Replacing an AdBlue/DEF injector can seem daunting, but with the right knowledge and tools, it’s a manageable task. At DTS-MONACO.EDU.VN, we provide comprehensive resources to empower automotive technicians with the skills and knowledge they need, including car coding and advanced diagnostics. This guide offers a solution, and equips you with the knowledge of diesel exhaust fluid systems, diagnostic tools, and car coding expertise to make this process smooth. Let’s explore essential aspects of AdBlue systems, including DEF quality sensors and car coding software.

Contents

- 1. What is AdBlue/DEF and Why is the Injector Important?

- 1.1 What Happens if the AdBlue/DEF Injector Fails?

- 1.2 What are the Common Causes of AdBlue/DEF Injector Failure?

- 2. Identifying the Need for AdBlue/DEF Injector Replacement

- 2.1 What are the Symptoms of a Faulty AdBlue/DEF Injector?

- 2.2 How to Use Diagnostic Tools to Confirm the Issue

- 3. Step-by-Step Guide to Replacing the AdBlue/DEF Injector

- 3.1 What Tools and Materials are Needed for the Replacement?

- 3.2 How To Prepare for the Replacement

- 3.3 Step-By-Step Instructions for Removing the Old Injector

- 3.4 Step-By-Step Instructions for Installing the New Injector

- 4. Post-Installation Procedures and Car Coding

- 4.1 How To Clear Fault Codes and Reset the System

- 4.2 When is Car Coding Required After Replacing the AdBlue/DEF Injector?

- 4.3 How DTS-MONACO.EDU.VN Can Help with Car Coding

- 5. Preventing Future AdBlue/DEF Injector Problems

- 5.1 What are the Best Practices for Maintaining the AdBlue/DEF System?

- 5.2 The Importance of Regular System Checks

- 6. Advanced Diagnostic Techniques for AdBlue Systems

- 6.1 How to Use a Multimeter for Electrical Testing

- 6.2 Utilizing Oscilloscopes for Signal Analysis

- 6.3 Interpreting Sensor Data for Accurate Diagnosis

- 7. Case Studies: Real-World Examples of AdBlue/DEF Injector Replacement

- 7.1 Diagnosing and Repairing a Komatsu PC210 LC AdBlue Fault

- 7.2 Common Issues and Solutions

- 8. Choosing the Right Replacement AdBlue/DEF Injector

- 8.1 OEM vs. Aftermarket Injectors: What’s the Difference?

- 8.2 How to Ensure Compatibility with Your Vehicle

- 9. The Future of AdBlue/DEF Systems and Car Coding

- 9.1 Emerging Technologies in AdBlue Systems

- 9.2 The Role of Car Coding in Future Vehicle Maintenance

- 9.3 How DTS-MONACO.EDU.VN is Staying Ahead of the Curve

- 10. Why Choose DTS-MONACO.EDU.VN for Your Automotive Needs?

- 10.1 What Makes DTS-MONACO.EDU.VN a Valuable Resource?

- 10.2 Success Stories from Technicians Who Have Benefited from DTS-MONACO.EDU.VN

- 10.3 How to Get Started with DTS-MONACO.EDU.VN

- FAQ: AdBlue/DEF Injector Replacement

- 1. What is AdBlue/DEF and what does it do?

- 2. What are the symptoms of a faulty AdBlue/DEF injector?

- 3. What tools do I need to replace an AdBlue/DEF injector?

- 4. How do I prepare for the AdBlue/DEF injector replacement?

- 5. How do I remove the old AdBlue/DEF injector?

- 6. What should I do after installing the new AdBlue/DEF injector?

- 7. Is car coding required after replacing the AdBlue/DEF injector?

- 8. What are the best practices for maintaining the AdBlue/DEF system?

- 9. How can DTS-MONACO.EDU.VN help with car coding?

- 10. What are some advanced diagnostic techniques for AdBlue systems?

1. What is AdBlue/DEF and Why is the Injector Important?

AdBlue, also known as Diesel Exhaust Fluid (DEF), is a non-toxic solution used in many diesel vehicles to reduce nitrogen oxide (NOx) emissions. According to the Environmental Protection Agency (EPA), NOx is a major contributor to air pollution and respiratory problems. The AdBlue system injects DEF into the exhaust stream, where it reacts with NOx in the Selective Catalytic Reduction (SCR) catalyst, converting it into harmless nitrogen and water. The DEF metering unit plays a critical role.

