Can ECOM be used to diagnose issues with integrated battery chargers in EVs/PHEVs? Absolutely, ECOM can be a valuable tool for diagnosing issues with integrated battery chargers in Electric Vehicles (EVs) and Plug-in Hybrid Electric Vehicles (PHEVs), allowing technicians to pinpoint problems quickly and efficiently, keeping you on the road. At DTS-MONACO.EDU.VN, we provide in-depth knowledge and resources to help you master EV diagnostics, ensuring accurate repairs and optimal vehicle performance through car coding. Explore the capabilities of diagnostic software and car diagnostics today.

Contents

- 1. What is ECOM and How Does it Relate to EV/PHEV Diagnostics?

- 2. How Can ECOM Diagnose Issues with Integrated Battery Chargers?

- 3. What Specific Issues Can ECOM Help Diagnose in EV/PHEV Chargers?

- 4. What Software is Compatible with ECOM for EV/PHEV Diagnostics?

- 5. Are There Any Limitations to Using ECOM for EV/PHEV Charger Diagnostics?

- 6. What are the Benefits of Using ECOM for EV/PHEV Charger Diagnostics Compared to Other Methods?

- 7. What Training is Required to Use ECOM Effectively for EV/PHEV Charger Diagnostics?

- 8. How Can DTS-MONACO.EDU.VN Help with EV/PHEV Charger Diagnostics Using ECOM?

- 9. What are Some Real-World Examples of Using ECOM for EV/PHEV Charger Diagnostics?

- 10. What Future Trends Can Be Expected in EV/PHEV Charger Diagnostics?

- 11. How Does Temperature Impact the Lifespan of EV Batteries?

- 12. What Role Does the State of Charge (SOC) Play in Battery Health?

- 13. What Impact Does DC Fast Charging (DCFC) Have on Battery Degradation?

- 14. What are the Key Differences Between AC and DC Charging for EV Batteries?

- 15. How Does Vehicle Usage Impact EV Battery Degradation?

- 16. What is the Role of Predictive Maintenance in EV Battery Health?

- 17. What are Battery Protection Buffers and How Do They Work?

- 18. What is the Purpose of the 12-Volt Battery in an EV?

- 19. What Happens to Electric Car Batteries When They Reach the End of Their Life?

- 20. What Best Practices Can Extend EV Battery Life?

- FAQ: ECOM and EV/PHEV Charger Diagnostics

- 1. What is the primary function of ECOM in EV/PHEV diagnostics?

- 2. How does ECOM assist in diagnosing issues with EV/PHEV integrated battery chargers?

- 3. Can ECOM diagnose slow charging problems in EVs/PHEVs?

- 4. Is it possible to perform component-level tests on EV/PHEV chargers using ECOM?

- 5. What types of software are compatible with ECOM for EV/PHEV diagnostics?

- 6. Are there limitations to using ECOM for EV/PHEV charger diagnostics?

- 7. How does ECOM compare to basic OBD-II scanners in diagnosing EV/PHEV charger issues?

- 8. What training is necessary to effectively use ECOM for EV/PHEV charger diagnostics?

- 9. How can DTS-MONACO.EDU.VN assist with EV/PHEV charger diagnostics using ECOM?

- 10. What future trends can be expected in EV/PHEV charger diagnostics?

1. What is ECOM and How Does it Relate to EV/PHEV Diagnostics?

ECOM (Ethernet Communication) is a diagnostic interface used for communication with vehicle control units, including those responsible for managing integrated battery chargers in EVs and PHEVs. It facilitates high-speed data transfer, which is essential for comprehensive diagnostics.

ECOM acts as a bridge between diagnostic software and the vehicle’s electronic control units (ECUs), enabling technicians to read diagnostic trouble codes (DTCs), access live data, perform component tests, and reprogram ECUs. Its capabilities are particularly useful for diagnosing complex issues within EV/PHEV charging systems. According to a report by the National Automotive Service Task Force (NASTF), ECOM interfaces are becoming increasingly vital as vehicle systems become more complex and reliant on Ethernet-based communication.

