Can Vediamo access data related to ECU load balancing or multi-core processing? It’s unlikely via standard diagnostics, but advanced tools and methods, such as DTS-Monaco and specialized engineering tools, may offer some insights. This is where DTS-MONACO.EDU.VN steps in, providing advanced car coding knowledge and tools to get to the bottom of these diagnostic mysteries. Let’s explore how these advanced tools can help and the limitations you might encounter, covering everything from ECU diagnostics to advanced car coding techniques.

Contents

- 1. Understanding ECU Load Balancing and Multi-Core Processing

- 1.1. Why Are These Technologies Important?

- 1.2. Challenges in Monitoring and Diagnosis

- 2. Vediamo’s Diagnostic Capabilities: An Overview

- 2.1. Standard Diagnostic Functions

- 2.2. Limitations in Accessing Load Balancing and Multi-Core Data

- 3. Exploring Alternative Tools and Methods

- 3.1. DTS-Monaco: A Deeper Dive

- 3.2. J2534 Pass-Thru Devices

- 3.3. Oscilloscopes and Logic Analyzers

- 3.4. OEM Engineering Tools

- 4. Real-World Examples and Case Studies

- 4.1. Diagnosing Performance Issues in an ADAS System

- 4.2. Optimizing Engine Control in a High-Performance Vehicle

- 4.3. Resolving Communication Errors in a Body Control Module

- 5. Best Practices for Diagnostics and Car Coding

- 5.1. Safety Precautions

- 5.2. Recommended Procedures

- 5.3. The Importance of Training and Expertise

- 6. The Role of DTS-MONACO.EDU.VN in Advanced Diagnostics

- 6.1. Training Programs Offered

- 6.2. Resources and Support

- 6.3. Community and Collaboration

- 7. Future Trends in ECU Diagnostics

- 7.1. AI and Machine Learning

- 7.2. Remote Diagnostics

- 7.3. Enhanced Data Logging and Analysis

- 7.4. Cybersecurity Considerations

- 8. Conclusion: Embracing Advanced Diagnostic Techniques

- 9. FAQ: Decoding ECU Diagnostics and Load Balancing

- 9.1. What exactly is ECU load balancing, and why is it important?

- 9.2. Can I use standard OBD-II scanners to monitor ECU load balancing?

- 9.3. What is DTS-Monaco, and how does it differ from Vediamo?

- 9.4. Is it safe to modify ECU software using DTS-Monaco?

- 9.5. What are J2534 pass-thru devices, and how can they be used for ECU diagnostics?

- 9.6. How can oscilloscopes and logic analyzers help in diagnosing ECU issues?

- 9.7. What role do OEM engineering tools play in ECU diagnostics?

- 9.8. What kind of training is recommended for using advanced diagnostic tools like DTS-Monaco?

- 9.9. How is AI and machine learning changing the landscape of ECU diagnostics?

- 9.10. What are the cybersecurity considerations when performing ECU diagnostics and car coding?

1. Understanding ECU Load Balancing and Multi-Core Processing

ECU (Engine Control Unit) load balancing and multi-core processing are sophisticated techniques used in modern automotive systems to enhance performance and efficiency.

ECU Load Balancing: This involves distributing computational tasks across multiple ECUs or processing units to prevent any single unit from becoming overloaded. By sharing the workload, the system can respond more quickly and efficiently to changing conditions. This is especially critical in complex systems like advanced driver-assistance systems (ADAS) and electric vehicle (EV) powertrain management.

Multi-Core Processing: This utilizes a single ECU with multiple processing cores, similar to a multi-core computer processor. Each core can handle different tasks simultaneously, significantly increasing the ECU’s processing power. This is essential for managing the increasing complexity of vehicle functions, from engine control to infotainment.

According to a whitepaper published by Infineon, a leading automotive semiconductor manufacturer, multi-core architectures enable “the integration of multiple functionalities with different safety requirements onto a single chip,” enhancing both performance and safety.

