Are There Different Hardware Versions Or Revisions Of The ECOM Interface? Yes, there are indeed different hardware versions or revisions of the ECOM (Enhanced Communication) interface, and understanding these variations is crucial for automotive technicians using diagnostic tools like DTS-Monaco. To fully utilize tools such as DTS-Monaco for car coding and advanced diagnostics, keeping up with hardware updates and compatibility is key, and DTS-MONACO.EDU.VN offers extensive information to help navigate this landscape. Knowing the specifications, capabilities, and limitations of each ECOM interface version enables technicians to optimize their workflow, avoid compatibility issues, and ensure reliable communication with vehicle systems, enhancing the quality of automotive services with expert coding assistance and specialized diagnostic software training.

Contents

- 1. Understanding the ECOM Interface in Automotive Diagnostics

- 1.1 The Role of ECOM in Car Coding

- 1.2 Advantages of Using a High-Quality ECOM Interface

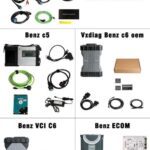

- 2. Identifying Different Hardware Versions of the ECOM Interface

- 2.1 Checking the Device Label

- 2.2 Using Diagnostic Software

- 2.3 Consulting the Manufacturer’s Documentation

- 2.4 Checking Online Forums and Communities

- 2.5 Contacting Technical Support

- 3. Key Differences Between ECOM Interface Revisions

- 3.1 Communication Protocol Support

- 3.2 Data Transfer Speed

- 3.3 Hardware and Software Compatibility

- 3.4 Enhanced Security Features

- 3.5 Physical Design and Durability

- 4. Compatibility Issues and Solutions

- 4.1 Software Incompatibility

- 4.2 Vehicle Compatibility

- 4.3 Connection Problems

- 4.4 Power Supply Issues

- 5. Choosing the Right ECOM Interface for Your Needs

- 5.1 Vehicle Coverage

- 5.2 Software Compatibility

- 5.3 Diagnostic Capabilities

- 5.4 Budget Considerations

- 5.5 Brand Reputation and Support

- 6. Maintaining and Updating Your ECOM Interface

- 6.1 Regular Cleaning and Inspection

- 6.2 Software and Firmware Updates

- 6.3 Proper Storage

- 6.4 Cable Management

- 6.5 Avoiding Physical Stress

- 7. Future Trends in ECOM Interface Technology

- 7.1 Wireless Connectivity

- 7.2 Cloud-Based Diagnostics

- 7.3 Enhanced Security Features

- 7.4 Artificial Intelligence (AI)

- 7.5 Integration with Mobile Devices

- 8. Case Studies: ECOM Interface in Action

- 8.1 Case Study 1: Diagnosing Intermittent Engine Problems

- 8.2 Case Study 2: Retrofitting Features with Car Coding

- 8.3 Case Study 3: Improving Vehicle Performance with ECU Tuning

- 8.4 Case Study 4: Resolving Complex Electrical Issues

- 8.5 Case Study 5: Performing Software Updates on ECUs

- 9. Training and Resources for ECOM Interface Users

- 9.1 Manufacturer Training Programs

- 9.2 Online Courses and Tutorials

- 9.3 Industry Conferences and Workshops

- 9.4 Online Forums and Communities

- 9.5 DTS-MONACO.EDU.VN

- 10. FAQs About ECOM Interface Hardware Versions

- 10.1. What is an ECOM interface?

- 10.2. Why are there different hardware versions of the ECOM interface?

- 10.3. How can I identify the hardware version of my ECOM interface?

- 10.4. What are the key differences between ECOM interface revisions?

- 10.5. What are the common compatibility issues with different ECOM interface versions?

1. Understanding the ECOM Interface in Automotive Diagnostics

What is the ECOM interface and why is it essential in modern automotive diagnostics? The ECOM (Enhanced Communication) interface is a specialized hardware device used to establish a communication bridge between a diagnostic computer and a vehicle’s electronic control units (ECUs). This interface is crucial for performing advanced diagnostic procedures, software updates, and car coding operations. Modern vehicles are equipped with numerous ECUs that manage various systems, such as engine control, transmission, anti-lock braking, and airbag deployment.

The ECOM interface acts as a translator, converting the diagnostic commands from the computer into a format that the vehicle’s ECUs can understand, and vice versa. Without a reliable ECOM interface, technicians cannot effectively communicate with these systems, making it impossible to diagnose complex issues, perform necessary software updates, or customize vehicle settings. This is why it’s an essential tool for automotive technicians aiming to provide comprehensive and advanced services.

