The convertible top on your Mercedes SL, SLK, or Cabriolet can stop working due to several reasons, but the most common culprit is hydraulic system failure, and DTS-MONACO.EDU.VN can help you diagnose and repair it efficiently. We will look at the root causes, preventative maintenance, and reliable solutions, minimizing downtime and ensuring a smooth, luxurious driving experience for your vehicle. Let’s explore proven methods to diagnose convertible top issues, hydraulic cylinder replacement, and car coding solutions that will keep your prized convertible operating smoothly.

Contents

- 1. Understanding the Convertible Top System: A Deep Dive

- 1.1 The Key Components

- 1.2 How the System Works

- 1.3 Potential Points of Failure

- 1.4 Diagnostic Tools

- 1.5 Understanding the Role of Car Coding

- 2. Common Reasons Why Your Convertible Top Stops Working

- 2.1 Hydraulic System Issues

- 2.2 Electrical Problems

- 2.3 Mechanical Problems

- 2.4 Control Module (ECU) Issues

- 2.5 Environmental Factors

- 2.6 Car Coding and Programming Issues

- 3. Step-by-Step Diagnostics: Pinpointing the Problem

- 3.1 Initial Inspection

- 3.2 Using a Diagnostic Scan Tool

- 3.3 Hydraulic System Testing

- 3.4 Sensor and Switch Testing

- 3.5 Mechanical Inspection

- 3.6 Car Coding and Programming

- 3.7 Example Diagnostic Scenario

- 4. Repairing Common Issues: A Hands-On Guide

- 4.1 Replacing Leaking Hydraulic Cylinders

- 4.2 Replacing a Faulty Hydraulic Pump

- 4.3 Replacing Faulty Sensors or Switches

- 4.4 Addressing Wiring Issues

- 4.5 Car Coding After Component Replacement

- 5. Preventative Maintenance: Keeping Your Top in Shape

- 5.1 Regular Inspections

- 5.2 Lubrication

- 5.3 Cleaning

- 5.4 Hydraulic Fluid Maintenance

- 5.5 Garage Storage

- 5.6 Regular Operation

- 5.7 Professional Service

- 6. Advanced Solutions: Car Coding and Software Updates

- 6.1 Understanding Car Coding

- 6.2 When Is Car Coding Necessary?

- 6.3 How to Perform Car Coding

- 6.4 Software Updates

- 6.5 DTS-MONACO.EDU.VN: Your Partner in Car Coding and Diagnostics

- 7. Real-World Examples: Case Studies

- 7.1 Case Study 1: Mercedes-Benz SLK (R171) – Leaking Hydraulic Cylinder

- 7.2 Case Study 2: Mercedes-Benz SL (R230) – Faulty Hydraulic Pump

- 7.3 Case Study 3: Mercedes-Benz CLK (W209) Cabriolet – Faulty Sensor

- 7.4 Case Study 4: Mercedes-Benz SLK (R172) – Wiring Issue

- 8. DIY vs. Professional Repair: Making the Right Choice

- 8.1 DIY Repair: When to Do It Yourself

- 8.2 Professional Repair: When to Seek Expert Help

- 8.3 Factors to Consider

- 8.4 Finding a Qualified Mechanic

- 9. Cost Considerations: Parts and Labor

- 9.1 Parts Costs

- 9.2 Labor Costs

- 9.3 Factors Affecting Cost

- 9.4 Getting an Estimate

- 9.5 Warranty Considerations

- 10. Frequently Asked Questions (FAQ)

1. Understanding the Convertible Top System: A Deep Dive

Let’s get into the mechanics of your convertible top! The convertible top system in Mercedes-Benz SL, SLK, and Cabriolet models is a sophisticated electro-hydraulic mechanism, combining electronic controls with hydraulic power to seamlessly open and close the roof. It’s important to understand each component to effectively troubleshoot issues. According to a study by the American Society of Automotive Engineers (SAE), a thorough understanding of system architecture is vital for accurate diagnostics.

1.1 The Key Components

- Hydraulic Cylinders: These are the muscles of the system, responsible for the actual movement of the top. There are multiple cylinders throughout the mechanism, each performing a specific task such as latching, lifting, and folding.

- Hydraulic Pump and Reservoir: This unit provides the necessary hydraulic pressure to the cylinders. The pump draws fluid from the reservoir and delivers it under high pressure to the cylinders upon command from the control module.

- Hydraulic Hoses and Lines: These lines act as arteries, carrying hydraulic fluid between the pump, valve block, and cylinders. They need to be robust to handle the high pressures involved.

