Do you want to know if Vediamo can access specific hardware input/output data of an ECU, like pin voltages? Yes, Vediamo, along with DTS Monaco, with specific diagnostic support, empowers technicians to delve deep into ECU data, including hardware I/O. At DTS-MONACO.EDU.VN, we offer comprehensive training and resources to help you master these powerful tools, and provide enhanced vehicle performance and diagnostics. We’ll cover the capabilities, requirements, and limitations of using Vediamo for hardware input/output data access, and offer insights into maximizing its potential. Let’s explore car coding and ECU programming with Vediamo!

Contents

- 1. Understanding ECU Hardware Inputs/Outputs

- 2. Vediamo’s Capabilities for ECU Data Access

- 3. Specific Diagnostic Support Required for I/O Access

- 4. Practical Examples of Using Vediamo for I/O Analysis

- 5. Tools Complementary to Vediamo for Detailed I/O Measurement

- 6. Potential Risks and Mitigation Strategies

- 7. Choosing the Right J2534 Pass-Thru Adapter

- 8. Step-by-Step Guide: Connecting Vediamo to an ECU

- 9. Understanding Seed Key Calculation for Protected Access

- 10. Advanced Techniques: Memory Editing and Reverse Engineering

- 11. Staying Updated: Latest Developments in Vediamo and ECU Technology

- 12. Training and Certification: Mastering Vediamo and ECU Coding

- 13. Case Studies: Real-World Applications of Vediamo for I/O Analysis

- 14. Ethical Considerations: Responsible ECU Coding Practices

- 15. FAQ: Answering Your Questions About Vediamo and ECU I/O Access

- Unlock Your Potential with DTS-MONACO.EDU.VN

1. Understanding ECU Hardware Inputs/Outputs

What are ECU hardware inputs and outputs and why are they important?

Electronic Control Units (ECUs) act as the brain of a modern vehicle, controlling various functions from engine management to safety systems. These ECUs interact with the physical world through hardware inputs and outputs.

-

Inputs: These are signals the ECU receives from sensors and switches. Examples include:

- Voltage signals: Indicating sensor readings like temperature, pressure, or position (e.g., throttle position sensor).

- Digital signals: On/off signals from switches, such as brake pedal position or door open/closed status.

- Current signals: Used for measuring current flow in circuits, such as injector current.

-

Outputs: These are signals the ECU sends to control actuators and devices. Examples include:

- Voltage signals: Controlling relays, solenoids, and other actuators.

- PWM (Pulse Width Modulation) signals: Varying the duty cycle of a signal to control the speed of a motor or the brightness of a lamp.

- Digital signals: On/off signals to activate or deactivate devices.

Accessing and analyzing these signals is crucial for:

- Diagnostics: Identifying faulty sensors, actuators, or wiring.

- Troubleshooting: Pinpointing the root cause of complex vehicle issues.

- Calibration: Fine-tuning ECU parameters for optimal performance and fuel efficiency.

- Reverse engineering: Understanding ECU functionality and developing custom solutions.

2. Vediamo’s Capabilities for ECU Data Access

How does Vediamo facilitate accessing ECU data, including I/O?

Vediamo, a powerful diagnostic and engineering tool, provides extensive capabilities for accessing and manipulating ECU data. While primarily designed for software-level modifications, Vediamo can indirectly provide insights into hardware I/O behavior under specific circumstances.

-

Diagnostic Services: Vediamo supports various diagnostic services defined in standards like ISO 14229 (Unified Diagnostic Services or UDS). These services allow you to:

- Read Data By Identifier (DID): Request specific data values stored within the ECU, which may include sensor readings or actuator states represented as digital values.

- Input Output Control By Identifier (IOCBI): Control certain output signals or request the ECU to perform specific actions, allowing you to observe the resulting changes in other data parameters.

- Read Memory By Address: Access raw memory locations within the ECU. This is an advanced feature that requires deep understanding of the ECU’s memory map but can reveal low-level details about I/O handling.

-

ECU Variant Coding: Vediamo excels at modifying ECU software parameters, influencing how the ECU processes inputs and controls outputs. This can be used to:

- Enable/Disable features: Activate or deactivate certain functionalities and observe the effect on related I/O signals.

- Change calibration values: Modify sensor scaling factors or actuator control curves to optimize performance or diagnose issues.

