DTS Monaco is a powerful diagnostic tool, and yes, it can send raw UDS (Unified Diagnostic Services) requests when needed for advanced diagnostics. DTS-MONACO.EDU.VN provides in-depth insights and training on how to leverage this capability for comprehensive vehicle diagnostics and car coding. Understanding this functionality empowers technicians and garage owners to perform intricate procedures and unlock vehicle customization options. This article will cover advanced diagnostic procedures, automotive repair solutions, and vehicle electronic systems.

Contents

- 1. Understanding DTS Monaco’s Capabilities for Raw UDS Requests

- 1.1 What are Raw UDS Requests?

- 1.2 Why Send Raw UDS Requests?

- 1.3 How DTS Monaco Facilitates Raw UDS Requests

- 1.4 Use Cases for Raw UDS Requests in DTS Monaco

- 1.5 Potential Risks and How to Mitigate Them

- 1.6 Conclusion

- 2. Detailed Explanation of Raw UDS Request Functionality

- 2.1 The Foundation: Unified Diagnostic Services (UDS)

- 2.2 Structure of a Raw UDS Request

- 2.3 How DTS Monaco Handles Raw UDS Requests

- 2.4 Key UDS Services and Their Applications

- 2.5 Example: Reading Engine Coolant Temperature

- 2.6 Advanced Techniques

- 2.7 Tips for Success

- 2.8 Conclusion

- 3. Step-by-Step Guide: Sending a Raw UDS Request with DTS Monaco

- 3.1 Prerequisites

- 3.2 Step 1: Launch DTS Monaco and Connect to the ECU

- 3.3 Step 2: Open the Diagnostic Services Tab

- 3.4 Step 3: Enter the Raw UDS Request

- 3.5 Step 4: Send the UDS Request

- 3.6 Step 5: Interpret the Response

- 3.7 Example: Reading and Interpreting Engine Coolant Temperature

- 3.8 Step 6: Advanced Techniques (Optional)

- 3.9 Tips for Success

- 3.10 Conclusion

- 4. Practical Applications of Raw UDS Requests in Automotive Repair

- 4.1 Diagnosing Intermittent Faults

- 4.2 Performing Component-Level Diagnostics

- 4.3 Recalibrating Sensors and Actuators

- 4.4 Accessing and Modifying ECU Parameters

- 4.5 Performing Security Access Procedures

- 4.6 Case Studies

- 4.7 Conclusion

- 5. Maximizing Diagnostic Efficiency with DTS Monaco and Raw UDS

- 5.1 Streamlining Diagnostic Workflows

- 5.2 Reducing Diagnostic Time

- 5.3 Enhancing Diagnostic Accuracy

- 5.4 Integrating with Other Diagnostic Tools

- 5.5 Training and Support

- 5.6 Case Studies

- 5.7 Conclusion

- 6. Common Challenges and Troubleshooting Tips When Using Raw UDS Requests

- 6.1 Communication Errors

- 6.2 Incorrect UDS Request Format

- 6.3 Security Access Issues

- 6.4 Data Interpretation Problems

- 6.5 ECU Incompatibility

- 6.6 Software Glitches

- 6.7 Hardware Issues

- 6.8 General Tips

1. Understanding DTS Monaco’s Capabilities for Raw UDS Requests

DTS Monaco stands out as a robust tool in the realm of automotive diagnostics, offering a wide array of functionalities that go beyond the standard diagnostic procedures. One of its key strengths lies in its ability to send raw UDS (Unified Diagnostic Services) requests, a feature that is particularly valuable for advanced diagnostics. Let’s delve deeper into understanding how DTS Monaco facilitates this and why it is important.

1.1 What are Raw UDS Requests?

Raw UDS requests are essentially direct commands sent to a vehicle’s electronic control units (ECUs) using the Unified Diagnostic Services protocol. This protocol is standardized under ISO 14229 and is used for diagnosing and managing vehicle systems. Unlike pre-defined diagnostic routines, raw UDS requests allow technicians to send custom commands, enabling them to access specific data and functionalities within the ECU.

1.2 Why Send Raw UDS Requests?

Sending raw UDS requests can be essential for several reasons:

- Accessing Non-Standard Data: Sometimes, the data you need is not available through standard diagnostic functions. Raw UDS requests let you retrieve this data directly.

- Performing Custom Tests: When standard tests are insufficient, you can create custom tests by sending specific UDS commands to diagnose issues.

- Bypassing Limitations: Certain diagnostic tools may have limitations on what they can access or modify. Raw UDS requests allow you to bypass these limitations.

- Advanced Diagnostics: For complex issues, such as intermittent faults or deep system analysis, raw UDS requests provide the necessary control and access.

- Research and Development: Automotive engineers and researchers use raw UDS requests to explore ECU functionalities and develop new diagnostic methods.

1.3 How DTS Monaco Facilitates Raw UDS Requests

DTS Monaco provides a user-friendly interface for composing and sending raw UDS requests. Here’s how it works:

- Manual Input: DTS Monaco allows technicians to manually enter UDS commands, specifying the service ID, sub-function parameters, and data identifiers.

- Scripting: For more complex tasks, technicians can create scripts that automate the sending of multiple UDS requests. This is particularly useful for repetitive tests or procedures.

- Data Interpretation: DTS Monaco can interpret the responses from the ECU, displaying the data in a readable format. This is crucial for understanding the results of your requests.

- Customizable Interface: The interface can be customized to display relevant data and parameters, making it easier to work with raw UDS requests.

1.4 Use Cases for Raw UDS Requests in DTS Monaco

Here are some practical scenarios where sending raw UDS requests in DTS Monaco can be beneficial:

- Reading Specific Memory Locations: Accessing specific memory locations within the ECU to retrieve calibration data or diagnostic information.

- Activating Hidden Features: Activating or deactivating certain vehicle features that are not accessible through standard diagnostic functions.

- Performing Component Tests: Directly controlling and testing individual components, such as injectors, solenoids, or sensors.

- Flashing ECUs: Updating or reflashing ECU firmware by sending specific UDS commands to initiate the programming sequence.

