Identify Issues: Look for deviations from the expected values, such as:

- Incorrect actuator position

- Excessive current draw

- Failure to respond to commands

-

Document Findings: Record all test results and observations for further analysis and repair.

3.2. Example Scenario

Let’s consider an example where you are testing the air intake flap actuator on a Mercedes-Benz C-Class.

- Connect: Connect the DTS Monaco interface to the vehicle and launch the software.

- Select Vehicle: Select “Mercedes-Benz,” “C-Class,” and the appropriate model year.

- Access ECU: Choose the engine control unit (e.g., “ME9.7”).

- Actuator Test: Navigate to “Actuations” and select the “Air Intake Flap Actuator Test.”

- Run Test: Start the test and observe the actuator moving through its range of motion.

- Analyze Data: Check the actuator position feedback against the expected values. If the actuator does not reach the specified positions or if the current draw is too high, there may be an issue with the actuator or its wiring.

3.3. Common Problems and Solutions

When testing air intake flap actuators with DTS Monaco, you may encounter several common problems. Here are some solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Actuator does not respond | Electrical fault, mechanical failure | Check wiring and connections, test the actuator motor, inspect the flaps for obstructions. |

| Incorrect actuator position | Sensor malfunction, actuator damage | Replace the position sensor, replace the actuator. |

| Excessive current draw | Short circuit, actuator overload | Check wiring for shorts, inspect the actuator for mechanical resistance. |

| DTCs related to air intake flap | Various issues | Read and interpret the DTCs, perform further diagnostic tests based on the fault codes. |

| Communication errors with the ECU | Interface issues, incorrect ECU selection | Verify the interface connection, ensure the correct ECU is selected, restart the DTS Monaco software. |

| Software incompatibility or glitches | Outdated software version, software bugs | Update DTS Monaco to the latest version, check for known issues and patches, reinstall the software if necessary. |

| Physical damage to actuator or flaps | Impact, wear and tear | Visually inspect the actuator and flaps for any physical damage, replace damaged components. |

| Carbon buildup or debris accumulation | Lack of maintenance, poor fuel quality | Clean the intake manifold and flaps, use fuel additives to prevent future buildup, ensure proper maintenance schedules are followed. |

| Vacuum leaks (if applicable) | Damaged vacuum lines, faulty check valves | Inspect vacuum lines for cracks or leaks, replace damaged lines, check and replace faulty check valves. |

| Issues with the actuator motor | Worn brushes, internal short circuit | Test the actuator motor using a multimeter, replace the motor if it shows signs of wear or electrical issues. |

| Problems with the ECU driver circuit | Damaged transistors, faulty capacitors | Check the ECU driver circuit using a multimeter and oscilloscope, repair or replace the ECU if necessary. |

| Interference from aftermarket parts | Poorly installed or incompatible modifications | Remove or properly install aftermarket parts, ensure all modifications are compatible with the vehicle’s electrical system. |

| Environmental factors (e.g., moisture) | Corrosion, electrical shorts | Protect electrical components from moisture, use dielectric grease on connections, clean corroded terminals. |

| Inadequate power supply to the actuator | Weak battery, faulty relay | Check the battery voltage, test the actuator relay, replace faulty components. |

| Problems with the actuator linkage | Loose connections, worn joints | Check and tighten all connections, replace worn joints, lubricate moving parts. |

| Issues with the throttle body | Clogged or damaged throttle body | Clean the throttle body, replace damaged components, perform a throttle body adaptation. |

| Calibration issues | Incorrect sensor readings, maladjusted components | Calibrate the actuator and related sensors, adjust mechanical components as needed. |

| Binding or sticking flaps | Mechanical obstruction, lack of lubrication | Remove any obstructions, lubricate the flaps and actuator mechanism, ensure free movement. |

| Issues with the wiring harness | Frayed wires, loose connectors | Inspect the wiring harness for damage, repair or replace damaged wires, ensure all connectors are securely attached. |

| Problems with the actuator ground | Poor ground connection, corrosion | Check and clean the ground connection, ensure a solid ground path. |

| ECU software issues | Corrupted software, outdated version | Reflash the ECU with the latest software version, ensure the software is not corrupted. |

4. Advanced Diagnostics and Coding

Beyond basic testing, DTS Monaco allows for advanced diagnostics and coding related to air intake flap actuators.

