Replacing your transmission cooler lines can seem daunting, but with the right steps, it’s manageable. DTS-MONACO.EDU.VN provides comprehensive resources to guide you through this process, ensuring a smooth and successful replacement. By following these steps and utilizing the right tools, you can save money and gain valuable experience in auto repair and utilize car coding tools.

Contents

- 1. What are Transmission Cooler Lines and Why Do They Need Replacing?

- 2. What Tools and Materials Do I Need to Replace Transmission Cooler Lines?

- 3. How To Prepare Your Vehicle for Transmission Cooler Line Replacement?

- 4. What Is The Step-by-Step Guide to Replacing Transmission Cooler Lines?

- 5. What Common Issues and How To Troubleshoot Them?

- 6. What Are Some Safety Precautions To Take During Transmission Cooler Line Replacement?

- 7. How Does Car Coding Relate to Transmission Maintenance?

- 8. How Can DTS-Monaco Software Help with Transmission Diagnostics and Coding?

- 9. What Are the Benefits of Professional Training in Car Coding and DTS-Monaco?

- 10. FAQ: Frequently Asked Questions About Transmission Cooler Line Replacement

1. What are Transmission Cooler Lines and Why Do They Need Replacing?

Transmission cooler lines are the conduits that carry transmission fluid to and from the transmission cooler. These lines are crucial for maintaining the proper operating temperature of your transmission. Over time, they can corrode, leak, or become damaged, necessitating replacement.

Transmission Cooler Lines Defined

Transmission cooler lines are typically made of metal or a combination of metal and rubber hoses. They connect the transmission to the cooler, usually located in the radiator or a separate unit in front of the radiator. The lines circulate transmission fluid, which dissipates heat, preventing overheating and potential damage to the transmission.

Why Replacement is Necessary

- Corrosion: In regions with road salt, like the Northeast, the lines are prone to rust and corrosion.

- Leaks: Small leaks can quickly turn into significant issues, leading to low transmission fluid levels and potential transmission failure.

- Damage: Physical impacts or wear and tear can cause cracks or breaks in the lines.

- Age: Over time, rubber hoses can degrade, becoming brittle and prone to leaks.

According to a study by the National Institute for Automotive Service Excellence (ASE), regular inspection and maintenance of transmission cooler lines can prevent costly repairs and extend the life of the transmission system.

2. What Tools and Materials Do I Need to Replace Transmission Cooler Lines?

Having the right tools and materials on hand is essential for a successful transmission cooler line replacement. Here’s a comprehensive list:

Essential Tools:

- Wrenches: Both open-ended and closed-end wrenches, including flare nut wrenches for fittings (sizes vary, but 17mm and 19mm are common).

- Sockets: A set of sockets, including a 6-point socket for removing fittings.

- Cutting Tool: A pipe cutter or hacksaw for cutting the old lines.

- Pliers: For removing clamps and hoses.

- Screwdrivers: Both flathead and Phillips head screwdrivers.

- Torque Wrench: To ensure proper tightening of fittings.

- Jack and Jack Stands: To safely lift and secure the vehicle.

- Drip Pan: To catch transmission fluid.

- Safety Glasses and Gloves: For personal protection.

- Penetrating Oil: Such as PB Blaster, to loosen rusted fittings.

- Wire Brush: To clean threads and fittings.

- Drill and Tap Set: For repairing broken bolts.

Necessary Materials:

- New Transmission Cooler Lines: Ensure they are the correct fit for your vehicle.

- New Clamps: To secure the lines.

- Transmission Fluid: To replace what is lost during the process.

- Thread Sealant: To prevent leaks at fittings.

- Rags or Shop Towels: For cleaning up spills.

Optional but Helpful Tools:

- Heat Gun or Torch: To help loosen rusted fittings.

- Flare Nut Crowfoot Wrench Set: Provides better grip on fittings.

- Inspection Mirror: To inspect hard-to-reach areas.