- Security Access: Bypassing security measures to gain access to protected functions within the ECU.

1.5 Potential Risks and How to Mitigate Them

While sending raw UDS requests can be powerful, it also comes with potential risks:

- ECU Damage: Incorrectly formatted requests or sending commands to the wrong memory location can damage the ECU.

- System Instability: Modifying critical parameters without proper knowledge can lead to system instability or vehicle malfunction.

- Security Vulnerabilities: Bypassing security measures can create vulnerabilities that could be exploited.

To mitigate these risks:

- Training and Expertise: Ensure that technicians are properly trained and have a thorough understanding of UDS protocols and ECU architecture. DTS-MONACO.EDU.VN offers specialized training programs to enhance these skills.

- Backup and Documentation: Always back up the ECU’s original configuration before making any changes. Document each step of the process to ensure that you can revert to the original state if needed.

- Use Reliable Data: Rely on trusted sources for UDS command information. Consult official documentation and verified databases to ensure accuracy.

- Test in a Controlled Environment: When possible, test your raw UDS requests in a controlled environment, such as a test bench, before applying them to a vehicle.

- Consult Experts: If you are unsure about a particular procedure, consult with experienced professionals or seek guidance from DTS-MONACO.EDU.VN’s support team.

1.6 Conclusion

DTS Monaco’s ability to send raw UDS requests opens up a world of possibilities for advanced vehicle diagnostics and customization. However, it is crucial to approach this functionality with caution and expertise. By understanding the principles of UDS, following best practices, and staying informed through resources like DTS-MONACO.EDU.VN, you can harness the power of raw UDS requests while minimizing the risks.

2. Detailed Explanation of Raw UDS Request Functionality

To fully appreciate the capabilities of DTS Monaco in sending raw UDS requests, it’s essential to dive into the technical details and understand the nuances of this functionality. This section will provide a detailed explanation, covering the underlying principles, the structure of UDS requests, and how DTS Monaco handles them.

2.1 The Foundation: Unified Diagnostic Services (UDS)

Unified Diagnostic Services (UDS) is a communication protocol used for diagnosing and managing electronic control units (ECUs) in vehicles. Standardized under ISO 14229, UDS defines a set of services that allow diagnostic tools to interact with ECUs. These services include reading and writing data, requesting diagnostic information, performing routines, and more.

2.2 Structure of a Raw UDS Request

A raw UDS request is essentially a command sent to the ECU in a specific format. The basic structure of a UDS request includes:

- Service ID (SID): A one-byte code that specifies the diagnostic service to be performed. For example,

0x10is the SID for Diagnostic Session Control, and0x22is the SID for Read Data By Identifier. - Sub-Function (Sub-Function Parameter): Some services require a sub-function parameter to further specify the operation. For example, the Diagnostic Session Control service (

0x10) uses sub-functions to switch between different diagnostic sessions (e.g., default session, programming session). - Data Identifier (DID): A two-byte code that identifies a specific data item within the ECU. For example, a DID might represent the engine temperature, vehicle speed, or a specific calibration parameter.

- Data (Data Parameter): Additional data required by the service. This could include the value to be written to a memory location or parameters for a specific routine.

Here’s an example of a raw UDS request to read the engine coolant temperature (assuming the DID for engine coolant temperature is 0xF190):

22 F1 9022is the Service ID for Read Data By Identifier.F1 90is the Data Identifier for engine coolant temperature.

2.3 How DTS Monaco Handles Raw UDS Requests

DTS Monaco provides a flexible interface for constructing and sending raw UDS requests. Here’s how it works:

- Manual Input: Users can manually enter the UDS request in hexadecimal format. DTS Monaco allows you to specify the SID, sub-function, DID, and data parameters.

- Scripting: For more complex tasks, you can create scripts that automate the process of sending multiple UDS requests. This is particularly useful for performing a sequence of diagnostic steps.

- Data Interpretation: DTS Monaco can interpret the response from the ECU, displaying the data in a readable format. This involves parsing the response data based on the UDS protocol and displaying it in a user-friendly manner.

- Customizable Interface: The interface can be customized to display relevant data and parameters, making it easier to work with raw UDS requests. You can create custom layouts and define data mappings to streamline the diagnostic process.

2.4 Key UDS Services and Their Applications

Understanding the different UDS services is crucial for effectively using raw UDS requests. Here are some key services and their applications:

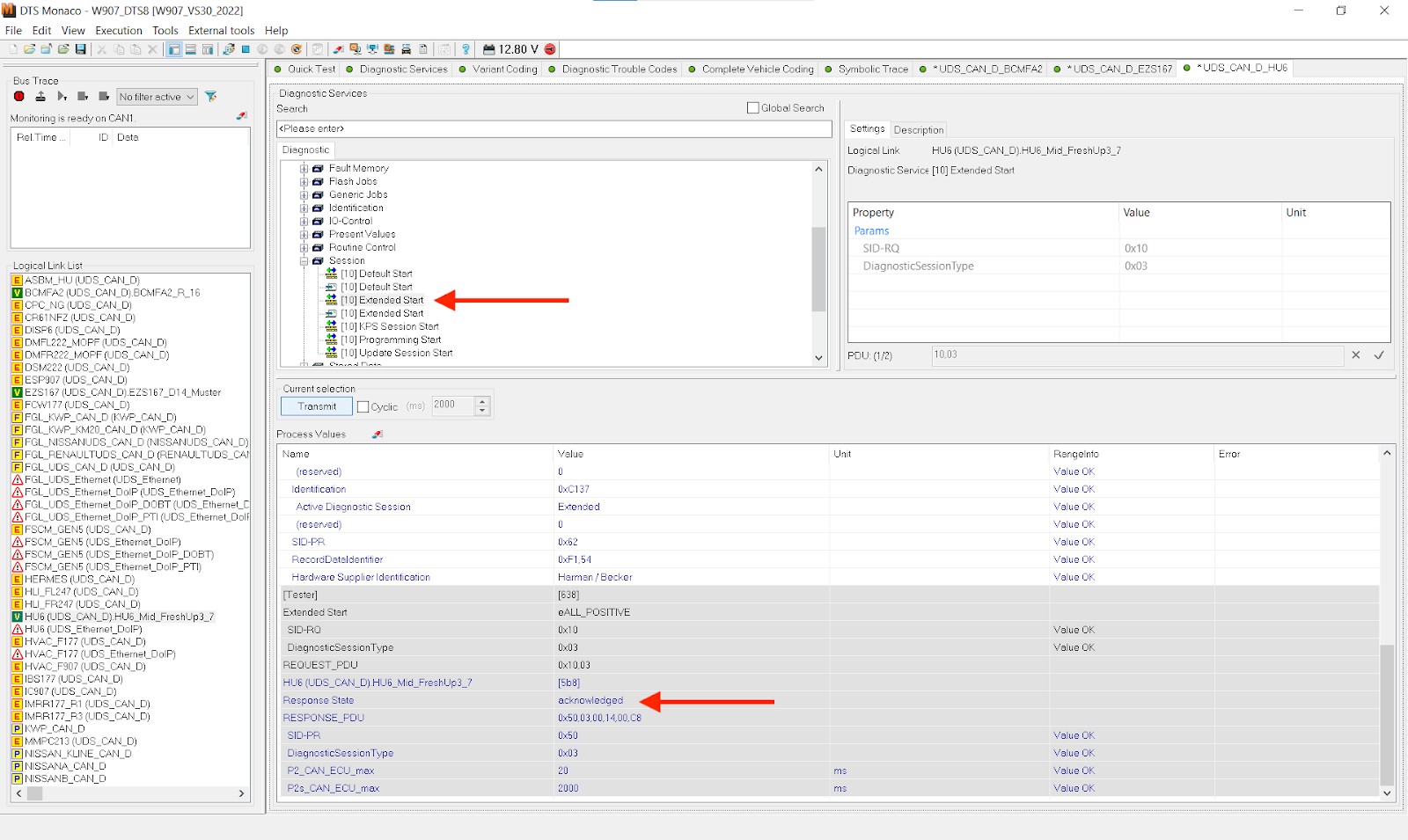

- Diagnostic Session Control (SID:

0x10): Used to switch between different diagnostic sessions. Sub-functions include:0x01: Default session0x02: Programming session0x03: Extended diagnostic session

- Read Data By Identifier (SID:

0x22): Used to read the value of a specific data item. Requires the DID of the data item to be read. - Write Data By Identifier (SID:

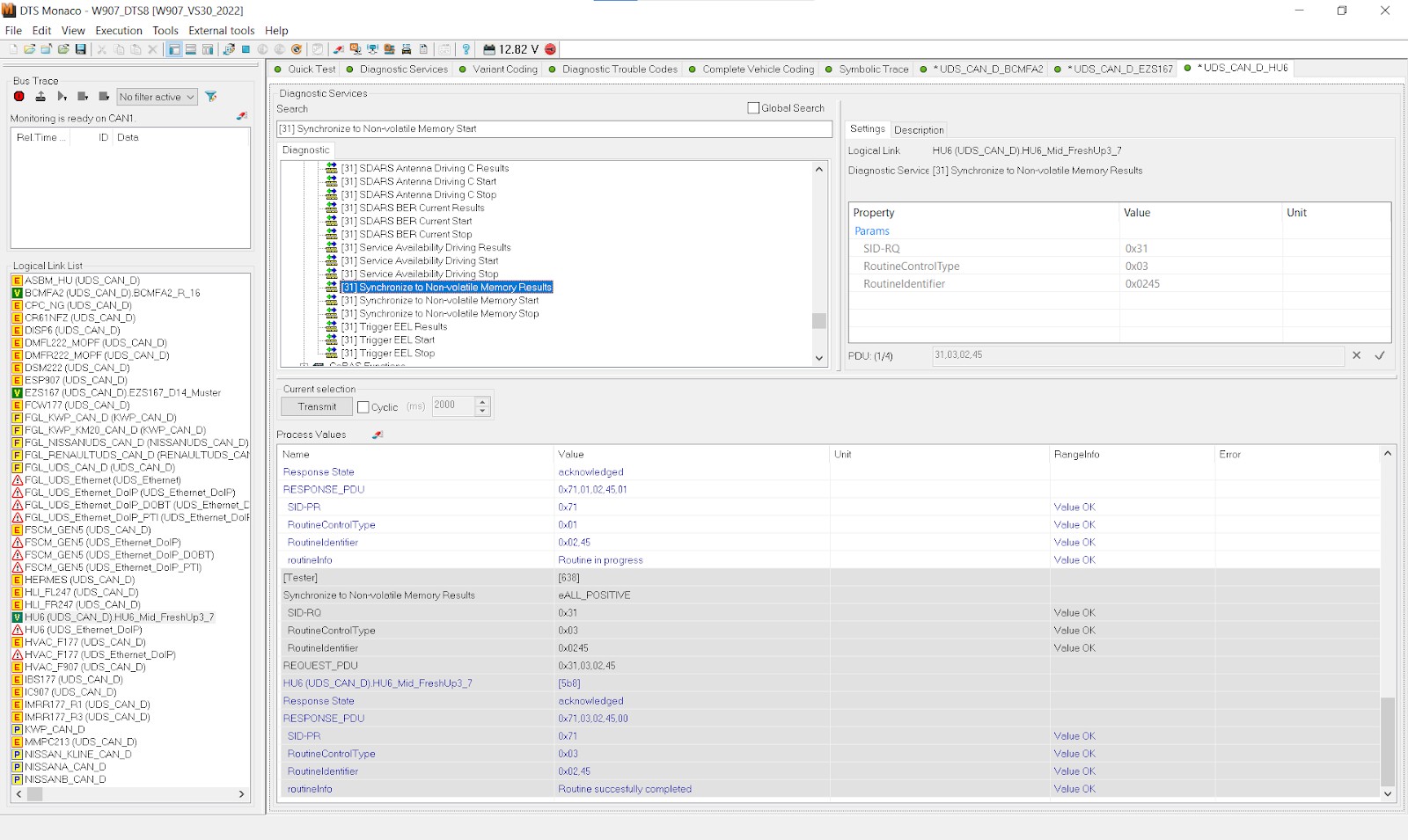

0x2E): Used to write a new value to a specific data item. Requires the DID of the data item and the new value to be written. - Routine Control (SID:

0x31): Used to start, stop, or request the results of a specific routine. Requires a routine identifier (RID) and a control option (e.g., start, stop, request results). - Input Output Control By Identifier (SID:

0x2F): Used to control the input or output of a specific component. Requires the DID of the component and a control option (e.g., activate, deactivate). - Security Access (SID:

0x27): Used to unlock protected functions within the ECU. Requires a security access level and a key to unlock the function.

