Does ECOM support the SAE J1939 protocol for commercial vehicles? Yes, specific ECOM variants or firmware often support the SAE J1939 protocol, which is critical for commercial vehicle diagnostics and communication. This support enables technicians and engineers to effectively interact with the vehicle’s network, extract valuable data, and perform necessary maintenance or upgrades, and DTS-MONACO.EDU.VN is an excellent resource for learning more about this. Understanding ECOM capabilities is important for anyone working with commercial vehicles and their advanced electronic systems. With the correct tools and knowledge, you can optimize your diagnostic and car coding processes.

Contents

- 1. Understanding the ECOM and SAE J1939 Protocol

- 1.1. Defining ECOM

- 1.2. Overview of SAE J1939 Protocol

- 1.3. The Role of ECOM in Supporting SAE J1939

- 2. Checking ECOM Variant/Firmware Compatibility

- 2.1. Consulting the ECOM Device Documentation

- 2.2. Checking the Manufacturer’s Website

- 2.3. Performing Compatibility Tests

- 3. Benefits of ECOM Supporting SAE J1939

- 3.1. Enhanced Diagnostic Capabilities

- 3.2. Streamlined Maintenance Procedures

- 3.3. Improved Vehicle Uptime

- 4. Common Issues and Troubleshooting

- 4.1. Connection Problems

- 4.2. Protocol Incompatibility

- 4.3. Software Glitches

- 5. Case Studies: ECOM and SAE J1939 in Action

- 5.1. ECOM for Diagnostics in Fleet Management

- 5.2. ECOM for Engine Performance Analysis

- 5.3. ECOM for Emissions Testing

- 6. Training and Certification for ECOM and SAE J1939

- 6.1. Vocational Schools

- 6.2. Industry Associations

- 6.3. Equipment Manufacturers

- 7. Future Trends in ECOM and SAE J1939

- 7.1. Wireless Connectivity

- 7.2. Advanced Data Analytics

- 7.3. Cloud-Based Platforms

- 8. Selecting the Right ECOM Device

- 8.1. Protocol Support

- 8.2. Compatibility

- 8.3. Ease of Use

- 9. Maintaining and Updating ECOM Devices

- 9.1. Cleaning the Device

- 9.2. Checking Cables and Connectors

- 9.3. Updating the Firmware

- 10. Resources for Learning More

- 10.1. Industry Publications

- 10.2. Online Forums

- 10.3. Manufacturer Websites

- FAQ: ECOM and SAE J1939 Protocol

- 1. Does every ECOM device support the SAE J1939 protocol?

- 2. How do I update the firmware on my ECOM device to ensure SAE J1939 compatibility?

- 3. What are the main advantages of using an ECOM device that supports SAE J1939?

- 4. What should I do if my ECOM device is not connecting to the vehicle’s SAE J1939 network?

- 5. Are there any specific certifications needed to work with ECOM devices and SAE J1939?

- 6. Can ECOM devices be used for remote diagnostics with SAE J1939?

- 7. How can advanced data analytics improve the use of ECOM with SAE J1939?

- 8. What are the key criteria to consider when selecting an ECOM device for SAE J1939 applications?

- 9. How often should I maintain my ECOM device to ensure optimal performance with SAE J1939?

- 10. Where can I find the latest technical information and support for ECOM devices and SAE J1939?

1. Understanding the ECOM and SAE J1939 Protocol

What is ECOM, and how does it relate to the SAE J1939 protocol? ECOM (Embedded Communication Object Manager) is a vital interface for vehicle diagnostics and programming, and it often supports the SAE J1939 protocol, enabling seamless communication with commercial vehicles. According to a report by the American Trucking Associations, the increasing complexity of commercial vehicle electronics requires robust diagnostic tools like ECOM to ensure efficient maintenance and repair. ECOM enables technicians to read diagnostic trouble codes (DTCs), monitor sensor data, and reprogram ECUs, facilitating comprehensive vehicle management. Understanding the nuances of ECOM is essential for those in the automotive repair industry, especially with the growing adoption of advanced vehicle technologies. This foundational knowledge enhances the ability to troubleshoot and maintain modern commercial vehicles effectively.

1.1. Defining ECOM

What exactly is ECOM in the context of automotive diagnostics? ECOM, or Embedded Communication Object Manager, serves as a crucial interface device enabling communication between a diagnostic computer and a vehicle’s electronic control units (ECUs). According to a study by the Society of Automotive Engineers (SAE), ECOM devices are designed to handle multiple communication protocols, ensuring compatibility across various vehicle makes and models. ECOM streamlines the diagnostic process by facilitating quick and reliable data transfer, essential for modern automotive repair and maintenance.