Having these tools and materials readily available will streamline the replacement process and help prevent unexpected delays. According to automotive experts at DTS-MONACO.EDU.VN, investing in quality tools can make the job easier and ensure a more reliable repair.

3. How To Prepare Your Vehicle for Transmission Cooler Line Replacement?

Proper preparation is crucial before starting any automotive repair. Here’s how to prepare your vehicle for transmission cooler line replacement:

Step-by-Step Preparation:

- Gather Tools and Materials: Ensure you have all the necessary tools and materials listed in Section 2.

- Park on a Level Surface: Park your vehicle on a level surface and engage the parking brake.

- Safety First: Wear safety glasses and gloves to protect yourself from debris and fluids.

- Lift the Vehicle: Use a jack to lift the vehicle and securely place it on jack stands. Never work under a vehicle supported only by a jack.

- Locate Transmission Cooler Lines: Identify the transmission cooler lines running from the transmission to the cooler (usually in the radiator).

- Inspect the Lines: Examine the lines for signs of corrosion, leaks, or damage.

- Prepare Work Area: Place a drip pan under the area where you will be disconnecting the lines to catch any leaking transmission fluid.

- Loosen Fittings (If Possible): Apply penetrating oil to the fittings and allow it to soak for several minutes to help loosen them.

- Remove Underbody Panels: If necessary, remove any underbody panels to gain better access to the transmission cooler lines.

Taking these preparatory steps will ensure a safer and more efficient replacement process. According to experienced technicians at DTS-MONACO.EDU.VN, proper preparation can save time and prevent complications during the repair.