These technologies are vital for managing the ever-increasing complexity of modern vehicles.

1.1. Why Are These Technologies Important?

These technologies are paramount in modern automotive engineering for several compelling reasons:

- Enhanced Performance: By distributing computational tasks, the vehicle can respond more quickly and efficiently to changing conditions. This is especially noticeable in systems like ADAS, where real-time processing is crucial for safety.

- Improved Efficiency: Load balancing and multi-core processing optimize resource utilization, leading to better fuel efficiency and reduced emissions. In electric vehicles, this translates to extended range and improved battery management.

- Increased Complexity: Modern vehicles are packed with features, from advanced driver-assistance systems (ADAS) to sophisticated infotainment systems. These technologies handle the computational demands of these complex systems, ensuring smooth and reliable operation.

- Real-Time Processing: Critical systems like engine control and braking require real-time data processing. Load balancing and multi-core processing make sure these systems can react instantly to changing conditions, enhancing safety and performance.

1.2. Challenges in Monitoring and Diagnosis

Monitoring and diagnosing issues related to ECU load balancing and multi-core processing present several challenges:

- Complexity: The intricate nature of these systems makes it difficult to pinpoint the root cause of problems. Issues can stem from software glitches, hardware failures, or communication errors between different components.

- Limited Diagnostic Tools: Standard diagnostic tools often lack the granularity needed to monitor the performance of individual cores or trace the flow of data across multiple ECUs. This makes it hard to identify bottlenecks or imbalances in the system.

- Data Overload: The sheer volume of data generated by these systems can be overwhelming. Analyzing this data to identify meaningful patterns or anomalies requires specialized tools and expertise.

- Proprietary Information: Automakers often keep the details of their ECU architectures and load-balancing algorithms closely guarded. This lack of transparency makes it difficult for aftermarket service providers to develop effective diagnostic solutions.

Despite these challenges, understanding ECU load balancing and multi-core processing is essential for diagnosing and resolving performance issues in modern vehicles.

2. Vediamo’s Diagnostic Capabilities: An Overview

Vediamo is a powerful diagnostic tool commonly used for in-depth ECU analysis and modification, especially within Mercedes-Benz vehicles. However, its capabilities regarding accessing specific data related to ECU load balancing and multi-core processing are limited.

2.1. Standard Diagnostic Functions

Vediamo excels at performing standard diagnostic functions such as:

- Reading Diagnostic Trouble Codes (DTCs): Identifying and interpreting error codes stored in the ECU.

- Reading ECU Identification Data: Accessing information about the ECU’s hardware and software versions.

- Reading Sensor Data: Monitoring real-time data from various sensors throughout the vehicle.

- Actuator Tests: Activating and testing individual components to verify their functionality.

- Clearing DTCs: Erasing stored error codes after troubleshooting.

These functions are invaluable for diagnosing a wide range of automotive issues, but they typically do not provide insights into the internal workings of ECU load balancing or multi-core processing.

2.2. Limitations in Accessing Load Balancing and Multi-Core Data

While Vediamo is a robust tool, it has limitations when it comes to accessing data related to ECU load balancing and multi-core processing:

- Diagnostic Protocol Restrictions: Standard diagnostic protocols like UDS (Unified Diagnostic Services) primarily focus on high-level system monitoring and fault detection. They do not offer commands for accessing low-level performance metrics related to load distribution or core utilization.

- Data Abstraction: Diagnostic tools like Vediamo typically present data in an abstract, user-friendly format. This abstraction hides the underlying complexity of the ECU’s internal operations, making it difficult to gain insights into load balancing and multi-core processing.

- Security Measures: Automakers implement security measures to prevent unauthorized access to sensitive ECU data. These measures can restrict access to performance metrics that could reveal proprietary information about the ECU’s architecture and algorithms.