1.2. Overview of SAE J1939 Protocol

What does the SAE J1939 protocol entail? The SAE J1939 protocol is a standardized communication protocol used in heavy-duty vehicles for communication and diagnostics. As outlined in the SAE J1939 standards, this protocol defines how ECUs communicate with each other, enabling the exchange of critical data such as engine parameters, diagnostic information, and control commands. This standardization promotes interoperability and simplifies the diagnostic process for commercial vehicles. The J1939 protocol has significantly improved vehicle maintenance and diagnostics by providing a common language for different vehicle components to communicate.

1.3. The Role of ECOM in Supporting SAE J1939

How does ECOM facilitate the use of the SAE J1939 protocol? ECOM acts as the bridge between diagnostic tools and the vehicle’s communication network, enabling effective use of the SAE J1939 protocol. According to Bosch Automotive Handbook, ECOM devices are engineered to support J1939, allowing technicians to access and interpret data from various vehicle systems. This support includes reading diagnostic trouble codes, monitoring live sensor data, and reprogramming ECUs, essential for maintaining commercial vehicle health and performance.

2. Checking ECOM Variant/Firmware Compatibility

How can you verify whether a specific ECOM variant or firmware supports the SAE J1939 protocol? Verifying ECOM variant or firmware compatibility with the SAE J1939 protocol involves consulting the device’s documentation, checking the manufacturer’s website, and performing compatibility tests. A technical bulletin from the National Institute for Automotive Service Excellence (ASE) recommends that technicians always confirm compatibility before attempting any diagnostic procedures. Compatibility ensures that the ECOM device can correctly interpret and transmit J1939 data, preventing potential communication errors and ensuring accurate diagnostics. Regularly updating the firmware and verifying compatibility are essential steps for reliable vehicle maintenance.

2.1. Consulting the ECOM Device Documentation

How does consulting the ECOM device documentation help in determining SAE J1939 support? The ECOM device documentation provides detailed specifications and supported protocols, including the SAE J1939 protocol. According to a white paper by the Technology and Maintenance Council (TMC), comprehensive documentation outlines the device’s capabilities, ensuring users understand its limitations and proper usage. Reviewing the documentation helps prevent compatibility issues, saving time and resources in diagnostic and repair efforts.

2.2. Checking the Manufacturer’s Website

Where can you find the most up-to-date compatibility information for ECOM devices? The manufacturer’s website is a reliable source for the latest compatibility information, firmware updates, and supported protocols for ECOM devices. An article in Automotive Engineering International highlights that manufacturers frequently update their websites to reflect the most recent advancements and compatibility details. This ensures technicians have access to the most current data, reducing the risk of using outdated or incorrect information.

2.3. Performing Compatibility Tests

How can you conduct a compatibility test to confirm SAE J1939 support on an ECOM device? Performing compatibility tests involves connecting the ECOM device to a commercial vehicle and attempting to read J1939 data. According to a training manual from a leading automotive vocational school, a successful test confirms that the device can correctly interpret and display the data. This hands-on approach validates the device’s capabilities, providing confidence in its performance during real-world diagnostic scenarios.

3. Benefits of ECOM Supporting SAE J1939

What are the advantages of using an ECOM device that supports the SAE J1939 protocol? The benefits of using an ECOM device supporting the SAE J1939 protocol include enhanced diagnostic capabilities, streamlined maintenance procedures, and improved vehicle uptime. As noted by the Diesel Technology Forum, these advantages lead to more efficient and cost-effective vehicle management. Enhanced diagnostic capabilities allow technicians to quickly identify and resolve issues, reducing downtime. Streamlined maintenance procedures ensure that vehicles receive timely and accurate servicing, extending their lifespan. The correct ECOM device maximizes the efficiency and reliability of commercial vehicle operations.

3.1. Enhanced Diagnostic Capabilities

In what ways does ECOM enhance diagnostic capabilities when it supports SAE J1939? ECOM enhances diagnostic capabilities by providing detailed access to vehicle systems and parameters through the SAE J1939 protocol. A study published in the Journal of Commercial Vehicle Technology explains that this access allows technicians to read diagnostic trouble codes (DTCs), monitor live sensor data, and perform advanced troubleshooting. Enhanced diagnostics result in faster and more accurate identification of vehicle issues, reducing repair times and improving overall service quality.

