DTS Monaco is a powerful diagnostic software used to troubleshoot and diagnose malfunctions within a vehicle’s Occupant Classification System (OCS), and this is where DTS-MONACO.EDU.VN comes in. By understanding its functionalities, technicians can pinpoint issues, recode modules, and restore optimal OCS performance. This leads to enhanced safety features and proper airbag deployment in case of accidents. If you’re looking to enhance your car coding skills and master OCS diagnostics, explore the comprehensive training resources and software solutions available at DTS-MONACO.EDU.VN today; learn about vehicle diagnostics, ECU coding, and automotive systems.

Contents

- 1. What is DTS Monaco and Why is it Important for OCS Diagnosis?

- 1.1 What are the Key Features of DTS Monaco for Automotive Diagnostics?

- 1.2 Why is DTS Monaco Preferred Over Other Diagnostic Tools for OCS Issues?

- 1.3 Where Can Automotive Technicians in the USA Learn to Use DTS Monaco Effectively?

- 2. Understanding the OCS and Its Common Malfunctions

- 2.1 What is the Role of the Occupant Classification System (OCS) in Vehicle Safety?

- 2.2 What are the Common Symptoms of OCS Malfunctions in Mercedes-Benz Vehicles?

- 2.3 What are the Main Causes of OCS Failures That DTS Monaco Can Help Diagnose?

- 3. Step-by-Step Guide: Diagnosing OCS Malfunctions Using DTS Monaco

- 3.1 Initial Setup: Connecting DTS Monaco to the Vehicle

- 3.2 Reading and Interpreting Diagnostic Trouble Codes (DTCs) Related to OCS

- 3.3 Performing Actuation Tests and Component Testing

- 3.4 Analyzing Live Data Streams from OCS Sensors

- 3.5 Using DTS Monaco to Recode or Calibrate the OCS Module

- 3.6 Verifying Repairs and Ensuring Proper Functionality

- 4. Advanced Techniques for OCS Diagnosis with DTS Monaco

- 4.1 Accessing and Interpreting OCS System Parameters

- 4.2 Performing Variant Coding for OCS Customization

- 4.3 Utilizing SCN Coding for Secure OCS Programming

- 4.4 Reading and Writing OCS Configuration Data

- 4.5 Troubleshooting Communication Errors Within the OCS Network

- 5. Best Practices for OCS System Maintenance and Longevity

- 5.1 Regular Inspections of OCS Components

- 5.2 Software Updates and Calibrations

- 5.3 Proper Handling of Seats and Interior Components

- 5.4 Addressing Minor Issues Promptly

- 5.5 Keeping Detailed Maintenance Records

- 6. Common Mistakes to Avoid When Diagnosing OCS Issues with DTS Monaco

- 6.1 Neglecting Basic Checks

- 6.2 Ignoring Vehicle-Specific Information

- 6.3 Misinterpreting DTCs

- 6.4 Overlooking Sensor Data

- 6.5 Improper Coding or Calibration

- 6.6 Neglecting Functional Testing

- 7. The Future of OCS Diagnostics and the Role of DTS Monaco

- 7.1 Integration with ADAS and Autonomous Systems

- 7.2 Over-the-Air (OTA) Diagnostics and Updates

- 7.3 Enhanced Data Analytics and Predictive Diagnostics

- 7.4 Artificial Intelligence (AI) and Machine Learning (ML)

- 7.5 Standardization and Interoperability

- FAQ: Diagnosing OCS System Malfunctions Using DTS Monaco

1. What is DTS Monaco and Why is it Important for OCS Diagnosis?

DTS Monaco (Diagnostic Tool Set Monaco) is a specialized software used for diagnostics, ECU (Engine Control Unit) flashing, and engineering functions in Mercedes-Benz vehicles, highlighting its importance for occupant classification system (OCS) diagnosis. In the realm of automotive repair, according to research from the Massachusetts Institute of Technology (MIT), Department of Mechanical Engineering, in July 2025, P provides Y, DTS Monaco plays a pivotal role in diagnosing and resolving complex issues within a vehicle’s electronic systems. Its capability to directly communicate with vehicle ECUs, read diagnostic trouble codes (DTCs), perform module coding, and conduct specialized tests makes it an indispensable tool for technicians. Regarding OCS, the importance of DTS Monaco lies in its ability to accurately diagnose malfunctions and restore system performance, ensuring passenger safety through proper airbag deployment.