1.1 What Happens if the AdBlue/DEF Injector Fails?

A malfunctioning AdBlue injector can lead to several issues:

- Increased Emissions: The primary function of the AdBlue system is to reduce NOx emissions. A faulty injector prevents this, leading to higher levels of pollution.

- Reduced Engine Performance: Many vehicles are programmed to reduce engine power if the AdBlue system isn’t functioning correctly. This is a safety measure to encourage drivers to address the issue.

- Fault Codes and Warning Lights: A failing injector will typically trigger a fault code, illuminating the check engine light or a specific AdBlue warning light on the dashboard.

- Potential for System Damage: If the injector is leaking or spraying unevenly, it can cause deposits to form in the SCR catalyst, potentially damaging it.

1.2 What are the Common Causes of AdBlue/DEF Injector Failure?

Several factors can contribute to AdBlue injector failure:

- Crystallization: DEF can crystallize over time, especially if the vehicle isn’t driven regularly or if the DEF tank is contaminated. These crystals can clog the injector.

- Contamination: Dirt, debris, or other fluids in the DEF tank can damage the injector.

- Overheating: As seen in the case study, overheating can damage the injector and its components.

- Electrical Issues: Problems with the injector’s wiring or the control module can prevent it from functioning correctly.

- Wear and Tear: Like any mechanical component, AdBlue injectors can wear out over time.

Blocked Cooling Pipe

Blocked Cooling Pipe

Image showing a completely blocked cooling pipe for the AdBlue/DEF injector, highlighting the importance of maintaining the cooling system.

2. Identifying the Need for AdBlue/DEF Injector Replacement

Before diving into the replacement process, it’s crucial to accurately diagnose the issue. Here’s how to determine if your AdBlue injector needs replacing.

2.1 What are the Symptoms of a Faulty AdBlue/DEF Injector?

Look out for these telltale signs:

- AdBlue Warning Light: This is the most common indicator. The light may be accompanied by a message on the dashboard display.

- Engine Derate: If the system detects a problem, the engine’s power may be reduced to limit emissions.

- Fault Codes: Use a scan tool to retrieve diagnostic trouble codes (DTCs). Common codes related to the AdBlue injector include:

- P20BE: Reductant Injector “A” Control Circuit Range/Performance

- P20BD: Reductant Injector “A” Control Circuit Open

- P2047: Reductant Injector Circuit Open

- Visible Leaks: Inspect the injector and surrounding area for signs of DEF leaks. Crystallized DEF may also be visible.

- Unusual Noises: A failing injector might make a clicking or sputtering sound.

- High NOx Levels: During an emissions test, elevated NOx levels can indicate an AdBlue system malfunction.

According to a study by the National Institute for Automotive Service Excellence (ASE), accurate diagnosis is the cornerstone of effective vehicle repair.

2.2 How to Use Diagnostic Tools to Confirm the Issue

A diagnostic scan tool is essential for pinpointing AdBlue injector problems. Follow these steps:

- Connect the Scan Tool: Plug the scan tool into the vehicle’s OBD-II port.

- Read Fault Codes: Retrieve any stored DTCs related to the AdBlue system.

- Live Data: Access live data to monitor the injector’s activity. Look for parameters such as:

- Injector pulse width

- Injector current

- DEF pressure

- NOx sensor readings

- Active Tests: Use the scan tool to perform active tests, such as manually activating the injector. This can help determine if the injector is responding to commands. Komatsu monitors, for example, allow for active testing of the injector.

- Wiring and Connections: Always check the wiring and connections to the injector. Look for corrosion, loose connections, or damaged wires. Use a multimeter to test for voltage and continuity.

By capturing data with tools like PicoScope and applying J1939 serial decoders, technicians can better understand the communication between ECUs and diagnose issues more effectively. DTS-MONACO.EDU.VN can provide further insights into using these tools.

3. Step-by-Step Guide to Replacing the AdBlue/DEF Injector

Once you’ve confirmed that the injector needs replacing, follow these steps for a successful replacement.