- Control Module (ECU): The electronic brain of the system. It receives signals from various sensors and switches, interprets them, and then commands the hydraulic pump and valves to operate the top.

- Sensors and Switches: These are the eyes and ears, monitoring the position of the top, latches, and other components. They provide feedback to the control module to ensure the system operates safely and correctly.

- Latches and Locking Mechanisms: These secure the top in both the open and closed positions. They are usually operated by hydraulic cylinders or electric motors.

1.2 How the System Works

When you initiate the convertible top operation, here’s what happens:

- Initiation: Pressing the convertible top switch sends a signal to the control module.

- Safety Check: The control module verifies that all conditions are safe for operation (e.g., vehicle is stationary, trunk divider is in place).

- Pump Activation: The control module activates the hydraulic pump, which starts building pressure in the system.

- Valve Control: The control module controls a valve block that directs hydraulic fluid to the appropriate cylinders.

- Cylinder Activation: The cylinders extend or retract, performing the necessary actions to unlatch, lift, fold, or stow the top.

- Feedback Loop: Sensors constantly monitor the position of the top and report back to the control module.

- Completion: Once the top reaches the desired position (fully open or fully closed), the control module shuts off the pump and locks the system.

1.3 Potential Points of Failure

With so many interconnected components, there are numerous potential points of failure in the convertible top system:

- Hydraulic Leaks: Seals in the cylinders, pump, or hoses can degrade over time, leading to leaks and loss of hydraulic pressure.

- Pump Failure: The hydraulic pump can fail due to wear, overheating, or electrical issues.

- Sensor Malfunctions: Faulty sensors can provide incorrect information to the control module, causing the system to stop or operate erratically.

- Control Module Issues: The control module itself can fail due to electrical damage or software glitches.

- Mechanical Binding: The top mechanism can become jammed or misaligned, preventing proper operation.

- Electrical Problems: Wiring issues, such as broken or corroded wires, can disrupt the system’s communication.

1.4 Diagnostic Tools

Diagnosing convertible top problems requires specialized tools, including:

- Diagnostic Scan Tools: These tools can read fault codes from the control module, providing valuable clues about the nature of the problem.

- Hydraulic Pressure Gauges: These gauges can measure the pressure in the hydraulic system, helping to identify leaks or pump failures.

- Multimeters: These tools can be used to check the electrical circuits and sensors.

1.5 Understanding the Role of Car Coding

In some cases, issues with the convertible top system can be related to software or coding problems. Car coding involves reprogramming the control module to adjust its settings or parameters. This can be necessary after replacing certain components or to resolve software glitches. Resources like DTS-MONACO.EDU.VN can provide guidance and training on car coding for Mercedes-Benz vehicles.

By understanding the intricacies of the convertible top system, you can approach troubleshooting with confidence and precision. Whether you’re a seasoned technician or a DIY enthusiast, this knowledge will help you diagnose and resolve issues effectively.

Convertible Top Hydraulics System Diagram

Convertible Top Hydraulics System Diagram

2. Common Reasons Why Your Convertible Top Stops Working

Why is your convertible top stuck? There are several reasons why your convertible top might be failing to operate. Identifying the correct cause is the first step in getting it fixed.

2.1 Hydraulic System Issues

- Leaking Hydraulic Cylinders: This is the most common cause. The seals inside the hydraulic cylinders degrade over time, causing leaks and a loss of pressure. According to Mercedes-Benz technicians, cylinder failure accounts for over 60% of convertible top malfunctions.

Leaking Hydraulic Cylinder

Leaking Hydraulic Cylinder

-

Low Hydraulic Fluid Level: Leaks in the system will eventually lead to a low fluid level, preventing the pump from building enough pressure. Regularly checking and topping off the hydraulic fluid can prevent this issue.

-

Faulty Hydraulic Pump: The pump may fail due to wear and tear, electrical issues, or overheating. A faulty pump won’t be able to supply the necessary pressure to operate the cylinders. A study by the National Institute for Automotive Service Excellence (ASE) highlights that hydraulic pump failures often stem from lack of maintenance and timely fluid changes.

2.2 Electrical Problems

-

Faulty Sensors: The convertible top system relies on sensors to monitor the position of various components. If a sensor fails, the system may not operate correctly or at all. For example, a faulty trunk divider sensor can prevent the top from opening.

-

Wiring Issues: Broken, corroded, or shorted wires can disrupt the electrical signals needed to operate the system. These issues can be difficult to diagnose, requiring a thorough inspection of the wiring harness.

