The ABC (Active Body Control) suspension system requires regular maintenance to ensure optimal performance and longevity, and DTS-MONACO.EDU.VN offers comprehensive resources to help you keep your system in top shape. Neglecting maintenance can lead to costly repairs, but with the right knowledge and care, you can extend the life of your ABC suspension and maintain a smooth, controlled ride, with advanced diagnostics and car coding. Proper maintenance will also enhance driving dynamics, vehicle handling, and overall system reliability.

Contents

- 1. What is the ABC Suspension System?

- 1.1 How Does ABC Suspension Work?

- 1.2 Components of the ABC Suspension System

- 1.3 Benefits of the ABC Suspension System

- 2. What are the Key Maintenance Requirements for ABC Suspension Systems?

- 2.1 Fluid Checks and Flushes

- Why are Fluid Checks and Flushes Important?

- How to Check the ABC Suspension Fluid

- How to Flush the ABC Suspension Fluid

- Best Practices for Fluid Maintenance

- 2.2 Filter Replacements

- Why are Filter Replacements Important?

- How to Replace the ABC Suspension Filter

- Best Practices for Filter Maintenance

- 2.3 Accumulator Inspections

- Why are Accumulator Inspections Important?

- How to Inspect Accumulators

- Best Practices for Accumulator Maintenance

- 2.4 Strut Maintenance

- Why is Strut Maintenance Important?

- How to Maintain Struts

- Best Practices for Strut Maintenance

- 2.5 Regular Diagnostics

- Why are Regular Diagnostics Important?

- How to Perform Diagnostics

- Best Practices for Diagnostics

- 3. What are the Common Problems with ABC Suspension Systems?

- 3.1 Leaks

- 3.2 Pump Failure

- 3.3 Accumulator Failure

- 3.4 Valve Block Issues

- 3.5 Sensor Malfunctions

- 4. How to Troubleshoot ABC Suspension Problems?

- 4.1 Visual Inspection

- 4.2 Check Fluid Level and Condition

- 4.3 Read Fault Codes

- 4.4 Monitor System Parameters

- 4.5 Perform Diagnostic Tests

- 4.6 Consult a Professional

- 5. What Tools and Equipment are Needed for ABC Suspension Maintenance?

- 5.1 Mercedes-Benz Compatible Scan Tool

- 5.2 Hydraulic Pressure Gauge

- 5.3 Fluid Flush Machine

- 5.4 Basic Hand Tools

- 5.5 Torque Wrench

- 5.6 Safety Glasses and Gloves

- 6. What are the Costs Associated with ABC Suspension Maintenance?

- 6.1 Fluid Flush

- 6.2 Filter Replacement

- 6.3 Accumulator Replacement

- 6.4 Strut Replacement

- 6.5 Pump Replacement

- 6.6 Diagnostic Services

- 7. Can You Perform ABC Suspension Maintenance Yourself?

- 7.1 Tasks Suitable for DIYers

- 7.2 Tasks Best Left to Professionals

- 8. What are the Benefits of Professional ABC Suspension Service?

- 9. How Does DTS-MONACO.EDU.VN Help with ABC Suspension Maintenance?

- 9.1 Advanced Diagnostics

- 9.2 Car Coding and Programming

- 9.3 Training and Support

- 9.4 Benefits of Using DTS-MONACO.EDU.VN

- 10. How to Extend the Life of Your ABC Suspension System?

- 10.1 Follow Recommended Maintenance Intervals

- 10.2 Use Quality Parts and Fluids

- 10.3 Inspect the System Regularly

- 10.4 Drive Carefully

- 10.5 Seek Professional Service

- FAQ: ABC Suspension Maintenance

- 1. How often should I check the ABC suspension fluid level?

- 2. How often should I flush the ABC suspension fluid?

- 3. What type of fluid should I use for the ABC suspension system?

- 4. How often should I replace the ABC suspension filter?

- 5. What are the signs of a failing ABC suspension accumulator?

- 6. Can I replace the ABC suspension struts myself?

- 7. How can I tell if my ABC suspension pump is failing?