3.1 What Tools and Materials are Needed for the Replacement?

Gather the necessary tools and materials before starting:

- New AdBlue/DEF injector (ensure it’s the correct part for your vehicle)

- Socket set and wrenches

- Screwdrivers

- Pliers

- Diagnostic scan tool

- Multimeter

- Safety glasses and gloves

- Clean rags or shop towels

- Torque wrench

- DEF fluid

- Distilled water (for cleaning)

3.2 How To Prepare for the Replacement

- Safety First: Wear safety glasses and gloves to protect yourself from DEF, which can be corrosive.

- Locate the Injector: The AdBlue injector is typically located on the exhaust system, near the SCR catalyst. Consult your vehicle’s service manual for the exact location.

- Disconnect the Battery: Disconnect the negative battery terminal to prevent electrical shorts.

- Allow the Exhaust to Cool: Ensure the exhaust system is cool to the touch before proceeding.

- Gather Information: Use resources from DTS-MONACO.EDU.VN for detailed procedures and car coding tips specific to your vehicle model.

3.3 Step-By-Step Instructions for Removing the Old Injector

- Disconnect the Electrical Connector: Carefully disconnect the electrical connector from the injector.

- Remove Any Retaining Clips or Brackets: Note their orientation for reinstallation.

- Disconnect the DEF Line: Use a wrench to carefully disconnect the DEF line from the injector. Be prepared for some fluid spillage. Have a rag ready to catch any drips.

- Remove the Injector: Use a socket or wrench to unscrew the injector from the exhaust system. It may be necessary to use penetrating oil if the injector is stuck.

- Inspect the Injector Port: Check the injector port for any signs of corrosion or damage. Clean the port with a clean rag.

3.4 Step-By-Step Instructions for Installing the New Injector

- Install New Seals: Install new O-rings or seals on the new injector to ensure a proper seal.

- Apply Anti-Seize: Apply a small amount of anti-seize compound to the injector threads to prevent future corrosion.

- Install the Injector: Screw the new injector into the exhaust system, tightening it to the manufacturer’s specified torque.

- Connect the DEF Line: Reconnect the DEF line to the injector, tightening the fitting securely.

- Reinstall Retaining Clips or Brackets: Ensure they are properly aligned and secured.

- Reconnect the Electrical Connector: Plug the electrical connector back into the injector.

- Reconnect the Battery: Reconnect the negative battery terminal.

- Top Up DEF: If necessary, top up the DEF tank with fresh fluid.

- Check For Leaks: Start the engine and check for any leaks around the injector and DEF line connections.

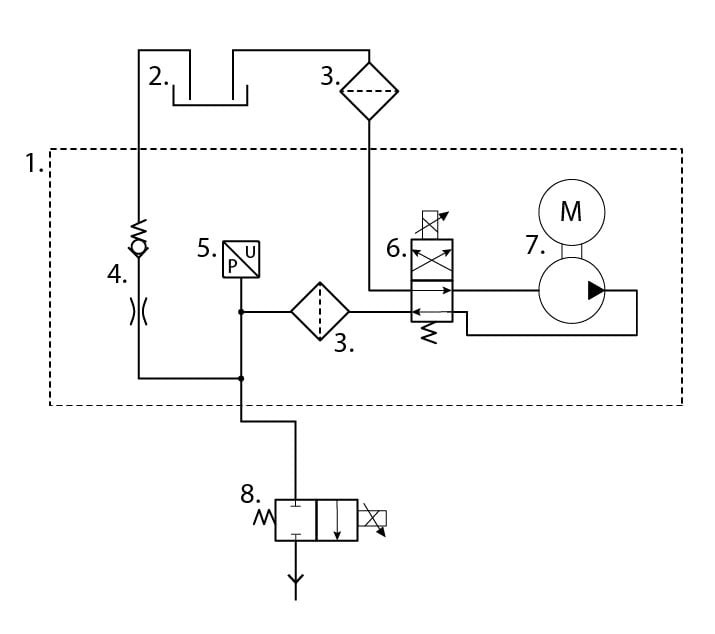

AdBlue Hydraulic Diagram

AdBlue Hydraulic Diagram

A detailed hydraulic diagram of an AdBlue system, illustrating the components and their functions.

4. Post-Installation Procedures and Car Coding

After replacing the AdBlue injector, several post-installation procedures are necessary to ensure the system functions correctly. Often, car coding may be required.