1.1 The Role of ECOM in Car Coding

What is the specific role of ECOM in car coding and how does it facilitate advanced modifications? Car coding, also known as vehicle programming, involves modifying the software parameters of a vehicle’s ECUs to enable or disable certain features, customize vehicle behavior, or adapt the vehicle to specific regional requirements. The ECOM interface plays a pivotal role in this process by providing a stable and secure communication channel.

During car coding, large amounts of data are transferred between the diagnostic computer and the vehicle’s ECUs. Any interruption or data corruption during this process can lead to serious malfunctions or even brick the ECU. The ECOM interface ensures that the data is transmitted reliably and accurately, minimizing the risk of errors. Additionally, it supports various communication protocols, such as CAN (Controller Area Network), LIN (Local Interconnect Network), and Ethernet, which are used by different vehicle manufacturers. This versatility allows technicians to work on a wide range of vehicles with a single interface.

1.2 Advantages of Using a High-Quality ECOM Interface

What advantages do high-quality ECOM interfaces offer compared to standard diagnostic tools? Using a high-quality ECOM interface provides several key advantages over standard diagnostic tools:

-

Enhanced Reliability: High-quality interfaces are built with robust components and undergo rigorous testing to ensure reliable performance. This reduces the risk of communication errors and ensures stable connections during critical procedures.

-

Faster Data Transfer: Advanced ECOM interfaces support faster data transfer rates, which significantly reduces the time required for software updates and car coding operations. This can save technicians valuable time and increase their productivity.

-

Broader Vehicle Compatibility: High-quality interfaces often support a wider range of vehicle makes and models, as well as various communication protocols. This allows technicians to work on a more diverse range of vehicles without needing multiple interfaces.

-

Advanced Features: Some ECOM interfaces come with advanced features such as built-in security protocols, voltage monitoring, and automatic error correction. These features enhance the safety and efficiency of diagnostic and coding procedures.

-

Future-Proofing: Investing in a high-quality ECOM interface ensures that technicians are equipped to handle future vehicle technologies and communication protocols. This can save money in the long run by avoiding the need for frequent hardware upgrades.

By understanding the importance of the ECOM interface and its role in modern automotive diagnostics and car coding, technicians can make informed decisions about their equipment and stay ahead in an increasingly complex industry. Resources like those offered by DTS-MONACO.EDU.VN are invaluable for staying up-to-date with the latest advancements and best practices.

2. Identifying Different Hardware Versions of the ECOM Interface

How can automotive technicians identify different hardware versions of the ECOM interface and why is it important? Identifying different hardware versions of the ECOM interface is crucial for automotive technicians because each version may have different capabilities, compatibility, and limitations. Knowing the specific version helps technicians ensure they are using the correct software and procedures for the vehicle they are working on, avoiding potential damage or errors.

Here are several methods for identifying ECOM interface hardware versions:

2.1 Checking the Device Label

Where can technicians typically find the hardware version information on the ECOM interface itself? The most straightforward way to identify the hardware version is by checking the device label. The label is usually located on the device’s housing and contains important information such as the model number, serial number, and hardware version.

The hardware version is often indicated by a revision number or a version code. For example, it might be labeled as “HW Rev. 2.0” or “Version A.” This label provides a quick and easy way to determine the specific hardware version of the ECOM interface.

2.2 Using Diagnostic Software

How can diagnostic software help in identifying the ECOM interface hardware version? Many diagnostic software applications, such as DTS-Monaco, can automatically detect the hardware version of the connected ECOM interface. When the interface is connected to the computer and the software is launched, the software typically displays the device information, including the hardware version, in the settings or configuration menu.

This method is particularly useful because it provides a reliable and accurate way to identify the hardware version without having to physically inspect the device label. Additionally, the software may also provide information about the firmware version and any available updates.

2.3 Consulting the Manufacturer’s Documentation

Where can technicians find comprehensive information about ECOM interface hardware versions and specifications? The manufacturer’s documentation is an invaluable resource for identifying ECOM interface hardware versions. The documentation usually includes detailed specifications, features, and compatibility information for each version of the device.

Technicians can find the manufacturer’s documentation on the company’s website or in the user manual that comes with the ECOM interface. The documentation may also include diagrams, troubleshooting tips, and other useful information that can help technicians better understand and use the device.

2.4 Checking Online Forums and Communities

How can online forums and communities assist in identifying and understanding ECOM interface hardware versions? Online forums and communities dedicated to automotive diagnostics and car coding can be a great source of information for identifying ECOM interface hardware versions. These forums often have discussions and threads where technicians share their experiences and knowledge about different devices.