4.1. ECU Programming

In some cases, issues with the air intake flap actuator may require ECU programming. This involves flashing the ECU with updated software or reconfiguring its parameters. DTS Monaco supports ECU programming, allowing you to perform these tasks directly.

4.1.1. When to Use ECU Programming

- Software Updates: To apply software updates that improve actuator performance or address known issues.

- Module Replacement: When replacing the ECU, programming is necessary to match it to the vehicle.

- Custom Tuning: To fine-tune the ECU parameters for optimized engine performance.

4.1.2. How to Perform ECU Programming with DTS Monaco

- Obtain the Correct Software: Ensure you have the correct software file for the ECU.

- Connect to the ECU: Establish a communication session with the ECU using DTS Monaco.

- Select Programming Function: Navigate to the ECU programming section in DTS Monaco.

- Flash the ECU: Follow the on-screen instructions to flash the ECU with the new software.

- Verify Programming: After programming, verify that the process was successful and that the ECU is functioning correctly.

4.2. Variant Coding

Variant coding involves customizing the vehicle’s settings and parameters. This can be useful for adjusting the behavior of the air intake flap actuator or related systems.

4.2.1. Use Cases for Variant Coding

- Adjusting Actuator Response: To modify how the actuator responds to different engine conditions.

- Disabling Fault Codes: In some cases, you may need to disable fault codes related to the air intake flap actuator (though this should be done with caution and only when necessary).

- Enabling New Features: To enable new features that rely on the air intake system.

4.2.2. Steps for Variant Coding with DTS Monaco

- Connect to the ECU: Establish a communication session with the ECU using DTS Monaco.

- Access Variant Coding: Navigate to the variant coding section in DTS Monaco.

- Modify Parameters: Change the desired parameters according to your needs.

- Apply Changes: Save the changes and verify that they have been applied successfully.

4.3. Live Data Monitoring

Monitoring live data is crucial for diagnosing issues with the air intake flap actuator. DTS Monaco allows you to observe real-time data parameters from sensors and actuators, providing valuable insights into their operation.

4.3.1. Key Data Parameters to Monitor

- Actuator Position: The current position of the air intake flap actuator.

- Target Position: The desired position of the actuator as commanded by the ECU.

- Current Draw: The amount of current being drawn by the actuator motor.

- Sensor Voltages: The voltages from the position sensors.

- Engine Load: The current load on the engine.

- Engine Speed: The current speed of the engine.

4.3.2. How to Use Live Data for Diagnostics

- Connect to the ECU: Establish a communication session with the ECU using DTS Monaco.

- Select Live Data: Navigate to the live data monitoring section in DTS Monaco.

- Choose Parameters: Select the key data parameters to monitor.

- Observe Data: Observe the data while the engine is running and under different conditions.

- Analyze Data: Look for anomalies or deviations from the expected values.

5. Best Practices for Using DTS Monaco

To ensure accurate and reliable results when using DTS Monaco, follow these best practices.

5.1. Software Updates

Keep your DTS Monaco software up to date with the latest version. Software updates often include bug fixes, new features, and improved vehicle coverage.

5.2. Proper Interface and Connections

Use a reliable interface (e.g., a high-quality multiplexer) and ensure all connections are secure. Poor connections can lead to communication errors and inaccurate data.

5.3. Vehicle Information

Always select the correct vehicle make, model, and year in DTS Monaco. Using incorrect vehicle information can lead to incorrect diagnostic procedures and potential damage to the vehicle.

5.4. Battery Voltage

Ensure the vehicle’s battery voltage is stable during diagnostic and programming procedures. Low battery voltage can cause communication errors and incomplete programming.