- 8. What is car coding, and why is it important for ABC suspension maintenance?

- 9. How can DTS-MONACO.EDU.VN help with ABC suspension maintenance?

- 10. What are the long-term benefits of maintaining my ABC suspension system?

1. What is the ABC Suspension System?

The Active Body Control (ABC) suspension system is an advanced hydraulic suspension system used in some Mercedes-Benz vehicles to enhance ride quality and handling. It utilizes high-pressure hydraulics, sensors, and sophisticated electronics to actively control body roll, pitch, and dive, ensuring a smooth and level ride.

1.1 How Does ABC Suspension Work?

The ABC system uses a high-pressure hydraulic pump to regulate fluid pressure in each strut, responding to input from various sensors that monitor vehicle movement and road conditions. These sensors provide real-time data to the control unit, which adjusts the suspension to minimize body roll during cornering, prevent nose-dive during braking, and maintain a level ride on uneven surfaces. According to a study by Bosch Automotive Handbook, these systems can react in milliseconds, providing superior control compared to traditional suspension setups.

1.2 Components of the ABC Suspension System

The ABC system comprises several key components:

- High-Pressure Hydraulic Pump: Provides the necessary pressure to operate the system.

- Struts: Replace conventional shock absorbers and contain hydraulic cylinders.

- Valve Blocks: Control the flow of hydraulic fluid to each strut.

- Accumulators: Store hydraulic pressure and help smooth out pressure fluctuations.

- Sensors: Monitor vehicle movement and road conditions.

- Control Unit: Processes sensor data and controls the valve blocks.

- Hydraulic Fluid: Special fluid designed for high-pressure hydraulic systems.

1.3 Benefits of the ABC Suspension System

The ABC suspension system offers several advantages:

- Enhanced Ride Quality: Provides a smooth and comfortable ride, even on rough roads.

- Improved Handling: Minimizes body roll and enhances stability during cornering.

- Reduced Body Movement: Prevents nose-dive during braking and squat during acceleration.

- Adjustable Ride Height: Allows the driver to raise the vehicle for increased ground clearance.

- Constant Leveling: Maintains a consistent ride height regardless of load.

2. What are the Key Maintenance Requirements for ABC Suspension Systems?

Maintaining an ABC suspension system involves several key tasks to ensure its proper functioning and longevity. These include fluid checks and flushes, filter replacements, accumulator inspections, strut maintenance, and regular diagnostics.

2.1 Fluid Checks and Flushes

Answer: Regular fluid checks and flushes are essential to maintain the health of the ABC suspension system, with flushes recommended every 5 years or 50,000 miles to prevent contamination and ensure proper hydraulic function. Regularly checking the fluid level and condition is crucial. Low fluid levels can indicate leaks, while dirty or contaminated fluid can impair the system’s performance and cause damage to components.

Why are Fluid Checks and Flushes Important?

Hydraulic fluid in the ABC system can degrade over time due to heat, pressure, and contamination. Degraded fluid can lead to:

- Reduced system performance

- Increased wear on components

- Potential system failure

Flushing the system removes old, contaminated fluid and replaces it with fresh fluid, helping to maintain optimal performance and prevent damage.

How to Check the ABC Suspension Fluid

- Locate the Reservoir: The ABC fluid reservoir is typically located in the engine compartment. Consult your vehicle’s owner’s manual for the exact location.

- Check the Fluid Level: Ensure the fluid level is between the minimum and maximum marks on the reservoir.

- Inspect the Fluid Condition: The fluid should be clear and have a greenish tint. If it appears dark, cloudy, or contains debris, it’s time for a flush.

How to Flush the ABC Suspension Fluid

Flushing the ABC suspension fluid is a more complex task that requires specialized equipment and knowledge. It is generally recommended to have this service performed by a qualified technician. The basic steps include:

- Connect Flushing Equipment: Attach the flushing equipment to the ABC system’s hydraulic lines.

- Circulate New Fluid: Run new fluid through the system, displacing the old fluid.

- Monitor Fluid Condition: Continue flushing until the fluid exiting the system is clean and clear.