2.5 Example: Reading Engine Coolant Temperature

Let’s walk through an example of reading the engine coolant temperature using a raw UDS request in DTS Monaco.

- Identify the DID: First, you need to identify the Data Identifier (DID) for the engine coolant temperature. Let’s assume the DID is

0xF190. - Construct the UDS Request: The UDS request to read the engine coolant temperature is:

22 F1 90 - Enter the Request in DTS Monaco: In DTS Monaco, you would enter this request in the manual input field or create a script to send the request.

- Send the Request: Send the request to the ECU.

- Interpret the Response: The ECU will respond with the engine coolant temperature. DTS Monaco will display the response data, which you can then interpret to determine the temperature value.

2.6 Advanced Techniques

Here are some advanced techniques for working with raw UDS requests in DTS Monaco:

- Session Management: Use the Diagnostic Session Control service (

0x10) to switch to an extended diagnostic session for more advanced diagnostics and programming. - Security Access: Use the Security Access service (

0x27) to unlock protected functions within the ECU. This may require obtaining a security key from the vehicle manufacturer. - Data Manipulation: Use the Read Data By Identifier (

0x22) and Write Data By Identifier (0x2E) services to read and modify calibration parameters, adaptation values, and other ECU settings. - Routine Control: Use the Routine Control service (

0x31) to perform specific diagnostic routines, such as component tests, system checks, and calibration procedures.

2.7 Tips for Success

To ensure success when working with raw UDS requests in DTS Monaco, keep the following tips in mind:

- Documentation: Always refer to the vehicle manufacturer’s documentation for UDS specifications and data identifiers.

- Backup: Always back up the ECU’s original configuration before making any changes.

- Testing: Test your UDS requests in a controlled environment before applying them to a vehicle.

- Expert Advice: Consult with experienced professionals or seek guidance from DTS-MONACO.EDU.VN’s support team if you are unsure about a particular procedure.

2.8 Conclusion

Understanding the detailed aspects of raw UDS request functionality in DTS Monaco empowers technicians and engineers to perform advanced diagnostics, customization, and programming. By mastering the UDS protocol, understanding the structure of UDS requests, and following best practices, you can unlock the full potential of DTS Monaco.

3. Step-by-Step Guide: Sending a Raw UDS Request with DTS Monaco

To make the process of sending raw UDS requests more accessible, here’s a step-by-step guide that walks you through the process using DTS Monaco. This guide is designed to be practical and easy to follow, ensuring that you can confidently perform advanced diagnostics.

3.1 Prerequisites

Before you begin, make sure you have the following:

- DTS Monaco Software: Ensure that you have the DTS Monaco software installed and properly configured on your computer.

- Vehicle Interface: You will need a compatible vehicle interface (e.g., a J2534 device) to connect your computer to the vehicle’s diagnostic port.

- Vehicle Connection: Establish a stable connection between your computer and the vehicle using the vehicle interface.

- UDS Documentation: Have the vehicle manufacturer’s UDS documentation on hand. This documentation will provide the necessary information about UDS services, data identifiers, and security access levels.

- Backup: Perform a full backup of the ECU’s configuration before proceeding.