Technicians can search for specific information about the ECOM interface they are using or ask questions to the community. Other members may be able to provide insights, tips, and advice on identifying the hardware version and understanding its capabilities. However, it’s important to verify the information from these sources with official documentation to ensure accuracy.

2.5 Contacting Technical Support

When in doubt, who can technicians turn to for definitive information about their ECOM interface? Contacting technical support is always a reliable option for identifying ECOM interface hardware versions. The manufacturer’s technical support team has access to detailed information about all versions of the device and can provide accurate and up-to-date information.

Technicians can contact technical support via phone, email, or online chat. They should be prepared to provide the model number and serial number of the ECOM interface, as well as any other relevant information that can help the support team identify the hardware version.

By using these methods, automotive technicians can confidently identify the hardware version of their ECOM interface and ensure they are using the correct software and procedures for their diagnostic and coding tasks. Resources like DTS-MONACO.EDU.VN can further assist technicians in staying informed about the latest ECOM interface technologies and best practices.

3. Key Differences Between ECOM Interface Revisions

What are the key differences between various ECOM interface revisions that technicians should be aware of? Understanding the key differences between ECOM interface revisions is essential for technicians to ensure they are using the right tools and procedures for specific vehicles and diagnostic tasks. Different revisions may offer varying levels of compatibility, performance, and features, which can significantly impact the efficiency and accuracy of automotive diagnostics and car coding.

3.1 Communication Protocol Support

How does communication protocol support vary across different ECOM interface revisions? One of the most significant differences between ECOM interface revisions is the level of support for various communication protocols. Modern vehicles use a range of protocols, including CAN (Controller Area Network), LIN (Local Interconnect Network), Ethernet, and others.

Older ECOM interface revisions may only support a limited number of protocols, which means they may not be compatible with newer vehicles or specific ECUs that use advanced communication methods. Newer revisions typically offer broader protocol support, allowing technicians to work on a wider range of vehicles and systems. For example, some newer interfaces support CAN FD (Flexible Data-Rate), which is used in many modern vehicles for faster and more reliable communication.

3.2 Data Transfer Speed

How does the data transfer speed differ among ECOM interface revisions and why is it important? The data transfer speed of an ECOM interface can significantly affect the time required for diagnostic procedures, software updates, and car coding operations. Older revisions may have slower data transfer rates, which can lead to longer waiting times and reduced efficiency.

Newer revisions typically offer faster data transfer speeds, allowing technicians to perform tasks more quickly. This is particularly important for large software updates or complex car coding procedures that involve transferring large amounts of data. Faster data transfer speeds can save technicians valuable time and increase their productivity.

3.3 Hardware and Software Compatibility

What compatibility issues might arise when using different ECOM interface revisions with various software and hardware configurations? Hardware and software compatibility is another crucial difference between ECOM interface revisions. Older revisions may not be compatible with the latest diagnostic software or may require specific drivers or firmware updates to function correctly.

Newer revisions are often designed to be backward-compatible with older software and hardware, but this is not always the case. Technicians should always check the compatibility information provided by the manufacturer to ensure that their ECOM interface is compatible with their diagnostic software and the vehicles they are working on. Using incompatible hardware and software can lead to communication errors, system malfunctions, or even damage to the vehicle’s ECUs.

3.4 Enhanced Security Features

How do enhanced security features in newer ECOM interface revisions protect against unauthorized access and potential cyber threats? As vehicles become more connected and reliant on software, security is becoming increasingly important. Newer ECOM interface revisions often include enhanced security features to protect against unauthorized access and potential cyber threats.

These features may include encryption, authentication protocols, and secure boot mechanisms. They help ensure that only authorized users can access and modify the vehicle’s ECUs, preventing malicious attacks or unauthorized modifications. Older revisions may lack these security features, making them more vulnerable to security breaches.

3.5 Physical Design and Durability

What improvements in physical design and durability can be expected in newer ECOM interface revisions? The physical design and durability of ECOM interfaces can also vary between revisions. Newer revisions may be built with more robust materials and improved designs to withstand the rigors of daily use in a workshop environment.

This can include features such as reinforced connectors, ruggedized housings, and improved cooling systems. These improvements can help extend the lifespan of the ECOM interface and reduce the risk of damage from drops, impacts, or extreme temperatures.

By understanding these key differences between ECOM interface revisions, automotive technicians can make informed decisions about their equipment and ensure they are using the right tools for the job. Resources like DTS-MONACO.EDU.VN provide valuable information and training to help technicians stay up-to-date with the latest advancements in automotive diagnostics and car coding.