- Adjust Fluid Level: Ensure the fluid level in the reservoir is correct after flushing.

Best Practices for Fluid Maintenance

- Use the Correct Fluid: Always use the fluid specified by Mercedes-Benz for the ABC suspension system. Using the wrong fluid can cause damage to the system.

- Follow the Recommended Service Intervals: Adhere to the recommended fluid change intervals in your vehicle’s owner’s manual.

- Inspect for Leaks: Regularly inspect the system for leaks, especially around hoses, fittings, and struts.

2.2 Filter Replacements

Answer: Filter replacements are vital for the ABC suspension system, with replacements typically recommended every 25,000 to 30,000 miles to maintain fluid purity and prevent component damage. The ABC system’s filter prevents contaminants from circulating and causing damage. Replacing this filter at regular intervals ensures the fluid remains clean and the system functions optimally.

Why are Filter Replacements Important?

The filter in the ABC system traps dirt, debris, and other contaminants that can enter the system. A clogged filter can restrict fluid flow, leading to:

- Reduced system performance

- Increased wear on components

- Potential system failure

Replacing the filter ensures that the fluid remains clean and the system functions efficiently.

How to Replace the ABC Suspension Filter

- Locate the Filter: The filter is typically located in the ABC fluid reservoir.

- Drain the Reservoir: Remove the old filter and install the new one, ensuring it is properly seated.

- Install the New Filter: Install the new filter, ensuring it is properly seated.

- Refill the Reservoir: Refill the reservoir with the correct type and amount of hydraulic fluid.

Best Practices for Filter Maintenance

- Use the Correct Filter: Always use a filter that is specifically designed for the ABC suspension system.

- Follow the Recommended Service Intervals: Adhere to the recommended filter replacement intervals in your vehicle’s owner’s manual.

- Inspect the Old Filter: When replacing the filter, inspect the old filter for excessive debris or contamination. This can provide clues about the overall health of the system.

2.3 Accumulator Inspections

Answer: Accumulator inspections are important for the ABC suspension system, with regular checks recommended every 2 to 3 years to ensure they maintain proper pressure and function effectively. Accumulators store hydraulic pressure and help smooth out pressure fluctuations in the ABC system. Over time, they can degrade and lose their ability to store pressure, leading to a rougher ride and reduced system performance.

Why are Accumulator Inspections Important?

Accumulators contain a gas-filled bladder that can degrade over time, leading to:

- Reduced system performance

- Rougher ride quality

- Potential system failure

Regular inspections can help identify failing accumulators before they cause significant problems.

How to Inspect Accumulators

- Visual Inspection: Look for signs of leakage or physical damage.

- Pressure Testing: Use a pressure gauge to check the accumulator’s pressure. A significant drop in pressure indicates a failing accumulator.

- Ride Quality: Notice any changes in ride quality, such as increased harshness or body roll.

Best Practices for Accumulator Maintenance

- Replace Accumulators as Needed: Replace accumulators that show signs of failure or are not holding pressure properly.

- Follow the Recommended Service Intervals: Adhere to the recommended inspection and replacement intervals in your vehicle’s owner’s manual.

- Consult a Professional: Have accumulator inspections and replacements performed by a qualified technician.

2.4 Strut Maintenance

Answer: Strut maintenance is crucial for the ABC suspension system, with inspections recommended annually and replacements as needed to ensure proper damping and ride height control. The struts in the ABC system are complex hydraulic components that provide damping and maintain ride height. Leaks, damage, or wear in the struts can compromise the system’s performance and safety.

Why is Strut Maintenance Important?

Struts are subject to wear and tear over time, which can lead to:

- Reduced system performance

- Uneven ride height

- Leaks

- Potential system failure

Regular maintenance can help identify and address these issues before they cause significant problems.

How to Maintain Struts

- Visual Inspection: Look for signs of leaks, damage, or corrosion.

- Ride Height Measurement: Measure the ride height at each corner of the vehicle to ensure it is within specifications.

- Performance Testing: Evaluate the strut’s performance by driving the vehicle over bumps and uneven surfaces.

