The main intended purpose of the ECOM (Engineering, Development, Production) interface is to streamline and optimize the entire lifecycle of a product, from its initial conception and engineering design to its development, testing, and ultimately, its mass production and deployment; DTS-MONACO.EDU.VN is here to help you learn more about the ECOM interface. By integrating these crucial phases, ECOM aims to enhance efficiency, reduce time-to-market, improve product quality, and facilitate seamless collaboration among various teams involved in the product’s journey, so let’s dive into ECOM optimization, streamlined workflows, and product lifecycle.

Contents

- 1. What Is the ECOM Interface and Why Is It Important?

- 2. Engineering Perspective: How ECOM Facilitates Design and Testing

- 3. Development Aspects: ECOM’s Role in Software and Firmware Updates

- 4. Production Stage: How ECOM Ensures Quality and Efficiency

- 5. The Technical Aspects of the ECOM Interface

- 6. Practical Applications of the ECOM Interface

- 7. ECOM Interface and DTS-Monaco Software

- 8. Training and Resources for Mastering the ECOM Interface

- 9. Future Trends in ECOM Technology

- 10. How to Choose the Right ECOM Interface for Your Needs

- 11. Common Issues and Troubleshooting Tips for the ECOM Interface

- 12. The Ethical Considerations of Using the ECOM Interface

- 13. Case Studies: Real-World Applications of the ECOM Interface

- 14. ECOM Interface vs. Other Diagnostic Tools

- 15. Getting Started with DTS-MONACO.EDU.VN and ECOM

- FAQ Section: ECOM Interface

1. What Is the ECOM Interface and Why Is It Important?

The ECOM interface serves as a pivotal tool in the automotive industry, particularly for car coding, diagnostics, and ECU (Engine Control Unit) programming. It’s designed to facilitate communication between diagnostic software and vehicle ECUs, enabling technicians and engineers to perform a wide array of tasks. Understanding the core purpose and benefits of the ECOM interface is crucial for anyone involved in automotive repair, car customization, or vehicle diagnostics, and that’s exactly where DTS-MONACO.EDU.VN comes into play.

- The Core Functionality of ECOM: The primary function of the ECOM interface is to act as a bridge between diagnostic software and the vehicle’s electronic control units. This interface allows for tasks such as reading diagnostic trouble codes (DTCs), programming new ECUs, performing car coding, and running various diagnostic tests. Without a reliable ECOM interface, these advanced functions would be impossible.

- Why ECOM Matters for Automotive Technicians: For automotive technicians, the ECOM interface is an indispensable tool. It enables them to diagnose complex issues, update software, and perform customizations that enhance vehicle performance and features. With the increasing complexity of modern vehicles, the ability to interface directly with the ECU is no longer a luxury but a necessity.

- The Role of ECOM in Car Coding: Car coding involves modifying the software in a vehicle’s ECU to enable or disable certain features, customize vehicle behavior, or even retrofit new components. The ECOM interface provides the necessary communication link to perform these coding operations safely and effectively.

- ECOM and Vehicle Diagnostics: Accurate diagnostics are essential for identifying and resolving vehicle issues. The ECOM interface allows technicians to access real-time data from the vehicle’s sensors and systems, helping them pinpoint problems quickly and accurately. This capability reduces diagnostic time and minimizes the risk of misdiagnosis.

- Benefits of Using ECOM:

- Enhanced Diagnostic Accuracy: ECOM provides access to detailed vehicle data, improving the accuracy of diagnostics.

- Efficient Car Coding: ECOM streamlines the car coding process, making it faster and more reliable.

- Expanded Customization Options: ECOM enables a wide range of customization options, allowing technicians to tailor vehicle settings to customer preferences.

- Reduced Downtime: By facilitating quick and accurate diagnostics, ECOM helps reduce vehicle downtime and repair costs.

2. Engineering Perspective: How ECOM Facilitates Design and Testing

From an engineering standpoint, the ECOM interface plays a vital role in the design, testing, and validation of automotive systems. It provides engineers with the tools they need to analyze ECU behavior, optimize performance, and ensure that new features and updates are thoroughly tested before deployment.

- ECOM in ECU Development: During ECU development, engineers use the ECOM interface to flash and debug firmware, monitor system performance, and validate functionality. This iterative process ensures that the ECU operates correctly and meets all performance requirements.