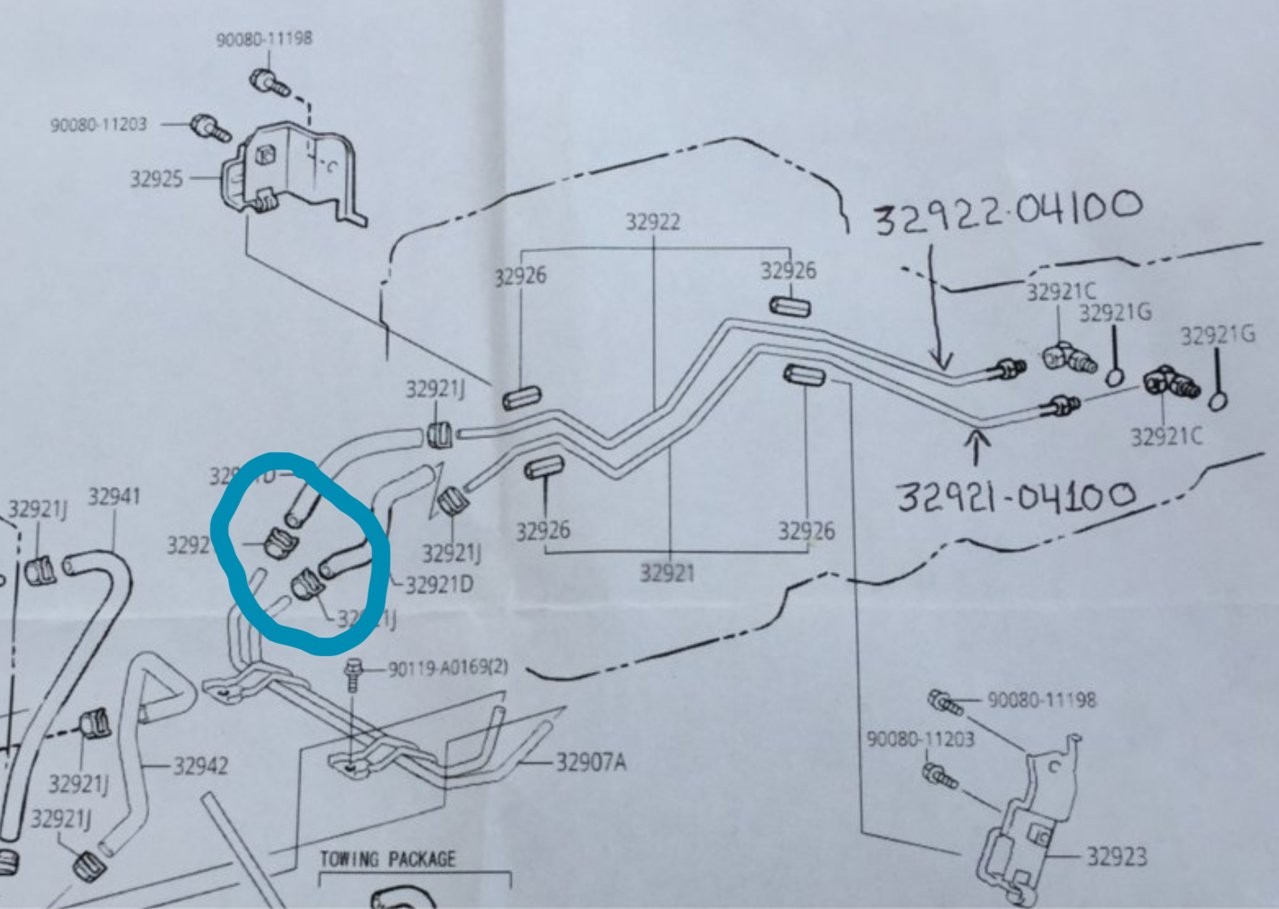

Checking Transmission Cooler Lines

Checking Transmission Cooler Lines

4. What Is The Step-by-Step Guide to Replacing Transmission Cooler Lines?

Follow this detailed guide to safely and effectively replace your transmission cooler lines:

Detailed Steps:

- Disconnect the Negative Battery Terminal: This prevents any electrical accidents during the repair.

- Locate the Front Connections: Find where the rubber hoses connect to the metal lines at the front of the vehicle.

- Remove Rubber Hoses: Use pliers to loosen the clamps and remove the rubber hoses from the metal lines. Have a drip pan ready to catch any fluid.

- Access the Clamps: Identify the clamps holding the hard lines to the engine or chassis.

- Remove the Clamps:

- If the clamps are rusted, carefully remove the entire clamp assembly (typically a 12mm bolt).

- Use penetrating oil and a wire brush to clean the threads before attempting to remove the bolts.

- Disconnect Lines from the Transmission:

- This is often the most challenging step due to rust and tight fittings.

- If the fittings are heavily rusted, cut the line near the fitting to allow the use of a 6-point socket or closed-end wrench (17mm).

- Use a second wrench (19mm) to hold the union and prevent it from turning.

- Apply steady pressure to break the lines loose.

- Remove the Old Lines: Carefully remove the old transmission cooler lines from the vehicle, taking note of their routing for easy reinstallation.

- Clean the Fittings: Clean the threads on the transmission and cooler fittings with a wire brush to ensure a good seal.

- Install the New Lines:

- Begin by loosely attaching the upper (outlet) line to the top of the transmission.

- Ensure the line aligns correctly with the clamps.

- Repeat the process for the lower (inlet) line.

- Secure the Lines in Clamps:

- Place the new lines into the clamps, ensuring the rubber pads are correctly positioned.

- If necessary, transfer the rubber pads from the old lines to the new ones.

- Tighten the clamps to secure the lines.

- Tighten the Fittings: Use a torque wrench to tighten the fittings at the transmission to the manufacturer’s specified torque.

- Reconnect Rubber Hoses: Reattach the rubber hoses at the front of the vehicle and secure them with new clamps.

- Refill Transmission Fluid:

- Refill the transmission with the correct type and amount of transmission fluid.

- Check the fluid level using the dipstick or following the manufacturer’s recommended procedure.