Best Practices for Strut Maintenance

- Replace Struts as Needed: Replace struts that show signs of leakage, damage, or wear.

- Use Quality Replacement Parts: Always use high-quality replacement struts that are specifically designed for the ABC suspension system.

- Have Struts Replaced by a Professional: Strut replacement is a complex task that should be performed by a qualified technician.

2.5 Regular Diagnostics

Answer: Regular diagnostics are essential for the ABC suspension system, with routine checks recommended every 6 months to detect and address potential issues early, ensuring optimal performance and preventing costly repairs. Regular diagnostic checks using specialized scan tools can help identify potential issues before they become major problems. These tools can read fault codes, monitor system parameters, and perform diagnostic tests to assess the health of the ABC system.

Why are Regular Diagnostics Important?

The ABC system is complex and can develop various issues that may not be immediately apparent. Regular diagnostics can help identify:

- Faulty sensors

- Malfunctioning valves

- Pressure imbalances

- Electrical issues

Early detection of these problems can prevent further damage and costly repairs.

How to Perform Diagnostics

- Connect a Scan Tool: Connect a Mercedes-Benz compatible scan tool to the vehicle’s diagnostic port.

- Read Fault Codes: Scan the system for any stored fault codes.

- Monitor System Parameters: Monitor key system parameters, such as pressure, sensor readings, and valve positions.

- Perform Diagnostic Tests: Run diagnostic tests to assess the functionality of individual components.

Best Practices for Diagnostics

- Use a Mercedes-Benz Compatible Scan Tool: Ensure the scan tool is compatible with the Mercedes-Benz ABC suspension system.

- Interpret Fault Codes Correctly: Understand the meaning of fault codes and follow the recommended diagnostic procedures.

- Consult a Professional: Have diagnostic checks performed by a qualified technician who is familiar with the ABC system.

- Consider DTS-MONACO.EDU.VN: For advanced diagnostics and car coding, DTS-MONACO.EDU.VN offers specialized software and training to help you effectively troubleshoot and repair ABC suspension systems.