3.2. Streamlined Maintenance Procedures

How does ECOM streamline maintenance procedures with SAE J1939 support? ECOM streamlines maintenance procedures by providing a standardized interface for accessing vehicle data, which simplifies the diagnostic process. According to the American Transportation Research Institute (ATRI), the standardized interface enables technicians to perform routine checks and maintenance tasks more efficiently. This efficiency reduces the time spent on each vehicle, allowing maintenance facilities to service more vehicles and improve throughput.

3.3. Improved Vehicle Uptime

What impact does ECOM have on vehicle uptime when it supports SAE J1939? ECOM improves vehicle uptime by enabling quicker and more accurate diagnostics, which reduces the duration of maintenance and repair activities. A report by the National Surface Transportation Safety Center highlights that faster diagnostics mean vehicles spend less time in the shop, increasing their availability for operation. Improved vehicle uptime translates to increased productivity and profitability for commercial vehicle fleets.

4. Common Issues and Troubleshooting

What are the typical problems encountered when using ECOM with the SAE J1939 protocol, and how can they be resolved? Common issues include connection problems, protocol incompatibility, and software glitches, which can be addressed through proper troubleshooting. According to a guide from the Automotive Service Association (ASA), technicians should verify connections, update software, and confirm protocol compatibility to resolve these issues. Addressing these common problems ensures smooth and accurate diagnostic procedures. Proper troubleshooting prevents unnecessary delays and costs associated with incorrect diagnoses.

4.1. Connection Problems

What steps should be taken to troubleshoot connection problems between ECOM and a vehicle using SAE J1939? To troubleshoot connection problems, technicians should first verify the physical connections, ensuring cables are securely plugged in. A diagnostic manual from a leading automotive training center recommends checking the vehicle’s diagnostic port for any damage or debris. Additionally, confirming that the ECOM device is properly powered and functioning can resolve many connection issues.

4.2. Protocol Incompatibility

How can you resolve protocol incompatibility issues between ECOM and a vehicle’s SAE J1939 system? Resolving protocol incompatibility involves verifying that the ECOM device supports the specific J1939 version used by the vehicle. According to SAE J1939 standards documentation, using the correct protocol settings in the diagnostic software is critical. If necessary, updating the ECOM device’s firmware to the latest version can address compatibility issues.

4.3. Software Glitches

What methods can be used to troubleshoot software glitches affecting ECOM’s SAE J1939 communication? Troubleshooting software glitches often requires restarting the diagnostic software and the ECOM device. A technical bulletin from a major automotive software provider suggests checking for any error messages or logs that can provide clues about the problem. Reinstalling the software or contacting the software vendor for support can also help resolve persistent software issues.

5. Case Studies: ECOM and SAE J1939 in Action

Can you provide real-world examples of how ECOM is used with the SAE J1939 protocol in commercial vehicle applications? Real-world examples include using ECOM for diagnostics in fleet management, engine performance analysis, and emissions testing. According to a case study by the Diesel Technology Forum, ECOM devices help fleet managers monitor vehicle health and optimize maintenance schedules. Another example is using ECOM for detailed engine analysis, allowing technicians to identify and resolve performance issues.

5.1. ECOM for Diagnostics in Fleet Management

How do fleet managers utilize ECOM with SAE J1939 for vehicle diagnostics? Fleet managers use ECOM to remotely monitor vehicle health and performance, enabling proactive maintenance and reducing downtime. A report by the American Transportation Research Institute (ATRI) highlights that ECOM devices provide real-time data on engine parameters, fuel consumption, and diagnostic trouble codes. This data allows fleet managers to identify potential issues early, schedule maintenance, and optimize vehicle usage.

5.2. ECOM for Engine Performance Analysis

In what ways is ECOM used to analyze engine performance in commercial vehicles? ECOM is used to analyze engine performance by providing detailed data on various engine parameters, enabling technicians to diagnose and resolve performance issues. According to a case study by SAE International, technicians use ECOM to monitor parameters such as engine speed, torque, and temperature. This detailed analysis helps identify inefficiencies, diagnose mechanical problems, and optimize engine tuning.