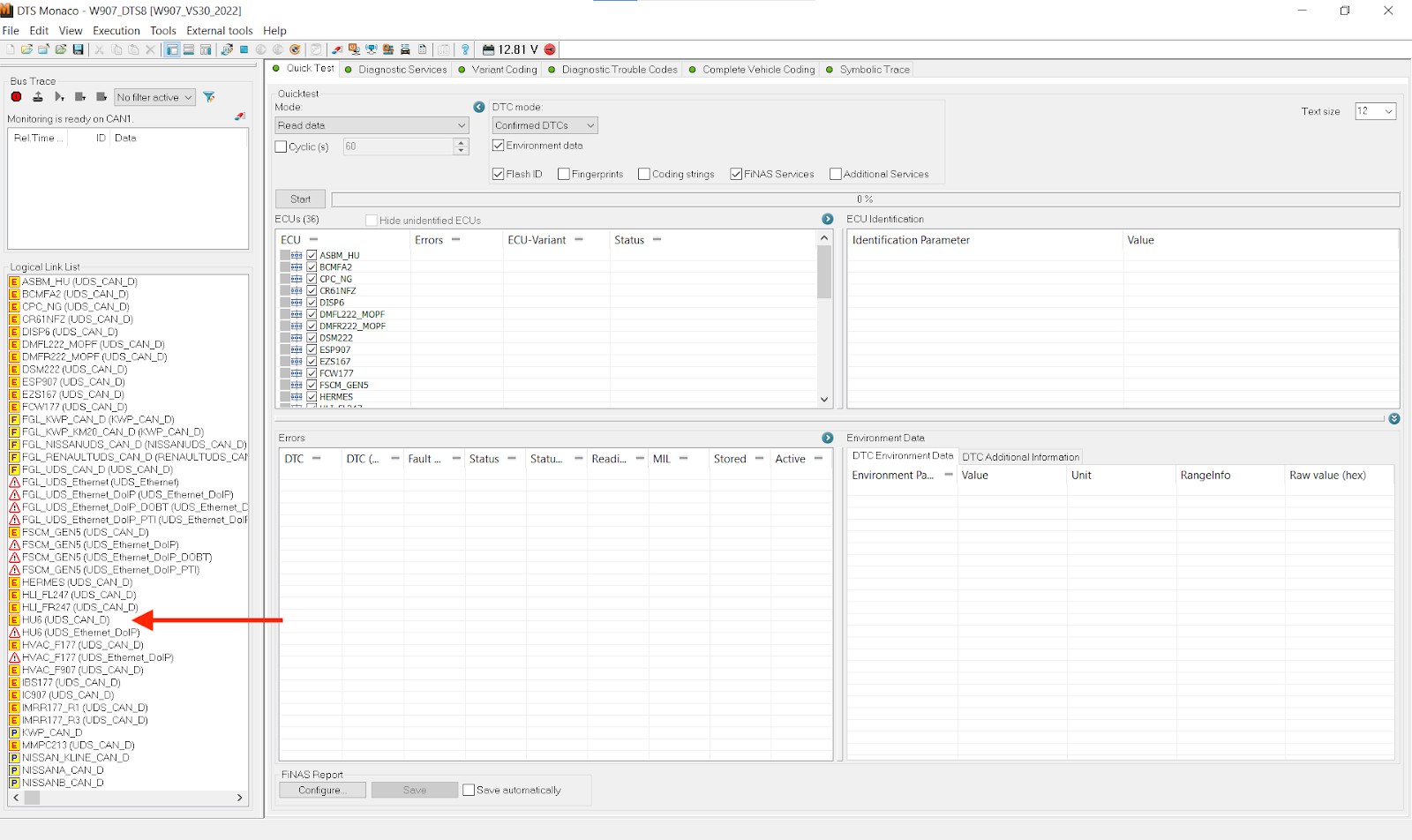

3.2 Step 1: Launch DTS Monaco and Connect to the ECU

- Open DTS Monaco: Launch the DTS Monaco software on your computer.

- Select Workspace: Choose the appropriate workspace for your vehicle. If you don’t have one, create a new workspace by selecting the correct ECU variant.

- Connect to the ECU: Establish a connection with the ECU you want to diagnose. Select the appropriate communication interface and ensure that the connection is stable.

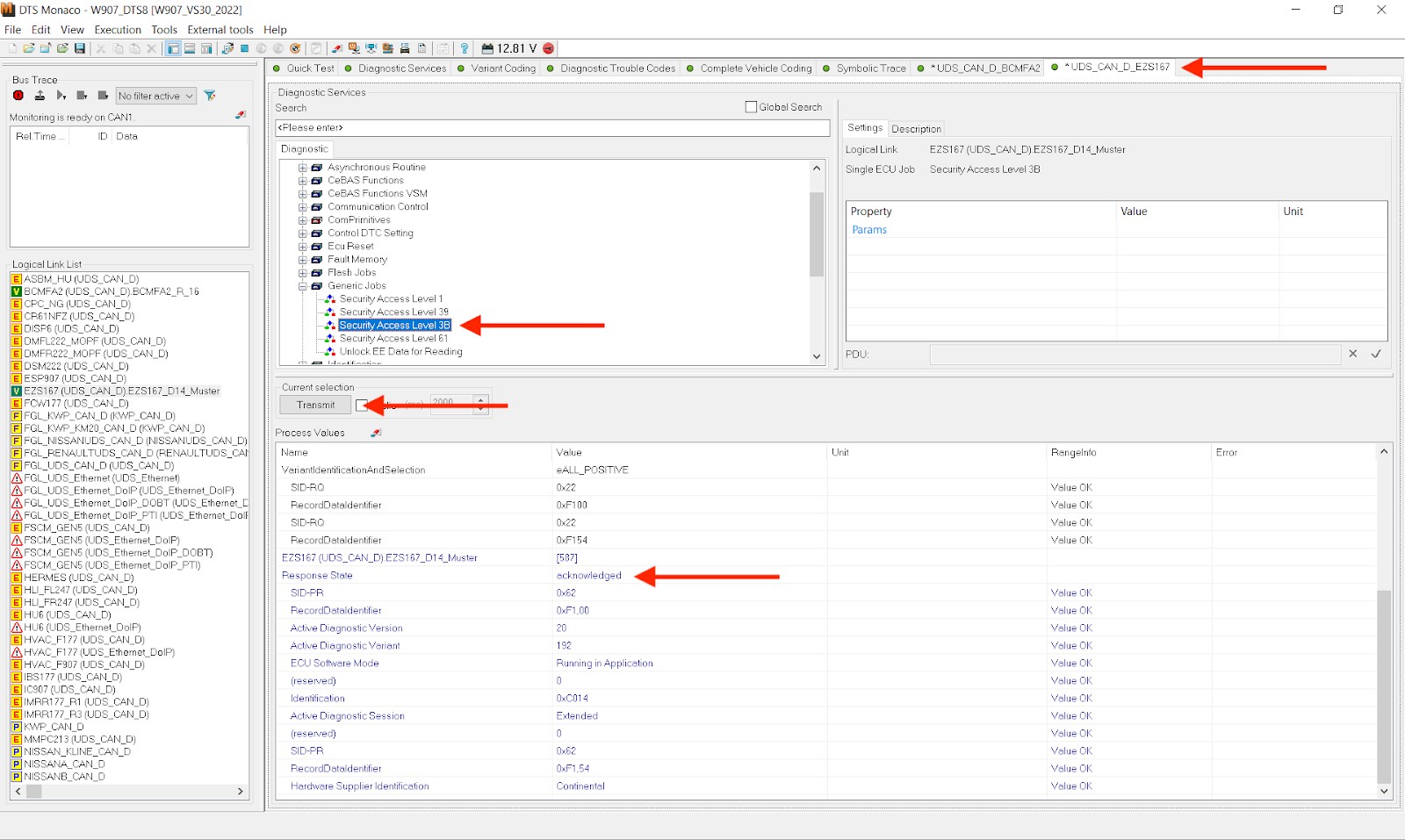

3.3 Step 2: Open the Diagnostic Services Tab

- Navigate to Diagnostic Services: Once connected to the ECU, navigate to the “Diagnostic Services” tab within DTS Monaco. This tab allows you to send raw UDS requests to the ECU.