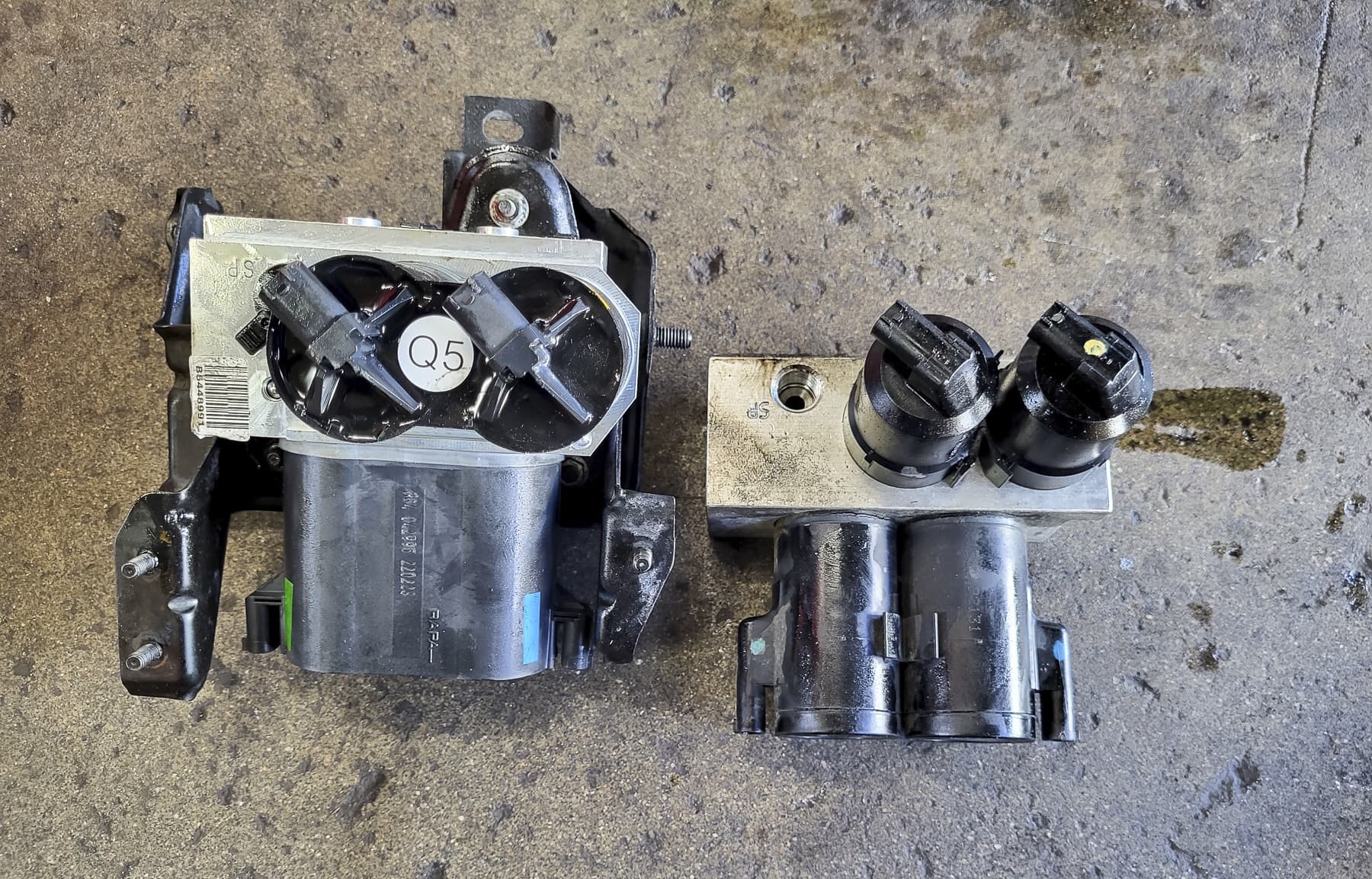

2003 Mercedes Benz SL500 – ABC suspension

2003 Mercedes Benz SL500 – ABC suspension

3. What are the Common Problems with ABC Suspension Systems?

ABC suspension systems, while advanced, are prone to certain issues. Understanding these common problems can help owners and technicians diagnose and address them effectively.

3.1 Leaks

Hydraulic fluid leaks are a common issue in ABC systems. Leaks can occur at hoses, fittings, struts, or valve blocks. Low fluid levels can cause the system to malfunction, leading to a rough ride, warning lights, and potential damage to the pump.

3.2 Pump Failure

The high-pressure hydraulic pump is a critical component of the ABC system. Over time, the pump can wear out or fail due to contamination, excessive load, or lack of maintenance. Symptoms of pump failure include:

- Warning lights

- Reduced system performance

- Noisy operation

- Complete system failure

3.3 Accumulator Failure

Accumulators store hydraulic pressure and help smooth out pressure fluctuations. Over time, the gas-filled bladder inside the accumulator can degrade, leading to:

- Rough ride quality

- Increased body roll

- Warning lights

3.4 Valve Block Issues

Valve blocks control the flow of hydraulic fluid to each strut. Malfunctions in the valve blocks can cause:

- Uneven ride height

- Suspension drop overnight

- Warning lights

3.5 Sensor Malfunctions

The ABC system relies on various sensors to monitor vehicle movement and road conditions. Faulty sensors can provide incorrect data to the control unit, leading to:

- Incorrect suspension adjustments

- Warning lights

- Reduced system performance

4. How to Troubleshoot ABC Suspension Problems?

Troubleshooting ABC suspension problems requires a systematic approach. Here are some steps to follow:

4.1 Visual Inspection

Start by performing a visual inspection of the system. Look for:

- Leaks

- Damaged components

- Corrosion

- Loose connections

4.2 Check Fluid Level and Condition

Ensure the fluid level is correct and the fluid is clean and free of contaminants.

4.3 Read Fault Codes

Use a Mercedes-Benz compatible scan tool to read any stored fault codes. Research the codes to understand the potential issues.