4. Compatibility Issues and Solutions

What are the common compatibility issues encountered with different ECOM interface versions and how can they be resolved? Compatibility issues can arise when using different ECOM interface versions, especially when working with various vehicle models and diagnostic software. Understanding these issues and knowing how to resolve them is essential for automotive technicians to ensure smooth and efficient diagnostic and car coding processes.

4.1 Software Incompatibility

What types of software incompatibility issues can occur with ECOM interfaces and how can technicians address them? Software incompatibility is a common issue that can occur when using different ECOM interface versions. This can manifest in several ways:

- Outdated Drivers: Older ECOM interfaces may require specific drivers to be installed on the diagnostic computer. If the drivers are outdated or incompatible with the operating system, the interface may not function correctly.

- Software Version Conflicts: Some diagnostic software applications may not be compatible with older ECOM interface revisions. This can result in communication errors or prevent the software from recognizing the interface altogether.

- Firmware Mismatches: The firmware of the ECOM interface must be compatible with the diagnostic software. If there is a mismatch, the interface may not function correctly or may exhibit erratic behavior.

To address software incompatibility issues, technicians can take the following steps:

- Update Drivers: Ensure that the latest drivers for the ECOM interface are installed on the diagnostic computer. These can usually be downloaded from the manufacturer’s website.

- Check Software Compatibility: Verify that the diagnostic software is compatible with the ECOM interface revision. Consult the software documentation or the manufacturer’s website for compatibility information.

- Update Firmware: If necessary, update the firmware of the ECOM interface to the latest version. This can usually be done using a firmware update utility provided by the manufacturer.

4.2 Vehicle Compatibility

How can vehicle compatibility issues affect the performance of ECOM interfaces and what steps can be taken to ensure proper functionality? Vehicle compatibility is another important consideration when using different ECOM interface versions. Older revisions may not support the communication protocols or diagnostic standards used by newer vehicles.

This can result in an inability to communicate with the vehicle’s ECUs or inaccurate diagnostic readings. To ensure vehicle compatibility, technicians should:

- Check Vehicle Coverage: Verify that the ECOM interface supports the make, model, and year of the vehicle being diagnosed. Consult the manufacturer’s documentation or vehicle coverage list for compatibility information.

- Use the Correct Communication Protocol: Ensure that the diagnostic software is configured to use the correct communication protocol for the vehicle. This may involve selecting the appropriate protocol in the software settings or using a specific adapter cable.

- Update Vehicle Definitions: Keep the vehicle definitions in the diagnostic software up-to-date. These definitions contain information about the vehicle’s ECUs and communication protocols, which is necessary for accurate diagnostics.

4.3 Connection Problems

What are the common causes of connection problems with ECOM interfaces and how can they be troubleshooted? Connection problems can also occur when using ECOM interfaces, especially if the cables are damaged or the connectors are dirty. These problems can manifest as intermittent communication, data errors, or a complete loss of connection.

To troubleshoot connection problems, technicians can:

- Check Cables and Connectors: Inspect the cables and connectors for any signs of damage, such as frayed wires or bent pins. Clean the connectors with a contact cleaner to remove any dirt or corrosion.

- Ensure Secure Connections: Make sure that the cables are securely connected to the ECOM interface, the diagnostic computer, and the vehicle’s diagnostic port.

- Test with a Different Cable: If possible, test with a different cable to rule out the possibility of a faulty cable.

4.4 Power Supply Issues

How can power supply issues affect the functionality of ECOM interfaces and what are the best practices for ensuring stable power? Power supply issues can also affect the functionality of ECOM interfaces. If the interface is not receiving enough power, it may not function correctly or may exhibit erratic behavior.

To ensure stable power, technicians should:

- Use a Reliable Power Source: Connect the ECOM interface to a reliable power source, such as a dedicated power outlet or a power conditioner.

- Check the Power Adapter: If the ECOM interface uses a power adapter, make sure that it is the correct voltage and amperage for the device.

- Avoid Overloading the Power Circuit: Avoid overloading the power circuit by plugging too many devices into the same outlet.

By understanding these compatibility issues and implementing the appropriate solutions, automotive technicians can ensure that their ECOM interfaces function correctly and efficiently, minimizing downtime and maximizing productivity. Resources like DTS-MONACO.EDU.VN offer valuable training and support to help technicians stay ahead in the rapidly evolving field of automotive diagnostics and car coding.

5. Choosing the Right ECOM Interface for Your Needs

How can automotive technicians choose the right ECOM interface to meet their specific diagnostic and car coding needs? Choosing the right ECOM interface is a critical decision for automotive technicians. The interface should be compatible with the vehicles they service, the diagnostic software they use, and the types of tasks they perform. Here are some key factors to consider when selecting an ECOM interface.