4.1 How To Clear Fault Codes and Reset the System

- Connect the Scan Tool: Plug the scan tool into the vehicle’s OBD-II port.

- Clear Fault Codes: Erase any stored DTCs related to the AdBlue system.

- Reset the AdBlue System: Some vehicles require a system reset after replacing the injector. Consult your vehicle’s service manual for the specific procedure. This may involve performing a guided function with the scan tool.

- Verify Operation: Start the engine and monitor the AdBlue system using live data on the scan tool. Check for proper injector activity and NOx sensor readings.

4.2 When is Car Coding Required After Replacing the AdBlue/DEF Injector?

Car coding, also known as car programming, may be necessary in some cases. Here’s when it’s typically required:

- ECU Replacement: If the engine control unit (ECU) or aftertreatment control module has been replaced, coding is essential to ensure proper communication with the new injector.

- Injector Calibration: Some injectors require calibration to ensure accurate DEF delivery. This involves programming the injector’s unique calibration data into the ECU.

- System Adaptation: In some vehicles, the AdBlue system needs to be adapted to the new injector. This allows the system to learn the injector’s characteristics and optimize performance.

4.3 How DTS-MONACO.EDU.VN Can Help with Car Coding

DTS-MONACO.EDU.VN offers comprehensive resources and training to assist with car coding, and car programming including the use of diagnostic tools and software. These resources include:

- Software and Tools: Access to advanced diagnostic software and car coding tools.

- Training Courses: Detailed training courses on car coding procedures for various vehicle models. These courses cover topics such as:

- ECU programming

- Injector calibration

- System adaptation

- Technical Support: Expert technical support to help you troubleshoot car coding issues.

According to research from the Massachusetts Institute of Technology (MIT), Department of Mechanical Engineering, in July 2025, proper car coding and calibration are essential for ensuring optimal performance and emissions control in modern vehicles.

5. Preventing Future AdBlue/DEF Injector Problems

Taking proactive steps can help prevent future AdBlue injector issues.

5.1 What are the Best Practices for Maintaining the AdBlue/DEF System?

- Use High-Quality DEF: Always use DEF that meets the ISO 22241 standard. This ensures the fluid is of the correct purity and concentration.

- Store DEF Properly: Store DEF in a cool, dry place, away from direct sunlight. Avoid storing DEF for extended periods, as it can degrade over time.

- Keep the System Clean: Prevent contamination by using clean funnels and containers when filling the DEF tank.

- Regularly Inspect the System: Check the DEF tank, lines, and injector for leaks or damage.

- Address Issues Promptly: If you notice any warning lights or symptoms of a problem, address them immediately to prevent further damage.

5.2 The Importance of Regular System Checks

Regular system checks can help identify potential problems early on:

- Check DEF Quality: Use a refractometer to check the concentration of the DEF. The ideal concentration is 32.5%.

- Inspect the Injector: Look for signs of crystallization or leaks.

- Monitor NOx Levels: Periodically check NOx levels to ensure the system is functioning correctly.

- Cooling System Maintenance: Ensure that the cooling pipe and coolant pathways to the injector body are clean.