- Check for Leaks:

- Start the engine and allow it to run for several minutes.

- Inspect all connections for leaks.

- Adjust fluid level as needed.

- Reinstall Underbody Panels: If removed, reinstall any underbody panels.

- Lower the Vehicle: Carefully lower the vehicle from the jack stands.

- Final Check: Take the vehicle for a short test drive and recheck for leaks and proper transmission function.

According to automotive repair guides and experts at DTS-MONACO.EDU.VN, following these steps carefully will help ensure a successful transmission cooler line replacement.

Removing Transmission Cooler Line Brackets

Removing Transmission Cooler Line Brackets

5. What Common Issues and How To Troubleshoot Them?

While replacing transmission cooler lines, you may encounter several common issues. Here’s how to troubleshoot them:

Common Issues and Solutions:

- Rusted Fittings:

- Issue: Fittings are heavily rusted and difficult to remove.

- Solution: Apply penetrating oil, use heat from a heat gun or torch, and use a flare nut wrench for better grip. If necessary, cut the line near the fitting to use a 6-point socket.

- Broken Bolts:

- Issue: Bolts holding the clamps break off due to rust.

- Solution: Use a drill and tap set to remove the broken bolt and re-tap the hole. Alternatively, replace the clamp assembly with new hardware.

- Leaks After Installation:

- Issue: Leaks are present at the fittings after installing the new lines.

- Solution: Ensure the fittings are properly tightened to the correct torque specification. Use thread sealant on the threads to prevent leaks. Inspect the lines for any damage.

- Incorrect Line Routing:

- Issue: Difficulty installing the new lines due to incorrect routing.

- Solution: Refer to photos or diagrams taken before removing the old lines to ensure the new lines are routed correctly.

- Incorrect Fluid Level:

- Issue: Transmission fluid level is too high or too low after refilling.

- Solution: Follow the manufacturer’s recommended procedure for checking and adjusting the transmission fluid level. Use the dipstick or consult the vehicle’s service manual.

- Clamp Issues:

- Issue: Rubber pads on the new lines are not in the correct position.

- Solution: Transfer the rubber pads from the old lines to the correct position on the new lines.

According to troubleshooting guides and experienced mechanics at DTS-MONACO.EDU.VN, addressing these common issues proactively can prevent further complications and ensure a successful repair.

Removing Transmission Cooler Line Clamp

Removing Transmission Cooler Line Clamp

6. What Are Some Safety Precautions To Take During Transmission Cooler Line Replacement?

Safety should always be a top priority when performing automotive repairs. Here are some essential safety precautions to take during transmission cooler line replacement:

Safety Measures:

- Wear Safety Glasses: Protect your eyes from debris, rust particles, and fluids.

- Wear Gloves: Protect your hands from sharp edges, chemicals, and hot surfaces.

- Disconnect the Battery: Prevent electrical shocks by disconnecting the negative battery terminal before starting any work.

- Use Jack Stands: Always use jack stands to support the vehicle after lifting it with a jack. Never work under a vehicle supported only by a jack.

- Handle Fluids Carefully: Transmission fluid can be hot and potentially harmful. Wear gloves and avoid skin contact. Clean up any spills immediately.

- Work in a Well-Ventilated Area: Some chemicals, like penetrating oil, can produce harmful fumes. Ensure adequate ventilation.

- Use the Right Tools: Using the correct tools for the job can prevent injuries and damage to the vehicle.

- Be Aware of Hot Surfaces: Exhaust components and other engine parts can be hot. Allow them to cool before working near them.

- Follow Torque Specifications: Use a torque wrench to tighten fittings and bolts to the manufacturer’s specified torque. Over-tightening can damage the components, while under-tightening can lead to leaks.

- Keep a Fire Extinguisher Nearby: Be prepared for potential fires when working with flammable fluids.