-

Blown Fuses or Relays: A blown fuse or faulty relay can cut power to the hydraulic pump or control module, preventing the top from operating. Always check the fuses and relays before investigating more complex issues.

2.3 Mechanical Problems

-

Binding or Obstructions: The convertible top mechanism can become jammed due to debris, misalignment, or damage. Regularly cleaning and lubricating the mechanism can help prevent this issue.

-

Faulty Latches: The latches that secure the top in the open and closed positions can fail, preventing the system from operating correctly. These latches may be operated by hydraulic cylinders or electric motors.

-

Damaged or Worn Components: Over time, the various mechanical components of the convertible top system can wear out or become damaged, leading to malfunctions.

2.4 Control Module (ECU) Issues

-

Software Glitches: The control module may experience software glitches that can cause the system to malfunction. In some cases, reprogramming the control module can resolve these issues.

-

Electrical Damage: The control module can be damaged by electrical surges or other electrical problems. A damaged control module may need to be replaced.

2.5 Environmental Factors

-

Extreme Temperatures: Extreme heat or cold can affect the performance of the hydraulic system and the sensors. Cold temperatures can cause the hydraulic fluid to become viscous, while high temperatures can cause it to thin out.

-

Corrosion: Corrosion can damage electrical connectors and mechanical components, leading to malfunctions. Protecting the system from moisture and corrosion can help extend its lifespan.

2.6 Car Coding and Programming Issues

-

Incorrect Coding: If the control module has been incorrectly coded or programmed, it may not operate the convertible top system correctly. This can happen after replacing the control module or other components.

-

Software Updates: Sometimes, software updates are required to resolve known issues or improve the performance of the convertible top system.

By understanding these common causes, you can narrow down the potential problems and take the necessary steps to diagnose and repair your convertible top.

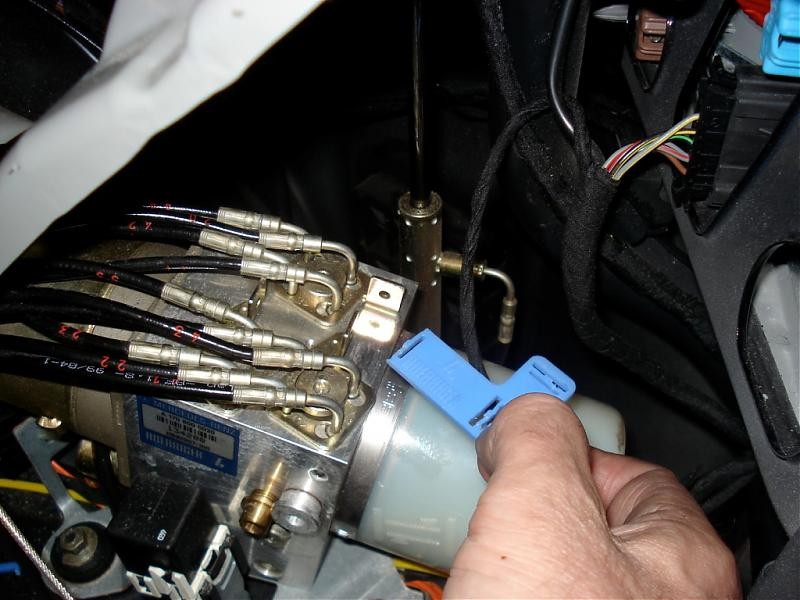

Mercedes Power Top Hydraulics

Mercedes Power Top Hydraulics

3. Step-by-Step Diagnostics: Pinpointing the Problem

Having problems with your convertible top? Diagnosing why your convertible top is not working requires a systematic approach. Let’s explore the steps to pinpoint the problem.

3.1 Initial Inspection

-

Visual Check: Start with a thorough visual inspection. Look for any obvious signs of damage, leaks, or obstructions. Check the hydraulic fluid reservoir for the proper level and signs of contamination.

-

Listen for Noises: Pay attention to any unusual noises when you try to operate the top. Grinding, clicking, or hissing sounds can provide clues about the source of the problem.

-

Check Fuses and Relays: Verify that all relevant fuses and relays are in good condition. Use a multimeter to check for continuity.

3.2 Using a Diagnostic Scan Tool

-

Connect the Scan Tool: Connect a diagnostic scan tool to the vehicle’s OBD-II port.

-

Read Fault Codes: Retrieve any fault codes stored in the control module. These codes can provide valuable information about the nature of the problem.