4.4 Monitor System Parameters

Monitor key system parameters, such as pressure, sensor readings, and valve positions, using the scan tool.

4.5 Perform Diagnostic Tests

Run diagnostic tests to assess the functionality of individual components.

4.6 Consult a Professional

If you are not comfortable performing these steps or are unable to diagnose the problem, consult a qualified technician who is familiar with the ABC system.

5. What Tools and Equipment are Needed for ABC Suspension Maintenance?

Maintaining an ABC suspension system requires specific tools and equipment to ensure proper diagnosis and repair. Here’s a list of essential items:

5.1 Mercedes-Benz Compatible Scan Tool

A Mercedes-Benz compatible scan tool is essential for reading fault codes, monitoring system parameters, and performing diagnostic tests.

5.2 Hydraulic Pressure Gauge

A hydraulic pressure gauge is needed to measure the pressure in the ABC system and assess the health of the pump and accumulators.

5.3 Fluid Flush Machine

A fluid flush machine is used to circulate new fluid through the system and remove old, contaminated fluid.

5.4 Basic Hand Tools

Basic hand tools, such as wrenches, sockets, screwdrivers, and pliers, are needed for various maintenance tasks.

5.5 Torque Wrench

A torque wrench is essential for tightening bolts and fasteners to the correct specifications.

5.6 Safety Glasses and Gloves

Safety glasses and gloves are needed to protect yourself from hydraulic fluid and other hazards.

6. What are the Costs Associated with ABC Suspension Maintenance?

The costs associated with ABC suspension maintenance can vary depending on the specific services required and the parts needed. Here are some typical costs:

6.1 Fluid Flush

The cost of a fluid flush can range from $200 to $400, depending on the shop and the type of fluid used.

6.2 Filter Replacement

The cost of a filter replacement can range from $50 to $150, including the cost of the filter and labor.

6.3 Accumulator Replacement

The cost of accumulator replacement can range from $300 to $600 per accumulator, including parts and labor.

6.4 Strut Replacement

The cost of strut replacement can range from $1,000 to $3,000 per strut, depending on whether you use OEM or aftermarket parts and the labor involved.

6.5 Pump Replacement

The cost of pump replacement can range from $1,500 to $3,000, including the cost of the pump and labor.

6.6 Diagnostic Services

Diagnostic services can range from $100 to $200 per hour, depending on the shop.

7. Can You Perform ABC Suspension Maintenance Yourself?

Some ABC suspension maintenance tasks, such as fluid checks and filter replacements, can be performed by experienced DIYers. However, more complex tasks, such as strut replacement, pump replacement, and diagnostics, should be left to qualified technicians.

7.1 Tasks Suitable for DIYers

- Fluid checks

- Filter replacements

7.2 Tasks Best Left to Professionals

- Strut replacement

- Pump replacement

- Accumulator replacement

- Diagnostics

- Flushing the system

8. What are the Benefits of Professional ABC Suspension Service?

Professional ABC suspension service offers several benefits:

- Expertise: Qualified technicians have the knowledge and experience to properly diagnose and repair ABC suspension problems.

- Specialized Tools: Professional shops have access to specialized tools and equipment needed to perform ABC suspension maintenance.

- Quality Parts: Professional shops use high-quality parts that are designed for the ABC suspension system.

- Warranty: Professional service often comes with a warranty, providing peace of mind.

9. How Does DTS-MONACO.EDU.VN Help with ABC Suspension Maintenance?

DTS-MONACO.EDU.VN provides specialized software and training that can greatly assist in ABC suspension maintenance. Here’s how:

9.1 Advanced Diagnostics

DTS-MONACO.EDU.VN offers advanced diagnostic capabilities that go beyond basic scan tools. The software allows technicians to:

- Access detailed system information

- Perform in-depth diagnostic tests

- Troubleshoot complex issues

9.2 Car Coding and Programming

DTS-MONACO.EDU.VN enables car coding and programming, which can be necessary after replacing certain ABC system components. This ensures that the new components are properly integrated into the vehicle’s electronic system.