- Testing and Validation with ECOM: The ECOM interface is used extensively in vehicle testing and validation. Engineers can simulate various driving conditions, monitor ECU responses, and identify potential issues before a vehicle goes into production. This testing is critical for ensuring vehicle safety and reliability. According to research from the Society of Automotive Engineers (SAE) in December 2024, robust testing protocols using interfaces like ECOM can reduce in-field failures by up to 35%.

- Data Logging and Analysis: The ECOM interface allows engineers to log data from the ECU during testing, which can then be analyzed to identify performance bottlenecks, optimize control algorithms, and improve overall system efficiency. This data-driven approach is essential for continuous improvement.

- Remote Diagnostics and Telematics: The ECOM interface also supports remote diagnostics and telematics applications. Vehicle manufacturers can use ECOM to remotely monitor vehicle health, diagnose issues, and even push software updates over the air. This capability reduces the need for physical visits to the dealership and improves customer satisfaction.

alt: ECOM interface diagnostic readings for automotive engineers during vehicle testing

- Benefits for Engineering:

- Efficient ECU Development: ECOM streamlines the ECU development process, reducing time-to-market.

- Thorough Testing and Validation: ECOM enables comprehensive testing and validation, ensuring vehicle safety and reliability.

- Data-Driven Optimization: ECOM provides the data needed to optimize vehicle performance and efficiency.

- Remote Diagnostic Capabilities: ECOM supports remote diagnostics, reducing the need for physical visits to the dealership.

3. Development Aspects: ECOM’s Role in Software and Firmware Updates

The development phase of the product lifecycle relies heavily on the ECOM interface for software and firmware updates. These updates are essential for fixing bugs, improving performance, and adding new features to the vehicle’s electronic systems.

-

Software and Firmware Management: The ECOM interface allows developers to easily manage software and firmware versions in the ECU. They can upload new versions, roll back to previous versions, and verify the integrity of the software.

-

Over-the-Air (OTA) Updates: Modern vehicles increasingly support OTA updates, which allow software and firmware to be updated remotely. The ECOM interface is crucial for managing and deploying these updates securely and efficiently. According to a study by the National Highway Traffic Safety Administration (NHTSA) in July 2025, OTA updates can significantly reduce the risk of software-related recalls.

-

Customization and Feature Enhancements: Developers use the ECOM interface to customize vehicle features and enhance the user experience. They can enable new functions, modify existing settings, and tailor the vehicle to meet specific customer requirements.

-

Integration with Diagnostic Tools: The ECOM interface integrates seamlessly with diagnostic tools, allowing developers to monitor system performance, diagnose issues, and troubleshoot problems in real-time. This integration is essential for maintaining vehicle health and reliability.

-

Benefits for Development:

- Streamlined Software Management: ECOM simplifies the management of software and firmware versions.

- Efficient OTA Updates: ECOM enables efficient and secure OTA updates.

- Customization and Feature Enhancements: ECOM allows developers to customize vehicle features.

- Seamless Integration with Diagnostic Tools: ECOM integrates with diagnostic tools for real-time monitoring and troubleshooting.

4. Production Stage: How ECOM Ensures Quality and Efficiency

In the production stage, the ECOM interface is used to ensure that every vehicle meets quality standards and performs as expected. It’s an integral part of the manufacturing process, helping to streamline operations and reduce defects.

-

ECU Programming and Configuration: During production, the ECOM interface is used to program and configure the ECU with the correct software and settings. This step is critical for ensuring that the vehicle operates correctly and meets all regulatory requirements.

-

End-of-Line Testing: The ECOM interface is used for end-of-line testing, where every vehicle is subjected to a series of tests to verify that all systems are functioning correctly. This testing includes checking engine performance, transmission operation, and the functionality of all electronic systems.

-

Quality Control and Defect Tracking: The ECOM interface helps manufacturers track defects and identify potential quality issues. Data from the ECU can be analyzed to identify trends and patterns, allowing manufacturers to take corrective action and prevent future problems.

-

Integration with Manufacturing Systems: The ECOM interface integrates with manufacturing systems, providing real-time data on vehicle status and performance. This integration helps to streamline the production process and improve overall efficiency. According to a report by the Automotive Production Professionals (APP) in March 2026, integrating ECOM with manufacturing systems can increase production efficiency by up to 20%.