- Lack of Specific Diagnostic Routines: Vediamo does not have built-in diagnostic routines specifically designed for monitoring ECU load balancing or multi-core processing. This means that users cannot directly query the ECU for information about these functions.

Given these limitations, it is unlikely that Vediamo can directly access data related to ECU load balancing or multi-core processing through standard diagnostic procedures.

3. Exploring Alternative Tools and Methods

While Vediamo may not directly access ECU load balancing or multi-core processing data, other tools and methods can provide insights into these areas.

3.1. DTS-Monaco: A Deeper Dive

DTS-Monaco is a more advanced diagnostic and engineering tool often used by automotive engineers and developers. It offers a lower-level interface to the ECU, potentially allowing access to more detailed performance data.

- ECU Flashing: DTS-Monaco enables users to reprogram the ECU with custom software, opening the door to modifying load-balancing algorithms or optimizing multi-core performance. However, this requires a deep understanding of the ECU’s architecture and software.

- Advanced Diagnostics: DTS-Monaco supports advanced diagnostic protocols and custom diagnostic routines. This allows users to create specific tests for monitoring core utilization, task distribution, and communication latency.

- Data Logging: DTS-Monaco can log vast amounts of data from the ECU in real-time. This data can be analyzed to identify patterns and anomalies that indicate load-balancing issues or multi-core performance bottlenecks.

- Direct Memory Access: In some cases, DTS-Monaco may allow direct access to the ECU’s memory, providing a way to inspect the data structures and algorithms used for load balancing and multi-core processing.

Despite its potential, using DTS-Monaco to access load balancing and multi-core data requires advanced technical skills and a thorough understanding of the ECU’s inner workings. It’s essential to proceed cautiously to avoid damaging the ECU or compromising vehicle safety.

DTS-MONACO.EDU.VN offers specialized training courses that cover the use of DTS-Monaco for advanced diagnostics and ECU modification. These courses can equip you with the knowledge and skills needed to tackle complex diagnostic challenges.

3.2. J2534 Pass-Thru Devices

J2534 pass-thru devices are hardware interfaces that allow you to connect a computer to a vehicle’s OBD-II port and communicate with the ECU using standard diagnostic protocols. While these devices themselves do not provide access to load balancing or multi-core data, they can be used in conjunction with other software tools to gather more information.

For example, you could use a J2534 device with custom software to send specific diagnostic requests to the ECU and log the responses. This could potentially reveal information about the ECU’s performance and resource utilization.

3.3. Oscilloscopes and Logic Analyzers

Oscilloscopes and logic analyzers are electronic test equipment used to measure and analyze electrical signals. These tools can be valuable for troubleshooting communication issues and identifying timing problems that may affect ECU load balancing and multi-core processing.