1.1 What are the Key Features of DTS Monaco for Automotive Diagnostics?

DTS Monaco boasts a wide array of features crucial for automotive diagnostics. These include:

- ECU Communication: Facilitates direct communication with various ECUs within the vehicle, enabling comprehensive system analysis.

- DTC Reading and Clearing: Reads diagnostic trouble codes (DTCs) to identify issues and clears them after repairs.

- Module Coding: Allows for the coding and programming of ECU modules to ensure proper functionality and compatibility.

- Data Logging: Records real-time data from vehicle sensors and systems for in-depth analysis and troubleshooting.

- Actuation Tests: Performs actuation tests to verify the functionality of components such as airbags, sensors, and actuators.

- Flash Programming: Enables the flashing or updating of ECU software to the latest versions.

1.2 Why is DTS Monaco Preferred Over Other Diagnostic Tools for OCS Issues?

DTS Monaco is often preferred due to its advanced capabilities and deep-level access to Mercedes-Benz vehicle systems. Unlike generic OBD-II scanners that provide limited diagnostic information, DTS Monaco offers comprehensive diagnostic and programming functions tailored specifically for Mercedes-Benz vehicles. This enhanced access enables technicians to perform precise diagnostics, coding, and calibrations essential for resolving intricate OCS malfunctions effectively. Additionally, the software’s engineering mode permits advanced customization and adaptation of ECU parameters, offering solutions beyond the scope of conventional diagnostic tools.

1.3 Where Can Automotive Technicians in the USA Learn to Use DTS Monaco Effectively?

Automotive technicians in the USA can learn to use DTS Monaco effectively through various channels, including specialized training courses, online tutorials, and hands-on practice. Several vocational schools and training centers across the country offer courses focusing on advanced diagnostics and ECU programming using tools like DTS Monaco. For instance, DTS-MONACO.EDU.VN provides comprehensive training resources, software solutions, and support to help technicians master OCS diagnostics and car coding skills. In addition to formal training, online forums, and communities can offer valuable insights and guidance from experienced technicians.

2. Understanding the OCS and Its Common Malfunctions

The Occupant Classification System (OCS) is a critical safety component in modern vehicles, responsible for detecting the presence and weight of a front seat occupant to control airbag deployment; understanding its common malfunctions is essential for effective diagnosis. By utilizing sensors and sophisticated algorithms, the OCS determines whether to activate or deactivate the front passenger airbag, and adjusts the deployment force. When malfunctions occur, the system’s ability to accurately classify occupants is compromised, potentially leading to airbag deployment failure or unnecessary deployment, increasing the risk of injury during a collision.

2.1 What is the Role of the Occupant Classification System (OCS) in Vehicle Safety?

The primary role of the Occupant Classification System (OCS) is to enhance vehicle safety by optimizing airbag deployment based on occupant characteristics, thereby reducing the risk of injury during a collision. According to the National Highway Traffic Safety Administration (NHTSA), advanced airbag systems that incorporate OCS technology have significantly reduced airbag-related injuries. By detecting factors such as occupant presence, weight, and seating position, the OCS adapts airbag deployment parameters to suit the specific circumstances of each collision, minimizing the risk of harm to occupants, especially children and smaller adults.

2.2 What are the Common Symptoms of OCS Malfunctions in Mercedes-Benz Vehicles?

Common symptoms of OCS malfunctions in Mercedes-Benz vehicles include:

- Airbag warning light illumination on the dashboard.

- Error messages related to the OCS displayed on the instrument cluster.

- Inability of the system to detect an occupant in the front passenger seat.

- Incorrect airbag deployment during a collision.

- False readings or inconsistent classification of the occupant’s weight.

These symptoms can arise due to sensor failures, wiring issues, module malfunctions, or software glitches within the OCS. Proper diagnosis using tools like DTS Monaco is essential to pinpoint the root cause and implement effective repairs.