2. How Can ECOM Diagnose Issues with Integrated Battery Chargers?

ECOM can diagnose issues with integrated battery chargers by providing access to diagnostic data and control functions within the EV/PHEV’s charging system. Here’s how:

- Reading Diagnostic Trouble Codes (DTCs): ECOM allows technicians to retrieve DTCs related to the charging system, providing specific information about detected faults.

- Accessing Live Data: Technicians can monitor real-time parameters such as voltage, current, temperature, and charging status, helping identify anomalies.

- Performing Component Tests: ECOM enables technicians to activate and test individual components of the charging system, such as relays, contactors, and sensors.

- Reprogramming ECUs: In some cases, software updates or reprogramming of the charging system ECU may be necessary to resolve certain issues, which ECOM facilitates.

For instance, if an EV is experiencing slow charging or failing to charge altogether, ECOM can be used to read DTCs that may indicate a fault in the charger’s control module or a malfunctioning sensor. Live data can then be monitored to check the voltage and current levels during charging, helping pinpoint the source of the problem. Technicians can also use ECOM to perform tests on individual components, such as the charging relay, to verify its functionality.

3. What Specific Issues Can ECOM Help Diagnose in EV/PHEV Chargers?

ECOM can help diagnose a wide range of issues in EV/PHEV chargers, including:

| Issue | Description | ECOM Diagnostic Capability |

|---|---|---|

| Charger Failure | The charger fails to initiate or complete the charging process. | DTCs indicating charger malfunction, live data monitoring of voltage and current during attempted charging, component tests to check charger relays and contactors. |

| Slow Charging | The vehicle charges at a slower rate than expected. | Live data monitoring of charging current and voltage to identify bottlenecks, DTCs related to reduced charging performance, component tests of thermal management system components. |

| Overheating | The charger or battery pack overheats during charging. | Live data monitoring of temperature sensors, DTCs related to thermal management system faults, component tests of cooling fans and pumps. |

| Communication Errors | The charger fails to communicate properly with the vehicle’s ECU. | DTCs related to communication errors, network diagnostics to identify issues with the CAN or Ethernet bus, ECU reprogramming to update communication protocols. |

| Input Voltage Issues | The charger is not receiving the correct input voltage from the power source. | Live data monitoring of input voltage, DTCs related to voltage abnormalities, component tests of voltage sensors and regulators. |

| Ground Faults | Current leakage to ground, posing a safety risk. | Insulation resistance tests, DTCs related to ground faults, live data monitoring of leakage current. |

| Contactor or Relay Failures | Malfunctioning contactors or relays that control the flow of current within the charger. | Component tests to verify proper operation of contactors and relays, DTCs related to contactor/relay faults, live data monitoring of contactor/relay status. |

| Software or Firmware Problems | Corrupted or outdated software/firmware that affects the charger’s functionality. | ECU reprogramming to update software/firmware, DTCs related to software/firmware errors, diagnostic logs to identify software-related issues. |

| Problems with Control Pilot Circuit | Issues with the control pilot circuit, which governs the communication between the charging station and the vehicle. | Signal integrity tests, DTCs related to control pilot circuit faults, live data monitoring of control pilot signals. |

| Issues with Proximity Detection Circuit | Problems with the proximity detection circuit, which ensures that the charging cable is securely connected before charging. | Signal integrity tests, DTCs related to proximity detection circuit faults, live data monitoring of proximity detection signals. |

By utilizing ECOM’s diagnostic capabilities, technicians can efficiently identify the root cause of charging system issues and perform targeted repairs, minimizing downtime and ensuring optimal vehicle performance.

4. What Software is Compatible with ECOM for EV/PHEV Diagnostics?

Several diagnostic software platforms are compatible with ECOM interfaces for EV/PHEV diagnostics. Some popular options include:

- Mercedes-Benz XENTRY/DAS: Used for diagnosing and programming Mercedes-Benz EVs and PHEVs.