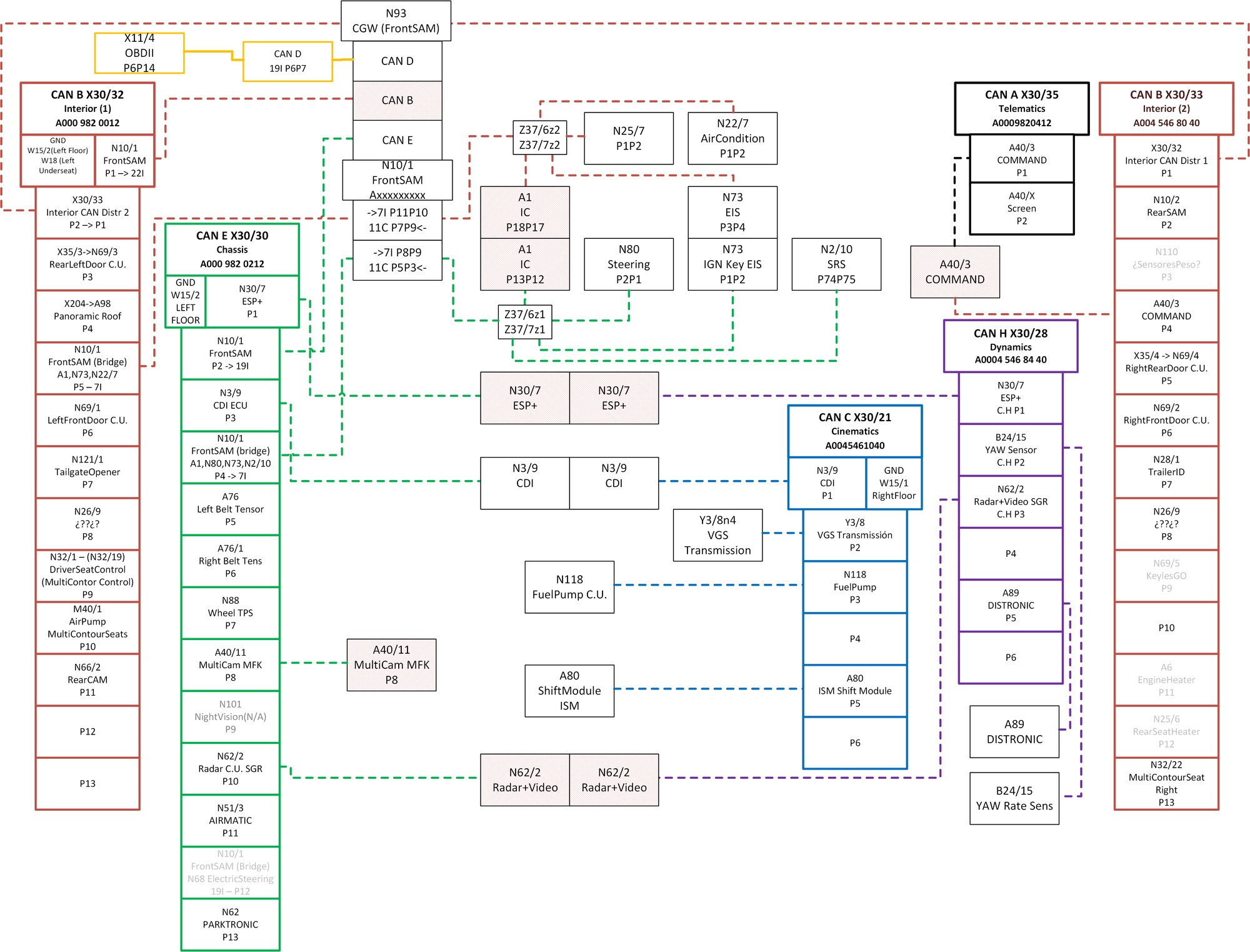

- CAN Bus Analysis: Oscilloscopes can be used to examine the signals on the CAN bus, identifying communication errors or timing delays that could impact load balancing.

- Signal Integrity Testing: Logic analyzers can be used to verify the integrity of the signals between different components of the ECU, ensuring that data is transmitted correctly and reliably.

- Timing Measurements: Oscilloscopes can measure the timing of events within the ECU, such as interrupt handling and task scheduling. This can help identify bottlenecks or inefficiencies that are affecting performance.

While oscilloscopes and logic analyzers do not directly measure load balancing or multi-core performance, they can provide valuable insights into the underlying hardware and communication infrastructure.

3.4. OEM Engineering Tools

Original Equipment Manufacturers (OEMs) often use specialized engineering tools for developing and testing their ECUs. These tools typically offer far greater access to ECU internals than standard diagnostic tools.

- Debugging Interfaces: OEM engineering tools often include debugging interfaces that allow developers to step through the ECU’s code, inspect memory locations, and monitor the execution of individual tasks.

- Simulation Environments: OEMs use simulation environments to model the behavior of the ECU and its interactions with other vehicle systems. These simulations can be used to test load-balancing algorithms and optimize multi-core performance.