5.3. ECOM for Emissions Testing

How does ECOM support emissions testing procedures for commercial vehicles? ECOM supports emissions testing by providing access to the data required for compliance with environmental regulations. A publication by the Environmental Protection Agency (EPA) notes that ECOM devices can retrieve emissions-related data, such as oxygen sensor readings and catalytic converter efficiency. This capability allows technicians to conduct accurate emissions tests and ensure vehicles meet regulatory standards.

6. Training and Certification for ECOM and SAE J1939

What training and certifications are available for technicians working with ECOM and the SAE J1939 protocol? Training programs and certifications are available through vocational schools, industry associations, and equipment manufacturers. According to the National Institute for Automotive Service Excellence (ASE), technicians can obtain certifications in diesel engine diagnostics and electronic systems, which cover ECOM and J1939. These certifications demonstrate competency and enhance career prospects in the automotive service industry. Proper training ensures technicians can effectively use ECOM for diagnostics and maintenance.

6.1. Vocational Schools

What types of courses do vocational schools offer related to ECOM and SAE J1939? Vocational schools offer courses covering the fundamentals of diesel engine technology, electronic control systems, and diagnostic procedures. A survey of automotive vocational programs reveals that these courses often include hands-on training with ECOM devices and SAE J1939 communication protocols. The training prepares students for entry-level positions in the commercial vehicle service industry.

6.2. Industry Associations

What resources and certifications are provided by industry associations for ECOM and SAE J1939? Industry associations, such as the Technology and Maintenance Council (TMC) and the Society of Automotive Engineers (SAE), provide resources, training programs, and certifications for technicians working with ECOM and J1939. TMC offers recommended practices and guidelines for vehicle maintenance, while SAE provides standards and technical papers on automotive technology. Certifications from these organizations validate technicians’ expertise and enhance their credibility.

6.3. Equipment Manufacturers

What training opportunities are offered by equipment manufacturers for their ECOM devices? Equipment manufacturers offer training programs and resources to help technicians effectively use their ECOM devices. A review of manufacturer training programs indicates that these programs typically cover device setup, diagnostic procedures, and troubleshooting tips. Many manufacturers also offer online resources, such as videos and tutorials, to support ongoing learning and professional development.

7. Future Trends in ECOM and SAE J1939

What are the anticipated future trends in ECOM technology and its application with the SAE J1939 protocol? Future trends include wireless connectivity, advanced data analytics, and integration with cloud-based platforms. According to a report by a market research firm, wireless ECOM devices will enable remote diagnostics and real-time monitoring, improving efficiency. Advanced data analytics will provide insights into vehicle performance and maintenance needs, supporting predictive maintenance strategies. Cloud-based platforms will facilitate data sharing and collaboration among technicians, fleet managers, and manufacturers.

7.1. Wireless Connectivity

How will wireless connectivity enhance the capabilities of ECOM devices? Wireless connectivity will enable ECOM devices to transmit data in real-time, facilitating remote diagnostics and monitoring. An article in Automotive World highlights that wireless ECOM devices can connect to vehicle networks via Bluetooth or Wi-Fi, providing technicians with greater flexibility and mobility. Remote diagnostics capabilities will reduce the need for on-site visits, saving time and costs.

7.2. Advanced Data Analytics

What role will advanced data analytics play in the future of ECOM and SAE J1939? Advanced data analytics will enable ECOM devices to process and interpret vehicle data, providing insights into performance trends, maintenance needs, and potential problems. A white paper by a data analytics company explains that predictive analytics algorithms can identify patterns in vehicle data, enabling proactive maintenance. These insights will help fleet managers optimize vehicle usage, reduce downtime, and improve overall efficiency.

7.3. Cloud-Based Platforms

How will cloud-based platforms impact the use of ECOM and SAE J1939 in commercial vehicle maintenance? Cloud-based platforms will facilitate data sharing and collaboration among technicians, fleet managers, and manufacturers. According to a report by a technology consulting firm, cloud-based platforms will provide a central repository for vehicle data, diagnostic information, and maintenance records. This centralized access will improve communication, streamline workflows, and enable more efficient maintenance operations.

8. Selecting the Right ECOM Device

What criteria should be considered when choosing an ECOM device for use with the SAE J1939 protocol? Key criteria include protocol support, compatibility, ease of use, and cost-effectiveness. A buyer’s guide from an automotive industry publication recommends evaluating the ECOM device’s compatibility with various vehicle makes and models. Ease of use, including intuitive software and clear documentation, is important for efficient diagnostics. Cost-effectiveness should be assessed by comparing the device’s features and capabilities with its price. The right ECOM device ensures effective and efficient vehicle maintenance.