3.4 Step 3: Enter the Raw UDS Request

- Manual Input: In the “Diagnostic Services” tab, you will find a field where you can manually enter the raw UDS request.

- Enter the Request: Enter the UDS request in hexadecimal format. For example, to read the engine coolant temperature (assuming the DID is

0xF190), you would enter:22 F1 90 - Verify the Request: Double-check the UDS request to ensure that it is correctly formatted and that you have entered the correct Service ID and Data Identifier.

3.5 Step 4: Send the UDS Request

- Transmit the Request: Click the “Transmit” button to send the UDS request to the ECU.

- Monitor the Response: DTS Monaco will display the response from the ECU in the response window. Monitor the response to see the data returned by the ECU.

3.6 Step 5: Interpret the Response

- Analyze the Response: Analyze the response data to extract the information you need. The format of the response data will depend on the specific UDS service and data identifier you used.

- Consult Documentation: Refer to the vehicle manufacturer’s UDS documentation to understand the format of the response data and how to interpret it.

- Convert the Data: If necessary, convert the response data from hexadecimal format to a more readable format, such as decimal or ASCII.

3.7 Example: Reading and Interpreting Engine Coolant Temperature

Let’s continue with the example of reading the engine coolant temperature.

- Send the Request: You have already sent the request

22 F1 90to the ECU. - Receive the Response: The ECU responds with the data

41 23. - Interpret the Data: According to the vehicle manufacturer’s documentation, the engine coolant temperature is encoded as a single byte value in degrees Celsius, with an offset of -40. Therefore, the temperature is calculated as:

Temperature = 41 - 40 = 1 degree Celsius

3.8 Step 6: Advanced Techniques (Optional)

- Session Management: If you need to perform more advanced diagnostics, use the Diagnostic Session Control service (

0x10) to switch to an extended diagnostic session. - Security Access: If you need to access protected functions within the ECU, use the Security Access service (

0x27) to unlock the function. - Scripting: For repetitive tasks, create a script to automate the process of sending multiple UDS requests. This can save time and reduce the risk of errors.

3.9 Tips for Success

- Verify Connection: Always verify that you have a stable connection to the ECU before sending any UDS requests.

- Double-Check Requests: Double-check your UDS requests to ensure that they are correctly formatted.

- Consult Documentation: Always consult the vehicle manufacturer’s documentation for UDS specifications and data identifiers.

- Backup: Always back up the ECU’s original configuration before making any changes.

- Testing: Test your UDS requests in a controlled environment before applying them to a vehicle.

- Expert Advice: Consult with experienced professionals or seek guidance from DTS-MONACO.EDU.VN’s support team if you are unsure about a particular procedure.

3.10 Conclusion

By following this step-by-step guide, you can confidently send raw UDS requests with DTS Monaco and perform advanced diagnostics on vehicle ECUs. Remember to always prioritize safety and consult the vehicle manufacturer’s documentation to ensure that you are using the correct UDS services and data identifiers.

4. Practical Applications of Raw UDS Requests in Automotive Repair

Raw UDS requests are not just theoretical exercises; they have numerous practical applications in automotive repair. This section will explore several real-world scenarios where the ability to send raw UDS requests can be invaluable in diagnosing and resolving complex vehicle issues.

4.1 Diagnosing Intermittent Faults

Intermittent faults can be particularly challenging to diagnose because they do not occur consistently. Raw UDS requests can help you identify the root cause of these faults by allowing you to monitor specific parameters and perform targeted tests.

- Monitoring Sensor Data: Use raw UDS requests to continuously monitor sensor data over an extended period. This can help you identify patterns or anomalies that occur only under certain conditions.

- Activating Components: Use raw UDS requests to activate or deactivate specific components to see if this triggers the fault. For example, you can activate a fuel injector or a solenoid valve to see if this causes the engine to misfire.

- Logging Data: Use raw UDS requests to log data from multiple sensors and components simultaneously. This can provide a comprehensive view of the system’s behavior and help you correlate the fault with specific events.

4.2 Performing Component-Level Diagnostics

Raw UDS requests can be used to perform detailed diagnostics at the component level, allowing you to isolate faults to specific parts of the vehicle.

- Testing Fuel Injectors: Use raw UDS requests to activate individual fuel injectors and measure their response time and flow rate. This can help you identify faulty injectors that are not delivering the correct amount of fuel.

- Testing Solenoid Valves: Use raw UDS requests to activate solenoid valves and measure their response time and actuation force. This can help you identify faulty valves that are not opening or closing properly.

- Testing Sensors: Use raw UDS requests to read the output of sensors and compare it to the expected value. This can help you identify faulty sensors that are providing inaccurate data.

Engine Coolant Temperature Sensor

Engine Coolant Temperature Sensor

4.3 Recalibrating Sensors and Actuators

In some cases, sensors and actuators may need to be recalibrated to ensure that they are functioning correctly. Raw UDS requests can be used to perform these recalibrations.

- Throttle Position Sensor (TPS) Calibration: Use raw UDS requests to recalibrate the TPS to ensure that the ECU is receiving accurate information about the throttle position.

- Mass Air Flow (MAF) Sensor Calibration: Use raw UDS requests to recalibrate the MAF sensor to ensure that the ECU is receiving accurate information about the amount of air entering the engine.

- Fuel Injector Calibration: Use raw UDS requests to calibrate the fuel injectors to ensure that they are delivering the correct amount of fuel.

4.4 Accessing and Modifying ECU Parameters

Raw UDS requests can be used to access and modify ECU parameters, allowing you to fine-tune the engine’s performance and optimize fuel efficiency.

- Fuel Trim Adjustments: Use raw UDS requests to adjust the fuel trim values to compensate for changes in engine components or operating conditions.

- Ignition Timing Adjustments: Use raw UDS requests to adjust the ignition timing to optimize engine performance and reduce emissions.

- Idle Speed Adjustments: Use raw UDS requests to adjust the idle speed to ensure that the engine is idling smoothly.