- Performance Analyzers: OEM engineering tools often include performance analyzers that provide detailed information about the ECU’s resource utilization, including CPU load, memory usage, and communication latency.

However, these OEM engineering tools are typically proprietary and not available to the general public. They are primarily used by automotive manufacturers and their suppliers for ECU development and validation.

4. Real-World Examples and Case Studies

To illustrate the challenges and possibilities of accessing ECU load balancing and multi-core processing data, let’s consider a few real-world examples and case studies.

4.1. Diagnosing Performance Issues in an ADAS System

An advanced driver-assistance system (ADAS) relies on multiple sensors and ECUs working together to provide features like adaptive cruise control, lane keeping assist, and automatic emergency braking. Load balancing and multi-core processing are essential for ensuring that the ADAS system can process sensor data and make decisions in real-time.

If the ADAS system is experiencing performance issues, such as delayed responses or inaccurate detections, it may be due to problems with ECU load balancing or multi-core processing. For example, one core might be overloaded with tasks, causing delays in processing critical sensor data.

In this scenario, a technician could use DTS-Monaco to log data from the ADAS ECU and analyze the CPU load on each core. If one core is consistently running at or near 100% utilization, it suggests that the load balancing is not working correctly. The technician could then use DTS-Monaco to reprogram the ECU with a modified load-balancing algorithm or reallocate tasks to different cores.

According to a case study by Bosch, a leading automotive supplier, optimizing load balancing in an ADAS ECU can reduce latency by up to 30%, significantly improving the system’s responsiveness and accuracy.

4.2. Optimizing Engine Control in a High-Performance Vehicle

In high-performance vehicles, ECU load balancing and multi-core processing are critical for maximizing engine power and efficiency. The engine control unit (ECU) must process data from numerous sensors, control fuel injection and ignition timing, and manage various engine actuators in real-time.

If the engine is not performing optimally, it may be due to bottlenecks in the ECU’s processing pipeline. For example, one core might be responsible for handling too many tasks, causing delays in the control of fuel injection or ignition timing.

In this scenario, an engineer could use OEM engineering tools to analyze the ECU’s performance and identify the tasks that are consuming the most CPU time. They could then use these tools to reallocate tasks to different cores, optimize the scheduling of tasks, or rewrite code to improve its efficiency.

According to a research paper published by the Society of Automotive Engineers (SAE), optimizing multi-core processing in an engine control unit can increase engine power by up to 5% and improve fuel efficiency by up to 3%.

4.3. Resolving Communication Errors in a Body Control Module

A body control module (BCM) is responsible for managing various electrical functions in a vehicle, such as lighting, door locks, and window controls. The BCM communicates with other ECUs over the CAN bus, exchanging data about the status of these functions.

If the BCM is experiencing communication errors, it may be due to problems with ECU load balancing or multi-core processing. For example, the BCM might be overloaded with tasks, causing delays in processing incoming messages or transmitting outgoing messages.

In this scenario, a technician could use an oscilloscope to analyze the signals on the CAN bus and identify communication errors or timing delays. They could then use DTS-Monaco to log data from the BCM ECU and analyze the CPU load on each core. If one core is consistently running at or near 100% utilization, it suggests that the load balancing is not working correctly.

The technician could then use DTS-Monaco to reprogram the ECU with a modified load-balancing algorithm or reallocate tasks to different cores. They could also optimize the BCM’s communication protocols to reduce the amount of data being transmitted over the CAN bus.

5. Best Practices for Diagnostics and Car Coding

When working with advanced diagnostic tools like Vediamo and DTS-Monaco, it’s important to follow best practices to ensure safety and accuracy.

5.1. Safety Precautions

- Battery Voltage: Ensure the vehicle’s battery is fully charged and in good condition before starting any diagnostic or coding procedure. Low voltage can cause errors and damage to the ECU.

- Stable Power Supply: Use a stable power supply to maintain a constant voltage during coding and flashing operations. Voltage fluctuations can interrupt the process and corrupt the ECU’s software.