5.1 Vehicle Coverage

What should technicians consider regarding vehicle coverage when selecting an ECOM interface? Vehicle coverage is one of the most important factors to consider when choosing an ECOM interface. The interface should support the makes, models, and years of vehicles that the technician regularly works on.

Technicians should check the manufacturer’s documentation or vehicle coverage list to verify compatibility. It’s also important to consider whether the interface supports the communication protocols used by those vehicles, such as CAN, LIN, Ethernet, and CAN FD.

5.2 Software Compatibility

How should technicians ensure that the ECOM interface is compatible with their preferred diagnostic software? Software compatibility is another critical consideration. The ECOM interface should be compatible with the diagnostic software that the technician uses, such as DTS-Monaco.

Technicians should check the software documentation or the manufacturer’s website to verify compatibility. They should also ensure that the interface comes with the necessary drivers and software updates to function correctly with their diagnostic software.

5.3 Diagnostic Capabilities

What diagnostic capabilities should technicians look for in an ECOM interface to meet their specific needs? The diagnostic capabilities of an ECOM interface can vary significantly. Some interfaces may only support basic diagnostic functions, while others may offer advanced features such as:

- ECU Programming: The ability to reprogram or update the software in a vehicle’s ECUs.

- Car Coding: The ability to customize vehicle settings and enable or disable certain features.

- Data Logging: The ability to record and analyze data from the vehicle’s sensors and systems.

- Actuator Testing: The ability to activate and test various components in the vehicle, such as relays, solenoids, and motors.

Technicians should choose an ECOM interface that offers the diagnostic capabilities they need to perform their tasks effectively.

5.4 Budget Considerations

How can technicians balance their needs with budget considerations when selecting an ECOM interface? The cost of ECOM interfaces can vary widely, depending on their features, capabilities, and brand. Technicians should set a budget and choose an interface that offers the best value for their money.

It’s important to consider not only the initial cost of the interface but also the ongoing costs, such as software updates, subscription fees, and maintenance. Technicians should also weigh the cost of the interface against the potential benefits, such as increased efficiency, reduced downtime, and the ability to perform more complex diagnostic and coding tasks.

5.5 Brand Reputation and Support

Why are brand reputation and the availability of technical support important factors when choosing an ECOM interface? Brand reputation and the availability of technical support are important factors to consider when choosing an ECOM interface. A reputable brand is more likely to offer a reliable and high-quality product, as well as good customer support.

Technicians should look for brands that have a proven track record in the automotive diagnostic industry and that offer comprehensive technical support, including documentation, training, and troubleshooting assistance. They should also check online reviews and forums to see what other technicians have to say about the brand and its products.

By carefully considering these factors, automotive technicians can choose the right ECOM interface to meet their specific needs and ensure they are equipped to perform their tasks effectively. Resources like DTS-MONACO.EDU.VN provide valuable information and training to help technicians make informed decisions and stay ahead in the rapidly evolving field of automotive diagnostics and car coding.

6. Maintaining and Updating Your ECOM Interface

What are the best practices for maintaining and updating an ECOM interface to ensure optimal performance and longevity? Maintaining and updating an ECOM interface is crucial for ensuring its optimal performance and longevity. Regular maintenance and timely updates can help prevent compatibility issues, improve reliability, and enhance the interface’s capabilities. Here are some best practices for maintaining and updating your ECOM interface:

6.1 Regular Cleaning and Inspection

How can regular cleaning and inspection help maintain the ECOM interface in good working condition? Regular cleaning and inspection are essential for keeping the ECOM interface in good working condition. Dust, dirt, and debris can accumulate on the connectors and housing, which can lead to connection problems and reduced performance.

Technicians should clean the ECOM interface regularly with a soft, dry cloth. They should also inspect the cables and connectors for any signs of damage, such as frayed wires, bent pins, or corrosion. If any damage is found, the cables or connectors should be replaced immediately.

6.2 Software and Firmware Updates

Why is it important to keep the ECOM interface’s software and firmware up-to-date? Keeping the ECOM interface’s software and firmware up-to-date is crucial for ensuring compatibility with the latest vehicles and diagnostic software. Manufacturers regularly release updates to address bugs, improve performance, and add new features.

Technicians should check the manufacturer’s website regularly for software and firmware updates. They should also subscribe to the manufacturer’s newsletter or follow them on social media to stay informed about the latest updates.

6.3 Proper Storage

What are the recommended practices for storing the ECOM interface to prevent damage and prolong its lifespan? Proper storage is essential for preventing damage to the ECOM interface and prolonging its lifespan. The interface should be stored in a clean, dry, and secure location when not in use.