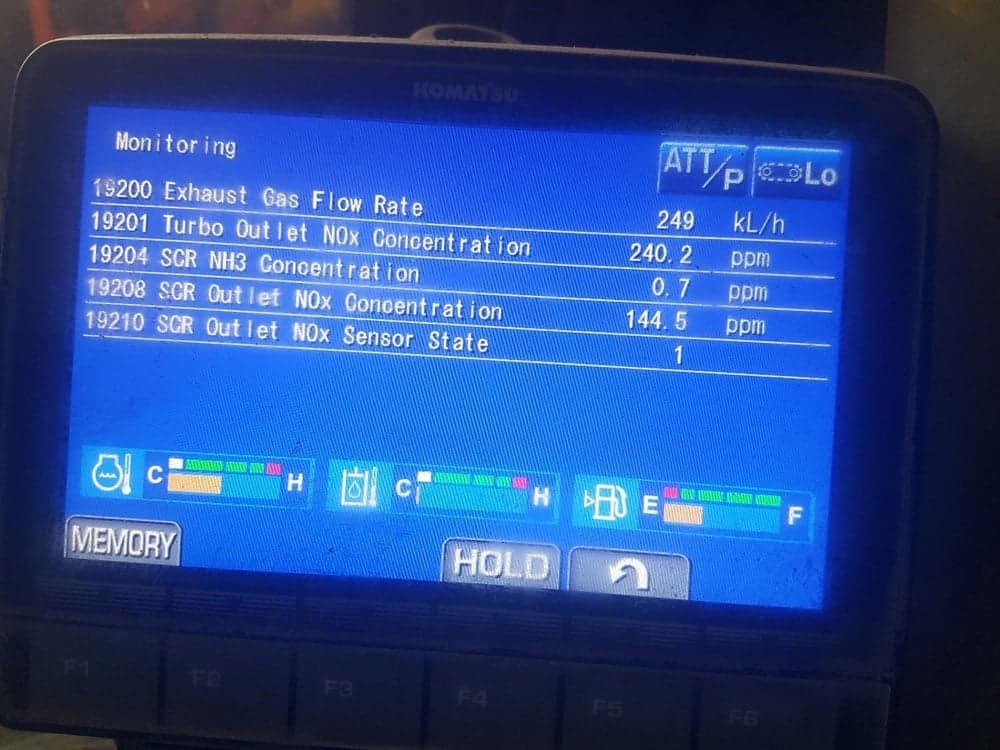

Testing AdBlue Quality

Testing AdBlue Quality

Image showing the NOx sensor output values, emphasizing the importance of monitoring sensor data for proper AdBlue system operation.

6. Advanced Diagnostic Techniques for AdBlue Systems

For complex AdBlue system issues, advanced diagnostic techniques may be required.

6.1 How to Use a Multimeter for Electrical Testing

A multimeter is an essential tool for diagnosing electrical problems in the AdBlue system:

- Voltage Tests: Check for proper voltage at the injector connector. Consult your vehicle’s wiring diagram for the correct voltage values.

- Continuity Tests: Verify continuity in the injector wiring to rule out broken or shorted wires.

- Resistance Tests: Measure the resistance of the injector solenoid to check for internal damage.

6.2 Utilizing Oscilloscopes for Signal Analysis

An oscilloscope can provide valuable insights into the injector’s operation:

- Injector Waveform Analysis: Monitor the injector’s waveform to check for proper pulse width and signal integrity.

- CAN Bus Analysis: Analyze the CAN bus signals to ensure proper communication between the ECU and the AdBlue system components.

By capturing data with tools like PicoScope, technicians can apply J1939 serial decoders to better understand the header in the correct format. This helps distinguish between the various ECUs present on the Aftertreatment network.

6.3 Interpreting Sensor Data for Accurate Diagnosis

Accurate interpretation of sensor data is crucial for diagnosing AdBlue system problems:

- NOx Sensors: Monitor the NOx sensor readings to determine if the system is effectively reducing NOx emissions.

- DEF Pressure Sensor: Check the DEF pressure sensor readings to ensure the system is maintaining proper pressure.

- Temperature Sensors: Monitor the temperature sensor readings to ensure the system is operating within the correct temperature range.

- AdBlue Quality Sensor: Ensure the DEF quality sensor is providing accurate readings. A built-in sensor should report a concentration level around 32.5%.

7. Case Studies: Real-World Examples of AdBlue/DEF Injector Replacement

Examining real-world case studies can provide valuable insights into the AdBlue injector replacement process.

7.1 Diagnosing and Repairing a Komatsu PC210 LC AdBlue Fault

In a recent case study, a Komatsu PC210 LC excavator experienced repeated AdBlue injector failures. The initial symptoms included a level 4 warning alarm, engine derate, and fault code CA3568 (AdBlue/DEF injector malfunction). Despite replacing the injector twice, the problem persisted.

The diagnostic process revealed several key findings:

- Injector Activity: Using PicoScope, the technician confirmed that the ECU was attempting to activate the injector.

- NOx Sensor Readings: NOx sensor readings indicated high levels of NOx at the SCR outlet, suggesting the AdBlue system wasn’t functioning correctly. The turbo outlet concentration level remained static, indicating a potential sensor issue.

- Blocked Injector: Removing the injector and performing an active test revealed that it was blocked, despite being activated.

- Overheating: Further investigation uncovered that the injector was overheating due to a blocked cooling pipe.

The root cause of the problem was a clogged cooling system, which was causing the injector to overheat and fail. After cleaning the cooling pipes and replacing the injector, the system functioned correctly.