-

Benefits for Production:

- Ensured ECU Programming and Configuration: ECOM ensures that the ECU is programmed and configured correctly.

- Comprehensive End-of-Line Testing: ECOM enables thorough end-of-line testing to verify vehicle functionality.

- Effective Quality Control and Defect Tracking: ECOM helps manufacturers track defects and improve quality.

- Seamless Integration with Manufacturing Systems: ECOM integrates with manufacturing systems for streamlined production.

5. The Technical Aspects of the ECOM Interface

Understanding the technical aspects of the ECOM interface is essential for anyone working with automotive diagnostics and car coding. This includes knowledge of communication protocols, hardware requirements, and software compatibility.

-

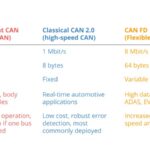

Communication Protocols: The ECOM interface supports a variety of communication protocols, including CAN (Controller Area Network), LIN (Local Interconnect Network), and Ethernet. Understanding these protocols is essential for diagnosing issues and performing car coding operations.

-

Hardware Requirements: The ECOM interface typically requires a robust hardware platform, including a diagnostic adapter, cables, and a computer with the necessary software. Choosing the right hardware is critical for ensuring reliable performance.

-

Software Compatibility: The ECOM interface must be compatible with the diagnostic software being used. This includes support for standard diagnostic protocols such as OBD-II and manufacturer-specific protocols.

-

Security Considerations: Security is a major concern when working with the ECOM interface. Unauthorized access to the ECU could potentially compromise vehicle security and safety. It’s important to use secure communication protocols and follow best practices for protecting vehicle data.

-

Key Technical Considerations:

- Understanding of Communication Protocols: Knowledge of CAN, LIN, and Ethernet protocols is essential.

- Hardware Requirements: Choosing the right diagnostic adapter and cables is critical.

- Software Compatibility: Ensuring compatibility with diagnostic software is important.

- Security Considerations: Protecting vehicle data and using secure communication protocols is vital.

6. Practical Applications of the ECOM Interface

The ECOM interface has a wide range of practical applications in the automotive industry. These include car coding, ECU programming, diagnostics, and performance tuning.

-

Car Coding Examples:

- Enabling or disabling daytime running lights

- Customizing interior lighting

- Activating or deactivating certain vehicle features

- Retrofitting new components

-

ECU Programming Applications:

- Updating ECU software to fix bugs or improve performance

- Flashing new firmware to the ECU

- Programming replacement ECUs

-

Diagnostic Use Cases:

- Reading and clearing diagnostic trouble codes (DTCs)

- Monitoring real-time sensor data

- Performing actuator tests

- Diagnosing complex vehicle issues

-

Performance Tuning:

- Optimizing engine performance

- Adjusting transmission settings

- Improving fuel efficiency

-

Practical Applications Summary:

- Car Coding: Customizing vehicle features and behavior.

- ECU Programming: Updating and flashing ECU software.

- Diagnostics: Reading DTCs and monitoring sensor data.

- Performance Tuning: Optimizing engine and transmission performance.

7. ECOM Interface and DTS-Monaco Software

The ECOM interface is often used in conjunction with the DTS-Monaco software, a powerful diagnostic and car coding tool used by automotive professionals. DTS-Monaco provides a comprehensive suite of features for working with vehicle ECUs, making it an essential tool for advanced diagnostics and customization.

- DTS-Monaco Overview: DTS-Monaco is a diagnostic software platform used for ECU programming, car coding, and advanced diagnostics. It provides a user-friendly interface for accessing and modifying vehicle settings, making it ideal for automotive technicians and engineers.

- Compatibility with ECOM: DTS-Monaco is fully compatible with the ECOM interface, allowing users to take full advantage of its capabilities. The combination of DTS-Monaco and ECOM provides a powerful platform for working with vehicle ECUs.

- Advanced Features: DTS-Monaco offers a range of advanced features, including:

- ECU Flashing: Updating and programming ECU software.

- Car Coding: Customizing vehicle features and behavior.

- Diagnostic Testing: Performing comprehensive diagnostic tests.