- BMW ISTA: Used for diagnosing and programming BMW EVs and PHEVs.

- Volkswagen ODIS: Used for diagnosing and programming Volkswagen Group EVs and PHEVs (e.g., Audi, Porsche).

- Tesla Toolbox: Used for diagnosing and servicing Tesla vehicles.

- Techstream: Used for diagnosing and servicing Toyota/Lexus vehicles.

These software platforms provide comprehensive diagnostic capabilities, including DTC reading, live data monitoring, component testing, and ECU reprogramming, all accessible through the ECOM interface.

5. Are There Any Limitations to Using ECOM for EV/PHEV Charger Diagnostics?

While ECOM is a powerful tool for EV/PHEV charger diagnostics, there are some limitations to consider:

- Compatibility: ECOM interfaces and diagnostic software may not be universally compatible with all EV/PHEV models. Technicians need to ensure they have the correct tools for the specific vehicle they are working on.

- Training: Proper training is required to effectively use ECOM and interpret diagnostic data. Technicians need to understand EV/PHEV charging systems and diagnostic procedures.

- Software Updates: Diagnostic software requires regular updates to support new EV/PHEV models and incorporate the latest diagnostic information.

- Security: Accessing and modifying vehicle ECUs through ECOM may require security credentials or authorization, depending on the manufacturer.

- Cost: ECOM interfaces and diagnostic software can be expensive, which may be a barrier to entry for some independent repair shops.

Despite these limitations, ECOM remains an indispensable tool for diagnosing and repairing EV/PHEV charging systems, enabling technicians to provide efficient and accurate service.

6. What are the Benefits of Using ECOM for EV/PHEV Charger Diagnostics Compared to Other Methods?

Compared to other diagnostic methods, such as basic OBD-II scanners or manual inspection, ECOM offers several advantages:

- Comprehensive Data Access: ECOM provides access to a wider range of diagnostic data and control functions compared to basic OBD-II scanners, allowing for more in-depth analysis.

- Component-Level Diagnostics: ECOM enables technicians to perform component-level tests, which are not possible with manual inspection or basic scanners.

- Faster Troubleshooting: By providing detailed diagnostic information and automated testing capabilities, ECOM can significantly speed up the troubleshooting process.

- Remote Diagnostics: Some ECOM-based diagnostic systems support remote diagnostics, allowing technicians to diagnose and repair vehicles from a remote location.

- Future-Proofing: As EV/PHEV technology becomes more complex, ECOM’s advanced diagnostic capabilities will become increasingly essential for effective servicing.

According to a study by the Electric Vehicle Training Program (EVTP), technicians who use advanced diagnostic tools like ECOM can diagnose and repair EV/PHEV charging systems up to 50% faster than those who rely on traditional methods.

7. What Training is Required to Use ECOM Effectively for EV/PHEV Charger Diagnostics?

To use ECOM effectively for EV/PHEV charger diagnostics, technicians should receive comprehensive training in the following areas:

- EV/PHEV Technology: Understanding the fundamentals of EV/PHEV operation, including battery technology, charging systems, and electric drivetrain components.

- Diagnostic Procedures: Learning how to use diagnostic software and hardware, interpret DTCs, access live data, and perform component tests.

- Electrical Safety: Training in safe handling of high-voltage electrical systems, including proper use of personal protective equipment (PPE) and isolation procedures.

- Networking and Communication: Understanding vehicle communication protocols such as CAN, LIN, and Ethernet, and how to troubleshoot network-related issues.

- Software Reprogramming: Learning how to safely reprogram vehicle ECUs using ECOM and diagnostic software.

Several organizations offer training programs for EV/PHEV diagnostics, including:

- National Institute for Automotive Service Excellence (ASE): Offers certifications for EV/PHEV technicians.