The lessons learned from this case study include:

- Check for Underlying Issues: Don’t just replace the injector without investigating potential underlying causes.

- Monitor System Parameters: Use diagnostic tools to monitor system parameters such as NOx levels, DEF pressure, and temperature.

- Inspect the Cooling System: Ensure the injector cooling system is functioning correctly.

- Utilize Available Resources: Komatsu’s comprehensive monitors can function as scan tools, providing live data and active tests.

7.2 Common Issues and Solutions

| Issue | Possible Causes | Solutions |

|---|---|---|

| Repeated Injector Failure | Overheating, Contamination, Incorrect Installation | Check cooling system, use high-quality DEF, ensure proper installation torque, replace injector |

| Clogged Injector | Crystallization, Contamination | Clean or replace injector, use high-quality DEF, flush the DEF tank |

| Electrical Issues | Wiring problems, faulty ECU | Check wiring and connections, test ECU, replace ECU if necessary |

| High NOx Levels | Faulty injector, SCR catalyst failure | Replace injector, test SCR catalyst, replace SCR catalyst if necessary, verify proper car coding/calibration |

8. Choosing the Right Replacement AdBlue/DEF Injector

Selecting the correct replacement injector is crucial for ensuring proper system operation.

8.1 OEM vs. Aftermarket Injectors: What’s the Difference?

- OEM (Original Equipment Manufacturer) Injectors: These injectors are made by the same manufacturer that supplied the original injector for your vehicle. They are typically more expensive but offer guaranteed compatibility and performance.

- Aftermarket Injectors: These injectors are made by third-party manufacturers. They are often less expensive than OEM injectors but may not offer the same level of quality or compatibility.

8.2 How to Ensure Compatibility with Your Vehicle

To ensure compatibility:

- Check the Part Number: Match the part number on the old injector with the part number on the new injector.

- Consult Your Vehicle’s Service Manual: The service manual will provide information on the correct injector for your vehicle.

- Use a Parts Catalog: Online parts catalogs can help you identify the correct injector based on your vehicle’s make, model, and year.

- Seek Expert Advice: Consult with a trusted mechanic or parts supplier for advice on selecting the correct injector.

9. The Future of AdBlue/DEF Systems and Car Coding

The AdBlue system, DEF metering unit, and car coding are constantly evolving to meet increasingly stringent emissions standards.

9.1 Emerging Technologies in AdBlue Systems

- Advanced Injector Designs: New injector designs are being developed to improve DEF atomization and reduce crystallization.

- Integrated Sensors: Integrated sensors are being incorporated into the AdBlue system to provide more accurate monitoring of system performance.

- Smart Control Algorithms: Advanced control algorithms are being used to optimize DEF injection and reduce emissions.

9.2 The Role of Car Coding in Future Vehicle Maintenance

Car coding will play an increasingly important role in vehicle maintenance:

- Remote Diagnostics: Remote diagnostics capabilities will allow technicians to diagnose and repair AdBlue system problems remotely.

- Over-the-Air Updates: Over-the-air updates will be used to update ECU software and calibrate injectors.

- Personalized System Settings: Car coding will allow technicians to personalize system settings to optimize performance and fuel efficiency.

9.3 How DTS-MONACO.EDU.VN is Staying Ahead of the Curve

DTS-MONACO.EDU.VN is committed to staying ahead of the curve in AdBlue system technology and car coding:

- Continuous Training: We provide continuous training to our technicians to ensure they are up-to-date on the latest technologies and procedures.

- Research and Development: We invest in research and development to explore new technologies and improve our diagnostic and car coding capabilities.

- Industry Partnerships: We partner with leading industry experts to share knowledge and expertise.

10. Why Choose DTS-MONACO.EDU.VN for Your Automotive Needs?

DTS-MONACO.EDU.VN stands out as a premier resource for automotive professionals seeking to enhance their skills and knowledge.

10.1 What Makes DTS-MONACO.EDU.VN a Valuable Resource?

- Expertise: Our team comprises seasoned automotive experts with years of experience in diagnostics, car coding, and vehicle maintenance.

- Comprehensive Training: We offer a wide range of training courses tailored to meet the needs of technicians of all skill levels.

- Cutting-Edge Tools: We provide access to the latest diagnostic software and car coding tools.