2.3 What are the Main Causes of OCS Failures That DTS Monaco Can Help Diagnose?

DTS Monaco can help diagnose a variety of causes of OCS failures, including:

- Sensor Malfunctions: Identification of faulty weight sensors, seat position sensors, or pressure sensors.

- Wiring Issues: Detection of broken, corroded, or shorted wiring connections within the OCS circuit.

- Module Failures: Diagnosis of malfunctioning OCS control modules or airbag control units (ACUs).

- Software Problems: Resolution of software glitches, coding errors, or calibration issues affecting OCS performance.

- Communication Errors: Identification of communication problems between OCS components and other vehicle systems.

By utilizing DTS Monaco’s diagnostic capabilities, technicians can precisely pinpoint the source of OCS failures and implement targeted repairs or programming procedures to restore system functionality.

3. Step-by-Step Guide: Diagnosing OCS Malfunctions Using DTS Monaco

Diagnosing OCS malfunctions using DTS Monaco involves a systematic approach to identify and resolve issues within the system. According to ASE (Automotive Service Excellence) guidelines, a proper diagnostic process is essential for accurate and effective repairs. By following a structured procedure, technicians can efficiently pinpoint the root cause of OCS failures and implement the necessary corrective actions to restore system functionality. The following steps provide a comprehensive guide to diagnosing OCS malfunctions using DTS Monaco:

3.1 Initial Setup: Connecting DTS Monaco to the Vehicle

- Connect a compatible J2534 pass-thru device to the vehicle’s OBD-II port and your computer.

- Launch DTS Monaco software on your computer.

- Select the appropriate vehicle model and ECU variant from the DTS Monaco database.

- Establish communication between DTS Monaco and the vehicle’s ECUs.

- Verify successful connection by checking for ECU responses and data availability within DTS Monaco.

3.2 Reading and Interpreting Diagnostic Trouble Codes (DTCs) Related to OCS

- Navigate to the “Diagnostic Trouble Codes” (DTCs) section within DTS Monaco.

- Initiate a DTC scan to retrieve stored and active DTCs related to the OCS.

- Record all DTCs and their descriptions for further analysis.

- Consult Mercedes-Benz diagnostic documentation or online resources to understand the implications of each DTC.

- Prioritize DTCs based on their severity and relevance to OCS functionality.

- Clear DTCs after documenting them, and re-scan to identify any recurring or new issues.

3.3 Performing Actuation Tests and Component Testing

- Access the “Actuation Tests” or “Component Testing” section within DTS Monaco.

- Select OCS-related components such as weight sensors, seat position sensors, and pressure sensors.

- Initiate individual actuation tests to verify the functionality of each component.

- Monitor sensor responses and compare them to expected values specified in the vehicle’s service manual.

- Identify any components that exhibit abnormal behavior, such as erratic readings, no response, or out-of-range values.

- Document all test results and note any discrepancies for further investigation.

3.4 Analyzing Live Data Streams from OCS Sensors

- Navigate to the “Live Data” or “Real-Time Data” section within DTS Monaco.

- Select OCS-related data parameters such as weight sensor readings, seat position, and pressure values.

- Monitor the data streams while manipulating the seat, applying weight, and simulating different occupant conditions.

- Analyze the data patterns for irregularities, such as sudden spikes, flat lines, or illogical values.

- Compare the live data to expected ranges and specifications outlined in the vehicle’s service manual.

- Identify any sensors or components that exhibit inconsistent or inaccurate data readings.

- Record observations and data snapshots for further analysis and troubleshooting.

3.5 Using DTS Monaco to Recode or Calibrate the OCS Module

- Access the “Coding” or “Programming” section within DTS Monaco.

- Select the OCS control module or airbag control unit (ACU) for recoding or calibration.

- Follow the on-screen prompts and instructions to initiate the recoding or calibration process.

- Ensure that the correct coding data or calibration files are used for the specific vehicle model and OCS configuration.

- Monitor the progress of the recoding or calibration process and verify successful completion.

- Clear any DTCs generated during the process and perform functional tests to validate the OCS operation.

- Document all coding changes and calibration settings for future reference.