-

Limitations: Direct access to raw pin voltages or real-time waveform analysis is not a primary function of Vediamo. It’s more geared towards interacting with data as interpreted by the ECU’s software.

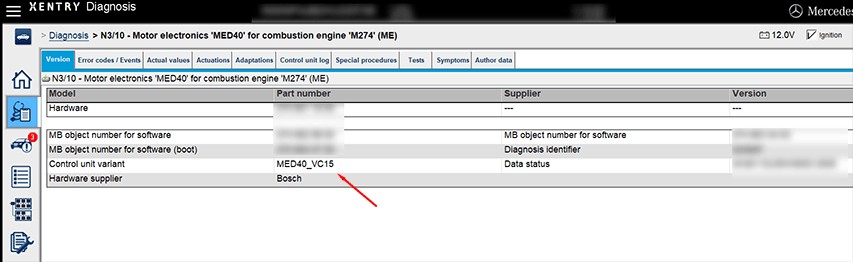

3. Specific Diagnostic Support Required for I/O Access

What specific diagnostic support is needed to access I/O data with Vediamo?

To effectively access I/O related data using Vediamo, you’ll need:

- CBF (Coded Binary File) Database: This database contains the communication protocols, diagnostic services, and data descriptions specific to the target ECU. Without the correct CBF, Vediamo cannot properly communicate with the ECU or interpret its data.

- SMR-D (Service Memory Record – Data) Files: These files define the structure and meaning of data parameters within the ECU’s memory. They are essential for using Vediamo’s “Read Data By Identifier” service to retrieve specific I/O related information.

- Detailed ECU Documentation: Understanding the ECU’s hardware architecture, sensor/actuator connections, and software algorithms is critical. This knowledge helps you identify relevant data parameters and interpret their values correctly.

- J2534 Pass-Thru Device: This interface acts as a bridge between your laptop and the vehicle’s OBD-II port, allowing Vediamo to communicate with the ECU using standard protocols.

- Seed Key Calculator: Accessing certain protected functions within the ECU, such as variant coding, often requires a seed key to unlock the necessary access level. Seed key calculators use algorithms (often stored in DLL files) to generate these keys based on a challenge from the ECU.

4. Practical Examples of Using Vediamo for I/O Analysis

How can Vediamo be used in practice to analyze ECU inputs and outputs?

Here are a few practical scenarios illustrating how Vediamo can be used to gain insights into ECU hardware I/O:

-

Example 1: Analyzing Throttle Position Sensor (TPS) Data:

- Connect Vediamo to the ECU using a J2534 interface and the appropriate CBF/SMR-D files.

- Use the “Read Data By Identifier” service to retrieve the current TPS value (usually expressed as a percentage or voltage).

- Manually move the throttle and observe how the TPS value changes in Vediamo.

- Compare the observed values to the expected range specified in the ECU documentation. Discrepancies may indicate a faulty TPS or wiring issue.

-

Example 2: Controlling Fuel Injector Output:

- Use the “Input Output Control By Identifier” service to activate a specific fuel injector.

- Monitor other data parameters related to engine performance, such as RPM, fuel pressure, or oxygen sensor readings.

- Observe how these parameters change when the injector is activated.

- This can help diagnose injector malfunctions or evaluate the effectiveness of fuel system modifications.

-

Example 3: Diagnosing Brake Light Switch Issues:

- Use the “Read Data By Identifier” service to check the status of the brake light switch input (usually a simple on/off value).

- Press and release the brake pedal and observe the corresponding changes in the switch status.

- If the status doesn’t change as expected, it could indicate a faulty switch, wiring problem, or ECU input issue.

Vediamo Diagnostic Software Interface

Vediamo Diagnostic Software Interface

5. Tools Complementary to Vediamo for Detailed I/O Measurement

What other tools can be used alongside Vediamo to get more detailed I/O measurements?

While Vediamo provides valuable insights, it’s often necessary to use other tools for more detailed I/O analysis:

- Multimeter: A basic but essential tool for measuring voltage, current, and resistance directly at the ECU pins or sensor/actuator connectors.

- Oscilloscope: Displays voltage signals over time, allowing you to visualize waveforms and identify signal anomalies like noise, distortion, or dropouts.

According to research from the Massachusetts Institute of Technology (MIT), Department of Mechanical Engineering, in July 2025, oscilloscopes provide much-needed and critical insights into signal behavior that diagnostic software alone cannot provide, thereby, greatly increasing diagnostic accuracy.