Technicians should avoid storing the interface in direct sunlight, extreme temperatures, or high humidity. They should also protect the interface from dust, dirt, and moisture by storing it in a protective case or bag.

6.4 Cable Management

How can proper cable management help prevent damage to the ECOM interface and ensure reliable connections? Proper cable management is important for preventing damage to the ECOM interface and ensuring reliable connections. Cables should be neatly organized and secured to prevent them from getting tangled, frayed, or damaged.

Technicians can use cable ties, Velcro straps, or cable organizers to keep the cables neatly organized. They should also avoid bending or twisting the cables excessively, as this can damage the wires and connectors.

6.5 Avoiding Physical Stress

How can technicians avoid physical stress on the ECOM interface to prevent damage and ensure longevity? Avoiding physical stress on the ECOM interface is crucial for preventing damage and ensuring its longevity. Technicians should handle the interface with care and avoid dropping it, bumping it, or exposing it to excessive force.

They should also avoid placing heavy objects on top of the interface or storing it in a location where it could be crushed or damaged.

By following these best practices for maintaining and updating their ECOM interfaces, automotive technicians can ensure that their tools are always in optimal condition and ready to perform their tasks effectively. Resources like DTS-MONACO.EDU.VN offer valuable training and support to help technicians stay informed about the latest ECOM interface technologies and best practices.

7. Future Trends in ECOM Interface Technology

What are the emerging trends in ECOM interface technology that automotive technicians should be aware of? The field of automotive diagnostics and car coding is constantly evolving, and ECOM interface technology is no exception. Automotive technicians need to stay informed about the latest trends and developments in order to remain competitive and provide the best possible service to their customers. Here are some emerging trends in ECOM interface technology that technicians should be aware of:

7.1 Wireless Connectivity

How is wireless connectivity transforming ECOM interfaces and what are the benefits for automotive technicians? Wireless connectivity is becoming increasingly common in ECOM interfaces. Wireless interfaces use Bluetooth or Wi-Fi to communicate with the diagnostic computer, eliminating the need for cables.

This offers several benefits for automotive technicians, including:

- Increased Mobility: Technicians can move freely around the vehicle without being tethered to the diagnostic computer.

- Improved Safety: Wireless interfaces eliminate the risk of tripping over cables or accidentally disconnecting the interface.

- Greater Convenience: Wireless interfaces are easier to set up and use than wired interfaces.

7.2 Cloud-Based Diagnostics

How are cloud-based diagnostics enhancing the capabilities of ECOM interfaces and providing new opportunities for technicians? Cloud-based diagnostics is another emerging trend in ECOM interface technology. Cloud-based interfaces connect to a remote server that provides access to diagnostic data, software updates, and other resources.

This offers several benefits for automotive technicians, including:

- Access to the Latest Data: Cloud-based interfaces always have access to the latest diagnostic data and software updates, ensuring that technicians are using the most up-to-date information.

- Remote Diagnostics: Cloud-based interfaces allow technicians to perform diagnostics remotely, which can be useful for troubleshooting problems on vehicles that are located far away.

- Collaboration: Cloud-based interfaces facilitate collaboration between technicians, allowing them to share diagnostic data and expertise.

7.3 Enhanced Security Features

What advancements are being made in ECOM interface security to protect against cyber threats and unauthorized access? As vehicles become more connected and reliant on software, security is becoming increasingly important. ECOM interfaces are now being designed with enhanced security features to protect against cyber threats and unauthorized access.

These features may include:

- Encryption: Encrypting the data that is transmitted between the ECOM interface and the vehicle’s ECUs.

- Authentication: Requiring users to authenticate themselves before they can access the interface.

- Secure Boot: Ensuring that the interface’s firmware has not been tampered with.

7.4 Artificial Intelligence (AI)

How is artificial intelligence being integrated into ECOM interfaces to improve diagnostic accuracy and efficiency? Artificial intelligence (AI) is beginning to be integrated into ECOM interfaces to improve diagnostic accuracy and efficiency. AI-powered interfaces can analyze diagnostic data and identify potential problems more quickly and accurately than human technicians.

AI can also be used to automate certain diagnostic tasks, such as reading fault codes and performing actuator tests. This can free up technicians to focus on more complex and challenging tasks.

7.5 Integration with Mobile Devices

How is the integration of ECOM interfaces with mobile devices transforming the diagnostic process for technicians? The integration of ECOM interfaces with mobile devices, such as smartphones and tablets, is another emerging trend. Mobile interfaces allow technicians to perform diagnostics using their mobile devices, which can be more convenient and efficient than using a laptop or desktop computer.