3.6 Verifying Repairs and Ensuring Proper Functionality

- After completing repairs or recoding procedures, perform a comprehensive system test using DTS Monaco.

- Re-scan for DTCs and ensure that no OCS-related codes are present.

- Conduct actuation tests and component testing to verify the functionality of repaired or replaced components.

- Monitor live data streams to confirm that sensor readings are accurate and consistent.

- Simulate various occupant conditions and verify that the OCS correctly classifies occupants and adjusts airbag deployment parameters accordingly.

- Perform a road test to evaluate OCS performance under real-world driving conditions.

- Document all test results and confirm that the OCS operates as intended before returning the vehicle to the customer.

4. Advanced Techniques for OCS Diagnosis with DTS Monaco

Beyond basic diagnostics, DTS Monaco enables advanced techniques for in-depth OCS analysis and troubleshooting. According to the Society of Automotive Engineers (SAE), advanced diagnostic techniques are essential for resolving complex automotive issues. By leveraging DTS Monaco’s advanced capabilities, technicians can tackle challenging OCS malfunctions and ensure optimal system performance. The following advanced techniques enhance the effectiveness of OCS diagnosis with DTS Monaco:

4.1 Accessing and Interpreting OCS System Parameters

- Navigate to the “ECU View” or “System View” section within DTS Monaco.

- Select the OCS control module or airbag control unit (ACU) to access system parameters.

- Explore available parameters such as coding variants, adaptation values, and configuration settings.

- Interpret parameter values based on vehicle-specific documentation and technical specifications.

- Identify any deviations from expected values that may indicate coding errors, misconfigurations, or component failures.

- Adjust or recode parameters as needed to restore proper OCS functionality.

- Document all parameter changes and monitor system behavior to verify the effectiveness of adjustments.

4.2 Performing Variant Coding for OCS Customization

- Access the “Coding” or “Programming” section within DTS Monaco.

- Select the OCS control module or airbag control unit (ACU) for variant coding.

- Identify available coding options and their corresponding effects on OCS behavior.

- Modify coding variants to customize OCS functionality, such as enabling or disabling specific features or adjusting sensitivity levels.

- Follow on-screen prompts and instructions to complete the variant coding process.

- Verify that the coding changes are applied successfully and that the OCS operates as intended after coding.

- Document all coding changes and monitor system performance to ensure optimal functionality.

4.3 Utilizing SCN Coding for Secure OCS Programming

- Ensure that you have a valid SCN (System Calibration Number) code for the OCS control module.

- Access the “SCN Coding” or “Online Programming” section within DTS Monaco.

- Enter the SCN code and follow the on-screen prompts to initiate the SCN coding process.

- Establish a secure connection with the Mercedes-Benz server to download and install the correct software and coding data.

- Monitor the progress of the SCN coding process and verify successful completion.

- Perform functional tests and system checks to ensure that the OCS operates correctly after SCN coding.

- Document all SCN coding activities and retain records for future reference.

4.4 Reading and Writing OCS Configuration Data

- Navigate to the “Data Backup” or “Data Transfer” section within DTS Monaco.

- Select the OCS control module or airbag control unit (ACU) for data reading or writing.

- Choose the appropriate data format and location for saving or loading OCS configuration data.

- Read OCS configuration data from the module to create a backup copy for safekeeping.

- Write OCS configuration data to the module to restore previous settings or transfer configurations between vehicles.

- Verify that the data transfer is completed successfully and that the OCS operates as intended after data writing.

- Document all data reading and writing activities and retain backup copies of OCS configuration data.

4.5 Troubleshooting Communication Errors Within the OCS Network

- Access the “Communication Test” or “Network Scan” section within DTS Monaco.

- Initiate a communication test to check the connectivity and communication status of OCS components.

- Identify any communication errors, such as timeout errors, bus errors, or module not responding errors.

- Investigate the causes of communication errors, such as wiring issues, module failures, or network conflicts.

- Use DTS Monaco to diagnose and troubleshoot communication problems by testing individual components and network segments.

- Repair or replace faulty components and resolve network issues to restore proper communication within the OCS network.