5.5. Data Backup

Before performing any programming or coding changes, back up the original ECU data. This allows you to restore the ECU to its original state if something goes wrong.

5.6. Training and Expertise

DTS Monaco is a powerful tool, but it requires training and expertise to use effectively. Consider taking a training course or working with an experienced technician to learn the ins and outs of the software.

5.7. Use Reputable Data Sources

Rely on reputable sources for diagnostic information, wiring diagrams, and technical specifications. Incorrect information can lead to misdiagnosis and incorrect repairs.

5.8. Follow Procedures Carefully

Adhere to the diagnostic and repair procedures outlined in the vehicle’s service manual. Deviating from these procedures can lead to incorrect repairs and potential damage to the vehicle.

5.9. Document All Work

Keep detailed records of all diagnostic and repair work performed. This includes fault codes, live data readings, actuator test results, and any coding changes made.

5.10. Stay Informed

Stay up-to-date with the latest automotive technology and diagnostic techniques. The automotive industry is constantly evolving, and it’s important to keep your skills and knowledge current.

6. Case Studies

6.1. Case Study 1: Diagnosing a Faulty Air Intake Flap Actuator on a BMW 3 Series

A technician was presented with a BMW 3 Series exhibiting a loss of power and poor fuel economy. The diagnostic trouble codes (DTCs) indicated an issue with the air intake flap actuator.

6.1.1. Diagnostic Process

-

Initial Scan: The technician performed an initial scan using DTS Monaco and retrieved the following DTC:

2A6F - Air intake flap control, plausibility

-

Live Data Monitoring: The technician monitored live data parameters related to the air intake flap actuator, including actuator position, target position, and engine load. The data showed that the actuator position was not matching the target position.

-

Actuator Test: The technician performed an actuator test using DTS Monaco. The test revealed that the actuator was not moving through its full range of motion.

-

Visual Inspection: A visual inspection of the actuator revealed that the flaps were stuck due to carbon buildup.

6.1.2. Solution

The technician cleaned the air intake flaps and lubricated the actuator mechanism. After cleaning, the actuator test showed that the actuator was now functioning correctly. The technician cleared the DTC and performed a road test to verify that the issue was resolved.

6.2. Case Study 2: ECU Programming on a Mercedes-Benz C-Class After Actuator Replacement

A technician replaced a faulty air intake flap actuator on a Mercedes-Benz C-Class. After replacing the actuator, the vehicle still exhibited performance issues.

6.2.1. Diagnostic Process

- Initial Scan: The technician performed an initial scan using DTS Monaco and found no DTCs related to the air intake flap actuator.

- Live Data Monitoring: The technician monitored live data parameters and noticed that the new actuator was not being properly controlled by the ECU.

- ECU Programming: The technician determined that the ECU needed to be programmed to recognize the new actuator. The technician used DTS Monaco to flash the ECU with the latest software version.

6.2.2. Solution

After programming the ECU, the technician performed an actuator test to verify that the new actuator was functioning correctly. The live data parameters now showed that the actuator was being properly controlled by the ECU. The technician performed a road test to verify that the performance issues were resolved.

7. The Future of Automotive Diagnostics

The field of automotive diagnostics is constantly evolving, driven by advancements in vehicle technology and the increasing complexity of automotive systems.

7.1. Trends in Automotive Diagnostics

- Remote Diagnostics: The ability to perform diagnostic tests remotely using cloud-based platforms.

- Artificial Intelligence (AI): The use of AI to analyze diagnostic data and provide insights and recommendations.

- Augmented Reality (AR): The use of AR to overlay diagnostic information onto the vehicle, providing technicians with a more intuitive view of the system.

- Predictive Maintenance: The use of data analytics to predict when components are likely to fail, allowing for proactive maintenance.

7.2. The Role of DTS Monaco in the Future

DTS Monaco is well-positioned to play a key role in the future of automotive diagnostics. Its advanced capabilities and comprehensive coverage make it a valuable tool for technicians working on complex automotive systems. As vehicle technology continues to evolve, DTS Monaco will likely adapt to incorporate new features and capabilities, ensuring that it remains a leading diagnostic tool.