Adhering to these safety precautions will help ensure a safe and successful transmission cooler line replacement. Safety guidelines from DTS-MONACO.EDU.VN emphasize the importance of prioritizing safety to prevent accidents and injuries.

Cutting Transmission Cooler Line for Removal

Cutting Transmission Cooler Line for Removal

7. How Does Car Coding Relate to Transmission Maintenance?

Car coding, while not directly involved in the physical replacement of transmission cooler lines, plays a crucial role in modern vehicle maintenance. Here’s how car coding relates to transmission maintenance:

Understanding Car Coding:

Car coding involves reprogramming or modifying the software in a vehicle’s electronic control units (ECUs) to change its behavior or enable new features. This can include adjusting transmission parameters, such as shift points, torque converter lockup, and adaptive learning.

Relationship to Transmission Maintenance:

- Optimizing Performance: Car coding can be used to optimize transmission performance for specific driving conditions or preferences. For example, you can adjust shift points for better fuel economy or improved acceleration.

- Enabling Features: In some vehicles, car coding can enable or disable certain transmission features, such as sport mode or manual shift mode.

- Clearing Fault Codes: After performing transmission maintenance or repairs, car coding tools can be used to clear any stored fault codes in the transmission control module (TCM).

- Adaptation Reset: Car coding can reset the transmission’s adaptive learning, which allows it to relearn the driver’s driving style and optimize shift patterns accordingly.

- Diagnostics: Advanced car coding tools, like DTS-Monaco, can provide in-depth diagnostic information about the transmission system, helping to identify potential issues before they become major problems.

Tools and Software:

- DTS-Monaco: A powerful diagnostic and car coding tool used by automotive professionals. It allows for advanced diagnostics, ECU programming, and adaptation resets.

- OBD-II Scanners: Basic OBD-II scanners can read and clear transmission-related fault codes.

- Specialized Coding Interfaces: Some vehicles require specialized coding interfaces and software for advanced transmission coding.

According to experts at DTS-MONACO.EDU.VN, car coding can enhance transmission performance and provide valuable diagnostic capabilities, making it an essential tool for modern automotive maintenance.

8. How Can DTS-Monaco Software Help with Transmission Diagnostics and Coding?

DTS-Monaco is a powerful diagnostic and car coding software widely used in the automotive industry. Here’s how it can assist with transmission diagnostics and coding:

Key Capabilities:

- Advanced Diagnostics: DTS-Monaco allows you to perform in-depth diagnostics of the transmission control module (TCM) and other related systems. It can read and interpret fault codes, view live data streams, and perform component tests to identify issues.

- ECU Programming: The software enables you to reprogram or flash the TCM with updated software or custom calibrations. This can improve transmission performance, fix software glitches, or enable new features.

- Coding and Configuration: DTS-Monaco allows you to modify the coding and configuration parameters of the TCM. This can be used to adjust shift points, torque converter lockup, and other settings to optimize transmission performance.

- Adaptation Reset: The software can reset the transmission’s adaptive learning, allowing it to relearn the driver’s driving style and optimize shift patterns.

- Variant Coding: DTS-Monaco supports variant coding, which allows you to adapt the transmission control module to different vehicle configurations or aftermarket modifications.

Benefits of Using DTS-Monaco:

- Comprehensive Diagnostics: Provides detailed diagnostic information to identify transmission issues accurately.

- Customization: Allows you to customize transmission settings to suit your driving preferences or specific needs.

- Efficiency: Streamlines the diagnostic and coding process, saving time and improving efficiency.

- Compatibility: Compatible with a wide range of vehicle makes and models.

DTS-MONACO.EDU.VN offers comprehensive training and support for using DTS-Monaco software, empowering automotive technicians to perform advanced transmission diagnostics and coding with confidence.

9. What Are the Benefits of Professional Training in Car Coding and DTS-Monaco?

Professional training in car coding and DTS-Monaco offers numerous benefits for automotive technicians and enthusiasts:

Advantages of Training:

- In-Depth Knowledge: Gain a comprehensive understanding of car coding principles, techniques, and best practices.