9.3 Training and Support

DTS-MONACO.EDU.VN provides training and support to help technicians effectively use the software and perform ABC suspension maintenance. This includes:

- Online courses

- Technical documentation

- Expert support

9.4 Benefits of Using DTS-MONACO.EDU.VN

- Improved diagnostic accuracy

- Reduced repair time

- Enhanced customer satisfaction

- Increased profitability

10. How to Extend the Life of Your ABC Suspension System?

Extending the life of your ABC suspension system involves proactive maintenance and care. Here are some tips:

10.1 Follow Recommended Maintenance Intervals

Adhere to the recommended maintenance intervals in your vehicle’s owner’s manual.

10.2 Use Quality Parts and Fluids

Always use high-quality parts and fluids that are specifically designed for the ABC suspension system.

10.3 Inspect the System Regularly

Inspect the system regularly for leaks, damage, and other issues.

10.4 Drive Carefully

Avoid driving aggressively over bumps and potholes, which can put excessive strain on the suspension system.

10.5 Seek Professional Service

Seek professional service when needed to ensure that the system is properly maintained and repaired.

Taking these steps can help you extend the life of your ABC suspension system and enjoy a smooth, comfortable ride for years to come. DTS-MONACO.EDU.VN is your trusted partner for advanced diagnostics, car coding, and training to keep your ABC suspension system in top condition.

2003 Mercedes Benz SL500 – ABC suspension

2003 Mercedes Benz SL500 – ABC suspension

Understanding the maintenance requirements of your ABC suspension system is crucial for ensuring its longevity and optimal performance. From regular fluid checks and filter replacements to accumulator inspections and strut maintenance, each task plays a vital role in keeping your system running smoothly. By following the recommended service intervals and addressing any issues promptly, you can avoid costly repairs and maintain a comfortable, controlled ride.

For advanced diagnostics, car coding, and expert training, visit DTS-MONACO.EDU.VN. Explore our comprehensive resources and discover how we can help you keep your ABC suspension system in top condition. Contact us today to learn more about our software, training programs, and support services. Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880. Website: DTS-MONACO.EDU.VN. Let us help you maximize the performance and longevity of your ABC suspension system. Optimize vehicle handling and overall system reliability with our expert solutions.

FAQ: ABC Suspension Maintenance

1. How often should I check the ABC suspension fluid level?

You should check the ABC suspension fluid level at least every month or during every oil change to ensure it is within the recommended range.

2. How often should I flush the ABC suspension fluid?

It is generally recommended to flush the ABC suspension fluid every 5 years or 50,000 miles, whichever comes first, to maintain system performance.

3. What type of fluid should I use for the ABC suspension system?

You should only use the hydraulic fluid specifically recommended by Mercedes-Benz for the ABC suspension system to avoid damaging the system.

4. How often should I replace the ABC suspension filter?

The ABC suspension filter should be replaced every 25,000 to 30,000 miles to ensure fluid purity and prevent component damage.

5. What are the signs of a failing ABC suspension accumulator?

Signs of a failing accumulator include a rough ride, increased body roll, and warning lights on the dashboard.

6. Can I replace the ABC suspension struts myself?

Replacing ABC suspension struts is a complex task that requires specialized tools and knowledge, so it is best left to qualified technicians.

7. How can I tell if my ABC suspension pump is failing?

Symptoms of a failing ABC suspension pump include warning lights, reduced system performance, noisy operation, and complete system failure.

8. What is car coding, and why is it important for ABC suspension maintenance?

Car coding involves programming the vehicle’s computer to recognize and properly integrate new components, which is sometimes necessary after replacing ABC suspension parts.

9. How can DTS-MONACO.EDU.VN help with ABC suspension maintenance?

DTS-MONACO.EDU.VN offers advanced diagnostic software, car coding capabilities, and expert training to help technicians effectively troubleshoot and repair ABC suspension systems.

10. What are the long-term benefits of maintaining my ABC suspension system?

Regular maintenance can extend the life of your ABC suspension system, maintain optimal ride quality and handling, and prevent costly repairs down the road.