- Electric Vehicle Training Program (EVTP): Provides hands-on training in EV/PHEV diagnostics and repair.

- Community Colleges and Vocational Schools: Offer courses in automotive technology with a focus on EVs and PHEVs.

DTS-MONACO.EDU.VN: Provides specialized training programs for using DTS-Monaco software for car coding and diagnostics. Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880. Website: DTS-MONACO.EDU.VN

8. How Can DTS-MONACO.EDU.VN Help with EV/PHEV Charger Diagnostics Using ECOM?

DTS-MONACO.EDU.VN offers comprehensive resources and training programs to help technicians master EV/PHEV charger diagnostics using ECOM and DTS-Monaco software. Here’s how we can assist:

- Specialized Training Courses: We provide hands-on training courses that cover all aspects of EV/PHEV diagnostics, including the use of ECOM interfaces and DTS-Monaco software.

- Software Support: Our experts can provide technical support for using DTS-Monaco software to diagnose and repair EV/PHEV charging systems.

- Diagnostic Guides: We offer detailed diagnostic guides and troubleshooting tips for common EV/PHEV charging system issues.

- Car Coding Expertise: We provide expertise in car coding, enabling technicians to reprogram ECUs and customize vehicle settings to optimize charging performance.

- Latest Updates and Information: We keep you informed about the latest advancements in EV technology and diagnostic techniques, ensuring you have the knowledge and tools to stay ahead of the curve.

ECOM Diagnostic Interface

ECOM Diagnostic Interface

By leveraging our resources and expertise, technicians can enhance their skills in EV/PHEV charger diagnostics and provide exceptional service to their customers.

9. What are Some Real-World Examples of Using ECOM for EV/PHEV Charger Diagnostics?

Here are a few real-world examples of how ECOM can be used to diagnose issues with integrated battery chargers in EVs/PHEVs:

- Scenario 1: Charging Interruption

- Problem: An EV owner reports that their vehicle stops charging intermittently.

- Solution: A technician uses ECOM to read DTCs and finds a code indicating a fault in the charger’s thermal management system. Live data monitoring reveals that the charger is overheating during charging. The technician performs component tests and discovers a malfunctioning cooling fan. Replacing the cooling fan resolves the issue.

- Scenario 2: Slow Charging

- Problem: A PHEV owner complains that their vehicle is charging at a slower rate than expected.

- Solution: The technician uses ECOM to access live data and observes that the charging current is lower than the specified value. DTCs indicate a fault in the charger’s control module. The technician reprograms the control module with the latest software, which restores the charging rate to normal.

- Scenario 3: Communication Error

- Problem: An EV displays a “Charging System Error” message on the dashboard.

- Solution: The technician uses ECOM to read DTCs and finds a code indicating a communication error between the charger and the vehicle’s ECU. The technician performs network diagnostics and identifies a faulty CAN bus connection. Repairing the connection resolves the communication error and restores the charging system to proper operation.

These examples illustrate the practical applications of ECOM in diagnosing and repairing EV/PHEV charging system issues.

10. What Future Trends Can Be Expected in EV/PHEV Charger Diagnostics?

As EV/PHEV technology continues to evolve, several trends can be expected in charger diagnostics:

- Increased Complexity: Charging systems will become more complex with the integration of new features such as bidirectional charging, wireless charging, and smart grid connectivity.

- Advanced Diagnostic Algorithms: Diagnostic software will incorporate more sophisticated algorithms to detect and diagnose a wider range of charging system faults.

- Remote Diagnostics and Over-the-Air Updates: Remote diagnostics and over-the-air software updates will become more common, allowing technicians to diagnose and repair vehicles remotely.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML technologies will be used to analyze diagnostic data and predict potential charging system failures.

- Standardization of Diagnostic Protocols: Efforts will be made to standardize diagnostic protocols across different EV/PHEV manufacturers, making it easier for technicians to service a variety of vehicles.