Mobile interfaces are often smaller and lighter than traditional interfaces, making them easier to carry around. They also typically come with user-friendly apps that make it easy to perform diagnostic tasks.

By staying informed about these future trends in ECOM interface technology, automotive technicians can prepare themselves for the changes that are coming and ensure that they are equipped to provide the best possible service to their customers. Resources like DTS-MONACO.EDU.VN offer valuable training and support to help technicians stay ahead in the rapidly evolving field of automotive diagnostics and car coding.

8. Case Studies: ECOM Interface in Action

How have ECOM interfaces been successfully used in real-world automotive diagnostic and car coding scenarios? Real-world case studies demonstrate the effectiveness and versatility of ECOM interfaces in automotive diagnostics and car coding. These examples showcase how technicians have used ECOM interfaces to solve complex problems, improve vehicle performance, and enhance customer satisfaction.

8.1 Case Study 1: Diagnosing Intermittent Engine Problems

How did an ECOM interface help diagnose and resolve an intermittent engine problem in a modern vehicle? A technician was faced with a challenging case involving a modern vehicle with intermittent engine problems. The vehicle would occasionally stall or run rough, but the symptoms were not consistent and did not trigger any fault codes.

The technician used an ECOM interface to monitor the vehicle’s sensors and systems in real-time. By analyzing the data, the technician was able to identify a faulty oxygen sensor that was causing the engine to run lean at certain times. The technician replaced the oxygen sensor, and the engine problems were resolved.

8.2 Case Study 2: Retrofitting Features with Car Coding

How was an ECOM interface used to successfully retrofit advanced features into a vehicle through car coding? A customer wanted to retrofit some advanced features into their vehicle, such as adaptive cruise control and lane departure warning. These features were not originally installed on the vehicle, but they were available as options on higher-end models.

The technician used an ECOM interface to access the vehicle’s ECUs and modify the software parameters. By enabling the necessary features in the software, the technician was able to successfully retrofit the adaptive cruise control and lane departure warning systems.

8.3 Case Study 3: Improving Vehicle Performance with ECU Tuning

How did an ECOM interface enable a technician to improve a vehicle’s performance through ECU tuning? A customer wanted to improve the performance of their vehicle, such as increasing horsepower and torque. The technician used an ECOM interface to access the vehicle’s ECU and modify the engine management software.

By adjusting parameters such as fuel injection, ignition timing, and boost pressure, the technician was able to increase the vehicle’s horsepower and torque without compromising its reliability or fuel economy. The customer was very pleased with the improved performance of their vehicle.

8.4 Case Study 4: Resolving Complex Electrical Issues

How was an ECOM interface used to diagnose and resolve complex electrical issues in a modern vehicle? A technician encountered a modern vehicle with complex electrical issues. The vehicle had multiple electrical faults, and the technician was struggling to identify the root cause of the problems.

The technician used an ECOM interface to access the vehicle’s electrical system and perform detailed diagnostics. By analyzing the data, the technician was able to identify a faulty wiring harness that was causing the electrical faults. The technician replaced the wiring harness, and the electrical issues were resolved.

8.5 Case Study 5: Performing Software Updates on ECUs

How was an ECOM interface used to perform necessary software updates on a vehicle’s ECUs? A technician needed to perform software updates on a vehicle’s ECUs to address known bugs and improve performance. The technician used an ECOM interface to connect to the vehicle’s ECUs and download the latest software updates from the manufacturer’s website.

By following the manufacturer’s instructions, the technician was able to successfully update the software on the vehicle’s ECUs, resolving the known bugs and improving the vehicle’s performance.

These case studies illustrate the wide range of applications for ECOM interfaces in automotive diagnostics and car coding. By using ECOM interfaces effectively, automotive technicians can solve complex problems, improve vehicle performance, and enhance customer satisfaction. Resources like DTS-MONACO.EDU.VN offer valuable training and support to help technicians master the use of ECOM interfaces and stay ahead in the rapidly evolving field of automotive diagnostics and car coding.

9. Training and Resources for ECOM Interface Users

What training programs and resources are available to help automotive technicians effectively use and maintain ECOM interfaces? Effective use of ECOM interfaces requires proper training and access to reliable resources. Automotive technicians can benefit from various training programs and resources that enhance their skills and knowledge in automotive diagnostics and car coding. Here are some valuable training and resources for ECOM interface users.

9.1 Manufacturer Training Programs

What types of training programs are offered by ECOM interface manufacturers to help technicians learn how to use their products effectively? Many ECOM interface manufacturers offer training programs to help technicians learn how to use their products effectively. These programs typically cover topics such as:

- Interface Setup and Configuration: How to properly set up and configure the ECOM interface for use with various vehicles and diagnostic software.