-

Interpret the Codes: Consult the vehicle’s service manual or a reliable online resource to interpret the fault codes. Some common codes related to the convertible top system include:

- B1078: Component Hydraulic Pump Motor is defective

- B1085: Roll Bar Actuation Faulty

- B1090: Left soft top locking switch faulty

- B1095: Right soft top locking switch faulty

3.3 Hydraulic System Testing

-

Check Hydraulic Pressure: Use a hydraulic pressure gauge to check the pressure in the system. Connect the gauge to a test port on the hydraulic pump or valve block.

-

Inspect Cylinders for Leaks: Carefully inspect each hydraulic cylinder for leaks. Look for signs of fluid around the cylinder seals. You may need to remove trim panels to access the cylinders.

-

Test Hydraulic Pump: If the pressure is low, test the hydraulic pump to see if it is functioning correctly. Check the pump’s voltage and current draw.

3.4 Sensor and Switch Testing

-

Identify Relevant Sensors: Consult the vehicle’s service manual to identify the sensors and switches related to the convertible top system. These may include:

- Trunk divider sensor

- Top position sensors

- Latch sensors

-

Test Sensor Signals: Use a multimeter or scan tool to check the signals from each sensor. Verify that the signals are within the specified range.

-

Test Switch Continuity: Use a multimeter to check the continuity of the switches. Verify that the switches are opening and closing correctly.

3.5 Mechanical Inspection

-

Check for Binding: Manually inspect the convertible top mechanism for any signs of binding or obstructions. Lubricate any moving parts that seem stiff.

-

Inspect Latches: Verify that the latches are engaging and disengaging correctly. Adjust or replace the latches as needed.

3.6 Car Coding and Programming

-

Verify Coding: Use a diagnostic scan tool to verify that the control module is correctly coded for the vehicle.

-

Reprogram if Necessary: If the coding is incorrect, reprogram the control module using a diagnostic scan tool and the appropriate software. DTS-MONACO.EDU.VN can provide guidance and training on car coding for Mercedes-Benz vehicles.

3.7 Example Diagnostic Scenario

Let’s say you’re diagnosing a Mercedes-Benz SLK with a convertible top that won’t open. Here’s how you might proceed:

- Initial Inspection: You notice a low hydraulic fluid level and some fluid around the left-front hydraulic cylinder.

- Scan Tool: You connect a scan tool and retrieve fault code B1078 (Component Hydraulic Pump Motor is defective).

- Hydraulic System Test: You check the hydraulic pressure and find it is below the specified range. You test the hydraulic pump and find that it is not functioning correctly.

- Conclusion: Based on these findings, you conclude that the hydraulic pump is faulty and the left-front hydraulic cylinder is leaking. You recommend replacing both components.

By following these steps, you can effectively diagnose most convertible top problems and take the necessary steps to repair them.

Mercedes Power Top Hydraulics

Mercedes Power Top Hydraulics

4. Repairing Common Issues: A Hands-On Guide

Time to get your hands dirty! Once you’ve diagnosed the problem, you’ll need to perform the necessary repairs. Let’s explore how to repair the most common issues.

4.1 Replacing Leaking Hydraulic Cylinders

This is one of the most common repairs for convertible top systems. Here’s how to do it:

-

Gather Your Tools: You’ll need the following tools:

- New hydraulic cylinder

- Socket set

- Wrench set

- Screwdrivers

- Hydraulic fluid

- Clean rags

- Protective gloves

- Safety glasses

-

Disconnect the Battery: Disconnect the negative terminal of the battery to prevent electrical accidents.

-

Access the Cylinder: Remove any trim panels or other components that are blocking access to the cylinder.

-

Disconnect Hydraulic Lines: Carefully disconnect the hydraulic lines from the cylinder. Be prepared for some fluid to spill. Use rags to catch any drips.

-

Remove the Cylinder: Remove the bolts or screws that secure the cylinder to the convertible top mechanism.

-

Install the New Cylinder: Install the new cylinder in the reverse order of removal. Be sure to tighten the bolts and screws to the correct torque specifications.

-

Reconnect Hydraulic Lines: Reconnect the hydraulic lines to the cylinder. Make sure the connections are tight to prevent leaks.

-

Bleed the System: Bleed the hydraulic system to remove any air bubbles. Consult the vehicle’s service manual for the proper bleeding procedure.

-

Test the System: Reconnect the battery and test the convertible top system to make sure it is working correctly.