By staying abreast of these trends and investing in the latest diagnostic tools and training, technicians can ensure they are well-prepared to service the next generation of EVs and PHEVs.

11. How Does Temperature Impact the Lifespan of EV Batteries?

Temperature profoundly affects EV battery lifespan. High temperatures accelerate battery degradation, while extremely low temperatures can reduce battery performance. Here’s a breakdown:

- High Temperatures: Exposure to high heat (above 80°F or 27°C) can cause the battery’s chemical components to break down more quickly, leading to a reduction in its ability to store energy. A Geotab study revealed that EVs in hot climates experience a faster rate of battery decline compared to those in temperate climates.

- Low Temperatures: Cold temperatures can temporarily reduce the battery’s capacity and charging efficiency. While the effect is generally reversible, prolonged exposure to very low temperatures can cause permanent damage.

- Thermal Management Systems: To mitigate the impact of temperature, EVs are equipped with thermal management systems that regulate battery temperature. Liquid cooling systems are more effective than air cooling systems in maintaining optimal battery temperature. For example, the 2015 Tesla Model S, which uses liquid cooling, has a lower degradation rate compared to the 2015 Nissan Leaf, which uses passive air cooling.

Maintaining an EV battery within its optimal temperature range is crucial for extending its lifespan and ensuring consistent performance.

12. What Role Does the State of Charge (SOC) Play in Battery Health?

The State of Charge (SOC) refers to the amount of energy stored in an EV battery compared to its total capacity. Maintaining the SOC within a specific range is crucial for battery health.

- Optimal SOC Range: Automakers recommend keeping the SOC between 20% and 80% for daily use. Operating the battery near full or empty can accelerate degradation.

- Charging Buffers: To protect the battery, manufacturers implement charging buffers that limit the charging capacity. These buffers prevent the battery from regularly hitting its maximum or minimum charge levels. For example, Tesla allows users to adjust the buffer size through software updates, improving battery longevity.

- Impact of Extreme SOC Levels: Regularly charging the battery to 100% or allowing it to discharge to 0% can cause increased stress on the battery cells, leading to faster degradation.

Adhering to the recommended SOC range and utilizing charging buffers can significantly extend the lifespan of an EV battery.

13. What Impact Does DC Fast Charging (DCFC) Have on Battery Degradation?

DC Fast Charging (DCFC) provides a quick way to recharge an EV battery, but it can also contribute to faster battery degradation.

- High Currents and Temperatures: DCFC involves high currents, which generate high temperatures within the battery. These high temperatures can strain the battery and accelerate degradation.

- Frequency of DCFC Use: Frequent use of DCFC, especially in hot climates, is strongly correlated with battery decline. A Geotab analysis showed that vehicles in hot climates that frequently used DCFC experienced greater battery degradation.

- Automaker Recommendations: Many automakers advise limiting the use of DCFC to prolong battery life. They recommend using Level 2 charging for regular charging needs and reserving DCFC for long trips.

While DCFC is convenient, it’s essential to use it judiciously and follow automaker recommendations to minimize its impact on battery health.

14. What are the Key Differences Between AC and DC Charging for EV Batteries?

AC (Alternating Current) and DC (Direct Current) charging methods differ in how they deliver electricity to the EV battery.

| Feature | AC Charging | DC Charging |

|---|---|---|

| Current Type | Alternating Current | Direct Current |

| Charging Speed | Slower | Faster |

| Voltage Levels | AC Level 1 (120 volts), AC Level 2 (240 volts) | High Voltage (400-800 volts) |

| Onboard Charger | Requires the vehicle’s onboard charger to convert AC to DC | Delivers DC directly to the battery, bypassing the onboard charger |

| Common Use Cases | Home charging, overnight charging, workplace charging | Public charging stations, long trips, situations where quick charging is needed |

| Impact on Battery | Generally less stressful on the battery due to lower charging rates | Can cause increased stress on the battery due to high currents and temperatures, especially with frequent use |

| Examples | Standard home outlets (Level 1), wall-mounted chargers (Level 2) | CHAdeMO, CCS, Tesla Supercharger |

Understanding the differences between AC and DC charging can help EV owners make informed decisions about how to charge their vehicles and optimize battery health.