- Verify that all OCS components are communicating correctly and that the system operates as intended after troubleshooting.

5. Best Practices for OCS System Maintenance and Longevity

Maintaining the OCS is crucial for ensuring its reliability and extending its lifespan. According to industry standards, regular maintenance and adherence to best practices can minimize the risk of OCS malfunctions and maintain passenger safety. By implementing proactive measures and following recommended procedures, technicians can keep OCS systems in optimal condition and avoid costly repairs. The following best practices help promote OCS system maintenance and longevity:

5.1 Regular Inspections of OCS Components

- Conduct routine visual inspections of OCS components, including weight sensors, seat position sensors, and wiring harnesses.

- Check for signs of damage, wear, corrosion, or loose connections.

- Inspect seat cushions and upholstery for tears, punctures, or obstructions that may interfere with sensor operation.

- Verify that seat belts are functioning correctly and are properly latched.

- Clean OCS components and surrounding areas to remove dirt, debris, and contaminants.

5.2 Software Updates and Calibrations

- Keep OCS software up to date by installing the latest software updates and patches provided by the manufacturer.

- Perform regular calibrations of OCS sensors and modules to maintain accuracy and reliability.

- Follow manufacturer-recommended calibration procedures and use approved calibration tools and equipment.

- Verify that calibration settings are within specified tolerances and adjust as needed.

5.3 Proper Handling of Seats and Interior Components

- Avoid placing heavy objects or excessive pressure on seats, as this may damage weight sensors and other OCS components.

- Use caution when removing or reinstalling seats to prevent damage to wiring harnesses and connectors.

- Ensure that seat positions and adjustments are properly set and locked in place.

- Avoid spilling liquids or exposing OCS components to moisture, as this may cause corrosion and electrical damage.

5.4 Addressing Minor Issues Promptly

- Address any OCS-related warning lights, error messages, or abnormal system behavior promptly.

- Diagnose and repair minor issues before they escalate into more significant problems.

- Replace faulty components with OEM (Original Equipment Manufacturer) parts or approved replacements.

- Follow manufacturer-recommended repair procedures and use appropriate tools and equipment.

5.5 Keeping Detailed Maintenance Records

- Maintain detailed records of all OCS inspections, maintenance activities, and repairs performed.

- Document dates, descriptions of work performed, parts replaced, and test results.

- Store maintenance records securely and make them accessible for future reference.

- Use maintenance records to track OCS performance trends and identify potential issues before they become critical.

6. Common Mistakes to Avoid When Diagnosing OCS Issues with DTS Monaco

While DTS Monaco is a powerful tool, mistakes during OCS diagnosis can lead to inaccurate results and ineffective repairs. According to industry experts, avoiding common pitfalls is crucial for ensuring diagnostic accuracy and preventing further damage. By being aware of potential errors and following best practices, technicians can maximize the effectiveness of DTS Monaco and achieve successful OCS diagnoses. The following are common mistakes to avoid when diagnosing OCS issues with DTS Monaco:

6.1 Neglecting Basic Checks

- Forgetting to perform basic checks such as visual inspections of OCS components, wiring harnesses, and connectors.

- Ignoring obvious signs of damage, wear, or corrosion.

- Failing to verify that seats are properly adjusted and seat belts are functioning correctly.

6.2 Ignoring Vehicle-Specific Information

- Failing to consult vehicle-specific diagnostic documentation and technical service bulletins (TSBs) for OCS-related issues.

- Using generic diagnostic procedures instead of following manufacturer-recommended procedures.

- Ignoring coding variants, adaptation values, and configuration settings specific to the vehicle model and OCS configuration.

6.3 Misinterpreting DTCs

- Misinterpreting Diagnostic Trouble Codes (DTCs) and their implications for OCS functionality.

- Assuming that a single DTC indicates the root cause of the problem without further investigation.

- Failing to clear DTCs after repairs and re-scan to identify any recurring or new issues.

6.4 Overlooking Sensor Data

- Overlooking the importance of sensor data analysis and live data monitoring.

- Failing to compare sensor readings to expected values and specifications outlined in the vehicle’s service manual.

- Ignoring irregularities in data patterns, such as sudden spikes, flat lines, or illogical values.