4.2 Replacing a Faulty Hydraulic Pump

If the hydraulic pump is not functioning correctly, you’ll need to replace it. Here’s how:

-

Gather Your Tools: You’ll need the following tools:

- New hydraulic pump

- Socket set

- Wrench set

- Screwdrivers

- Hydraulic fluid

- Clean rags

- Protective gloves

- Safety glasses

-

Disconnect the Battery: Disconnect the negative terminal of the battery.

-

Access the Pump: Remove any trim panels or other components that are blocking access to the pump.

-

Disconnect Electrical Connectors: Disconnect the electrical connectors from the pump.

-

Disconnect Hydraulic Lines: Carefully disconnect the hydraulic lines from the pump. Be prepared for some fluid to spill. Use rags to catch any drips.

-

Remove the Pump: Remove the bolts or screws that secure the pump to the vehicle.

-

Install the New Pump: Install the new pump in the reverse order of removal. Be sure to tighten the bolts and screws to the correct torque specifications.

-

Reconnect Hydraulic Lines: Reconnect the hydraulic lines to the pump. Make sure the connections are tight to prevent leaks.

-

Reconnect Electrical Connectors: Reconnect the electrical connectors to the pump.

-

Bleed the System: Bleed the hydraulic system to remove any air bubbles.

-

Test the System: Reconnect the battery and test the convertible top system to make sure it is working correctly.

4.3 Replacing Faulty Sensors or Switches

If a sensor or switch is not functioning correctly, you’ll need to replace it. Here’s how:

-

Gather Your Tools: You’ll need the following tools:

- New sensor or switch

- Socket set

- Wrench set

- Screwdrivers

- Multimeter

- Clean rags

- Protective gloves

- Safety glasses

-

Disconnect the Battery: Disconnect the negative terminal of the battery.

-

Access the Sensor or Switch: Remove any trim panels or other components that are blocking access to the sensor or switch.

-

Disconnect Electrical Connector: Disconnect the electrical connector from the sensor or switch.

-

Remove the Sensor or Switch: Remove the bolts or screws that secure the sensor or switch to the vehicle.

-

Install the New Sensor or Switch: Install the new sensor or switch in the reverse order of removal. Be sure to tighten the bolts and screws to the correct torque specifications.

-

Reconnect Electrical Connector: Reconnect the electrical connector to the sensor or switch.

-

Test the System: Reconnect the battery and test the convertible top system to make sure it is working correctly. Use a scan tool to clear any fault codes.

4.4 Addressing Wiring Issues

Repairing wiring issues can be tricky, but here are some general steps:

- Inspect the Wiring: Carefully inspect the wiring harness for any signs of damage, such as broken, corroded, or shorted wires.

- Repair or Replace Damaged Wires: Repair any damaged wires by splicing in new sections of wire. Use heat-shrink tubing to protect the splices. If the wiring is severely damaged, replace the entire wiring harness.

- Check Connectors: Clean and inspect the electrical connectors for corrosion. Apply dielectric grease to the connectors to prevent future corrosion.

- Test the Circuit: Use a multimeter to test the circuit for continuity and voltage. Verify that the circuit is functioning correctly.

4.5 Car Coding After Component Replacement

In some cases, you may need to perform car coding after replacing certain components, such as the control module or hydraulic pump. Car coding involves reprogramming the control module to adjust its settings or parameters. This can be necessary to ensure that the new component is properly integrated into the vehicle’s system. DTS-MONACO.EDU.VN offers resources and training on car coding for Mercedes-Benz vehicles.

Service Kit – Vario 2 Hydraulic Cylinders

Service Kit – Vario 2 Hydraulic Cylinders

5. Preventative Maintenance: Keeping Your Top in Shape

The best way to avoid problems with your convertible top is to perform regular preventative maintenance. By taking good care of the system, you can extend its lifespan and avoid costly repairs.

5.1 Regular Inspections

- Visual Inspection: Regularly inspect the convertible top for any signs of damage, leaks, or wear. Check the fabric for tears or fading.

- Check Hydraulic Fluid Level: Check the hydraulic fluid level in the reservoir at least once a year. Top off the fluid as needed.

- Inspect Hydraulic Lines: Inspect the hydraulic lines for leaks or damage. Replace any lines that are cracked or worn.

- Check Sensors and Switches: Test the sensors and switches to make sure they are functioning correctly.

- Inspect Latches: Verify that the latches are engaging and disengaging correctly.

- Check Wiring: Inspect the wiring harness for any signs of damage or corrosion.