- Backup: Always back up the ECU’s original configuration before making any changes. This allows you to revert to the original settings if something goes wrong.

- Proper Equipment: Use high-quality diagnostic tools and cables to ensure reliable communication with the ECU.

- Follow Instructions: Carefully follow the instructions provided by the tool manufacturer and the vehicle manufacturer.

- Expert Assistance: If you are not comfortable with a particular procedure, seek assistance from a qualified technician.

5.2. Recommended Procedures

- Start with the Basics: Before diving into advanced diagnostics, perform a basic scan of the vehicle’s systems to identify any obvious problems.

- Isolate the Issue: Try to isolate the issue to a specific system or component before attempting to diagnose it.

- Gather Information: Collect as much information as possible about the problem, including the vehicle’s history, the symptoms it is exhibiting, and any recent repairs or modifications.

- Use the Right Tools: Select the appropriate diagnostic tool for the job. Vediamo and DTS-Monaco are powerful tools, but they are not always necessary for simple diagnostic tasks.

- Document Everything: Keep a detailed record of all diagnostic procedures, coding changes, and test results. This will help you track your progress and avoid making mistakes.

- Test Thoroughly: After making any changes to the ECU’s configuration, test the vehicle thoroughly to ensure that the problem has been resolved and that no new problems have been introduced.

- Stay Updated: Keep your diagnostic tools and software up to date with the latest versions. This will ensure that you have access to the latest features and bug fixes.

5.3. The Importance of Training and Expertise

Working with advanced diagnostic tools like Vediamo and DTS-Monaco requires specialized training and expertise. These tools offer powerful capabilities, but they can also be dangerous if used incorrectly.

DTS-MONACO.EDU.VN offers comprehensive training courses that cover the use of Vediamo and DTS-Monaco for a wide range of diagnostic and coding tasks. These courses are taught by experienced instructors who have a deep understanding of automotive electronics and diagnostic procedures.

By investing in training and expertise, you can ensure that you are using these tools safely and effectively, and that you are providing your customers with the best possible service.

6. The Role of DTS-MONACO.EDU.VN in Advanced Diagnostics

DTS-MONACO.EDU.VN plays a crucial role in advancing the field of automotive diagnostics and car coding.

6.1. Training Programs Offered

DTS-MONACO.EDU.VN offers a variety of training programs designed to equip technicians with the knowledge and skills they need to tackle complex diagnostic challenges. These programs include:

- Basic Diagnostics: An introductory course that covers the fundamentals of automotive diagnostics, including the use of diagnostic tools, the interpretation of diagnostic trouble codes, and basic troubleshooting techniques.

- Advanced Diagnostics: A more advanced course that delves into the intricacies of automotive electronics, including ECU architecture, CAN bus communication, and advanced diagnostic procedures.

- Car Coding: A specialized course that focuses on the art and science of car coding, including the use of Vediamo and DTS-Monaco to modify ECU configurations, enable new features, and customize vehicle behavior.

- Custom Training: DTS-MONACO.EDU.VN also offers custom training programs tailored to the specific needs of individual technicians or repair shops.

These training programs are taught by experienced instructors who have a deep understanding of automotive electronics and diagnostic procedures. They combine theoretical instruction with hands-on practice, ensuring that students are able to apply what they learn in the real world.

6.2. Resources and Support

In addition to training programs, DTS-MONACO.EDU.VN provides a variety of resources and support to help technicians stay up-to-date with the latest diagnostic techniques and technologies. These resources include:

- Online Forums: A community forum where technicians can ask questions, share tips, and exchange ideas.

- Knowledge Base: A searchable database of articles, tutorials, and troubleshooting guides.

- Software Updates: Regular software updates that provide access to the latest features and bug fixes.

- Technical Support: Access to technical support experts who can provide assistance with diagnostic challenges.