- Diagnostic Procedures: How to use the ECOM interface to perform various diagnostic procedures, such as reading fault codes, monitoring sensors, and performing actuator tests.

- Car Coding and Programming: How to use the ECOM interface to perform car coding and programming tasks, such as retrofitting features and updating ECU software.

- Troubleshooting: How to troubleshoot common problems that may arise when using the ECOM interface.

These training programs may be offered online, in-person, or through a combination of both. Technicians should check the manufacturer’s website or contact their sales representative for more information.

9.2 Online Courses and Tutorials

What online courses and tutorials are available to help technicians learn how to use ECOM interfaces and perform car coding? Numerous online courses and tutorials are available to help technicians learn how to use ECOM interfaces and perform car coding. These resources can be a convenient and affordable way to enhance your skills and knowledge.

Some popular online learning platforms that offer courses on automotive diagnostics and car coding include:

- Udemy

- Coursera

- Skillshare

- YouTube

Technicians should look for courses that are taught by experienced instructors and that cover the specific ECOM interface and diagnostic software that they use.

9.3 Industry Conferences and Workshops

How can industry conferences and workshops provide valuable learning opportunities for ECOM interface users? Industry conferences and workshops can provide valuable learning opportunities for ECOM interface users. These events typically feature presentations, demonstrations, and hands-on training sessions on the latest diagnostic technologies and techniques.

Attending industry conferences and workshops can help technicians:

- Stay Up-to-Date: Learn about the latest trends and developments in automotive diagnostics and car coding.

- Network with Peers: Connect with other technicians and share knowledge and experiences.

- See New Products: Get a first-hand look at the latest ECOM interfaces and diagnostic software.

- Earn Certifications: Obtain certifications that demonstrate their expertise in automotive diagnostics and car coding.

9.4 Online Forums and Communities

How can online forums and communities provide support and knowledge-sharing opportunities for ECOM interface users? Online forums and communities can be a great source of support and knowledge for ECOM interface users. These forums typically have discussions and threads where technicians share their experiences, ask questions, and offer advice.

Some popular online forums and communities for automotive technicians include:

- iATN (International Automotive Technicians Network)

- Automotive Forums

- Reddit (r/MechanicAdvice)

Technicians can use these forums to get help with troubleshooting problems, learn new techniques, and stay informed about the latest developments in the industry.

9.5 DTS-MONACO.EDU.VN

How does DTS-MONACO.EDU.VN support ECOM interface users with training and resources? DTS-MONACO.EDU.VN is a valuable resource for ECOM interface users, providing comprehensive training and support for automotive diagnostics and car coding.

DTS-MONACO.EDU.VN offers:

- Detailed Information: In-depth articles and guides on using DTS-MONACO software and ECOM interfaces.

- Training Programs: Structured training programs to enhance your skills in car coding and advanced diagnostics.

- Technical Support: Expert technical support to help you troubleshoot issues and optimize your workflow.

- Community Forum: A platform to connect with other technicians, share knowledge, and learn from each other.

By leveraging these training programs and resources, automotive technicians can enhance their skills, improve their knowledge, and stay ahead in the rapidly evolving field of automotive diagnostics and car coding.

10. FAQs About ECOM Interface Hardware Versions

What are some frequently asked questions about ECOM interface hardware versions? Here are some frequently asked questions about ECOM interface hardware versions, along with detailed answers to help automotive technicians better understand this important topic:

10.1. What is an ECOM interface?

An ECOM (Enhanced Communication) interface is a hardware device used to establish a communication bridge between a diagnostic computer and a vehicle’s electronic control units (ECUs). It is essential for performing advanced diagnostic procedures, software updates, and car coding operations.

10.2. Why are there different hardware versions of the ECOM interface?

Different hardware versions of the ECOM interface exist to support new communication protocols, improve data transfer speeds, enhance security features, and address compatibility issues with newer vehicles and diagnostic software.

10.3. How can I identify the hardware version of my ECOM interface?

You can identify the hardware version of your ECOM interface by checking the device label, using diagnostic software, consulting the manufacturer’s documentation, checking online forums, or contacting technical support.

10.4. What are the key differences between ECOM interface revisions?

The key differences between ECOM interface revisions include communication protocol support, data transfer speed, hardware and software compatibility, enhanced security features, and physical design and durability.

10.5. What are the common compatibility issues with different ECOM interface versions?

Common compatibility issues include software incompatibility, vehicle compatibility, connection problems, and power supply issues.