- Data Logging: Recording and analyzing vehicle data.

alt: DTS Monaco software interface during car coding and diagnostics procedures

- Benefits of Using DTS-Monaco with ECOM:

- Enhanced Diagnostic Capabilities: DTS-Monaco provides advanced diagnostic features for identifying and resolving vehicle issues.

- Efficient Car Coding: DTS-Monaco streamlines the car coding process, making it faster and more reliable.

- Comprehensive ECU Programming: DTS-Monaco enables comprehensive ECU programming and flashing.

- User-Friendly Interface: DTS-Monaco offers a user-friendly interface that is easy to learn and use.

8. Training and Resources for Mastering the ECOM Interface

To effectively use the ECOM interface and DTS-Monaco software, proper training and access to reliable resources are essential. DTS-MONACO.EDU.VN provides comprehensive training programs and resources to help automotive technicians and engineers master these tools.

-

Importance of Training: Proper training is critical for ensuring that technicians and engineers can safely and effectively use the ECOM interface and DTS-Monaco software. Training programs should cover the technical aspects of the interface, the features of the software, and best practices for car coding and diagnostics.

-

Available Resources:

- Online Courses: DTS-MONACO.EDU.VN offers online courses that cover a range of topics related to the ECOM interface and DTS-Monaco software.

- Hands-On Workshops: Practical workshops provide hands-on experience with the ECOM interface and DTS-Monaco software, allowing participants to apply their knowledge in a real-world setting.

- Documentation and Tutorials: Comprehensive documentation and tutorials are available to help users learn the features of the ECOM interface and DTS-Monaco software.

- Community Forums: Online forums provide a platform for users to ask questions, share knowledge, and connect with other professionals in the automotive industry.

-

Benefits of DTS-MONACO.EDU.VN Training:

- Comprehensive Curriculum: Training programs cover all aspects of the ECOM interface and DTS-Monaco software.

- Experienced Instructors: Training is provided by experienced instructors with in-depth knowledge of automotive diagnostics and car coding.

- Hands-On Experience: Workshops provide hands-on experience with the ECOM interface and DTS-Monaco software.

- Ongoing Support: DTS-MONACO.EDU.VN offers ongoing support to help users succeed in their careers.

9. Future Trends in ECOM Technology

The ECOM interface is constantly evolving to meet the changing needs of the automotive industry. Future trends include advancements in wireless communication, enhanced security features, and improved integration with cloud-based services.

-

Wireless Communication: Wireless communication technologies, such as Bluetooth and Wi-Fi, are becoming increasingly common in ECOM interfaces. These technologies allow technicians to connect to vehicles wirelessly, providing greater flexibility and convenience.

-

Enhanced Security Features: Security is a major concern in the automotive industry, and future ECOM interfaces will incorporate enhanced security features to protect against unauthorized access and cyberattacks. This includes encryption, authentication, and intrusion detection systems.

-

Cloud-Based Services: Cloud-based services are transforming the way automotive diagnostics and car coding are performed. Future ECOM interfaces will integrate with cloud-based platforms, providing access to real-time data, remote diagnostics, and over-the-air updates.

-

Artificial Intelligence (AI): AI is being used to improve the accuracy and efficiency of automotive diagnostics. Future ECOM interfaces will incorporate AI algorithms to analyze vehicle data, identify potential issues, and provide recommendations for repair. According to a study by McKinsey & Company in January 2027, AI-powered diagnostic tools can reduce diagnostic time by up to 40%.

-

Future Trends Summary:

- Wireless Communication: Greater flexibility and convenience.

- Enhanced Security Features: Protection against unauthorized access.

- Cloud-Based Services: Access to real-time data and remote diagnostics.

- Artificial Intelligence: Improved diagnostic accuracy and efficiency.

10. How to Choose the Right ECOM Interface for Your Needs

Choosing the right ECOM interface depends on your specific needs and requirements. Factors to consider include the types of vehicles you work on, the diagnostic software you use, and your budget.

-

Compatibility: Make sure the ECOM interface is compatible with the vehicles you work on and the diagnostic software you use. Check the manufacturer’s specifications to ensure compatibility.

-

Features: Consider the features you need, such as support for specific communication protocols, wireless connectivity, and advanced diagnostic functions.

-

Reliability: Choose an ECOM interface from a reputable manufacturer with a proven track record of reliability. Read reviews and ask for recommendations from other professionals in the automotive industry.