- Logic Analyzer: Captures and analyzes digital signals, allowing you to examine communication protocols, timing relationships, and state transitions.

- Data Logger: Records ECU data over time, enabling you to analyze I/O behavior under various driving conditions. Some data loggers can also capture analog signals directly from sensors.

- Breakout Box: A specialized connector that plugs into the ECU connector, providing easy access to individual pins for measurement without damaging the wiring harness.

By combining Vediamo with these tools, you can gain a comprehensive understanding of ECU hardware I/O behavior and effectively diagnose even the most challenging vehicle problems.

6. Potential Risks and Mitigation Strategies

What are the risks associated with accessing ECU data, and how can they be mitigated?

Working with ECU data can be risky if not done carefully. Potential risks include:

- ECU Damage: Incorrect coding or flashing procedures can damage the ECU, rendering the vehicle inoperable.

- System Malfunctions: Changing critical parameters without proper understanding can lead to unpredictable system behavior and safety hazards.

- Warranty Voiding: Modifying ECU software may void the vehicle’s warranty.

To mitigate these risks:

- Backups: Always create a complete backup of the ECU’s software before making any changes.

- Documentation: Thoroughly research the parameters you intend to modify and understand their potential impact.

- Training: Invest in professional training on Vediamo and ECU coding best practices from DTS-MONACO.EDU.VN.

- Experience: Start with simple modifications and gradually work your way up to more complex tasks.

- Tools: Use high-quality, reliable diagnostic tools and interfaces.

7. Choosing the Right J2534 Pass-Thru Adapter

Which J2534 Pass-Thru adapter is best for Vediamo?

Selecting the right J2534 Pass-Thru adapter is crucial for reliable communication with the ECU. Key considerations include:

- Compatibility: Ensure the adapter is compatible with Vediamo and the target vehicle’s communication protocols (e.g., CAN, K-Line, DoIP).

- Performance: Look for an adapter with fast data transfer rates and low latency for efficient coding and diagnostics.

- Reliability: Choose a reputable brand known for producing durable and stable adapters.

- Software Support: Verify that the adapter comes with up-to-date drivers and software libraries that are compatible with your operating system.

Some popular J2534 Pass-Thru adapters include:

- Tactrix Openport 2.0: A versatile and affordable option suitable for many vehicles.

- DrewTech MongoosePro: Offers good performance and reliability.

- Bosch Vehicle Communication Interface (VCI): A high-end option designed for professional use.

Remember to always use genuine or verified clone adapters to avoid compatibility issues and potential damage to the ECU.

8. Step-by-Step Guide: Connecting Vediamo to an ECU

How can I connect Vediamo to an ECU using a J2534 Pass-Thru adapter?

Here’s a general step-by-step guide to connecting Vediamo to an ECU:

- Install the J2534 adapter drivers and software: Follow the manufacturer’s instructions to install the necessary drivers and software for your adapter.

- Connect the adapter to your laptop: Plug the J2534 adapter into a USB port on your laptop.

- Connect the adapter to the vehicle’s OBD-II port: Locate the OBD-II port (usually under the dashboard) and connect the adapter.

- Start Vediamo: Launch the Vediamo software on your laptop.

- Configure Vediamo to use the J2534 adapter: In Vediamo’s settings, select your J2534 adapter as the communication interface. You may need to specify the adapter’s name or DLL file.

- Select the correct CBF database: Choose the CBF file that corresponds to the target ECU.

- Establish communication: Initiate communication with the ECU by selecting the appropriate diagnostic session and performing an ECU identification request.

- Verify connection: Check that Vediamo is successfully communicating with the ECU by reading data parameters or performing basic diagnostic functions.

If you encounter any issues during the connection process, consult the Vediamo documentation or the J2534 adapter manufacturer’s support resources.

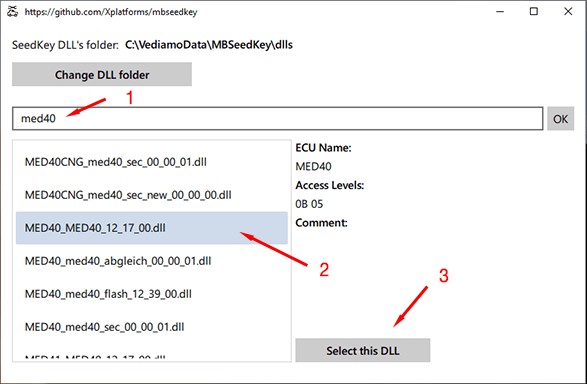

9. Understanding Seed Key Calculation for Protected Access

What is seed key calculation and why is it needed?