4.5 Performing Security Access Procedures

Some diagnostic and programming functions require security access to the ECU. Raw UDS requests can be used to perform these security access procedures.

- Seed-Key Authentication: Use raw UDS requests to perform seed-key authentication, which involves sending a seed value to the ECU and receiving a key value in return. This key is then used to unlock protected functions within the ECU.

- Bypassing Security Measures: In some cases, raw UDS requests can be used to bypass security measures that prevent you from accessing or modifying certain ECU parameters. However, this should only be done with caution and with a thorough understanding of the risks involved.

4.6 Case Studies

Here are a couple of case studies that illustrate the practical applications of raw UDS requests in automotive repair:

- Case Study 1: Diagnosing a Misfire on a BMW 3 Series: A BMW 3 Series was experiencing a persistent misfire on cylinder 3. Standard diagnostic procedures did not reveal the cause of the misfire. Using raw UDS requests, the technician was able to activate the fuel injector on cylinder 3 and measure its response time. The response time was significantly slower than the other injectors, indicating a faulty injector. Replacing the fuel injector resolved the misfire.

- Case Study 2: Recalibrating a Throttle Position Sensor on a Toyota Camry: A Toyota Camry was experiencing erratic idling and poor throttle response. The technician suspected that the throttle position sensor (TPS) was not calibrated correctly. Using raw UDS requests, the technician was able to recalibrate the TPS and restore the engine to its normal operating condition.

Throttle Position Sensor

Throttle Position Sensor

4.7 Conclusion

Raw UDS requests are a powerful tool for automotive technicians, enabling them to perform advanced diagnostics, component-level testing, and ECU modifications. By mastering the use of raw UDS requests, you can diagnose and resolve complex vehicle issues that would be difficult or impossible to address with standard diagnostic procedures.

5. Maximizing Diagnostic Efficiency with DTS Monaco and Raw UDS

In the fast-paced world of automotive repair, efficiency is key. Technicians need to diagnose and repair vehicles quickly and accurately to maximize productivity and customer satisfaction. DTS Monaco, with its ability to send raw UDS requests, offers a powerful means of boosting diagnostic efficiency. Let’s explore how this can be achieved.

5.1 Streamlining Diagnostic Workflows

DTS Monaco allows technicians to streamline their diagnostic workflows by providing a centralized platform for accessing and manipulating vehicle data.

- Customizable Interface: The DTS Monaco interface can be customized to display the most relevant data and parameters for a specific diagnostic task. This reduces the need to switch between multiple screens or tools, saving time and effort.

- Scripting Capabilities: DTS Monaco’s scripting capabilities allow technicians to automate repetitive diagnostic tasks. This can be particularly useful for performing a sequence of tests or logging data over an extended period.

- Data Logging: DTS Monaco can log data from multiple sensors and components simultaneously. This provides a comprehensive view of the system’s behavior and helps technicians quickly identify patterns or anomalies.

5.2 Reducing Diagnostic Time

By enabling technicians to perform targeted tests and access specific data, DTS Monaco can significantly reduce the amount of time required to diagnose a vehicle issue.

- Pinpointing Faults: Raw UDS requests allow technicians to pinpoint faults to specific components or circuits. This eliminates the need for time-consuming trial-and-error troubleshooting.

- Accessing Hidden Data: DTS Monaco can access hidden data and parameters that are not available through standard diagnostic procedures. This can provide valuable insights into the vehicle’s operation and help technicians quickly identify the root cause of a problem.

- Remote Diagnostics: DTS Monaco can be used for remote diagnostics, allowing technicians to diagnose and repair vehicles from a remote location. This can be particularly useful for supporting field technicians or diagnosing vehicles in remote areas.

5.3 Enhancing Diagnostic Accuracy

DTS Monaco enhances diagnostic accuracy by providing technicians with access to detailed vehicle data and advanced diagnostic tools.

- Precise Data: Raw UDS requests provide technicians with access to precise data from sensors and components. This allows them to make more informed decisions about the cause of a problem and the best course of action.

- Component Testing: DTS Monaco enables technicians to perform detailed component-level testing, ensuring that components are functioning correctly before replacing them.

- Calibration Procedures: DTS Monaco can be used to perform calibration procedures, ensuring that sensors and actuators are properly calibrated and functioning within their specified parameters.

5.4 Integrating with Other Diagnostic Tools

DTS Monaco can be integrated with other diagnostic tools to create a comprehensive diagnostic solution.

- Data Sharing: DTS Monaco can share data with other diagnostic tools, allowing technicians to access a wider range of information and perform more advanced analyses.

- Remote Access: DTS Monaco can be accessed remotely, allowing technicians to collaborate with experts and share diagnostic data in real-time.

- Cloud Integration: DTS Monaco can be integrated with cloud-based diagnostic platforms, providing technicians with access to a vast library of diagnostic information and resources.

DTS Monaco Diagnostic Interface

DTS Monaco Diagnostic Interface

5.5 Training and Support

To maximize the benefits of DTS Monaco, technicians need to be properly trained on its features and capabilities. DTS-MONACO.EDU.VN offers comprehensive training programs that cover all aspects of DTS Monaco, including raw UDS requests.

- Hands-On Training: DTS-MONACO.EDU.VN provides hands-on training that allows technicians to practice using DTS Monaco in a real-world environment.

- Expert Instructors: DTS-MONACO.EDU.VN’s instructors are experienced automotive technicians who are experts in DTS Monaco.

- Support Resources: DTS-MONACO.EDU.VN provides a variety of support resources, including online documentation, video tutorials, and a dedicated support team.

5.6 Case Studies

Here are a couple of case studies that illustrate how DTS Monaco can be used to maximize diagnostic efficiency:

- Case Study 1: Diagnosing an ABS Fault on a Mercedes-Benz C-Class: A Mercedes-Benz C-Class was experiencing an ABS fault. Using DTS Monaco, the technician was able to quickly identify a faulty wheel speed sensor. By sending raw UDS requests, the technician was able to verify the sensor’s output and confirm that it was not providing accurate data. Replacing the wheel speed sensor resolved the ABS fault.