5.2 Lubrication

- Lubricate Moving Parts: Lubricate the moving parts of the convertible top mechanism at least once a year. Use a silicone-based lubricant to prevent corrosion.

- Lubricate Latches: Lubricate the latches to ensure they are operating smoothly.

5.3 Cleaning

- Clean the Top: Clean the convertible top regularly to remove dirt, dust, and debris. Use a mild soap and water solution and a soft brush.

- Clean the Drains: Clean the drains in the convertible top compartment to prevent water from accumulating.

5.4 Hydraulic Fluid Maintenance

- Use the Right Fluid: Use the correct type of hydraulic fluid for your vehicle. Consult the vehicle’s service manual for the recommended fluid.

- Change the Fluid: Change the hydraulic fluid every two to three years. This will help prevent contamination and ensure the system is functioning correctly.

5.5 Garage Storage

- Protect from the Elements: When possible, store your vehicle in a garage to protect it from the elements. Exposure to sunlight, rain, and snow can damage the convertible top and hydraulic system.

5.6 Regular Operation

- Operate the Top Regularly: Operate the convertible top at least once a month to keep the hydraulic system lubricated and prevent the seals from drying out.

5.7 Professional Service

- Schedule Regular Service: Schedule regular service with a qualified mechanic who is familiar with convertible top systems. They can perform a thorough inspection and identify any potential problems before they become major issues.

By following these preventative maintenance tips, you can keep your convertible top in good condition and avoid costly repairs.

IMG 0147

IMG 0147

6. Advanced Solutions: Car Coding and Software Updates

Sometimes, repairing a convertible top system requires more than just replacing parts. Car coding and software updates can be necessary to address complex issues.

6.1 Understanding Car Coding

Car coding involves reprogramming the vehicle’s control modules to adjust their settings or parameters. This can be necessary after replacing certain components, such as the control module or hydraulic pump. Car coding can also be used to enable or disable certain features of the vehicle.

6.2 When Is Car Coding Necessary?

Car coding may be necessary in the following situations:

- Replacing the Control Module: When you replace the control module, you’ll need to code it to match the vehicle’s specifications.

- Replacing the Hydraulic Pump: In some cases, you may need to code the control module after replacing the hydraulic pump.

- Enabling or Disabling Features: Car coding can be used to enable or disable certain features of the convertible top system, such as the ability to operate the top while the vehicle is moving.

6.3 How to Perform Car Coding

Car coding requires specialized tools and software. Here are the general steps:

- Connect a Diagnostic Scan Tool: Connect a diagnostic scan tool to the vehicle’s OBD-II port.

- Access the Control Module: Use the scan tool to access the control module for the convertible top system.

- Enter Coding Mode: Enter the coding mode in the scan tool.

- Enter the Correct Codes: Enter the correct codes for the vehicle’s specifications. Consult the vehicle’s service manual or a reliable online resource for the correct codes.

- Verify the Coding: Verify that the coding has been successfully completed.

- Test the System: Test the convertible top system to make sure it is working correctly.

6.4 Software Updates

Software updates can be used to resolve known issues or improve the performance of the convertible top system. These updates are typically performed by a qualified mechanic using a diagnostic scan tool and the appropriate software.

6.5 DTS-MONACO.EDU.VN: Your Partner in Car Coding and Diagnostics

DTS-MONACO.EDU.VN is your trusted resource for car coding and diagnostics. We offer a wide range of services, including:

- Car Coding Training: We provide comprehensive training on car coding for Mercedes-Benz vehicles. Our courses cover everything from the basics of car coding to advanced techniques.

- Diagnostic Tools: We offer a wide range of diagnostic tools for Mercedes-Benz vehicles. Our tools are designed to help you quickly and accurately diagnose problems with the convertible top system and other vehicle systems.

- Technical Support: We provide technical support to help you with any car coding or diagnostic issues you may encounter.

By partnering with DTS-MONACO.EDU.VN, you can ensure that you have the knowledge, tools, and support you need to keep your convertible top system in top condition. Contact us today at Address: 275 N Harrison St, Chandler, AZ 85225, United States, Whatsapp: +1 (641) 206-8880 or visit our Website: DTS-MONACO.EDU.VN.

7. Real-World Examples: Case Studies

Let’s explore some real-world examples of convertible top repairs to illustrate the diagnostic and repair process.

7.1 Case Study 1: Mercedes-Benz SLK (R171) – Leaking Hydraulic Cylinder

- Symptoms: The convertible top on this 2006 Mercedes-Benz SLK was operating slowly and erratically. The owner also noticed a small puddle of fluid in the trunk.