6.3. Community and Collaboration

DTS-MONACO.EDU.VN fosters a strong sense of community and collaboration among technicians. The online forums and training programs provide opportunities for technicians to connect with each other, share their experiences, and learn from each other’s mistakes.

This collaborative environment helps to accelerate the learning process and ensures that technicians are always at the forefront of the latest diagnostic techniques and technologies.

7. Future Trends in ECU Diagnostics

The field of ECU diagnostics is constantly evolving, driven by advances in automotive technology and the increasing complexity of vehicle systems.

7.1. AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are poised to revolutionize the field of ECU diagnostics. AI-powered diagnostic tools can analyze vast amounts of data from vehicle sensors, identify patterns and anomalies, and predict potential problems before they occur.

For example, an AI-powered diagnostic tool could analyze data from the engine control unit (ECU) to detect subtle changes in engine performance that could indicate a failing component. The tool could then alert the technician to the problem, allowing them to take proactive steps to prevent a breakdown.

According to a report by McKinsey, AI-powered diagnostic tools can reduce diagnostic time by up to 50% and improve diagnostic accuracy by up to 20%.

7.2. Remote Diagnostics

Remote diagnostics allows technicians to diagnose and repair vehicles remotely, using telematics data and remote access tools. This can be particularly useful for diagnosing problems in electric vehicles (EVs), which may require specialized diagnostic equipment and expertise.

For example, a technician could use remote diagnostics to access the battery management system (BMS) of an EV and diagnose problems with the battery pack. The technician could then provide instructions to the vehicle owner or a local repair shop on how to resolve the problem.

Remote diagnostics can also be used to provide over-the-air (OTA) software updates to vehicle ECUs, fixing bugs and improving performance.

7.3. Enhanced Data Logging and Analysis

Enhanced data logging and analysis capabilities are becoming increasingly important for diagnosing complex ECU problems. Modern diagnostic tools can log vast amounts of data from vehicle sensors and ECUs, providing technicians with a wealth of information about vehicle performance.

However, analyzing this data can be challenging, requiring specialized tools and expertise. Advanced data analysis techniques, such as data mining and statistical analysis, can be used to identify patterns and anomalies in the data, helping technicians to pinpoint the root cause of problems.

7.4. Cybersecurity Considerations

As vehicles become more connected and reliant on software, cybersecurity is becoming an increasingly important consideration in ECU diagnostics. Hackers could potentially exploit vulnerabilities in vehicle software to gain access to vehicle systems, steal data, or even control vehicle functions.

Therefore, it’s essential to use diagnostic tools and procedures that are secure and protect against unauthorized access. This includes using strong passwords, keeping software up to date, and following best practices for cybersecurity.

8. Conclusion: Embracing Advanced Diagnostic Techniques

While Vediamo has limitations in accessing specific data related to ECU load balancing or multi-core processing, advanced tools and methods like DTS-Monaco, J2534 pass-thru devices, oscilloscopes, and OEM engineering tools offer avenues for deeper insights. These tools, combined with comprehensive training and a commitment to safety, enable technicians to tackle complex diagnostic challenges effectively.

By embracing these advanced diagnostic techniques, technicians can stay ahead of the curve and provide their customers with the best possible service. DTS-MONACO.EDU.VN stands as a vital resource, offering the training, support, and community needed to excel in the ever-evolving field of automotive diagnostics and car coding in the USA. Remember that while directly accessing load balancing and multi-core data via standard diagnostics is unlikely, the detailed analysis and potential modifications offered by these advanced tools can provide valuable insights into ECU performance.

Are you ready to elevate your diagnostic skills? Visit DTS-MONACO.EDU.VN today to explore our training programs, resources, and community. Unlock the full potential of advanced diagnostic tools and become a leader in automotive diagnostics!