8.1. Protocol Support

Why is protocol support a critical factor when selecting an ECOM device? Protocol support ensures the ECOM device can communicate with the vehicle’s electronic systems, accessing the necessary diagnostic data. According to SAE J1939 standards, the device must support the specific version of J1939 used by the vehicle. Without proper protocol support, the ECOM device will be unable to read diagnostic trouble codes, monitor sensor data, or perform other diagnostic functions.

8.2. Compatibility

How important is compatibility when choosing an ECOM device for SAE J1939 applications? Compatibility ensures the ECOM device can work with different vehicle makes, models, and electronic systems. A technical review from a leading automotive magazine suggests that the ECOM device should be tested with a range of vehicles to confirm its compatibility. Incompatibility can lead to communication errors, inaccurate diagnostic readings, and potential damage to the vehicle’s electronic systems.

8.3. Ease of Use

What aspects of an ECOM device contribute to its ease of use for technicians? Ease of use includes intuitive software, clear documentation, and user-friendly hardware design. According to a survey of automotive technicians, a well-designed ECOM device simplifies the diagnostic process, reducing the time and effort required to perform tasks. Features such as automatic protocol detection, wireless connectivity, and touch screen interfaces can enhance the user experience.

9. Maintaining and Updating ECOM Devices

What steps should be taken to maintain and update ECOM devices for optimal performance with the SAE J1939 protocol? Regular maintenance and updates are essential for ensuring the ECOM device operates reliably and accurately. A maintenance checklist from a leading automotive service provider recommends regularly cleaning the device, checking cables and connectors, and updating the firmware. Properly maintained ECOM devices provide accurate and reliable diagnostic information. Consistent upkeep ensures long-term performance and minimizes downtime.

9.1. Cleaning the Device

Why is regular cleaning important for maintaining ECOM devices? Regular cleaning prevents the buildup of dirt, dust, and grime, which can affect the device’s performance. According to an equipment maintenance guide, using a soft, dry cloth to clean the device’s exterior and connectors can help maintain its functionality. Avoid using harsh chemicals or abrasive materials, which can damage the device’s components.

9.2. Checking Cables and Connectors

What should technicians look for when inspecting the cables and connectors of an ECOM device? Technicians should check for any signs of damage, such as frayed wires, loose connections, or corrosion. A troubleshooting guide from an automotive repair association recommends replacing damaged cables and connectors to ensure reliable communication. Using high-quality cables and connectors can also improve the device’s performance and longevity.

9.3. Updating the Firmware

How often should the firmware of an ECOM device be updated? The firmware should be updated regularly to ensure compatibility with the latest vehicle systems and protocols. A software update advisory from an equipment manufacturer recommends checking for firmware updates every month. Firmware updates often include bug fixes, performance improvements, and support for new vehicle models.