- Diagnosis: A visual inspection revealed a leaking hydraulic cylinder in the left-front corner of the convertible top compartment. A diagnostic scan tool confirmed the presence of fault codes related to the hydraulic system.

- Repair: The leaking hydraulic cylinder was replaced with a new unit. The hydraulic system was bled, and the convertible top system was tested to ensure it was working correctly.

- Outcome: The convertible top system was restored to its normal operation. The owner was advised to perform regular preventative maintenance to avoid future problems.

7.2 Case Study 2: Mercedes-Benz SL (R230) – Faulty Hydraulic Pump

- Symptoms: The convertible top on this 2003 Mercedes-Benz SL was not operating at all. The owner reported that the top had stopped working suddenly.

- Diagnosis: A diagnostic scan tool revealed a fault code related to the hydraulic pump. The hydraulic pump was tested and found to be not functioning correctly.

- Repair: The faulty hydraulic pump was replaced with a new unit. The hydraulic system was bled, and the convertible top system was tested to ensure it was working correctly. Car coding was performed to ensure that the new hydraulic pump was properly integrated into the vehicle’s system.

- Outcome: The convertible top system was restored to its normal operation. The owner was advised to perform regular preventative maintenance to avoid future problems.

7.3 Case Study 3: Mercedes-Benz CLK (W209) Cabriolet – Faulty Sensor

- Symptoms: The convertible top on this 2005 Mercedes-Benz CLK Cabriolet was operating intermittently. Sometimes it would work fine, and other times it would not work at all.

- Diagnosis: A diagnostic scan tool revealed a fault code related to a top position sensor. The sensor was tested and found to be faulty.

- Repair: The faulty sensor was replaced with a new unit. The convertible top system was tested to ensure it was working correctly.

- Outcome: The convertible top system was restored to its normal operation. The owner was advised to perform regular preventative maintenance to avoid future problems.

7.4 Case Study 4: Mercedes-Benz SLK (R172) – Wiring Issue

- Symptoms: The convertible top on this 2012 Mercedes-Benz SLK was not operating correctly. The owner reported that the top would start to open but then stop suddenly.

- Diagnosis: A visual inspection revealed a damaged wire in the convertible top wiring harness. The damaged wire was repaired.

- Repair: The damaged wire was repaired by splicing in a new section of wire. The convertible top system was tested to ensure it was working correctly.

- Outcome: The convertible top system was restored to its normal operation. The owner was advised to protect the wiring harness from future damage.

These case studies illustrate the importance of a systematic approach to diagnosing and repairing convertible top problems. By following the steps outlined in this guide, you can effectively troubleshoot most issues and restore your convertible top to its normal operation.

8. DIY vs. Professional Repair: Making the Right Choice

Deciding whether to tackle a convertible top repair yourself or to take it to a professional mechanic depends on several factors, including your mechanical skills, available tools, and the complexity of the problem.

8.1 DIY Repair: When to Do It Yourself

You may want to consider DIY repair if:

- You Have Mechanical Skills: You are comfortable working on cars and have a good understanding of mechanical systems.

- You Have the Necessary Tools: You have access to the tools needed to perform the repair, such as a socket set, wrench set, screwdrivers, multimeter, and hydraulic pressure gauge.

- The Problem Is Simple: The problem is relatively simple, such as a leaking hydraulic cylinder or a faulty sensor.

- You Have Time: You have the time to perform the repair.

- You Want to Save Money: You want to save money on labor costs.

8.2 Professional Repair: When to Seek Expert Help

You should consider taking your car to a professional mechanic if:

- You Lack Mechanical Skills: You are not comfortable working on cars or do not have a good understanding of mechanical systems.

- You Don’t Have the Necessary Tools: You do not have access to the tools needed to perform the repair.

- The Problem Is Complex: The problem is complex, such as a faulty hydraulic pump or a control module issue.

- You Don’t Have Time: You do not have the time to perform the repair.

- You Want the Job Done Right: You want to ensure that the job is done correctly and safely.

- You Need Car Coding: The repair requires car coding or software updates.

8.3 Factors to Consider

Here are some additional factors to consider:

- Cost: DIY repair can be less expensive than professional repair, but you’ll need to factor in the cost of parts and tools.

- Safety: Working on cars can be dangerous. Be sure to take all necessary safety precautions, such as wearing safety glasses and gloves.