- Hands-On Experience: Develop practical skills through hands-on exercises and real-world case studies.

- Expert Guidance: Learn from experienced instructors who are experts in car coding and DTS-Monaco software.

- Industry-Recognized Certification: Earn a certification that demonstrates your expertise and enhances your career prospects.

- Access to Resources: Access exclusive training materials, software updates, and technical support.

- Improved Diagnostic Skills: Enhance your ability to diagnose and troubleshoot complex automotive issues using car coding techniques.

- Increased Efficiency: Streamline your workflow and improve efficiency by mastering the tools and techniques of car coding.

- Enhanced Career Opportunities: Open up new career opportunities in automotive diagnostics, tuning, and customization.

DTS-MONACO.EDU.VN Training Programs:

DTS-MONACO.EDU.VN offers comprehensive training programs in car coding and DTS-Monaco software, designed to meet the needs of both beginners and experienced professionals. These programs cover a wide range of topics, including:

- Introduction to Car Coding: Basic principles, protocols, and tools.

- DTS-Monaco Software Training: Hands-on training in using DTS-Monaco for diagnostics, coding, and programming.

- Advanced Coding Techniques: Variant coding, adaptation reset, and custom calibration.

- Troubleshooting and Diagnostics: Identifying and resolving common car coding issues.

Investing in professional training from DTS-MONACO.EDU.VN can significantly enhance your skills and career prospects in the rapidly evolving automotive industry.

10. FAQ: Frequently Asked Questions About Transmission Cooler Line Replacement

Here are some frequently asked questions about transmission cooler line replacement:

Q1: How often should I replace my transmission cooler lines?

It depends on the environment and condition of the lines. In areas with road salt, inspect annually and replace every 5-7 years or as needed.

Q2: Can I drive with a leaking transmission cooler line?

No, driving with a leak can cause low fluid levels and severe transmission damage.

Q3: Can I repair a transmission cooler line instead of replacing it?

Small leaks in rubber hoses can sometimes be temporarily patched, but it’s best to replace the entire line for a reliable fix.

Q4: Are aftermarket transmission cooler lines as good as OEM lines?

Quality varies. Choose reputable brands and ensure the lines meet or exceed OEM specifications.

Q5: How do I know which transmission fluid to use?

Refer to your vehicle’s owner’s manual or the transmission fluid dipstick for the correct type.

Q6: What is the purpose of the rubber pads on the transmission cooler lines?

They dampen vibrations and prevent chafing against other components.

Q7: Can I replace the transmission cooler lines myself, or should I take it to a professional?

If you have mechanical experience and the right tools, you can do it yourself. Otherwise, a professional is recommended.

Q8: How much does it cost to have a professional replace transmission cooler lines?

Costs vary, but expect to pay between $300 and $900, depending on the vehicle and labor rates.

Q9: What are the signs of a failing transmission cooler line?

Look for leaks, low transmission fluid levels, and overheating.

Q10: Where can I find reliable information and training on car coding and DTS-Monaco?

DTS-MONACO.EDU.VN offers comprehensive resources, training programs, and support for car coding and DTS-Monaco software.

Replacing your transmission cooler lines is a critical maintenance task that can prevent costly transmission repairs. By following these guidelines and utilizing resources from DTS-MONACO.EDU.VN, you can confidently tackle this project. Car coding and advanced diagnostics with tools like DTS-Monaco can further enhance your ability to maintain and optimize your vehicle’s performance.

Ready to take your automotive skills to the next level? Visit DTS-MONACO.EDU.VN today to explore our comprehensive training programs, software solutions, and expert support for car coding and advanced diagnostics. Contact us at Whatsapp: +1 (641) 206-8880 or visit our location at 275 N Harrison St, Chandler, AZ 85225, United States to learn more and get started on your journey to becoming a car coding expert.