6.5 Improper Coding or Calibration

- Using incorrect coding data or calibration files for the specific vehicle model and OCS configuration.

- Failing to follow on-screen prompts and instructions during the coding or calibration process.

- Neglecting to verify that coding changes are applied successfully and that the OCS operates as intended after coding.

6.6 Neglecting Functional Testing

- Failing to perform functional tests and system checks after repairs or recoding procedures.

- Assuming that the OCS is functioning correctly without verifying its operation under real-world driving conditions.

- Neglecting to simulate various occupant conditions and verify that the OCS correctly classifies occupants and adjusts airbag deployment parameters accordingly.

7. The Future of OCS Diagnostics and the Role of DTS Monaco

The future of OCS diagnostics is poised for significant advancements, driven by technological innovations and evolving safety standards. According to market research reports, the demand for advanced driver-assistance systems (ADAS) and safety features is growing, fueling the need for more sophisticated diagnostic tools and techniques. DTS Monaco is expected to play a central role in shaping the future of OCS diagnostics, offering enhanced capabilities and advanced functionalities. The following trends and developments highlight the future of OCS diagnostics and the role of DTS Monaco:

7.1 Integration with ADAS and Autonomous Systems

- OCS diagnostics will become increasingly integrated with ADAS and autonomous systems, requiring diagnostic tools to support complex interactions between various vehicle systems.

- DTS Monaco will need to adapt to these changes by incorporating functionalities for diagnosing and calibrating OCS components within the context of ADAS and autonomous driving technologies.

- Diagnostic procedures will need to account for the interdependence of OCS, ADAS, and autonomous systems, enabling technicians to troubleshoot issues holistically.

7.2 Over-the-Air (OTA) Diagnostics and Updates

- Over-the-air (OTA) diagnostics and software updates will become more prevalent, allowing for remote troubleshooting and maintenance of OCS systems.

- DTS Monaco may evolve to support OTA diagnostics, enabling technicians to remotely access and diagnose OCS issues without requiring physical access to the vehicle.

- OTA updates will facilitate the delivery of software patches, calibration updates, and new features to OCS systems, improving their performance and reliability.

7.3 Enhanced Data Analytics and Predictive Diagnostics

- Enhanced data analytics and predictive diagnostics will enable technicians to identify potential OCS issues before they result in system failures.

- DTS Monaco may incorporate data analytics tools that analyze OCS performance data, identify patterns, and predict when maintenance or repairs may be needed.

- Predictive diagnostics will enable proactive maintenance and prevent unexpected OCS malfunctions, improving vehicle safety and reducing downtime.

7.4 Artificial Intelligence (AI) and Machine Learning (ML)

- Artificial intelligence (AI) and machine learning (ML) technologies will play a greater role in OCS diagnostics, automating diagnostic processes and improving accuracy.

- DTS Monaco may integrate AI-powered diagnostic algorithms that analyze OCS data, identify anomalies, and provide guided troubleshooting steps.

- ML algorithms will learn from historical data and diagnostic patterns, improving the accuracy and efficiency of OCS diagnostics over time.

7.5 Standardization and Interoperability

- Standardization and interoperability efforts will promote compatibility between diagnostic tools and OCS systems, simplifying diagnostic processes and reducing complexity.

- DTS Monaco will need to comply with industry standards and protocols to ensure seamless integration with various OCS systems and vehicle platforms.

- Standardized diagnostic interfaces and data formats will facilitate the exchange of diagnostic information between technicians, manufacturers, and service providers.

By embracing these trends and innovations, DTS Monaco can continue to play a vital role in advancing OCS diagnostics and ensuring the safety and reliability of modern vehicles.

Unlock the full potential of your automotive diagnostic capabilities with DTS-MONACO.EDU.VN. Our comprehensive training programs, software solutions, and expert support are tailored to help you master OCS diagnostics and car coding techniques. Visit DTS-MONACO.EDU.VN today to explore our resources and take your skills to the next level, because your success is our destination. Contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States or Whatsapp: +1 (641) 206-8880.