15. How Does Vehicle Usage Impact EV Battery Degradation?

Surprisingly, research indicates that high vehicle use does not significantly impact battery degradation, provided that frequent DC fast charging is avoided.

- Geotab Research: A Geotab study found that high-use electric vehicles do not experience significantly greater battery degradation than lower-use vehicles. This suggests that EVs can be confidently used in high-demand duty cycles without worrying about accelerated battery wear.

- Benefits of Regular Use: Keeping EVs in regular operation can promote optimal battery health by maintaining steady charge cycles and preventing prolonged inactivity.

- Considerations for High-Use Vehicles: While high vehicle use itself may not negatively impact battery life, frequent use of DC fast charging for high-use vehicles may contribute to faster degradation.

This finding is encouraging for fleet operators, as it means they can maximize the use of their EVs without compromising battery health.

16. What is the Role of Predictive Maintenance in EV Battery Health?

Predictive maintenance plays a crucial role in ensuring the long-term health and performance of EV batteries.

- Monitoring Battery Health: Predictive maintenance involves continuously monitoring various parameters of the battery, such as voltage, current, temperature, and state of charge, to detect early signs of degradation.

- Data Analysis: The data collected is analyzed to identify patterns and trends that may indicate potential issues.

- Proactive Actions: Based on the analysis, proactive actions can be taken to address the issues before they lead to more significant problems. These actions may include adjusting charging habits, optimizing thermal management, or scheduling maintenance.

- Benefits of Predictive Maintenance: Predictive maintenance can help extend battery life, improve vehicle reliability, and reduce the total cost of ownership.

Telematics data is invaluable for implementing predictive maintenance strategies. EV fleet management solutions can monitor real-time battery capacity, track degradation rates, and make data-driven decisions to extend vehicle life.

17. What are Battery Protection Buffers and How Do They Work?

Battery protection buffers are designed to prevent EV batteries from operating at extreme charge levels, which can accelerate degradation.

- Purpose: These buffers limit the usable state of charge (SOC) window for an EV, preventing the battery from charging too high or discharging too low.

- Implementation: Automakers implement buffers through manufacturer settings, ensuring the battery doesn’t regularly hit its maximum or minimum charge levels.

- Dynamic Adjustment: Some EVs, like the Chevrolet Volt (now discontinued), employed larger top and bottom buffers that dynamically adjusted as the battery aged. This design resulted in slower-than-average battery degradation.

- User-Adjustable Buffers: Some modern EVs, such as Teslas, allow users to set a custom charge limit (e.g., stopping at 75% instead of 100%), helping further extend battery life.

By preventing extreme charge levels, battery protection buffers help extend the lifespan of EV batteries.

18. What is the Purpose of the 12-Volt Battery in an EV?

While the high-voltage battery powers the EV’s drivetrain, the 12-volt battery plays a critical role in powering essential systems.

- Function: The 12-volt battery powers systems such as the lights, power windows, infotainment, and other auxiliary components.

- Importance: It ensures that all the low-voltage systems function properly, even when the vehicle is off.

- Maintenance: The 12-volt battery should be regularly checked, as it can wear out over time. Some manufacturers offer monitoring systems that help track the health of both the high-voltage and 12-volt batteries.

Maintaining the 12-volt battery is essential for the proper functioning of an EV’s auxiliary systems.

19. What Happens to Electric Car Batteries When They Reach the End of Their Life?

When an electric car battery reaches the end of its life, it can no longer store or supply enough energy to power the vehicle effectively.

- Replacement: Depending on the severity of the issue, the battery may need to be replaced entirely.

- Recycling Programs: Many EV manufacturers offer recycling programs to safely dispose of or repurpose dead batteries.