- Case Study 2: Calibrating an Airbag System on a Volkswagen Golf: A Volkswagen Golf had an airbag system that needed to be calibrated after a minor accident. Using DTS Monaco, the technician was able to perform the calibration procedure in a matter of minutes. By sending raw UDS requests, the technician was able to reset the airbag control unit and ensure that the airbag system was functioning correctly.

5.7 Conclusion

DTS Monaco, with its ability to send raw UDS requests, is a powerful tool for maximizing diagnostic efficiency in the automotive repair industry. By streamlining diagnostic workflows, reducing diagnostic time, enhancing diagnostic accuracy, and integrating with other diagnostic tools, DTS Monaco helps technicians diagnose and repair vehicles quickly and accurately.

6. Common Challenges and Troubleshooting Tips When Using Raw UDS Requests

While sending raw UDS requests with DTS Monaco can be incredibly powerful, it’s not without its challenges. This section addresses common issues encountered and provides troubleshooting tips to help you overcome these hurdles.

6.1 Communication Errors

- Challenge: Establishing a stable connection with the ECU can sometimes be problematic. Common error messages include “Connection Failed” or “ECU Not Responding.”

- Troubleshooting Tips:

- Verify Interface: Ensure that your vehicle interface (e.g., J2534 device) is properly connected to both your computer and the vehicle’s diagnostic port.

- Check Drivers: Verify that the drivers for your vehicle interface are up-to-date. Outdated or corrupted drivers can cause communication issues.

- Confirm Compatibility: Make sure that your vehicle interface is compatible with the vehicle you are trying to diagnose.

- Inspect Cables: Inspect the diagnostic cables for any signs of damage or wear.

- Restart: Try restarting both your computer and the vehicle to reset the communication channels.

- ECU Power: Ensure the ECU is properly powered. Check fuses and wiring related to the ECU power supply.

6.2 Incorrect UDS Request Format

- Challenge: Sending a UDS request with an incorrect format can result in error messages or unexpected behavior.

- Troubleshooting Tips:

- Refer to Documentation: Always refer to the vehicle manufacturer’s UDS documentation for the correct format of UDS requests.

- Double-Check Syntax: Double-check the syntax of your UDS request, paying close attention to the order of bytes, the Service ID, and the Data Identifier.

- Use Hex Editor: Use a hex editor to verify that the UDS request is formatted correctly.

- Example Requests: Compare your UDS request to known working examples to identify any discrepancies.

- Online Resources: Consult online forums and communities for examples of UDS requests for your vehicle make and model.

6.3 Security Access Issues

- Challenge: Accessing protected functions within the ECU may require security access. Failing to obtain security access can result in error messages or the inability to perform certain diagnostic or programming tasks.

- Troubleshooting Tips:

- Seed-Key Algorithm: Implement the seed-key algorithm to unlock the protected functions. This involves sending a seed value to the ECU and receiving a key value in return.

- Consult Documentation: Refer to the vehicle manufacturer’s documentation for the seed-key algorithm and the security access levels required for specific functions.

- Security Access Codes: Obtain the security access codes from the vehicle manufacturer.

- Bypass Security: Be cautious when attempting to bypass security measures. Doing so can void the vehicle’s warranty or cause damage to the ECU.

DTS Monaco Security Access

DTS Monaco Security Access

6.4 Data Interpretation Problems

- Challenge: Interpreting the response data from the ECU can be difficult, especially if you are not familiar with the data format.

- Troubleshooting Tips:

- Refer to Documentation: Consult the vehicle manufacturer’s documentation for the format of the response data.

- Data Converters: Use data converters to convert the response data from hexadecimal format to a more readable format, such as decimal or ASCII.

- Online Resources: Search online forums and communities for information on how to interpret the response data for your vehicle make and model.

- Data Analysis Tools: Use data analysis tools to visualize and analyze the response data.

- Consult Experts: Consult with experienced professionals or seek guidance from DTS-MONACO.EDU.VN’s support team if you are unsure about how to interpret the response data.

6.5 ECU Incompatibility

- Challenge: In some cases, the ECU may not be compatible with the UDS requests you are sending. This can result in error messages or the inability to perform certain diagnostic or programming tasks.

- Troubleshooting Tips:

- Verify Compatibility: Verify that the ECU is compatible with the UDS protocol.

- Check Firmware Version: Check the firmware version of the ECU and make sure that it is up-to-date.

- Consult Documentation: Consult the vehicle manufacturer’s documentation for information on the UDS services supported by the ECU.

- Use Alternative Protocols: If the ECU is not compatible with the UDS protocol, try using an alternative diagnostic protocol, such as KWP2000 or ISO 9141.

6.6 Software Glitches

- Challenge: DTS Monaco itself may experience glitches or bugs that can interfere with the diagnostic process.

- Troubleshooting Tips:

- Update Software: Make sure that you are using the latest version of DTS Monaco.

- Restart Software: Try restarting DTS Monaco to reset the software.

- Reinstall Software: If the problem persists, try reinstalling DTS Monaco.

- Check System Requirements: Verify that your computer meets the minimum system requirements for DTS Monaco.

- Contact Support: Contact the DTS Monaco support team for assistance.

6.7 Hardware Issues

- Challenge: Problems with your computer, vehicle interface, or diagnostic cables can also cause issues when using raw UDS requests.

- Troubleshooting Tips:

- Test Hardware: Test your hardware to make sure that it is functioning correctly.

- Replace Components: Replace any faulty components.

- Use Known-Good Hardware: Try using known-good hardware to rule out any hardware issues.

6.8 General Tips

- Document Everything: Keep a detailed log of all the steps you take and the results you obtain. This will help you track your progress and identify any potential problems.

- Take Breaks: If you are struggling to diagnose a problem, take a break and come back to it later with a fresh perspective.

- Ask for Help: Don’t be afraid to ask for help from experienced professionals or online communities.

By following these troubleshooting tips, you can overcome common challenges and successfully use raw UDS requests