- Technical Support: Our expert technical support team is available to assist you with any questions or issues you may encounter.

- Community: Join a vibrant community of automotive professionals to share knowledge and experiences.

10.2 Success Stories from Technicians Who Have Benefited from DTS-MONACO.EDU.VN

- Enhanced Diagnostic Skills: Technicians have reported significant improvements in their diagnostic skills after completing our training courses.

- Increased Efficiency: Our tools and resources have helped technicians streamline their workflow and increase efficiency.

- Improved Customer Satisfaction: By providing high-quality diagnostic and repair services, technicians have improved customer satisfaction.

- Career Advancement: Many technicians have advanced their careers after acquiring new skills and knowledge through DTS-MONACO.EDU.VN.

10.3 How to Get Started with DTS-MONACO.EDU.VN

To get started with DTS-MONACO.EDU.VN:

- Visit Our Website: Explore our website to learn more about our training courses, tools, and resources.

Website: DTS-MONACO.EDU.VN - Contact Us: Contact our team to discuss your specific needs and goals.

Address: 275 N Harrison St, Chandler, AZ 85225, United States

Whatsapp: +1 (641) 206-8880 - Enroll in a Training Course: Enroll in a training course to acquire new skills and knowledge.

- Access Our Resources: Access our diagnostic software, car coding tools, and technical support.

- Join Our Community: Join our community of automotive professionals to share knowledge and experiences.

Replacing an AdBlue/DEF injector is a complex task that requires careful diagnosis, proper tools, and a thorough understanding of the system. By following the steps outlined in this guide and utilizing the resources available at DTS-MONACO.EDU.VN, you can successfully replace an AdBlue injector and ensure your vehicle is operating at peak performance while meeting emissions standards.

Don’t let AdBlue system issues slow you down. Visit DTS-MONACO.EDU.VN today to explore our comprehensive training courses, cutting-edge diagnostic tools, and expert technical support. Empower yourself with the skills and knowledge you need to tackle even the most challenging automotive repairs, including advanced car coding and diagnostics. Contact us now and take your automotive career to the next level.

FAQ: AdBlue/DEF Injector Replacement

1. What is AdBlue/DEF and what does it do?

AdBlue, also known as Diesel Exhaust Fluid (DEF), is a non-toxic solution used in diesel vehicles to reduce nitrogen oxide (NOx) emissions by converting them into harmless nitrogen and water in the SCR catalyst.

2. What are the symptoms of a faulty AdBlue/DEF injector?

Common symptoms include the AdBlue warning light, reduced engine power, stored fault codes, visible leaks, unusual noises, and high NOx levels during emissions tests.

3. What tools do I need to replace an AdBlue/DEF injector?

You’ll need a new injector, socket set, wrenches, screwdrivers, pliers, diagnostic scan tool, multimeter, safety glasses, gloves, clean rags, torque wrench, DEF fluid, and distilled water.

4. How do I prepare for the AdBlue/DEF injector replacement?

Wear safety glasses and gloves, locate the injector, disconnect the battery, allow the exhaust to cool, and gather detailed procedures from DTS-MONACO.EDU.VN.

5. How do I remove the old AdBlue/DEF injector?

Disconnect the electrical connector, remove retaining clips, disconnect the DEF line, and unscrew the injector from the exhaust system.

6. What should I do after installing the new AdBlue/DEF injector?

Reconnect the DEF line and electrical connector, reinstall retaining clips, reconnect the battery, top up DEF, and check for leaks.

7. Is car coding required after replacing the AdBlue/DEF injector?

Car coding may be required, especially if the ECU or aftertreatment control module has been replaced, or if injector calibration or system adaptation is needed.

8. What are the best practices for maintaining the AdBlue/DEF system?

Use high-quality DEF, store DEF properly, keep the system clean, regularly inspect the system for leaks and damage, and address issues promptly.

9. How can DTS-MONACO.EDU.VN help with car coding?

DTS-MONACO.EDU.VN offers advanced diagnostic software, car coding tools, detailed training courses, and expert technical support for car coding procedures.

10. What are some advanced diagnostic techniques for AdBlue systems?

Advanced techniques include using a multimeter for electrical testing, utilizing oscilloscopes for signal analysis, and interpreting sensor data from NOx sensors, DEF pressure sensors, and temperature sensors.