- Repurposing: In some cases, EV batteries can be repurposed for other applications, such as energy storage in homes or businesses.

- Design for Longevity: EV batteries are designed to last for many years, and manufacturers are continuously working to improve their durability and longevity.

Responsible disposal and repurposing of EV batteries are essential for minimizing their environmental impact.

20. What Best Practices Can Extend EV Battery Life?

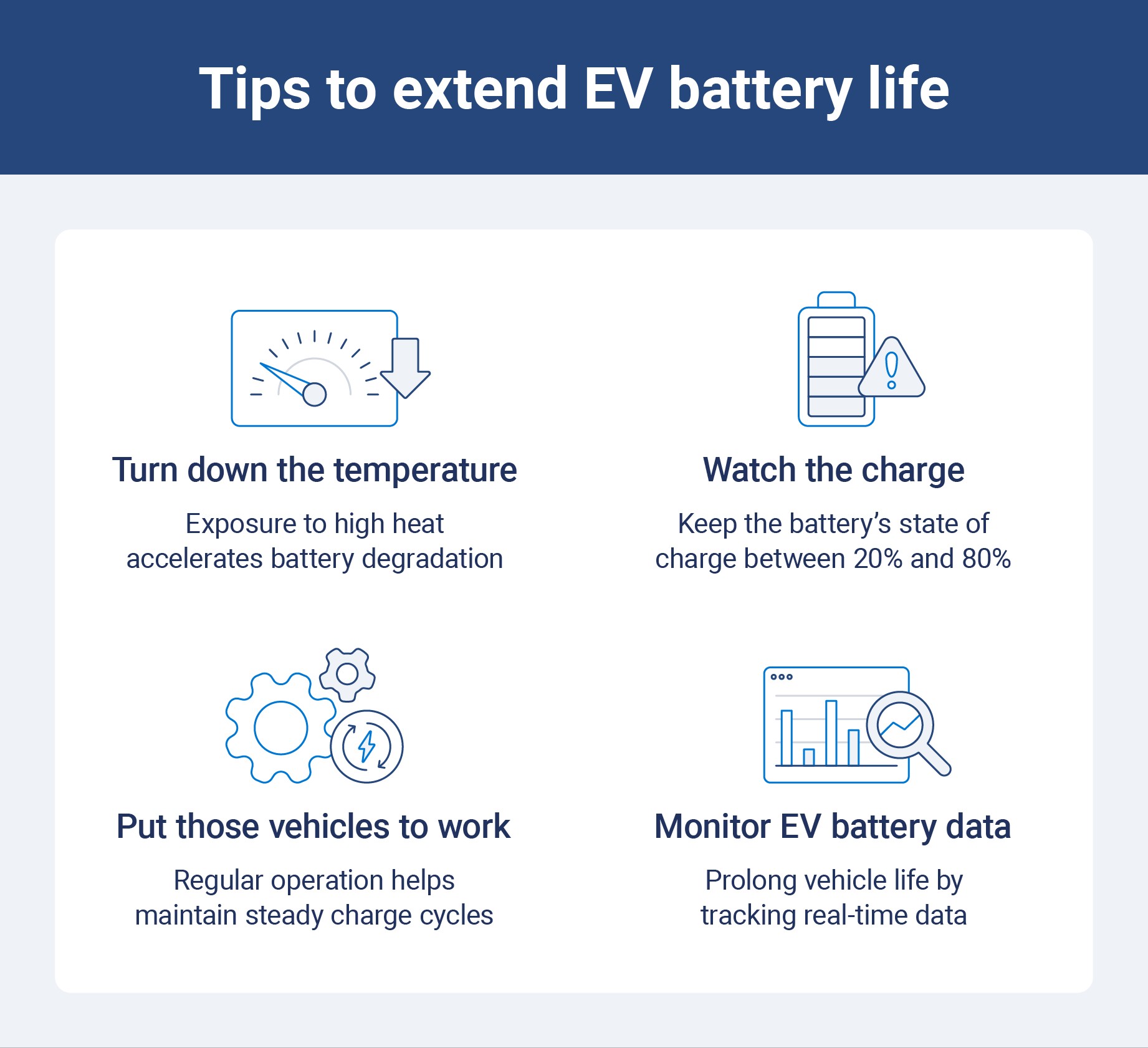

Several best practices can help extend the life of EV batteries:

- Moderate Temperatures: Keep EVs in moderate temperature conditions whenever possible. If you’re deciding which vehicle to purchase, consider models with liquid cooling for the battery.

- Optimal Charging Habits: Minimize DC fast charging and avoid leaving vehicles with a full or empty charge. Keep the battery’s state of charge between 20% and 80%, particularly for extended periods of inactivity.

- Regular Use: Maximize the use of your EVs. High vehicle use does not negatively impact EV battery life, so you can reduce the total cost of ownership by increasing road hours.

- Monitor Battery Data: Use telematics data to monitor real-time battery capacity, track degradation rates, and make data-driven decisions to extend vehicle life.

By following these best practices, EV owners and fleet managers can maximize the lifespan and performance of their EV batteries.

Ready to take your EV/PHEV diagnostic skills to the next level? Visit DTS-MONACO.EDU.VN today to explore our training programs, software solutions, and expert resources. Learn more about car coding, diagnostic software, and car diagnostics. Contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880. Website: DTS-MONACO.EDU.VN and start mastering the art of EV/PHEV diagnostics!

FAQ: ECOM and EV/PHEV Charger Diagnostics

1. What is the primary function of ECOM in EV/PHEV diagnostics?

ECOM (Ethernet Communication) serves as a high-speed diagnostic interface, enabling communication with vehicle control units, including those managing integrated battery chargers in EVs and PHEVs.

2. How does ECOM assist in diagnosing issues with EV/PHEV integrated battery chargers?

ECOM provides access to diagnostic data, allowing technicians to read DTCs, monitor live data, perform component tests, and reprogram ECUs, all crucial for diagnosing charging system issues.

3. Can ECOM diagnose slow charging problems in EVs/PHEVs?

Yes, ECOM can monitor real-time parameters like voltage and current during charging, helping identify bottlenecks or anomalies that cause slow charging.

4. Is it possible to perform component-level tests on EV/PHEV chargers using ECOM?

Yes, ECOM allows technicians to activate and test individual components of the charging system, such as relays, contactors, and sensors, ensuring each part functions correctly.

5. What types of software are compatible with ECOM for EV/PHEV diagnostics?

Software platforms like Mercedes-Benz XENTRY/DAS, BMW ISTA, and Volkswagen ODIS are compatible with ECOM, providing comprehensive diagnostic capabilities.

6. Are there limitations to using ECOM for EV/PHEV charger diagnostics?

Yes, limitations include compatibility issues with certain EV/PHEV models, the need for specialized training, and the cost of ECOM interfaces and diagnostic software.

7. How does ECOM compare to basic OBD-II scanners in diagnosing EV/PHEV charger issues?

ECOM offers comprehensive data access and component-level diagnostics compared to basic OBD-II scanners, which provide more in-depth analysis and faster troubleshooting.

8. What training is necessary to effectively use ECOM for EV/PHEV charger diagnostics?

Training should cover EV/PHEV technology, diagnostic procedures, electrical safety, networking and communication protocols, and software reprogramming.

9. How can DTS-MONACO.EDU.VN assist with EV/PHEV charger diagnostics using ECOM?

DTS-MONACO.EDU.VN provides specialized training courses, software support, diagnostic guides, car coding expertise, and the latest updates on EV technology.

10. What future trends can be expected in EV/PHEV charger diagnostics?

Future trends include increased complexity, advanced diagnostic algorithms, remote diagnostics, AI and ML integration, and standardization of diagnostic protocols.