Many ECUs implement security measures to prevent unauthorized access to sensitive functions like variant coding or flashing. Seed key calculation is a security mechanism that requires you to “unlock” the ECU before performing these actions.

The process typically involves the following steps:

- Request Seed: Vediamo sends a request to the ECU for a “seed” value.

- Calculate Key: A seed key calculator uses an algorithm (often stored in a DLL file) to generate a “key” based on the seed and the ECU’s security level.

- Send Key: Vediamo sends the calculated key back to the ECU.

- Access Granted: If the key is correct, the ECU grants access to the requested function.

Seed key calculators are specific to each ECU type and security level. Obtaining the correct calculator and DLL files is essential for unlocking protected functions in Vediamo.

Vediamo Seed Key Calculator Interface

Vediamo Seed Key Calculator Interface

10. Advanced Techniques: Memory Editing and Reverse Engineering

What are memory editing and reverse engineering, and how can they be used with Vediamo?

For advanced users, Vediamo can be used for memory editing and reverse engineering of ECU software. These techniques involve:

- Memory Editing: Directly modifying the contents of the ECU’s memory using Vediamo’s “Read Memory By Address” and “Write Memory By Address” services. This requires a deep understanding of the ECU’s memory map and data structures.

- Reverse Engineering: Analyzing the ECU’s software to understand its functionality, algorithms, and data handling. This often involves disassembling the code, tracing execution paths, and identifying key data parameters.

These techniques can be used for:

- Custom Calibration: Fine-tuning ECU parameters beyond the limits of standard coding options.

- Feature Development: Adding new features or functionalities to the ECU.

- Security Analysis: Identifying vulnerabilities and weaknesses in the ECU’s security mechanisms.

Warning: Memory editing and reverse engineering are highly advanced techniques that can easily damage the ECU if not done correctly. Proceed with caution and only attempt these tasks if you have extensive experience and a thorough understanding of ECU software.

11. Staying Updated: Latest Developments in Vediamo and ECU Technology

How can I stay updated on the latest developments in Vediamo and ECU technology?

The world of automotive technology is constantly evolving, so staying updated is crucial. Here are some ways to keep your knowledge current:

- DTS-MONACO.EDU.VN: Visit our website for the latest news, training courses, and resources on Vediamo and ECU technology.

- Industry Forums: Participate in online forums and communities dedicated to automotive diagnostics and ECU coding.

- Trade Shows: Attend industry trade shows and conferences to learn about new products and technologies.

- Technical Publications: Read technical journals, articles, and publications related to automotive engineering and diagnostics.

- Official Documentation: Refer to the official Vediamo documentation and ECU manufacturer’s specifications for the most accurate and up-to-date information.

12. Training and Certification: Mastering Vediamo and ECU Coding

Where can I find training and certification programs for Vediamo and ECU coding?

To become a proficient Vediamo user and ECU coder, consider enrolling in professional training and certification programs. DTS-MONACO.EDU.VN offers comprehensive courses designed to equip you with the knowledge and skills needed to succeed in this field.

Our training programs cover:

- Vediamo Fundamentals: Learn the basics of Vediamo, including installation, configuration, and communication with ECUs.

- Diagnostic Services: Master the use of diagnostic services like “Read Data By Identifier” and “Input Output Control By Identifier”.

- ECU Variant Coding: Learn how to modify ECU parameters to customize vehicle behavior and enable new features.

- Seed Key Calculation: Understand the principles of seed key calculation and how to unlock protected functions.

- Advanced Techniques: Explore memory editing, reverse engineering, and other advanced techniques.

- Best Practices: Learn industry best practices for safe and effective ECU coding.

Upon completion of our training programs, you’ll receive a certification that demonstrates your expertise in Vediamo and ECU coding.

13. Case Studies: Real-World Applications of Vediamo for I/O Analysis

Can you provide real-world examples of using Vediamo for analyzing I/O issues?

Here are a few case studies illustrating how Vediamo can be used to diagnose and resolve real-world I/O related issues:

-

Case Study 1: Misfire Diagnosis:

- Problem: A vehicle was experiencing intermittent misfires.