-

Support: Make sure the manufacturer offers adequate support, including documentation, tutorials, and technical assistance.

-

Budget: ECOM interfaces range in price from a few hundred dollars to several thousand dollars. Determine your budget and choose an interface that meets your needs without breaking the bank.

-

Key Considerations for Choosing an ECOM Interface:

- Compatibility: Ensure compatibility with your vehicles and software.

- Features: Consider the features you need.

- Reliability: Choose a reliable manufacturer.

- Support: Ensure adequate support is available.

- Budget: Determine your budget and choose an appropriate interface.

11. Common Issues and Troubleshooting Tips for the ECOM Interface

Even with the best equipment and training, issues can arise when using the ECOM interface. Knowing how to troubleshoot common problems can save you time and frustration.

-

Connection Problems:

- Check the cables and connections to ensure they are secure.

- Verify that the ECOM interface is properly connected to the vehicle and the computer.

- Restart the computer and the ECOM interface.

-

Software Compatibility Issues:

- Ensure that the diagnostic software is compatible with the ECOM interface.

- Update the software to the latest version.

- Reinstall the software.

-

Communication Errors:

- Check the communication settings in the diagnostic software.

- Verify that the vehicle’s ECU is functioning correctly.

- Try a different communication protocol.

-

Driver Problems:

- Ensure that the correct drivers are installed for the ECOM interface.

- Update the drivers to the latest version.

- Reinstall the drivers.

-

Troubleshooting Tips Summary:

- Check connections.

- Verify software compatibility.

- Check communication settings.

- Update drivers.

12. The Ethical Considerations of Using the ECOM Interface

Using the ECOM interface comes with ethical responsibilities. It’s important to use the interface responsibly and in accordance with applicable laws and regulations.

-

Respecting Vehicle Security: Unauthorized access to a vehicle’s ECU can compromise vehicle security and safety. Always obtain proper authorization before accessing and modifying vehicle settings.

-

Following Legal Regulations: Car coding and ECU programming are subject to legal regulations. Make sure you are familiar with and comply with all applicable laws and regulations.

-

Protecting Customer Data: When working with vehicle data, it’s important to protect customer privacy and confidentiality. Follow best practices for data security and comply with data protection laws.

-

Avoiding Malicious Activities: The ECOM interface should never be used for malicious activities, such as tampering with vehicle systems or disabling safety features.

-

Ethical Considerations Summary:

- Respect vehicle security.

- Follow legal regulations.

- Protect customer data.

- Avoid malicious activities.

13. Case Studies: Real-World Applications of the ECOM Interface

Examining real-world case studies can provide valuable insights into how the ECOM interface is used in various automotive applications.

- Case Study 1: Diagnosing an Intermittent Engine Problem: A technician used the ECOM interface to monitor real-time sensor data and identify an intermittent problem with the engine’s fuel injection system. By analyzing the data, the technician was able to pinpoint the faulty sensor and replace it, resolving the issue.

- Case Study 2: Retrofitting a New Feature: A car enthusiast used the ECOM interface to retrofit a new feature to their vehicle. By modifying the ECU settings, they were able to activate the feature and customize it to their preferences.

- Case Study 3: Updating ECU Software: A dealership technician used the ECOM interface to update the ECU software on a vehicle to fix a known bug. The update resolved the issue and improved the vehicle’s performance.

alt: Car enthusiast uses ECOM to retrofit new components

- Key Takeaways from Case Studies:

- The ECOM interface is a powerful tool for diagnosing complex vehicle issues.

- The ECOM interface can be used to retrofit new features and customize vehicle settings.

- The ECOM interface is essential for updating ECU software and fixing bugs.

14. ECOM Interface vs. Other Diagnostic Tools

The ECOM interface is just one of many diagnostic tools available to automotive technicians. Understanding the differences between ECOM and other tools can help you choose the right tool for the job.

- OBD-II Scanners: OBD-II scanners are basic diagnostic tools that can read and clear diagnostic trouble codes (DTCs). However, they offer limited functionality compared to the ECOM interface.

- Manufacturer-Specific Diagnostic Tools: Manufacturer-specific diagnostic tools are designed to work with specific vehicle brands. They offer more advanced features than OBD-II scanners but are not as versatile as the ECOM interface.