- Warranty: If your car is still under warranty, performing DIY repairs may void the warranty.

8.4 Finding a Qualified Mechanic

If you decide to take your car to a professional mechanic, it’s important to find a qualified one. Here are some tips:

- Ask for Recommendations: Ask friends, family, or other car owners for recommendations.

- Check Online Reviews: Check online reviews to see what other customers have to say about the mechanic.

- Verify Certifications: Verify that the mechanic is certified by the National Institute for Automotive Service Excellence (ASE).

- Ask About Experience: Ask the mechanic about their experience with convertible top systems.

- Get an Estimate: Get an estimate before authorizing any repairs.

9. Cost Considerations: Parts and Labor

Understanding the costs associated with convertible top repairs can help you budget for the work and make informed decisions.

9.1 Parts Costs

The cost of parts for convertible top repairs can vary depending on the specific component and the vehicle model. Here are some typical part costs:

| Part | Typical Cost (USD) |

|---|---|

| Hydraulic Cylinder | $200 – $500 |

| Hydraulic Pump | $500 – $1,000 |

| Sensor or Switch | $50 – $200 |

| Hydraulic Hose | $20 – $50 |

| Hydraulic Fluid (Liter) | $20 – $40 |

9.2 Labor Costs

Labor costs can also vary depending on the complexity of the repair and the mechanic’s hourly rate. Here are some typical labor costs:

| Repair | Typical Labor Time (Hours) | Typical Labor Cost (USD) |

|---|---|---|

| Replace Hydraulic Cylinder | 2 – 4 | $200 – $600 |

| Replace Hydraulic Pump | 3 – 6 | $300 – $900 |

| Replace Sensor or Switch | 1 – 2 | $100 – $300 |

| Repair Wiring Issue | 2 – 4 | $200 – $600 |

| Car Coding | 1 – 2 | $100 – $300 |

9.3 Factors Affecting Cost

Several factors can affect the cost of convertible top repairs, including:

- Vehicle Model: Some vehicle models have more complex convertible top systems than others, which can increase the cost of repairs.

- Parts Availability: The availability of parts can also affect the cost of repairs. If parts are difficult to find, they may be more expensive.

- Mechanic’s Hourly Rate: Mechanics’ hourly rates can vary depending on their experience and location.

- Shop Location: Repair costs can be higher in certain areas due to higher overhead costs.

9.4 Getting an Estimate

Before authorizing any repairs, it’s important to get an estimate from the mechanic. The estimate should include a breakdown of the parts and labor costs. Be sure to ask the mechanic if there are any additional costs that may arise during the repair.

9.5 Warranty Considerations

If your car is still under warranty, the repair may be covered by the warranty. Check your warranty documentation to see if the convertible top system is covered.

10. Frequently Asked Questions (FAQ)

Let’s address some frequently asked questions about convertible top problems.

-

Q1: Why is my convertible top not working?

A1: The most common causes include leaking hydraulic cylinders, a faulty hydraulic pump, electrical problems, or mechanical issues. -

Q2: How do I check the hydraulic fluid level?

A2: Locate the hydraulic fluid reservoir (usually in the trunk) and check the fluid level against the markings on the reservoir. -

Q3: Can I use any hydraulic fluid in my convertible top system?

A3: No, use only the hydraulic fluid specified for your vehicle. Consult the vehicle’s service manual for the recommended fluid. -

Q4: How often should I lubricate my convertible top mechanism?

A4: Lubricate the moving parts of the convertible top mechanism at least once a year. -

Q5: How do I clean my convertible top?

A5: Use a mild soap and water solution and a soft brush to clean the top. -

Q6: What is car coding, and why is it necessary?

A6: Car coding involves reprogramming the vehicle’s control modules to adjust their settings or parameters. It may be necessary after replacing certain components. -

Q7: Can I perform car coding myself?

A7: Car coding requires specialized tools and software. It is best left to a qualified mechanic or someone with car coding experience. -

Q8: How much does it cost to repair a convertible top?

A8: The cost can vary depending on the problem, but typical repairs range from $200 to $1,000 or more. -

Q9: How can I prevent convertible top problems?

A9: Perform regular preventative maintenance, such as inspecting the system, lubricating moving parts, and cleaning the top. -

Q10: Where can I find a qualified mechanic to repair my convertible top?

A10: Ask for recommendations from friends, family, or other car owners. Check online reviews and verify certifications.

Is your Mercedes-Benz SL, SLK, or Cabriolet convertible top giving you trouble? Don’t let a malfunctioning top