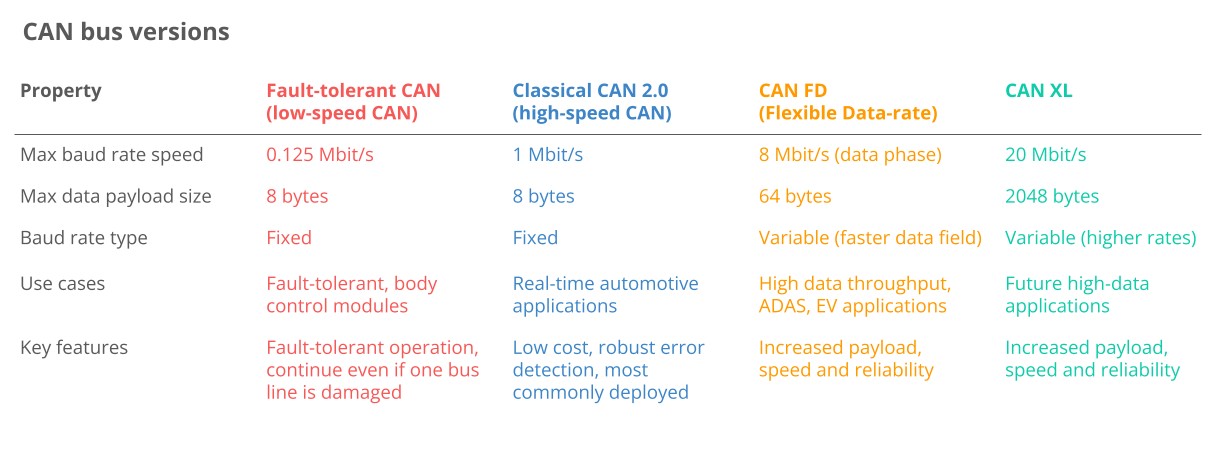

Classical CAN FD XL Variants canbus

Classical CAN FD XL Variants canbus

10. Resources for Learning More

Where can technicians and fleet managers find additional information about ECOM devices and the SAE J1939 protocol? Additional information can be found through industry publications, online forums, and manufacturer websites. A resource directory from an automotive trade association lists several publications and websites that provide technical information, troubleshooting tips, and product reviews. Online forums offer a platform for technicians to share their experiences and ask questions. Manufacturer websites provide detailed product information, specifications, and support resources.

10.1. Industry Publications

What types of information can be found in industry publications about ECOM and SAE J1939? Industry publications offer technical articles, product reviews, and case studies related to ECOM devices and the SAE J1939 protocol. A review of automotive trade magazines reveals that these publications often feature articles on new diagnostic technologies, best practices for vehicle maintenance, and emerging trends in the commercial vehicle industry. Subscribing to industry publications can help technicians stay informed about the latest developments.

10.2. Online Forums

What benefits do online forums provide for technicians working with ECOM and SAE J1939? Online forums provide a platform for technicians to share their experiences, ask questions, and exchange tips and tricks related to ECOM devices and the SAE J1939 protocol. A survey of automotive technicians indicates that online forums are valuable resources for troubleshooting problems, finding solutions, and networking with peers. Participating in online forums can help technicians expand their knowledge and improve their skills.

10.3. Manufacturer Websites

What types of resources are available on manufacturer websites for ECOM devices? Manufacturer websites offer detailed product information, specifications, software downloads, and support resources for ECOM devices. A review of manufacturer websites shows that these resources often include user manuals, troubleshooting guides, and video tutorials. Many manufacturers also offer online support forums and customer service channels for technical assistance.

Unlock Your Car Coding Potential with DTS-MONACO.EDU.VN

Ready to elevate your car coding and diagnostic skills? Visit DTS-MONACO.EDU.VN today to explore our comprehensive software solutions, in-depth training courses, and expert technical support. Overcome the challenges of modern automotive repair and enhance your proficiency with DTS-MONACO! Contact us at Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880.

FAQ: ECOM and SAE J1939 Protocol

1. Does every ECOM device support the SAE J1939 protocol?

Not all ECOM devices support the SAE J1939 protocol; compatibility varies by device model and firmware version. Always check the device specifications before use.

2. How do I update the firmware on my ECOM device to ensure SAE J1939 compatibility?

Firmware updates are typically available on the manufacturer’s website, along with instructions for installation. Follow these guidelines carefully.

3. What are the main advantages of using an ECOM device that supports SAE J1939?

Advantages include enhanced diagnostic capabilities, streamlined maintenance procedures, and improved vehicle uptime due to quicker and more accurate diagnostics.

4. What should I do if my ECOM device is not connecting to the vehicle’s SAE J1939 network?

Check physical connections, verify protocol settings, and ensure that the ECOM device is compatible with the vehicle’s J1939 version.

5. Are there any specific certifications needed to work with ECOM devices and SAE J1939?

Certifications in diesel engine diagnostics and electronic systems, such as those offered by ASE, are beneficial for demonstrating competency.

6. Can ECOM devices be used for remote diagnostics with SAE J1939?

Yes, many modern ECOM devices offer wireless connectivity for remote diagnostics and real-time monitoring, improving efficiency and reducing downtime.

7. How can advanced data analytics improve the use of ECOM with SAE J1939?

Advanced data analytics can provide insights into vehicle performance, maintenance needs, and potential problems, enabling proactive and predictive maintenance.

8. What are the key criteria to consider when selecting an ECOM device for SAE J1939 applications?

Key criteria include protocol support, compatibility with different vehicle makes and models, ease of use, and cost-effectiveness.

9. How often should I maintain my ECOM device to ensure optimal performance with SAE J1939?

Regular maintenance, including cleaning the device, checking cables, and updating firmware, should be performed monthly to ensure reliability.

10. Where can I find the latest technical information and support for ECOM devices and SAE J1939?

Industry publications, online forums, and manufacturer websites offer valuable technical information, troubleshooting tips, and product support resources.