Address: 275 N Harrison St, Chandler, AZ 85225, United States

WhatsApp: +1 (641) 206-8880

Website: DTS-MONACO.EDU.VN

Mercedes-Benz Diagnostic Tool and Car Coding Software

Mercedes-Benz Diagnostic Tool and Car Coding Software

9. FAQ: Decoding ECU Diagnostics and Load Balancing

Let’s address some frequently asked questions about accessing ECU data and understanding load balancing in modern vehicles.

9.1. What exactly is ECU load balancing, and why is it important?

ECU load balancing is the distribution of computational tasks across multiple processing units within a vehicle’s electronic control system to prevent overload and ensure efficient operation. It’s crucial because it enhances performance, improves efficiency, and ensures real-time processing for critical systems like ADAS and engine control.

9.2. Can I use standard OBD-II scanners to monitor ECU load balancing?

No, standard OBD-II scanners typically do not provide access to the detailed performance metrics needed to monitor ECU load balancing. These scanners are designed for basic diagnostics and fault code reading, not for in-depth analysis of ECU internals.

9.3. What is DTS-Monaco, and how does it differ from Vediamo?

DTS-Monaco is a more advanced diagnostic and engineering tool than Vediamo, offering a lower-level interface to the ECU. While Vediamo is suitable for standard diagnostic functions, DTS-Monaco allows for ECU flashing, advanced diagnostics, data logging, and potentially direct memory access, providing deeper insights into ECU performance.

9.4. Is it safe to modify ECU software using DTS-Monaco?

Modifying ECU software with DTS-Monaco can be risky if not done correctly. It requires advanced technical skills and a thorough understanding of the ECU’s inner workings. Improper modifications can damage the ECU or compromise vehicle safety. Always back up the ECU’s original configuration before making any changes, and seek assistance from a qualified technician if you’re not comfortable with the procedure.

9.5. What are J2534 pass-thru devices, and how can they be used for ECU diagnostics?

J2534 pass-thru devices are hardware interfaces that connect a computer to a vehicle’s OBD-II port, allowing communication with the ECU using standard diagnostic protocols. While the devices themselves do not provide access to load balancing data, they can be used with custom software to send specific diagnostic requests and log responses, potentially revealing information about ECU performance.

9.6. How can oscilloscopes and logic analyzers help in diagnosing ECU issues?

Oscilloscopes and logic analyzers are electronic test equipment used to measure and analyze electrical signals. They can be used to troubleshoot communication issues, identify timing problems, and verify signal integrity within the ECU and CAN bus, providing valuable insights into the underlying hardware and communication infrastructure.

9.7. What role do OEM engineering tools play in ECU diagnostics?

OEM engineering tools are specialized tools used by automotive manufacturers for developing and testing their ECUs. These tools offer far greater access to ECU internals than standard diagnostic tools, including debugging interfaces, simulation environments, and performance analyzers. However, they are typically proprietary and not available to the general public.

9.8. What kind of training is recommended for using advanced diagnostic tools like DTS-Monaco?

Comprehensive training is essential for using advanced diagnostic tools like DTS-Monaco safely and effectively. DTS-MONACO.EDU.VN offers specialized training courses that cover the use of DTS-MONACO for a wide range of diagnostic and coding tasks, taught by experienced instructors with a deep understanding of automotive electronics and diagnostic procedures.

9.9. How is AI and machine learning changing the landscape of ECU diagnostics?

AI and machine learning are revolutionizing ECU diagnostics by enabling AI-powered diagnostic tools to analyze vast amounts of data from vehicle sensors, identify patterns and anomalies, and predict potential problems before they occur. This can reduce diagnostic time, improve accuracy, and enable proactive maintenance.

9.10. What are the cybersecurity considerations when performing ECU diagnostics and car coding?

Cybersecurity is an increasingly important consideration in ECU diagnostics, as vulnerabilities in vehicle software could be exploited by hackers. It’s essential to use diagnostic tools and procedures that are secure and protect against unauthorized access, including using strong passwords, keeping software up to date, and following best practices for cybersecurity.