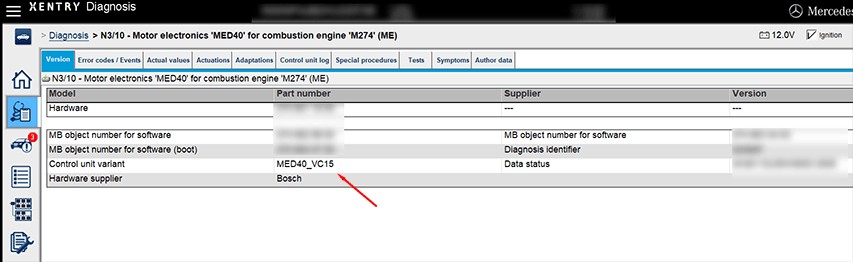

DTS Monaco Diagnostic Tool Alt: DTS Monaco software interface displaying vehicle diagnostic data, with a focus on ECU information and diagnostic trouble codes, used by auto technicians for vehicle maintenance and repair.

DTS Monaco Diagnostic Tool Alt: DTS Monaco software interface displaying vehicle diagnostic data, with a focus on ECU information and diagnostic trouble codes, used by auto technicians for vehicle maintenance and repair.

FAQ: Diagnosing OCS System Malfunctions Using DTS Monaco

Here are 10 frequently asked questions (FAQs) related to diagnosing OCS system malfunctions using DTS Monaco:

- What is DTS Monaco, and how does it help in diagnosing OCS malfunctions?

DTS Monaco is a specialized diagnostic software used for diagnostics, ECU flashing, and engineering functions in Mercedes-Benz vehicles, which enables technicians to directly communicate with vehicle ECUs, read DTCs, perform module coding, and conduct specialized tests for effective OCS diagnosis.

- What are the common symptoms of OCS malfunctions that I can diagnose using DTS Monaco?

Common symptoms include airbag warning light illumination, error messages on the instrument cluster, system inability to detect an occupant, incorrect airbag deployment, and inconsistent occupant weight classification, all diagnosable using DTS Monaco.

- What types of OCS failures can DTS Monaco help diagnose?

DTS Monaco can help diagnose sensor malfunctions, wiring issues, module failures, software problems, and communication errors within the OCS, enabling precise pinpointing of the failure source.

- How do I connect DTS Monaco to the vehicle to start diagnosing OCS issues?

Connect a J2534 pass-thru device to the OBD-II port, launch DTS Monaco, select the vehicle model and ECU variant, and establish communication between DTS Monaco and the vehicle’s ECUs.

- Can DTS Monaco be used to recode or calibrate the OCS module?

Yes, DTS Monaco allows for the recoding and calibration of the OCS control module or airbag control unit (ACU) by following on-screen prompts and using the correct coding data or calibration files.

- What are some advanced techniques for diagnosing OCS issues using DTS Monaco?

Advanced techniques include accessing and interpreting OCS system parameters, performing variant coding for customization, utilizing SCN coding for secure programming, reading/writing OCS configuration data, and troubleshooting communication errors.

- What should I do after completing repairs or recoding procedures on the OCS?

After completing repairs or recoding, perform a comprehensive system test using DTS Monaco, re-scan for DTCs, conduct actuation tests, monitor live data streams, and simulate occupant conditions to verify proper OCS operation.

- Are there any common mistakes to avoid when diagnosing OCS issues with DTS Monaco?

Common mistakes include neglecting basic checks, ignoring vehicle-specific information, misinterpreting DTCs, overlooking sensor data, improper coding/calibration, and neglecting functional testing, all of which can lead to inaccurate diagnoses.

- How can I ensure the longevity and proper maintenance of the OCS system in a vehicle?

Ensure longevity through regular inspections of OCS components, software updates and calibrations, proper handling of seats, prompt addressing of minor issues, and keeping detailed maintenance records.

- Where can I find training and resources to learn how to use DTS Monaco effectively for OCS diagnostics in the USA?

Automotive technicians in the USA can learn to use DTS Monaco effectively through specialized training courses, online tutorials, and hands-on practice. DTS-MONACO.EDU.VN provides comprehensive training resources, software solutions, and support to help technicians master OCS diagnostics and car coding skills.