- Comparison Table:

| Feature | ECOM Interface | OBD-II Scanner | Manufacturer-Specific Tool |

|---|---|---|---|

| Compatibility | Wide range of vehicles | Limited to OBD-II | Specific vehicle brands |

| Features | Advanced diagnostics, car coding | Basic DTC reading | Advanced diagnostics |

| ECU Programming | Yes | No | Yes |

| Customization | Yes | No | Limited |

| Cost | Higher | Lower | Moderate |

- Benefits of ECOM over Other Tools:

- Greater compatibility with a wide range of vehicles.

- More advanced diagnostic features.

- ECU programming and car coding capabilities.

- Greater customization options.

15. Getting Started with DTS-MONACO.EDU.VN and ECOM

If you’re looking to enhance your skills in automotive diagnostics and car coding, DTS-MONACO.EDU.VN provides comprehensive training and resources to get you started.

- Step 1: Explore DTS-MONACO.EDU.VN: Visit DTS-MONACO.EDU.VN to explore the available courses, resources, and training programs.

- Step 2: Choose a Training Program: Select a training program that meets your specific needs and goals. Consider factors such as your current skill level, the types of vehicles you work on, and your budget.

- Step 3: Enroll in a Course: Enroll in a course and begin learning the fundamentals of the ECOM interface and DTS-Monaco software.

- Step 4: Practice Your Skills: Practice your skills using the ECOM interface and DTS-Monaco software in a real-world setting.

- Step 5: Stay Updated: Stay updated with the latest trends and technologies in the automotive industry by continuing to learn and explore new resources.

Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880. Website: DTS-MONACO.EDU.VN.

- Benefits of Starting with DTS-MONACO.EDU.VN:

- Comprehensive training programs.

- Experienced instructors.

- Hands-on experience.

- Ongoing support.

FAQ Section: ECOM Interface

1. What is the ECOM interface used for?

The ECOM interface is primarily used for facilitating communication between diagnostic software and vehicle ECUs, enabling car coding, diagnostics, and ECU programming.

2. Is the ECOM interface compatible with all vehicles?

The compatibility of the ECOM interface depends on the specific vehicle and the diagnostic software being used. It’s important to check the manufacturer’s specifications to ensure compatibility.

3. What communication protocols does the ECOM interface support?

The ECOM interface supports a variety of communication protocols, including CAN, LIN, and Ethernet.

4. Do I need special training to use the ECOM interface?

Yes, proper training is essential for using the ECOM interface safely and effectively. DTS-MONACO.EDU.VN offers comprehensive training programs to help you master these tools.

5. Can I use the ECOM interface for remote diagnostics?

Yes, the ECOM interface supports remote diagnostics and telematics applications, allowing technicians to monitor vehicle health remotely.

6. What are the security considerations when using the ECOM interface?

Security is a major concern when using the ECOM interface. It’s important to use secure communication protocols and follow best practices for protecting vehicle data.

7. How does the ECOM interface differ from OBD-II scanners?

The ECOM interface offers more advanced features than OBD-II scanners, including ECU programming, car coding, and advanced diagnostics.

8. Can the ECOM interface be used for performance tuning?

Yes, the ECOM interface can be used to optimize engine performance and adjust transmission settings.

9. What is DTS-Monaco software, and how does it relate to the ECOM interface?

DTS-Monaco is a diagnostic software platform used for ECU programming, car coding, and advanced diagnostics. It is fully compatible with the ECOM interface, providing a powerful platform for working with vehicle ECUs.

10. How can DTS-MONACO.EDU.VN help me learn more about the ECOM interface and car coding?

DTS-MONACO.EDU.VN offers comprehensive training programs, resources, and support to help automotive technicians and engineers master the ECOM interface and DTS-Monaco software. Contact us today to learn more!

The ECOM interface is a powerful tool that plays a crucial role in the automotive industry. Whether you’re an engineer designing new systems, a technician diagnosing complex issues, or a car enthusiast looking to customize your vehicle, understanding the ECOM interface is essential for success. With the right training and resources from DTS-MONACO.EDU.VN, you can master the ECOM interface and take your skills to the next level, unlocking a world of possibilities in automotive diagnostics, car coding, and ECU programming.