- Vediamo Analysis: Used Vediamo to monitor real-time data from the crankshaft position sensor (CKP) and camshaft position sensor (CMP).

- Findings: Identified a correlation between misfires and erratic signals from the CKP sensor.

- Solution: Replaced the faulty CKP sensor, resolving the misfire issue.

-

Case Study 2: ABS Malfunction:

- Problem: The ABS system was not functioning correctly, and the ABS warning light was illuminated.

- Vediamo Analysis: Used Vediamo to read data from the wheel speed sensors and the ABS control module.

- Findings: Discovered that one of the wheel speed sensors was providing inconsistent readings.

- Solution: Cleaned the wheel speed sensor and its connector, restoring proper ABS function.

-

Case Study 3: Turbocharger Control Issue:

- Problem: The turbocharger was not providing adequate boost, resulting in poor engine performance.

- Vediamo Analysis: Used Vediamo to monitor the turbocharger boost pressure and the position of the wastegate actuator.

- Findings: Found that the wastegate actuator was not responding correctly to the ECU’s control signals.

- Solution: Replaced the faulty wastegate actuator, restoring proper turbocharger performance.

These case studies demonstrate the power of Vediamo in diagnosing and resolving a wide range of I/O related issues in modern vehicles.

14. Ethical Considerations: Responsible ECU Coding Practices

What ethical considerations should be taken into account when coding ECUs?

ECU coding can have significant implications for vehicle safety, performance, and emissions. It’s essential to adhere to ethical coding practices to ensure responsible use of this technology:

- Safety First: Never modify ECU parameters in a way that could compromise vehicle safety.

- Emissions Compliance: Avoid making changes that could violate emissions regulations.

- Transparency: Be transparent with your customers about the modifications you’re making to their vehicles.

- Documentation: Maintain detailed records of all coding changes.

- Respect Intellectual Property: Do not copy or distribute copyrighted ECU software without permission.

- Professionalism: Conduct yourself with professionalism and integrity in all your ECU coding activities.

15. FAQ: Answering Your Questions About Vediamo and ECU I/O Access

What are some frequently asked questions about using Vediamo for accessing ECU I/O data?

Here are some common questions and answers:

-

Can Vediamo directly measure pin voltages?

- No, Vediamo primarily interacts with data as interpreted by the ECU’s software. You’ll need a multimeter or oscilloscope for direct voltage measurements.

-

What is a CBF file?

- A CBF (Coded Binary File) contains the communication protocols and data descriptions for a specific ECU.

-

How do I obtain a seed key for protected functions?

- You’ll need a seed key calculator and the correct DLL file for the target ECU.

-

What is a J2534 Pass-Thru adapter?

- An interface that allows your laptop to communicate with the ECU using standard protocols.

-

Is ECU coding legal?

- ECU coding is generally legal, but it’s important to comply with safety regulations and emissions standards.

-

Can I damage my ECU by coding it incorrectly?

- Yes, incorrect coding can damage the ECU. Always create a backup and proceed with caution.

-

Where can I learn more about Vediamo and ECU coding?

- DTS-MONACO.EDU.VN offers comprehensive training courses and resources.

-

What is the difference between Vediamo and DTS Monaco?

- Vediamo is an older, more complex tool, while DTS Monaco is a newer, more user-friendly alternative.

-

Do I need to be a software engineer to use Vediamo?

- While a software engineering background is helpful, it’s not required. With proper training and practice, anyone can learn to use Vediamo effectively.

-

Can Vediamo be used on any car?

- Vediamo primarily supports Mercedes-Benz vehicles, but it can also be used on other brands with the appropriate CBF files and adapters.

Unlock Your Potential with DTS-MONACO.EDU.VN

Ready to take your automotive diagnostic skills to the next level? Visit DTS-MONACO.EDU.VN today to explore our comprehensive training programs, software solutions, and expert support. Whether you’re a seasoned technician or just starting your journey, we have the resources you need to master Vediamo, DTS Monaco, and the art of ECU coding. Contact us today at Address: 275 N Harrison St, Chandler, AZ 85225, United States. Whatsapp: +1 (641) 206-8880, or through our Website: DTS-MONACO.EDU.VN, and let us help you unlock the full potential of your diagnostic capabilities! Embrace the future of automotive technology with DTS-MONACO.EDU.VN, your trusted partner for ECU diagnostics and car coding excellence in the USA. Let’s revolutionize car diagnostics and coding together.