8. Why Choose DTS-MONACO.EDU.VN?

At DTS-MONACO.EDU.VN, we are dedicated to providing automotive technicians and engineers with the tools and knowledge they need to succeed in today’s rapidly evolving automotive industry. Here’s how we can help:

- Expert Guidance: We offer expert guidance and support on using DTS Monaco for advanced diagnostics and car coding.

- Training Courses: Our comprehensive training courses cover everything from basic diagnostics to advanced ECU programming.

- Software and Hardware: We provide access to the latest DTS Monaco software and compatible hardware interfaces.

- Technical Support: Our technical support team is available to answer your questions and help you troubleshoot any issues.

- Community Forum: Join our community forum to connect with other DTS Monaco users and share your knowledge and experiences.

9. Frequently Asked Questions (FAQs)

9.1. What is DTS Monaco used for?

DTS Monaco is a comprehensive diagnostic and car coding software used by automotive technicians and engineers. It allows for advanced diagnostics, programming, and module configuration.

9.2. Can DTS Monaco test air intake flap actuators?

Yes, DTS Monaco can test air intake flap actuators by performing functional tests, monitoring live data, and reading diagnostic trouble codes.

9.3. How do I connect DTS Monaco to my vehicle?

You connect DTS Monaco to your vehicle using a compatible interface (e.g., a multiplexer) that plugs into the vehicle’s OBD-II port.

9.4. What are the key features of DTS Monaco?

Key features of DTS Monaco include ECU identification, fault code reading and clearing, live data monitoring, actuator testing, ECU programming, and variant coding.

9.5. Do I need training to use DTS Monaco?

Yes, DTS Monaco is a powerful tool that requires training and expertise to use effectively. Consider taking a training course or working with an experienced technician.

9.6. What is ECU programming?

ECU programming involves flashing the ECU with updated software or reconfiguring its parameters. This can be necessary to improve performance, address known issues, or match a new ECU to the vehicle.

9.7. What is variant coding?

Variant coding involves customizing the vehicle’s settings and parameters. This can be useful for adjusting the behavior of the air intake flap actuator or related systems.

9.8. How often should I update my DTS Monaco software?

You should update your DTS Monaco software regularly to ensure you have the latest bug fixes, new features, and improved vehicle coverage.

9.9. What should I do if I encounter communication errors with the ECU?

If you encounter communication errors, verify the interface connection, ensure the correct ECU is selected, and restart the DTS Monaco software.

9.10. Where can I get support for DTS Monaco?

You can get support for DTS Monaco from DTS-MONACO.EDU.VN, which offers expert guidance, training courses, technical support, and a community forum.

10. Take Action Now

Ready to take your automotive diagnostic skills to the next level? Visit DTS-MONACO.EDU.VN today to learn more about our DTS Monaco software, training courses, and support services. Contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States or Whatsapp: +1 (641) 206-8880. Don’t miss out on the opportunity to enhance your diagnostic capabilities and stay ahead in the automotive industry.

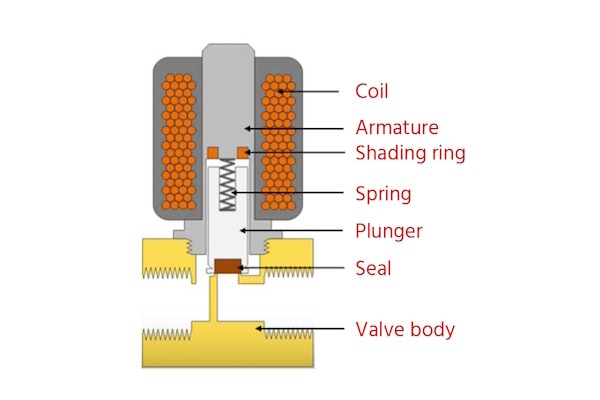

Components of a solenoid valve

Components of a solenoid valve

Figure 2: An illustration showing the various components that make up a solenoid valve, highlighting its construction and assembly.